- DL manuals

- Océ

- All in One Printer

- ColorStream

- User manual

Océ ColorStream User manual

Summary of ColorStream

Page 1

O more power when printing océ colorstream user manual continuous printing system.

Page 2

Copyright copyright © océ 2008–2009 all rights reserved. This documentation may not be reproduced, copied, changed or trans- mitted in any form, either in whole or in part, without written authorization from océ. Océ does not assume any responsibility or offer any guarantee regarding the information...

Page 3: Contents

Contents chapter 1 notes on the printing system documentation.............................................. 11 notes on the printing system documentation — overview................ 12 guide through the documentation......................................................... 13 notes on help..............

Page 4

Doors and covers..................................................................................... 54 internal view............................................................................................. 56 internal view — overview................................................................

Page 5

Managing user settings (key operator).............................................. 107 managing user settings (key operator) — overview.................. 107 extended password protection (option)......................................... 109 'add user' ..................................................

Page 6

Closing left doors............................................................................ 163 replacing the developer station.......................................................... 165 replacing the developer station — overview................................ 165 preparing the replacement ca...

Page 7

Optimizing the color printing................................................................ 239 optimizing the color printing — overview.................................... 239 performing a color test................................................................... 242 calibrating the colors of ...

Page 8

Replacing the developer - overview.............................................. 336 draining the developer mixture...................................................... 337 fill in developer................................................................................ 340 chapter 9 replacing expe...

Page 9

Replacing the cleaning brush............................................................... 433 replacing the cleaning brush — overview..................................... 433 removing the cleaning brush of the photoconductor unit........... 434 installing the cleaning brush of the photoconductor u...

Page 10

10 contents.

Page 11

Chapter 1 notes on the printing system documentation.

Page 12

Notes on the printing system documentation — overview introduction the purpose of this documentation is to ensure that all printing system-related work is carried out safely and correctly. It contains safety directives that must be strictly observed. Each section is divided into small, easy-to-under...

Page 13

Guide through the documentation introduction documentation available to you on the océ colorstream includes a printed user guide and help on the operator panel. This help is updated with every new version of the oper- ator panel software. Security this section gives you all necessary information on ...

Page 14

Replacing consumables this section describes in detail all the steps required to replace consumables. It also provides the order numbers and package units for all consumables. Replacing expendables this section describes in detail all the steps required to replace expendables. It also provides the o...

Page 15: Notes On Help

Notes on help notes on the help - overview help target group this help is designed for the "operator" and "key operator" user groups. This help should enable an "operator" or "key operator" to use the printing system safely, appro- priately and efficiently. Menus that are available to the service gr...

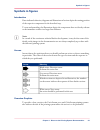

Page 16: Opening Help

Opening help to open help # proceed as follows: click on the following button in the frame toolbar: the help window opens. The navigation area is displayed initially: the width of the navigation area can be changed with the mouse. 1. Chapter 1 - notes on the printing system documentation 16 opening ...

Page 17

Function of the buttons in the help window # function button hides or displays the navigation area with the following tabs: ■ ‘contents’ on page 18 ■ ‘index’ on page 19 ■ ‘search’ on page 20 when the navigation area is hidden, more space is available to view the help topics. Switches between the las...

Page 18: Navigating In Help

Navigating in help contents to call up help topics via the contents # proceed as follows: click on the 'contents' tab. 1. Click the buttons of the individual help levels to fade them in and out. Example: [13] 2. Click on a help topic. 3. Chapter 1 - notes on the printing system documentation 18 cont...

Page 19: Index

Index introduction entries on the 'index' tab are sorted alphabetically. Any number of secondary keywords can be attached to a primary keyword. To select information via the index # proceed as follows: click on the "index" tab. 1. Scroll through the index entries or enter text (including partial wor...

Page 20: Search

Search introduction you can access the full text search function via the "search" tab. The full text search is used to find one or more specific words in the entire help. Uppercase or lowercase is not relevant for the search. Partial words cannot be found. To call up information via the full text se...

Page 21: Opening Direct Help

Opening direct help introduction context-sensitive direct help provides detailed information on all: ■ menus ■ operating elements in menus ■ errors and warnings # note when calling up the direct help, ensure that you have selected the element for which you wish to call up the help text. The selected...

Page 22

To call up the direct help # proceed as follows: select menu or 1. Select operating element or select message press f1. The help window opens. The navigation area is initially hidden, e. G.: 2. Chapter 1 - notes on the printing system documentation 22 opening direct help.

Page 23

Function of the buttons in the help window # function button hides or displays the navigation area with the following tabs: ■ ‘contents’ on page 18 ■ ‘index’ on page 19 ■ ‘search’ on page 20 when the navigation area is hidden, more space is available to view the help topics. Switches between the las...

Page 24: Symbol Conventions

Symbol conventions symbols in the text display of operating elements on the operator panel the operating element description is shown in inverted commas on the operator panel, e.G. 'configuration' menu. Notes note: this symbol indicates notes - tips for operating the océ colorstream. Safety directiv...

Page 25: Symbols In Figures

Symbols in figures introduction if not indicated otherwise, diagrams and illustrations of actions depict the starting position of the respective component for the described step. To ease understanding, the illustrations depict the components that are directly relevant to the immediate context in a l...

Page 26

# meaning overview graphic paper input left-hand side of printing system right-hand side of printing system filter module paper output chapter 1 - notes on the printing system documentation 26 symbols in figures.

Page 27: Other Documents

Other documents in addition to the user guide the following documents are also provided for every printing system, in addition to the user guide: # order number title a29246-x34-x-n-79 (multi-lingual) safety information a29249-x5-x-n-mm59 paper specification a29246-x27-x-n-mm80 'océ web buffer' user...

Page 28

Manufacturer of the printing system océ colorstream the printing system océ colorstream was manufactured by: océ printing systems gmbh postfach 1260 85581 poing germany chapter 1 - notes on the printing system documentation 28 manufacturer of the printing system.

Page 29: Statutory Requirements

Statutory requirements technical changes the information, data and instructions in this documentation were up-to-date at the time of going to press. The right of technical modifications due to further development of the printing system is reserved. For this reason, the information, illustrations and...

Page 30

Chapter 1 - notes on the printing system documentation 30 statutory requirements.

Page 31

Chapter 2 safety.

Page 32: Safety — Overview

Safety — overview security this section gives you all necessary information on how to safely and efficiently operate the printing system. Safety directives in addition to the safety directives in section ‘accident and damage prevention - overview’ on page 37 , you must also observe the safety direct...

Page 33: Intended Purpose

Intended purpose océ colorstream the océ colorstream printing system shall only be considered as being used for its in- tended purpose if the notices and instructions in this documentation are strictly observed: ■ the printing system is intended solely for printing materials that comply with the pap...

Page 34

Flagging of safety directives definition the following notational conventions are used for the safety directives in the text of the manual: # alert word type or source of danger and consequences of failure to observe the safety directives instructions on avoiding danger symbol different alert words ...

Page 35

Warning and information signs identification of danger points the following signs are affixed inside the printing system at potential danger points: # meaning label warning: live electric parts there are live electric parts behind safety covers bearing this sign. These safety covers may only be remo...

Page 36

Additional warning and information signs on the océ colorstream # meaning sign warning regarding laser beams components that produce laser beams are located behind pro- tective covers bearing this sign. These protective covers may only be removed by authorized océ service personnel. Chapter 2 - safe...

