Summary of BioTec ScreenMatic2

Page 1

Biotec screenmatic².

Page 2

- - 2 a btc0056 b btc0050 c btc0049.

Page 3

- - 3 d btc0051 e btc0052.

Page 4

- - 4 f btc0063 g btc0048.

Page 5

- - 5 h btc0058 i btc0059.

Page 6

- - 6 j btc0064 k btc0061.

Page 7

- - 7 l btc0062.

Page 8

- - 8 m btc0053.

Page 9

- - 9 n btc0055.

Page 10

- - 10 o btc0060 p btc0054.

Page 11

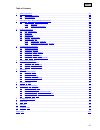

- en - 25 - en - table of contents 1 safety information ....................................................................................................................................... 26 1.1 electrical connection ..................................................................................

Page 12

- en - 26 translation of the original operating instructions 1 safety information this unit can be used by children aged 8 and above and by per- sons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they are supervised or have been instructed on how to use...

Page 13

- en - 27 2 information about these operating instructions welcome to oase living water. You made a good choice with the purchase of this product biotec screen- matic² 40000/60000/140000. Prior to commissioning the unit, please read the instructions of use carefully and fully familiarise yourself wi...

Page 14

- en - 28 b, c biotec screenmatic² 40000/60000/140000 1 inlets, 2 x 2 water distributor 3 distributor extension 4 brush for regularly cleaning the screenmatic screen 5 substrate tube – biotec screenmatic² 40000: 2 x – biotec screenmatic² 60000: 3 x – biotec screenmatic² 140000: 12 x 6 separating p...

Page 15

- en - 29 3.5.1 opening the container d • biotec screenmatic² 40000/60000: release the locking clips, lift up the cover and remove. • biotec screenmatic² 140000: lift the cover using the handles and remove. – screw the handles onto the cover. The handles are not fitted on delivery. Note! Only oper...

Page 16

- en - 30 optimum ambient and operating conditions optimum operating results can be obtained with careful planning, taking the ambient conditions into account. • as the filter is very heavy when filled, it must be placed on a suitable base (at least on slabs, but preferably on a poured concrete base...

Page 17

- en - 31 4.4 connecting the outlet • use suitable pipes. • do not use any right-angled bends. Bends with a maximum angle of 45° are very efficient. • standing water in pipes can freeze when there is a hard frost and cause pipes to burst. For this reason, lay the pipes and hoses with a gradient (50 ...

Page 18

- en - 32 5.1 biological filter starter the foam filters take several weeks to reach their full biological cleaning effect. We recommend using the oase filter starter biokick to ensure fast growth of bacterial populations. Micro-organisms colonise the filter system, multiply and ensure an enhanced q...

Page 19

- en - 33 6 operation 6.1 operating panel btc0046 1 led, 2 colours • lit green the screenmatic rotating screen unit is operational • flashes green cleaning active • flashes green/red malfunction (→ system messages) • flashes red malfunction (→ system messages) 2 button, start/stop manual cleaning (→...

Page 20

- en - 34 6.4 time-dependent cleaning the screenmatic rotating screen unit executes a cleaning cycle after a set interval depending on the ambient temperature. This ensures cleaning at regular intervals • if the sensor is soiled or defective, • if there is very little soiling on the screen and/or lo...

Page 21

- en - 35 7 remedy of faults malfunction possible cause remedy no flow of water filter pump not switched on switch on the filter pump, connect the power plug supply to filter system or return to pond blocked clean the supply and/or return water flow insufficient hose kinked or clogged check, clean o...

Page 22

- en - 36 8.2 cleaning foam filters m • it is necessary to clean the foam filters as soon as the water exceeds the 100% mark on the separating plate. • do not use any chemical cleaning agents as they would kill the filter bacteria. Prerequisite: • the filter pump is switched off. • the container i...

Page 23

- en - 37 how to proceed: o 1. Remove the screw for fastening the control device, remove the control device and place it carefully to the side. – if necessary, disconnect the motor cable plug from the control device. – mark the position of the control device on a side section for reassembly. 2. Ta...

Page 24

- en - 38 10 wear parts the following components are wear parts and are excluded from the warranty: • foam filters • substrate tubes • screenmatic screen 11 disposal do not dispose of this unit with domestic waste! For disposal purposes, please use the return system provided. Disable the unit before...

Page 25

319 btc0040

Page 26

320 pos. Biotec screenmatic² 40000/60000 16 42383 17 44178 18 44184 19 42325 20 44177 21 44183 22 42954 23 19512 24 19506 25 44337 26 25691 27 42949 28 44179 29 25000 30 45321 31 44182 32 34859 38 44308 39 42450 btc0041 btc0043 btc0044, btc0045.

Page 27

321 biotec screenmatic² pos. 40000 60000 33 34670 34670 34 42895 42896 35 26305 34733 36 25524 25524 37 42893 42894 btc0042.

Page 28

322 btc0034.

Page 29

323 pos. Biotec screenmatic² 140000 14 42384 15 44178 16 44186 17 42326 18 44177 19 44183 20 42954 21 19512 22 19506 23 44338 24 25691 25 42949 26 44179 27 25000 45 44308 46 42450 47 34367 btc0035 btc0036.

Page 30

324 pos. Biotec screenmatic² 140000 28 34670 29 42896 30 34733 31 25542 32 25922 33 25546 34 25547 35 25524 36 42894 btc0039.

Page 31

325 pos. Biotec screenmatic² 140000 37 19005 38 35255 39 24229 40 24230 41 34253 42 25996 43 34835 44 44188 btc0037, btc0038.