It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-6 of this booklet and to strictly adhere to the advice contained therein. Also, please study the entire contents of this instruction manual, so as to familia...

2 remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some fu...

4 notes this engine was designed for model aircraft. Do not attempt to use it for any other purpose. Mount the engine in your model securely, following the manufacturers' recommenda- tions, using appropriate screws and lock- nuts. Be sure to use the silencer (muffler) supplied with the engine. Frequ...

6 notes adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully retarded. Alternatively, the engine may be stopped by cutting off the fuel supply. Never try to stop the engine physically. Take care that loose clothing (ties, shirt slee...

8 notes when applying an electric starter do not over-prime. This could cause a hydraulic lock and damage the engine on application of the electric starter. If over-primed, remove glowplug, close needle-valve and apply starter to pump out surplus fuel. Cover the head with a rag to prevent pumped out...

10 basic engine parts cylinder head carburetor type 61a-be crankshaft propeller nut propeller washer drive hub crankcase cover plate glowplug beam mount lock nut 11 tools, accessories, etc. The following items are necessary for operating the engine. Before starting the choice of propeller depends on...

12 fuel o.S. Bio-ethanol fuel is not poisonous but harmful. Do not allow it to be swallowed. Always store it in a clearly marked container and out of the reach of children. Model engine fuel is also highly flammable. Keep it away from open flame, excessive heat, sources of sparks, or anything else w...

14 8mm tools hex screwdriver screwdriver necessary for engine installation. 1.5mm, 2.5mm necessary for carburetor adjustments. Phillips screwdriver no.2, etc. Socket screwdriver 5mm, 5.5mm, 7mm long socket wrench with plug grip recommended for easy removal and replacement of the angled and recessed ...

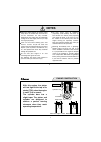

16 how to fasten the mounting screws. Hardwood mounting beams radial motor mount (cast aluminum) tighten second nut firmlydown onto first nut. Tighten this nut first. Steel washer 3mm steel nuts 3mm steel screw spring washer or lock washer 15mm min. 15mm min. Hardwood such as cherry or maple. Spring...

18 installing the glowplug install washer on glowplug and insert carefully into cylinder-head, making sure that it is not cross-threaded before tightening firmly. Glow plug washer needle-valve extension the needle-valve supplied with this engine is designed to incorporate an extension so that, when ...

20 suggested fuel tank capacity is approx 160- 180cc. This will allow 10-12 minute flights. Be sure to use a pressurized fuel system by connecting the muffler pressure nipple to the vent-pipe of the fuel tank. Fuel tank location make sure that the tank is well rinsed out with methanol or glow fuel b...

22 mixture controls the needle valve when set to produce maximum power at full throttle, this establishes the basic fuel/air mixture strength. The correct mixture is then maintained by the carburetor's built-in automatic mixture control system to cover the engine's requirements at reduced throttle s...

24 ! Starting be sure to use an electric starter to start the engine. Fill the fuel tank with fuel. When filled, prevent fuel flowing into the carburetor with a commercially available fuel stopper, etc. Release the stopper before starting the engine. 1. 2. Starting procedure is as follows: warning w...

26 when the engine is started, open the throttle slowly and adjust for the maximum r.P.M. With this needle-valve setting, the mixture is fairly rich. Close the needle-valve gradually until just short of the peak r.P.M. Disconnect the plug leads and further close the needle- valve to the optimum posi...

28 install the engine with the propeller intended for your model. Open the needle-valve to the advised starting setting and start the engine. If the engine stops when the glow plug battery is disconnected, open the needle- valve to the point where the engine does not stop.Run the engine for one minu...

30 15-30 degrees needle-valve adjustment diagram this diagram is for reference purposes only. Actual needle positions may differ from those shown. Note : practical best(optimum) needle-valve setting exhaust note starts to change. Disconnect battery leads from glowplug at about this point. Clear, hig...

32 mixture control valve adjustment with the engine running, close the throttle and allow it to idle for about five seconds, then open the throttle fully. If ,at this point, the engine hesitates to pick up with thick sound, the mixture is too rich. Correct this condition by turning the mixture contr...

34 1 2 3 symptom factor cause corrective action recharge the electric starter battery. Recharge lead-acid cell or replace dry battery. (note: an unused, or almost unused, dry battery may sometimes be of insufficient capacity if it is "old stock".) replace glowplug. Check that applied voltage is not ...

36 care and maintenance please pay attention to the matters described below to ensure that your engine serves you well in regard to performance, reliability and long life. As previously mentioned, it is vitally important to avoid operating the engine in conditions where dust, disturbed by the propel...

38 engine exploded view c.M3x16 c.M3x8 2 1 3 4 5 6 7 8 9 10 12 11 13 14 15 16 type of screw c...Cap screw 79871110 79871160 m3x8 m3x16 cap screw sets (10pcs ./sets ) code no . Si ze pcs . Used in an engine cylinder head retaining screw (5pcs.) cover plate retaining screw (4pcs.) 39 enginen pa r ts l...

40 1 2 4 5 7 s.M3x3 3 6 3-1 3-2 7-1 7-2 8 9 n.+m3.5x6 n.+m3x6 8-1 10 1-1 carburetor exploded view type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set screw 41 1 1-1 2 3 3-1 3-2 4 5 6 7 7-1 7-2 8 8-1 9 10 22081408 22081313 25781200 25781600 46066...

42 (71668100) be-3 (71531000) o.S.Glow plug o.S. Genuine parts & accessories radial motor mount non-bubble weight silencer extension adaptors o.S. Bio-ethanol glow fuel be-1(4l) (79710000) (26625340) (26625500) 14.5mm 42.0mm 35.0mm 42.0mm width screw hole pitch (71905200) (71531010) non-bubble weigh...

44 displacement bore stroke practical r.P.M. Power output weight specifications dimensions(mm) three view drawing 105.4 11 2 unf5/16-24 48.8 130.2 25 66.6 27.9 43 25 22 81.5 4 42.6 61 36.8 24 31.7 42.5 103 29.1 52 38.5 54.1 42 35.7 57.7 12.29 cc / 0.75 cu.In. 25.8 mm / 1.016 in. 23.5 mm / 0.925 in. ...