Page 37

Accident and damage prevention accident and damage prevention - overview overview you will find information on the following topics: ■ ‘personal representations’ on page 38 ■ ‘operation’ on page 39 ■ ‘transportation, assembly and installation, repair’ on page 42 ■ ‘fire, disposal’ on page 44 chapter...

Page 38: Personal Representations

Personal representations agent an agent is any individual or legal entity (corporate body) that uses or commissions the use of the printing system. Operator the operator ■ is trained directly on the printing system as to how to operate it and has been instructed on the tasks assigned to them. They a...

Page 39: Operation

Operation introduction observe the following instructions when operating the printing system: service personnel only operators, key operators and service personnel may operate the printing system. The printing system must not be operated by persons under the influence of alcohol or drugs, or by pers...

Page 40

Cleaning always use an industrial vacuum cleaner with a grounded suction tube, rubber nozzle and filter set for fine dust. An explosion-proof industrial vacuum cleaner must be used for large toner quantities because there can be a high build-up of static charge when draining toner spill. When cleani...

Page 41

System. The life cycle of the filter system is designed so that it does not have to be replaced during the lifetime of the printing system. During printing, the ozone concentration is below the maximum allowable work place concentration (mac) of 0.1 ppm (0.2 mg/m 3 ). With proper ventilation, harmfu...

Page 42

Transportation, assembly and installation, repair transport the printing system may only be transported by service personnel or authorized transport companies. Assembly and installation observe the following instructions when assembling and installing the printing system: ■ the printing system may o...

Page 43

The access ticket used by the service technician ensures that the printing system cannot be used via an lan from a remote operator panel during repair work. Chapter 2 - safety 43 transportation, assembly and installation, repair.

Page 44: Fire, Disposal

Fire, disposal fire observe the following instructions: ■ poisonous gases can occur in any fire. They can also result from the printing system océ colorstream. ■ self-contained breathing apparatus must be worn when fighting fire or smoke emission. Instructions to this effect should be deposited at t...

Page 45

Safety regulations and standards safety regulations and standards — overview introduction the printing system océ colorstream complies with the relevant safety requirements for information technology equipment. It meets the following national and international safety regulations and standards: safet...

Page 46

■ tÜv/gs ■ or similar electromagnetic compatibility # emvdirective ec directive for harmonization of the legal requirements of member states regarding electromagnetic compatibility (modified by directive 91/263/eec, 92/31/eec, and directive 93/68/eec) 89/336/ewg europe en 55024 en 55022 / class a us...

Page 47

■ rohs directive ■ tÜv/gs overview here you will find additional information on the following topics: ■ ‘ce mark’ on page 48 ■ ‘accident prevention regulation for replacement carts (option)’ on page 49 chapter 2 - safety 47 safety regulations and standards — overview.

Page 48: Ce Mark

Ce mark océ colorstream the printing system océ colorstream fulfills the requirements of the ec directives 89/336/ewg, "electromagnetic compatibility" and 73/23/ewg "low voltage direc- tive". The ce mark indicates that the printing system complies with these ec directives. The printing system is a c...

Page 49

Accident prevention regulation for replacement carts (option) technical inspection a technical inspection must be carried out annually by a technical expert as per bgv d8 "winches, lifting and pulling devices" or relevant country-specific regulations. The technical inspection includes the following ...

Page 50

Chapter 2 - safety 50 accident prevention regulation for replacement carts (option).

Page 51

Chapter 3 description of the printing system.

Page 52

Description of the printing system — overview description of the printing system this section shows the structure of the printing system, describes the operating elements and explains the printing principle. You will also find information on paper types and how to handle the paper. Overview you will...

Page 53: Main Modules

Main modules modular design the printing system has a modular structure consisting of the following main modules: 4 5 3 2 1 # designation unit paper input module 1 print unit 2 fuser module 3 filter module 4 console 5 # paper path direction chapter 3 - description of the printing system 53 main modu...

Page 54: Doors And Covers

Doors and covers introduction note: right-hand side means right in paper path direction. Left-hand side means left in paper path direction. Right-hand side of printing system left-hand side of printing system legend # meaning color these doors may be opened during printing without causing any advers...

Page 55

Meaning color these doors and covers must not be opened during printing. To avoid any danger, the entire printing system shuts down if they are opened. With the optional toner supply using 1 kg (2.2 lb) toner bottles, this door can be opened during printer operation without having to disconnect the ...

Page 56: Internal View

Internal view internal view — overview the most important components note: the figure shows the maximum configuration of the océ colorstream printing system with five developer stations in the upper and lower print unit. 11 9 10 5 6 12 1 2 3 4 5 6 7 7 8 # function component / designation in the pape...

Page 57

Function component / designation in the fuser module, the toner is fused on the front and rear sides of the paper by means of an infrared lamp. Fuser module/infrared lamp 4 in the print unit, the front and rear sides of the paper are printed at the same time via the upper and lower print units. Prin...

Page 58: Photoconductor Unit

Photoconductor unit important components of the photoconductor unit the illustration shows a cross section of the photoconductor unit in the upper print unit with five developer stations. 1 2 3 4 5 6 7 8 9 # function component / designation exposes the negatively charged photoconductor belt and neut...

Page 59

Function component / designation maintains a constant level of toner for the toner feed. Toner box 6 measures the quantity of toner for each color. Toner mark sensor 7 applies toner to areas on the photoconductor belt exposed by the led print head. Developer stations 8 establishes an image pattern f...

Page 60: Transfer Unit

Transfer unit important components of the transfer unit the illustration shows a cross section of the transfer unit in the upper print unit. 1 2 3 4 # function component / designation establishes the required potential difference on the transfer roller point between the transfer belt and paper by re...

Page 61: Filter Module

Filter module important components of the filter module # description component / designation the waste toner, which is drained from the print unit, is collected in the waste toner box. Waste toner box 1 the exhaust air is cleaned with a fine filter and sent out of the top of the filter module. Fine...

Page 62: Console

Console important components of the console 1 2 4 3 5 4 # description component screen 1 keyboard and mouse 2 storage for the user guide 3 toner supply 4 toner hoses on the printing system 5 color allocation in the console the developer stations for all colors are supplied by a toner suction system ...

Page 63

# color slot yellow 1 magenta 2 cyan 3 black 4 customtone or additional black, cyan, magenta or yellow toner bottles. 5/6 note: in the case of customtone printing systems, the color allocation in the console can be changed by service. Chapter 3 - description of the printing system 63 console.

Page 64: Printing Method

Printing method introduction the print image is created through an electrophotographic printing process with led print heads and two-component developers. With a full color printing system, the colors are generated using the subtractive color mixing technique, using the color separations cyan, magen...

Page 65

Description level the photoconductor belt is cleaned. 4 transfer is from the transfer belt to the paper web. In double-sided print operation, the upper and the lower printed page are transferred at the same time. ■ single color printing: black/white printing system for single color printing, the ink...

Page 66

Description level the paper is cooled in the paper cooling unit for further processing in the paper post-processing unit. 8 chapter 3 - description of the printing system 66 printing method.

Page 67: Operating Elements

Operating elements operating elements - overview the most important operating elements 1 1 1 2 2 3 4 5 # description number additional operator panels 1 operator attention light 2 on key 3 main switch 4 operator panel standard pc with screen, keyboard and mouse on external console close to the print...

Page 68

Note: additional operator panels can be used optionally. They do not have to be set up in close proximity to the printing system. The access ticket ensures that parameters are not set by different users at parallel operator panels. Overview you will find information on the following topics: ■ ‘on ke...

Page 69: On Key

On key display # function key the printing system is on. (green) transitional states (flashing yellow) the printing system is in standby mode (main switch is on). (yellow) the printing system is off. (off) chapter 3 - description of the printing system 69 on key.

Page 70: Additional Operator Panels

Additional operator panels three key operator panels three additional identical key operator panels are located on the corners of the printing system. Function of the keys note: the function of the keys corresponds to the function of the buttons in the operator panel toolbar (see ‘buttons and displa...

Page 71

Function key moves the paper slowly backwards without fusing while the button is being pressed. The paper speed increases the longer you press the button. However, synchronization is lost. Requirement: ■ this function can only be executed in the 'stop' status. Advr (= adv anced r everse) moves the l...

Page 72: Operator Attention Light

Operator attention light operator attention light (opal) — overview note: for the operator attention light (opal), service can switch the flash concept between the standard versions for bundle 11 and bundle 10. The following variants are preset: ■ colorstream and 'variostream 9400 / 9500 / 9600 / 97...

Page 73

Operator attention light (opal)/bundle 11 version displays the most important displays are summarized in the following table: # meaning display the printing system is in standby mode. (main switch is on). (off) print data is available; the printing process has started. (green) the printing system is...

Page 74

Meaning display there is an error message. (red) the printing system has been stopped by the post print processing unit (external stop). The printing system changes from the 'ready' status to the 'stop' status after a preset amount of time. (green/red) chapter 3 - description of the printing system ...

Page 75

Operator attention light (opal)/bundle 10 version displays the most important displays are summarized in the following table: # meaning display the printing system is in standby mode. (main switch is on). (off) the printing system is in the status ■ 'ready' ■ or 'energy saving mode ready' (the opera...

Page 76

Meaning display the printing system is in the 'operator intervention necessary' status. (flashing red) the printing system is not ready ('stop' status) or one of the 'npro', 'advf', 'advr', 'eject' or 'autofeed' keys has been pressed or the printing system is in a transitional status. (red) the prin...

Page 77

Operating elements in the printing system example all operating elements for normal, incident-free printing operation are designed in blue- green, e.G.: chapter 3 - description of the printing system 77 operating elements in the printing system.

Page 78: Paper Specifications

Paper specifications general information to ensure maximum system availability, the paper for the océ colorstream printing systemmust comply with the applicable paper specifications and be stored in an environ- ment with suitable ambient conditions. Non-compliance with the paper specifications can c...

Page 79

Can, for example, give the paper an excessive curl, make it bumpy, or alter its electrical resistance. Observe the following guidelines to ensure that the original high quality of the paper is not impaired in any way. ■ store the paper in its packaging until it is used. ■ do not store paper on the f...

Page 80

Chapter 3 - description of the printing system 80 paper specifications.

Page 81

Chapter 4 description of the opera- tor panel.

Page 82

Description of the operator panel — overview description of the operator panel this section describes the individual areas of the operator panel with the most important menus, buttons and icons. Overview the operator panel is divided into the following areas: description # description area ‘toolbar ...

Page 83: A Tool Bar

A tool bar toolbar — overview overview the toolbar can be used to quickly access the important functions of the printing system and to switch directly to frequently used menus. Description # description area ‘buttons and displays in the left area’ on page 84 1 ‘buttons and displays in the center are...

Page 84

Buttons and displays in the left area function of the buttons note: the function of the buttons corresponds to the function of the keys on the printing system's additional operator panels. # function button switches the printing system to ready for operation again from the 'stop' or 'operator interv...

Page 85

Function button transports the paper web forward at print speed while the button is pressed. The paper web is not printed. Already printed pages will still be fused. Requirement: ■ this function can only be executed in the 'stop' status. 'eject' moves the autofeed clamp to paper input position or st...

Page 86

Buttons and displays in the center area buttons # function button switches to the buttons under 'job control' in the 'emula- tions' menu. 'job control' switches to the 'channels' menu. The following buttons are available here: activates the channel, the printing system is online. The connecting icon...

Page 87

Function button indicates that remote access is activated. The service center can use this to perform remote diagnostics during print operation. Clicking the button deactivates remote access directly without having to go through the menu. Also indicates that remote service diagnosis is activated. If...

Page 88

Meaning display normal print operation. The set speed level appears in the menu 'print speed' in brackets. 'printing' [%] if necessary, process optimization is started by the device control during print operation. 'process optimization' the printing system switches from the 'stop' status to the 'rea...

Page 89

Meaning display the 'npro' key has been pressed. The last printed pages are being moved out of the printing system. Pages that are already printed will also be fused. 'job advance' the paper width sensor has detected that a paper web of a different width has been inserted. Paper web stop plates are ...

Page 90: Frame Toolbar

Frame toolbar buttons the buttons in the frame toolbar can be used to quickly access superordinate functions for the complete printing stream and to switch directly to frequently used menus. # function button switches to the 'user profile' menu. The language of the operator panel can be changed in t...

Page 91: Menu Tree

Menu tree menu tree — overview note: the menus displayed in the menu tree depend on the different rights for the individual user categories. This documentation describes all menu options normally set up for the user categories "operator" and "key operator". Information on the paper path manager can ...

Page 92

You can switch directly to the main menu from any menu. Click the following button in the toolbar for this purpose: overview you will find information on the following topics: ■ ‘'general' menus — overview’ on page 93 ■ ‘'colorstream' menus — overview’ on page 97 chapter 4 - description of the opera...

Page 93: 'General' Menus

'general' menus 'general' menus — overview overview you can define the user settings valid for the entire printing system in the 'general' menus. Note: menus that can only be opened by the "key operator" user by default are shown in bold in the table. # description menu the sub-menus contain the use...

Page 94: 'User Management' Menus

'user management' menus overview note: the menus listed in the table can only be accessed by the"key operator" user. The menus under 'user management' contain the user settings relating to the key oper- ator. # description menu add new users or user templates 'add user' delete users or user template...

Page 95: 'User' Menus

'user' menus overview the menus under 'user' contain the user settings relating to the operator. # description menu log a user on or off 'change user' select the operator panel language and change the password 'user profile' two different functions are combined into this menu: ■ facilitate screen cl...

Page 96: 'Security' Menus

'security' menus overview the menus under 'security' contain security-related settings and displays. # description menu requesting or releasing the access ticket for a specific operator panel in the printing system. 'access ticket' overview of the computer connected to the printing system. 'network ...

Page 97: 'Colorstream' Menus

'colorstream' menus 'colorstream' menus — overview display of basic information the following basic information on the printing system is displayed in the 'colorstream' menu: # description display number of all 12" pages previously printed in user operation further counters are displayed in the 'gen...

Page 98

'setup' menus in setups, special settings for frequently recurring print requests can be grouped together and saved. By loading a setup, the printing system can be configured quickly with the right parameters for a print request. If the printing system is powered up and it is not possible to load a ...

Page 99: 'Displays' Menus

'displays' menus 'displays' menus the sub-menus contain displays on current error and warning messages and the various counters on the printing system. 'errors and warnings' menu displays the current error and warning messages and information. 'general counter' menu displays page counters, warm-up t...

Page 100: 'Configuration' Menus

'configuration' menus 'configuration' menus the sub-menus contain the parameters relevant for setting the printing system. 'paper' the sub-menus contain the parameters for the paper webs to be printed. 'print parameters' menu the sub-menus contain specific parameters for the printing system. 'color'...

Page 101: 'Setup' Menus

'setup' menus 'setup' menus in setups, special settings for frequently recurring print requests can be grouped together and saved. By loading a setup, the printing system can be configured quickly with the right parameters for a print request. If the printing system is powered up and it is not possi...

Page 102

'replace consumables' menus 'changing consumables' menus the sub-menus contain the procedures for replacing consumables and expendables and for cleaning the printing system. A menu for identifying the toner used is also available. 'expert mode' menu procedure for replacing several expendables. As th...

Page 103

'cleaning the printing system' menu procedure for cleaning or inspecting the paper input module, paper path and paper output. 'swivel developer stations' menu procedure for swiveling the developer stations in the upper or lower print unit on or off. 'toner bottle identification' menu displays inform...

Page 104: Menu Display

Menu display introduction this area shows the menu selected in the menu tree. Direct help via the f1 key detailed information on all menus and operating controls is available directly in the op- erator panel via the context-sensitive direct help. The context-sensitive help system can be called up by...

Page 105

Chapter 5 working with the operator panel.

Page 106

Working with the operator panel — overview working with the operator panel this section explains how you manage all user settings, how you select or enter parameters on the operator panel, how you collect special settings for frequently recurring print jobs using setups, how you manage resources for...

Page 107

Managing user settings (key operator) managing user settings (key operator) — overview introduction by default, 3 user groups are pre-defined: operator, key operator and service. Any changes made to their associated user profiles will be reset when a new operator panel version is installed. However,...

Page 108

Overview as key operator, you can normally determine the following user settings: ■ ‘'add user' ’ on page 110 ■ ‘'delete user' ’ on page 111 ■ ‘set password / 'general' tab’ on page 112 ■ ‘releasing and blocking menus and elements/'user rights' tab’ on page 113 ■ ‘setting language/'user profile' tab...

Page 109

Extended password protection (option) introduction the "extended password protection" function can be activated by service as an option. Rules in this case, all users must use a password according to the following rules: ■ it contains at least 8 characters. ■ it contains at least 1 letter and 1 spec...

Page 110: 'Add User'

'add user' to add a user # proceed as follows: click on the 'general' -> 'user management' -> 'add user' menu. 1. Select user template. The settings for this user template will be adopted for the new user. These set- tings can then be adjusted in the 'user management' -> 'edit user' menu if necessar...

Page 111: 'Delete User'

'delete user' introduction all user-defined users and possible pre-defined users "sample operator" can be deleted, with the exception of the pre-defined user groups operator and key operator. To delete a user # proceed as follows: click on the 'general' -> 'user management' -> 'delete user' menu. 1....

Page 112

Set password / 'general' tab note: a password will remain valid indefinitely if the "extended password protection" function has not been activated by service. A password will remain valid for 3 months if the "extended password protection" function has been activated by service. When the password has...

Page 113: Tab

Releasing and blocking menus and elements/'user rights' tab note: you can activate or block menus and elements for self-created users. Menus and elements cannot be activated or blocked for the predefined user groups. For security reasons, the 'change user', 'user profile' and 'network management lan...

Page 114

Setting language/'user profile' tab introduction the operator panel language can be selected in the 'user profile' tab. The appearance of the operator panel cannot be changed for the user groups "operator" and "key operator." to set a language # proceed as follows: click on the 'general' -> 'user ma...

Page 115

Managing user settings (operator) managing user settings (operator) — overview overview as an operator, you can normally make the following user settings: ■ ‘log on as user and request an access ticket’ on page 116 ■ ‘change password / 'password' tab’ on page 118 ■ ‘changing language/'user profile' ...

Page 116

Log on as user and request an access ticket introduction to be able to set parameters on the operator panel, you must first log on as a user and then request the access ticket. The access ticket ensures that parameters are not set by different users at parallel operator panels. Note: a message will ...

Page 117

Proceed as follows: click on the 'request access ticket' button. If the access ticket has already been requested, the button is deactivated. Note the access ticket can also be requested and released directly via the buttons in the frame toolbar without going through the menu: 6. Chapter 5 - working ...

Page 118

Change password / 'password' tab note: a password will remain valid indefinitely if the "extended password protection" function has not been activated by service. A password will remain valid for 3 months if the "extended password protection" function has been activated by service. When the password...

Page 119

Changing language/'user profile' tab introduction the operator panel language can be selected in the 'user profile' tab. The appearance of the operator panel cannot be changed for the user groups "operator" and "key operator." to change the language # proceed as follows: click on the 'general' -> 'u...

Page 120: Log Off As User

Log off as user to log off as a user # proceed as follows: click on the 'general' -> 'user' -> 'change user' menu. 1. Select the desired user from the selection list. 2. Click on the 'log off' button. 3. Chapter 5 - working with the operator panel 120 log off as user.

Page 121

Selecting settings and entering values introduction all parameters of the printing system can be set at the operator panel. The following prerequisites have to be satisfied: ■ the necessary rights are available. These rights are assigned by the respective "key operator" in the 'edit user' menu. ■ th...

Page 122

Applying or resetting settings 'apply' / 'reset' if you change parameters in a menu, you have to save these changes before switching to another menu. # function button the current settings in the displayed menu are saved. 'apply' the current settings in the displayed menu are not saved, the settings...

Page 123: Working With Setups

Working with setups working with setups — overview 'setup' menus in setups, special settings for frequently recurring print requests can be grouped together and saved. By loading a setup, the printing system can be configured quickly with the right parameters for a print request. If the printing sys...

Page 124

Creating a new setup or changing a setup requirements requirements for saving setups: ■ the key operator or an operator authorized by the key operator must be logged on. ■ there can be no error message. To create a new setup or change a setup # proceed as follows: if the printing system has not yet ...

Page 125: Importing A Setup

Importing a setup introduction you can apply all setups that were created on another printing system océ colorstrea- musing the same software version. To import a setup # proceed as follows: if the printing system has not yet stopped, click the 'stop' button. 1. On the operator panel, select: ■ for ...

Page 126

Proceed as follows: if importing from a usb memory stick: insert the usb memory stick with the setups into the usb port. The usb port is located below the operator panel near the paper input. 5. In the dialog window, ■ open the \transfer\ directory and ■ select one or more setups. 6. Click the 'impo...

Page 127: Exporting A Setup

Exporting a setup introduction self-created setups can also be used for other printing systems océ colorstream. Prerequisites: ■ the key operator or an operator authorized by the key operator must be logged on. ■ the same software version must be installed for the printing systems involved, or a lat...

Page 128

Proceed as follows: select where the setup is to be exported: ■ usb memory stick ■ transfer area (a directory on the drive of the controller hard disk; used for remote data transfer of setups) 5. When exporting to a usb memory stick: insert the usb memory stick into the usb port. The usb port is loc...

Page 129: Managing Resources

Managing resources managing resources — overview resources in i mode the following can be installed or deleted in i mode ■ font tables (".Cdp" file format) ■ fonts (".Chs" file format) ■ fonts for pdf (optional; within pdf containers) ■ color mapping tables (= color mapping tables; ".Cmt" file forma...

Page 130: Installing Resources

Installing resources requirement the key operator or an operator authorized by the key operator must be logged on. To install a resource # proceed as follows: if the printing system has not yet stopped, click the 'stop' button. 1. Deactivate all channel links to the host. Also click the following bu...

Page 131

Proceed as follows: insert the usb memory stick with the new resources into the usb port. The usb port is located below the operator panel near the paper input. 3. On the operator panel, select: ■ for i mode: 'configuration' -> 'emulations' -> 'i mode' -> 'resource management' menu ■ for pcl mode: '...

Page 132: Deleting Resources

Deleting resources requirement the key operator or an operator authorized by the key operator must be logged on. To delete a resource # proceed as follows: if the printing system has not yet stopped, click the 'stop' button. 1. On the operator panel, select: ■ for i mode: 'configuration' -> 'emulati...

Page 133

Editing 'replace consumables' menus on the operator panel introduction the operator panel informs you about the current status of the printing system. Warnings or error messages indicate when consumables or expendables have to be refilled or replaced. You can also check the current counter status at...

Page 134

Prerequisites every time a consumable or expendable part is replaced, individual working steps must be carried out on the operator panel. Requirements for this: ■ the user rights are available for this menu ■ the access ticket for this operator panel is requested ■ the printing system is in the 'sto...

Page 135

Proceed as follows: select a print unit and an assembly, e.G. In the printer view, the selected consumable or expendable is highlighted in color. The printer view can also be completely hidden or shown by clicking the arrow icons. 2. Chapter 5 - working with the operator panel 135 editing 'replace c...

Page 136

Proceed as follows: click the 'next' button. A new menu window opens, in which all necessary work steps are displayed in the correct sequence, e.G. If necessary, you can return to the selection page via the 'back' button. 3. Perform all the displayed steps in the given order. The work steps are desc...

Page 137

Chapter 6 operating the printing system.

Page 138

Operating the printing system — overview operating the printing system this section describes how to power the printing system on and off and the procedure for inserting, affixing and removing the paper web, and also contains all other information that you will need to operate the printing system. O...

Page 139

Powering on the printing system attention: ensuring the cooling of the developer stations. The external recooler must always be activated during the printing operation. To power on the printing system # proceed as follows: if the external recooler is switched off, set the main circuit breaker of the...

Page 140

Proceed as follows: press the on key. 3. If necessary, power on the photo- conductor operator panel. The printing system is initialized (duration approx. 7 minutes). The printing system's current status information is displayed on the operator panel 4. Log on as a user and request an access ticket. ...

Page 141

Proceed as follows: activate the required channel on the operator panel. Click the 'channel control' button. The 'channels' menu is displayed. Click on the following button to activate the channel: during the time needed for activation, the connecting icon is shown in yellow. An activated channel is...

Page 142: To 'Ready'

After printing has stopped, switch the printing system back to 'ready' introduction a print stop may be caused by the following: ■ the 'stop' button was pressed on the operator panel or on an additional operator panel. ■ the printing system was stopped by an error message. ■ the controller has run o...

Page 143: Inserting The Paper Web

Inserting the paper web inserting the paper web attention: when inserting a paper web, make sure that there is no paper between the paper input and the paper output. A continuous paper supply from the high stack or unroller must be guaranteed during the entire insertion process. # note the printing ...

Page 144

Proceed as follows: press the clamp opener. This will retract the clamp rollers. 2. Ensure that the paper edge is straight and at right angles. Do this by bending a section of the paper web upwards and folding it so that the side edges are aligned. Only for heavy paper (that can- not be held by the ...

Page 145

Proceed as follows: align the paper web on the left side to the "0" mark of the ruler on the clamp opener. 5. Close the rocker. Hold on to the paper web while doing this to prevent it sliding sideways. 6. Press the clamp opener and push the paper web into the autofeed clamp to the stop point. 7. Lig...

Page 146

Proceed as follows: caution the flap of the paper output opens automatically. Do not stand directly in front of the flap. # press the 'autofeed' key on the additional operator panel. The autofeed clamp moves to the park position at the paper output together with the paper web in approx. 20 seconds. ...

Page 147

Insert the paper web below the data integrity sensor: ■ open the angle bracket. ■ insert the paper web below the data integrity sensor. Ob- serve the mark. ■ close the angle bracket. 11. If a paper web with a different width has been inserted, check the position of the pressure rollers in the paper ...

Page 148

Adjusting the pressure rollers introduction if a paper web with a different width was inserted, the position of the pressure rollers in the paper output must be checked. To avoid damage, the paper edge must not run directly along a pressure roller. To this end, the two pressure rollers on the right-...

Page 149

Proceed as follows: click the 'ok' button to start adjusting the pressure rollers: for information on the icons displayed on the operator panel under 'steps', see ‘explanation of icons’ on page 134 . 2. Bring pressure roller 1 to the position shown on the operator panel, then click the 'next' button...

Page 150

Synchronizing the paper path introduction with a synchronized paper path, the print image is set e.G. To a preprinted mark. To synchronize the paper path # proceed as follows: in the 'configuration' -> 'paper' -> 'preprinted marks' menu on the operator panel, select the desired synchronization. 1. U...

Page 151

Proceed as follows: press the 'ready' button to start printing. 3. # check the synchronization: if the synchronization is correct, the tractor hole or the preprint mark is positioned exactly at the marker on the lateral ruler for the respective form length after a stop. Assignment of the markers to ...

Page 152: Affixing The Paper Web

Affixing the paper web introduction instead of inserting a new paper web using the autofeed function, you can affix the new paper web to an already inserted paper web. In this case, the assemblies remain swiveled on, and the paper web does not have to be rethreaded into the paper post-processing uni...

Page 153

To affix the paper web # proceed as follows: cut off the end of the paper web at the unroller or paper input at a clean right angle. 1. Cut off the beginning of the new paper web at a clean right angle. 2. Affix the paper web with any popular adhesive (e. G. Scotch atg 700). Make sure that the shift...

Page 154

Proceed as follows: move the affixed paper web with the 'advf' button through the printing system until the adhesive strip has completely passed through the paper post- processing unit. Watch the paper web at the paper input, and correct the path of the paper web as needed by running your hand sidew...

Page 155: Removing The Paper Web

Removing the paper web attention: to be able to remove the paper web, the printing system must be in the 'stop' status. To remove the paper web # proceed as follows: if the printing system is not yet in the 'stop' status: press the 'stop' button. 1. If required: switch the paper post-processing unit...

Page 156: Printing System

Opening or closing the doors on the printing system opening or closing the doors on the printing system — overview introduction note: right-hand side means right in paper path direction. Left-hand side means left in paper path direction. Overview you will find information on the following topics: ■ ...

Page 157: Opening Right Doors

Opening right doors to open the doors on the right-hand side # proceed as follows: on the right-hand side of the printing system, open the doors as shown. 1. Press the button at the bottom right on the center cover. 2. Pull center cover forward by the lower side and then lift upwards to remove. 3. C...

Page 158

Proceed as follows: hang center cover on the desig- nated bracket on the left door. 4. Open the inner door. Do this by lifting up the handle slightly and releasing the latch. 5. Chapter 6 - operating the printing system 158 opening right doors.

Page 159: Closing Right Doors

Closing right doors to close the doors on the right-hand side # proceed as follows: on the right-hand side of the printing system, close the inner door. Bring the latch to a horizontal position, lift up the inner door slightly using the handle and in- sert into lock. 1. Caution the center cover is c...

Page 160

Proceed as follows: ■ first attach the center cover above. ■ push the bottom of the cen- ter cover against the printing system until it latches into place. The pin must be exact- ly in front of the switch . 2. Close doors. 3. Chapter 6 - operating the printing system 160 closing right doors.

Page 161: Opening Left Doors

Opening left doors to open the doors on the left-hand side # proceed as follows: on the left-hand side of the printing system, open the doors as shown. 1. Press the button at the bottom right on the center cover. 2. Pull the center cover forward on the lower side and then lift up- wards to remove. 3...

Page 162

Proceed as follows: hang the center cover on the bracket provided on the left- hand door. 4. Open the inner door. Do this by lifting up the handle slightly and releasing the latch. 5. Chapter 6 - operating the printing system 162 opening left doors.

Page 163: Closing Left Doors

Closing left doors to close the doors on the left-hand side # proceed as follows: on the left-hand side of the printing system, close the inner door. Bring the latch to a horizontal position, lift up the inner door slightly using the handle and in- sert into lock. 1. Caution the center cover is conn...

Page 164

Proceed as follows: ■ first attach the center cover above. ■ push the bottom of the cen- ter cover against the printing system until it latches into place. The pin must be exact- ly in front of the switch. 2. Close doors. 3. Chapter 6 - operating the printing system 164 closing left doors.

Page 165

Replacing the developer station replacing the developer station — overview introduction a replacement cart is required to replace a developer station. Caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the repl...

Page 166

Attention: avoid incidence of light all 10 slots must be occupied either with developer stations or light protection covers. If a developer station is removed and stored without being replaced by another developer station, a light protection cover must be fitted in this slot. If you wish to re-insta...

Page 167

# description component sliding bracket 1 hoisting lift 2 brake bracket 3 developer station adapter 4 locking mechanism 5 developer station shelf (optional) a movable developer station shelf is recommended to store the developer station, which can be used for the safe storage of up to four developer...

Page 168

Overview you will find information on the following topics: ‘preparing the replacement cart’ on page 169 ■ ‘removing the developer station’ on page 171 ■ ‘storing the developer station in the developer station shelf’ on page 177 ■ ‘putting the developer station on the stacking tray’ on page 181 ■ ‘r...

Page 169

Preparing the replacement cart caution: before each use, check the replacement cart for operational readiness. If you find serious defects that could cause health hazards or material damage, the device must not be used. Attention: the replacement cart batteries should be recharged every night, or oc...

Page 170

To adjust the height of the sliding bracket # proceed as follows: undo the black rotating handles by turning them counterclock- wise. 1. Adjust the height of the sliding bracket and lock it by turning the black turning knobs clockwise. 2. Chapter 6 - operating the printing system 170 preparing the r...

Page 171

Removing the developer station removing the developer station caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer station to the lowest position of t...

Page 172

Proceed as follows: if the doors are not yet open, open them now: to remove a developer station in the upper print unit; open all doors on the left-hand side of the printing system. To remove a developer station in the lower print unit; open all doors on the right-hand side of the printing system. 3...

Page 173

Proceed as follows: push the maintenance cart in front of the developer station. ■ to move a developer station over a shorter section, move the brake bracket to the cen- ter position. This means all four wheels are free and the lift can be freely moved. ■ to move a developer station over a longer se...

Page 174

Proceed as follows: push the brake bracket down- wards. 7. Caution observe height and alignment of the hoisting lift the hoisting lift mandrel must be carefully inserted up to the stop point. Unlock the hoisting lift and push the hoisting lift mandrel careful- ly into the notch below the devel- oper...

Page 175

Proceed as follows: pull the developer station on to the hoisting lift up to the stop point. The developer station au- dibly snaps into place. 10. Detach the brake bracket, unlock the hoisting lift and move the maintenance cart as far from the print module as is necessary to prevent any collision be...

Page 176

Proceed as follows: move the maintenance cart with the developer station to the devel- oper station shelf or to a stacking tray: ■ to move a developer station over a shorter section, move the brake bracket to the cen- ter position. This means all four wheels are free and the lift can be freely moved...

Page 177

Storing the developer station in the developer station shelf caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer station to the lowest position of th...

Page 178

To store the developer station in the developer station shelf # proceed as follows: push both brake brackets of the developer station shelf down- wards. 1. Align the maintenance cart at a right angle to the developer sta- tion shelf and move the hoisting lift of the maintenance cart to the required ...

Page 179

Proceed as follows: carefully slide the hoisting lift mandrel as far as it will go into the notch below the developer station. If the hoisting lift mandrel does not slide easily into the notch, correct the height and/or align- ment of the hoisting lift. 3. Lock the hoisting lift and check that it is...

Page 180

Proceed as follows: unlock the hoisting lift and carefully detach the maintenance cart from the developer station module. 6. ‘removing the developer station from the developer station shelf’ on page 183 . 7. Chapter 6 - operating the printing system 180 storing the developer station in the developer...

Page 181

Putting the developer station on the stacking tray caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer station to the lowest position of the hoisting...

Page 182

Proceed as follows: release locking mechanism and move the hoisting lift away from the developer station. 2. ■ if a developer station is to be re-installed: ‘replacing the developer station from the stacking tray’ on page 187 . ■ if no developer station is to be installed, a light protection cover m...

Page 183: Shelf

Installing the developer station removing the developer station from the developer station shelf caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer ...

Page 184

To remove the developer station from the developer station shelf # proceed as follows: push both brake brackets of the developer station shelf down- wards. 1. Align the maintenance cart at a right angle to the developer sta- tion shelf and move the hoisting lift of the maintenance cart to the height...

Page 185

Proceed as follows: carefully slide the hoisting lift mandrel as far as it will go into the notch below the developer station. If the hoisting lift mandrel does not slide easily into the notch, correct the height and/or align- ment of the hoisting lift. 3. Lock the hoisting lift. Pull the maintenanc...

Page 186

Proceed as follows: detach the brake bracket of the maintenance cart, unlock the hoisting lift and move the main- tenance cart as far from the devel- oper station shelf as is necessary to prevent any collision between the developer station and the developer station shelf during operation. 6. ‘instal...

Page 187

Replacing the developer station from the stacking tray caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer station to the lowest position of the hois...

Page 188

Proceed as follows: insert the rolls of the replace- ment cart halfway into the guides of the developer station adapter. Pull the locking mechanism in the direction of the arrow and push the replacement cart in completely until it snaps in. The two green arrows on the right and left of the replaceme...

Page 189

Installing the developer station caution: ■ heavy weight note the heavy weight of the developer station (approx. 70 kg/145.35 lb) and the correct functioning of the locks on the replacement cart. ■ danger of tilting lower the developer station to the lowest position of the hoisting lift before trans...

Page 190

To install the developer station # proceed as follows: push the maintenance cart in front of the print module. ■ to move a developer station over a shorter section, move the brake bracket to the cen- ter position. This means all four wheels are free and the lift can be freely moved. ■ to move a deve...

Page 191

Proceed as follows: unlock the hoisting lift and push the hoisting lift mandrel careful- ly into the notch below the devel- oper station to the stop point. If the hoisting lift mandrel does not slide easily into the notch, correct the height and/or align- ment of the hoisting lift. 3. Lock the hoist...

Page 192

Proceed as follows: unlock the hoisting lift and carefully detach the replacement cart from the print module. 6. Caution make sure there is sufficient distance between the replacement cart and devel- oper station. Detach the brake bracket and move the replacement cart as far from the developer stati...

Page 193

Proceed as follows: remove the toner feed hose from the parking tube, insert it into the two mountings and attach it to the developer station. If the developer station is cooled via a cooling air tube, reconnect the tube to the developer station. 8. ■ if an additional developer station is to be repl...

Page 194

Replacing the light protection cover removing the light protection cover caution: hot surfaces on developer stations after a longer period of printing, the motor of the developer station may be hot. Do not touch the motor. Attention: avoid damage to remove a light protection cover, all developer sta...

Page 195

Proceed as follows: if the doors are not yet open, open them now: to remove a light protection cover in the upper print unit; open all doors on the left-hand side of the printing system. To remove a light protection cover in the lower print unit; open all doors on the right-hand side of the printing...

Page 196

Proceed as follows: pull the lock downwards and then pull the light protection cover out of the guides by the handle. 5. Remove further light protection covers as necessary. To do so, repeat the process from step 4. 6. If a developer station is to be installed instead of the light protection cover: ...

Page 197

Installing the light protection cover attention: avoid incidence of light all 10 slots must be occupied either with developer stations or light protection covers. If a developer station is removed and stored without being replaced by another developer station, a light protection cover must be fitted...

Page 198

Completing developer station replacement to complete the replacement of the developer stations # proceed as follows: caution observe the position of the cooling air tubes make sure that the cooling air tubes are positioned in such a way that they do not obstruct the developer stations when swiveling...

Page 199: Checking The Print Image

Checking the print image introduction to check the printed paper web at the paper output, printing can be interrupted with a web inspection stop. To check the print image # proceed as follows: press the 'ready' button on an additional operator panel during printing. The print operation is interrupt-...

Page 200: Printing Test Print Jobs

Printing test print jobs printing test print jobs — overview introduction preinstalled test print jobs can be started via the 'test print' menu. These print jobs, which are grouped in test sequences, can be used to optimize the print quality for a certain application. These optimized settings can th...

Page 201

Note: you will find detailed information about the individual test print jobs in the following sections: ■ print quality test for full-color printing ‘'5c_printqualityinspection.600' test print job’ on page 202 ■ test of the color functionality of the controller in 'i mode' ‘test print job 'colorpro...

Page 202

'5c_printqualityinspection.600' test print job test sequences the individual test sequences can be assessed to judge the print quality. Chapter 6 - operating the printing system 202 '5c_printqualityinspection.600' test print job.

Page 203

Chapter 6 - operating the printing system 203 '5c_printqualityinspection.600' test print job.

Page 204

Chapter 6 - operating the printing system 204 '5c_printqualityinspection.600' test print job.

Page 205

Description # settings on operator panel description test sequence 'configuration' -> 'color' -> 'contrast' menu optical density: designation of full tone coloration on the full tone bar at right angles to the print orientation. 1 'configuration' -> 'color' -> 'contrast' -> 'fine adjustment' menu de...

Page 206

Settings on operator panel description test sequence 'configuration' -> 'print param- eters' -> 'transfer optimization' menu designation of passage behavior at places printed on both sides. 4 'configuration' -> 'paper' -> 'shift' menu designation of print image posi- tioning on front and back pages....

Page 207

Test print job "colorproof.Ipds" test print job 'colorproof.Ipds' — overview introduction the colorproof test print jobs can be used to test the color functionality of the controller: ■ the 'colorproof.Ipds' test print job is designed for 'i mode' without 'abobe pdf print engine'. ■ the 'colorproof....

Page 208

Test print job 'colorproof.Ipds' — page 1 color spaces the page shows an extract from the individual printer color spaces. Ptoca color spaces the different ptoca color spaces are addressed in the upper area. For ptoca, 'satu- ration' is used as the default 'rendering intent' in color management. Cha...

Page 209

# description color space the oca color space including all oca names is addressed in the first row. This color space contains a small number of pre- defined colors. ■ the primary colors are always printed with 100% application and without a raster. ■ the (r, g, b) secondary colors are each printed ...

Page 210

Description color space the rgb values are printed as gif. The rgb values are inte- grated into the image as indexed colors. Gif all three color rows must conform color-wise in a vertical direction. Device color spaces the individual rgb values are converted into cmyk values. Color management is not...

Page 211

Test print job 'colorproof.Ipds' — page 2 embedded color profiles color profiles # description color profile in the first section, the tiff (lzw) and jpeg-images from page 1 are used, whereby a srgb profile is added for every color field (embedded profile): the two tiff and jpeg color rows must corr...

Page 212

Description color profile tiff and jpeg-images without embedded profile are used in the third section. However, a wide gamut audit profile is as- signed here. The two tiff and jpeg image rows within this section must correspond. They must also correspond with the images from the second section, as t...

Page 213

Test print job 'colorproof.Ipds' — page 3 full tone coloration full tone bars with the primary colors (cmyk) are printed across the width of the page. This means that full tone coloration can be tested across the entire print area. Tone transfer path the srgb tone transfer curve can be used to check...

Page 214

Test print job 'colorproof.Ipds' — page 4 highlight color raster angle and raster width all color stations are addressed using the 'i mode' color number via the highlight color. The printed gauges can be used to read out the raster angle and raster width for every color station. A moiré circle is cr...

Page 215

Test print job 'colorproof.Ipds' — page 5 color mapping table in the first row, each oca color is activated for foreground and background without mapping (overlapping squares). The second row shows the oca colors with the color mappingtable (cmt) currently selected in the printing system. The remain...

Page 216

Test print job 'colorproof.Ipds' — page 6/7 reference images this test page uses reference images from eci (© by european color initiative www.Eci.Org). Jpeg compression is used on page 6 of the test job, and tiff (lzw) format on page 7. Extract from the description of these images from eci: # descr...

Page 217

Description illustration this image is used to assess the correct tonal reproduction in dark areas. Also, brown tones are extremely sensitive to even the smallest incorrect setting of print colors in relation to one another. 5 neutral colors are difficult to achieve without a color cast. As is the c...

Page 218

Test print job "colorproof.Ipds_pdf" test print job 'colorproof.Ipds_pdf' — overview introduction the colorproof test print jobs can be used to test the color functionality of the controller: ■ the 'colorproof.Ipds' test print job is designed for 'i mode' without 'abobe pdf print engine'. ■ the 'col...

Page 219

Test print job 'colorproof.Ipds_pdf' — page 8 pdf color spaces the page shows an extract from the individual printer color spaces controlled under pdf. The entire pdf page is integrated as a ipds object container. The color fields correspond to the ipds-oca colors. Pdf does not know any color names ...

Page 220

# description color rows the rgb values corresponding to the ptoca colors are dis- played in srgb (range from 0 to 1, where "0" equals no satura- tion and "1" (= 255 with rgb) represents maximum satura- tion). The print output should correspond to theoca colors. Srgb color space according to iec 619...

Page 221

# description color rows the corresponding rgb values of the oca colors were con- verted to srgb. These are the same color values as those in the first color row with the scale of 0 to 1. Devicergb here the four color stations are accessed directly. They are sent color values on a scale of 0 to 1. I...

Page 222

Test print job 'colorproof.Ipds_pdf' — page 9 pdf tone transfer curves in the upper area, full tone bars with the primary colors (cmyk) are printed across the width of the page. Full tone coloration can be tested across the entire print area. In the lower area, tone transfer curves with primary and ...

Page 223

Test print job 'colorproof.Ipds_pdf' — page 10 pdf highlight color raster angle and raster width the printed gauges can be used to read the pdf raster angle and raster width for each print station. A moiré circle is created for every color station. The radial line in the center of the moiré indicate...

Page 224

Note: in the case of the fifth tone transfer curve, the relevant color is only displayed if the fifth color station is installed and "hlc5" is entered as the 'alias' for this color station. Otherwise, the color gradient appears in gray. The first pixels should be visible from 3% onwards. The optical...

Page 225

Test print job 'colorproof.Ipds_pdf' — page 11/12 referenzbilder this test page uses reference images from eci (© by european color initiative www.Eci.Org). The reference images are embedded in the pdf, which is itself integrated as the ipds object container. Jpeg compression is used on page 11 of t...

Page 226

Description illustration this image is used to assess the correct tonal reproduction in dark areas. Also, brown tones are extremely sensitive to even the smallest incorrect setting of print colors in relation to one another. 5 neutral colors are difficult to achieve without a color cast. As is the c...

Page 227

Test print job "colorproof.Pcl" test print job 'colorproof.Pcl' — overview introduction the colorproof test print jobs can be used to test the color functionality of the controller. The 'colorproof.Pcl' test print job is designed for 'pcl mode'. Each test page contains information on the current con...

Page 228

Test print job 'colorproof.Pcl' — page 1 color spaces the page shows an extract from the individual printer color spaces. Description # description item the rectangles in the upper area are composed of polygons filled with palette colors. The color palettes are defined in the rgb, cmy and cie l*a*b*...

Page 229

Description item in the lower area, full tone bars with the primary colors are printed across the width of the page. Full tone coloration can be tested across the entire print area. Full tone bars chapter 6 - operating the printing system 229 test print job 'colorproof.Pcl' — page 1.

Page 230

Test print job 'colorproof.Pcl' — page 2 palette management description # description item three different color palettes have been defined and saved: ■ marked red: rgb ■ marked cyan: cmy ■ marked violet: cie l*a*b* upper area then the active palette was deleted and the four-color rectangle was prin...

Page 231

Test print job 'colorproof.Pcl' — page 3 embedded color profiles description # description item here, jpeg images are used, where a profile is added for every color field (embedded profile). In the first row, the halftone images are printed as a reference in the rgb color space. The color profiles s...

Page 232

Test print job 'colorproof.Pcl' — pages 4-10 reference images these test page use reference images from eci (© by european color initiative www.Eci.Org). Description of images extract from the description of these images from eci: # description illustration this image is printed exclusively with the...

Page 233

Description illustration even slight color shifts are plainly visible in images with skin tones. This image is therefore ideal for visual assessment of the test print quality. 4 minor incorrect settings in the ratio of individual colors result in clearly visible color shifts in the reproduction of i...

Page 234

Test print job 'colorproof.Pcl' — page 11 hpgl/2 all graphical elements on this page are described in hpgl/2. If this page is reproduced correctly then the hpgl/2 function of the controller is largely free of errors. Chapter 6 - operating the printing system 234 test print job 'colorproof.Pcl' — pag...

Page 235

Description # description item all color stations are addressed via the 'color index'. You can adjust the 'color index' on the operator panel in the 'pcl simple color' menu. The printed gauges can be used to read out the raster angle and raster width for every print station. A moiré circle is create...

Page 236

Test print job 'colorproof.Pcl' — page 12 font test description a test line is printed using all of the available internal fonts. Chapter 6 - operating the printing system 236 test print job 'colorproof.Pcl' — page 12.

Page 237

'spotcolorpalette.Pcl' test print job introduction this test print job can be used to test the color palette in the hlc color space. Each test page contains information on the current configuration of the printing system in the left-hand margin. Pcl basic colors a color component can be assigned to ...

Page 238

Example: basic color 1 cyan, basic color 2 magenta, basic color 3 yellow example: basic color 1 yellow, basic color 2 magenta, basic color 3 cyan chapter 6 - operating the printing system 238 'spotcolorpalette.Pcl' test print job.

Page 239

Optimizing the color printing optimizing the color printing — overview introduction the colors can be manually tested by using the 'color check' menu. In doing so the full and half tone of each individual color is measured and optimized using a reference test print job. This mode can last up to 20 m...

Page 240

# recommendation application ‘performing a color test’ on page 242 for very high quality requirements after longer phases without full color printing for very high quality requirements after longer period of time in standby for very high quality requirements if the color control is switched on again...

Page 241

Recommendation application perform automatic calibration (see ‘calibrating the colors of the printing system — overview’ on page 244 ). If the 'color check' has been performed unsuccess- fully twice in succession if the tone transfer curve is still insufficient after 'color check' has been completed...

Page 242: Performing A Color Test

Performing a color test introduction the colors can be manually tested via the 'color check' menu. In doing so the full and half tone of each individual color is measured and optimized using a reference test print job. This mode can last up to 20 minutes. When optimization is complete, normal print ...

Page 243

Proceed as follows: click the 'activate' button. This mode can last up to 20 minutes. 'result of color check:' ■ 'successful' or ■ 'not successful' 2. Note: if the 'color check' function is carried out unsuccessfully twice in succession, then auto- matic calibration should be carried out (see ‘calib...

Page 244

Calibrating the colors of the printing system calibrating the colors of the printing system — overview introduction all the colors used in the printing system can be calibrated and as a result the active raster kit adjusted by using the 'calibrate color' menu. Two different types of color calibratio...

Page 245

■ if the tone transfer curve is still insufficient after 'color check' has been completed successfully examples: light raster not visible, dark raster not distinguishable, graduations throughout ■ if the 'color check' has been performed unsuccessfully twice in succession ■ for an error message trigg...

Page 246

Printing test pages for color calibration introduction requirements for printing test pages for color calibration: ■ the printing system is in the 'stop' status. ■ no other print job must be active. ■ the channel must be deactivated ('channels' menu). Note: the widest possible paper should be used t...

Page 247

Proceed as follows: under 'calibration type', select: ■ 'automatic determination of correction data by inline sensor' the measured values from the control strips, which are determined auto- matically during the print operation, are used to calculate the new raster kit. ■ 'manual printout scanning vi...

Page 248

Proceed as follows: note before the color calibration is started, the current settings are automatically stored in a "calibration setup". When the color calibration is cancelled, this configuration is then restored. The following additional steps are required for manual scanning of the print- outs: ...

Page 249

Scanning test pages for color calibration introduction the measuring device required for the manual scanning of the test print pages is supplied with all océ colorstream printing systems by default; the guide rail and clipboard are also provided. Note: ■ the scan program can be operated independentl...

Page 250

Proceed as follows: on the 'configuration' page, enter or select the following: ■ 'enter id no.': the id number printed on the test page. ■ 'number of test pages for upper print unit'/'number of test pages for lower print unit': number of test pages from the upper or lower print unit that are to be ...

Page 251

Proceed as follows: to warm up the measuring de- vice, depress the button on the left side of the measuring device for approximately 20 seconds. If the measuring device has been taken out of the cup: place the measuring device back in the cup. 6. Click the 'start' button on the operator panel to sta...

Page 252

Proceed as follows: scan the test strips: ■ place the measuring device in the guide rails as shown and move it next to the first test strip. ■ depress the button on the left of the measuring device until you hear a beep. ■ draw the measuring device across the entire test strip with a slow and smooth...

Page 253

Analyzing test pages for color calibration to analyze test pages for color calibration # proceed as follows: if you have not yet selected the 'evaluate' menu, choose the following on the operator panel: 'configuration' -> 'color' -> 'calibrate color' -> 'evaluate' menu click the 'next' button. The s...

Page 254

Proceed as follows: the system displays the recorded data for each color station in the upper and lower print units. Each field in the test strips is displayed in color: ■ green the values for this field are ok; no correction is necessary. ■ red the values for this field were measured outside of the...

Page 255

Correcting color separation shifts introduction in the case of color printing, the individual color separations are first collected in succession on the transfer belt and then transferred together to the paper web. Under certain circum- stances, the longitudinal register between black and the variou...

Page 256