- DL manuals

- Oce

- Printer

- CS9265

- Installation Manual

Oce CS9265 Installation Manual

Summary of CS9265

Page 1

Océ cs9265 océ cs9290 installation guide low solvent.

Page 2

Cs9200 low solvent series printers 2 ap-40301 – rev. 2.0 – 02/05/2008.

Page 3

Cs9200 low solvent series printers 3 ap-40301 – rev. 2.0 – 02/05/2008 copyright notice copyright © 2008 océ-technologies b.V. All rights reserved. Océ reserves the right to modify the information contained in this manual at any time without prior notice. This document may not be reproduced by any me...

Page 4

Cs9200 low solvent series printers 4 ap-40301 – rev. 2.0 – 02/05/2008.

Page 5

Cs9200 low solvent series printers 5 ap-40301 – rev. 2.0 – 02/05/2008 table of contents 1 installation environment......................................................................................................... 9 1.1 installation environment requirements .......................................

Page 6

Cs9200 low solvent series printers 6 ap-40301 – rev. 2.0 – 02/05/2008 step-by-step plan 1. Check installation environment ► refer to chapter 1 2. Unpack the printer, stand and boxes ► refer to chapter 3 3. Check in-the-box configuration ► refer to chapter 2 4. Assemble the printer / winder ► refer t...

Page 7

Cs9200 low solvent series printers 7 ap-40301 – rev. 2.0 – 02/05/2008 introduction after reading this manual, an authorized service technician will be able to install océ’s cs9265/cs9290 smoothly. The complete installation procedure, from unpacking until sending a test file, is described in detail. ...

Page 8

Cs9200 low solvent series printers 8 ap-40301 – rev. 2.0 – 02/05/2008.

Page 9: 1 Installation Environment

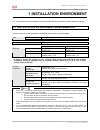

Cs9200 low solvent series printers 9 ap-40301 – rev. 2.0 – 02/05/2008 1 installation environment it is very important that the installation environment fulfils following conditions to obtain stable print quality. 1.1 installation environment requirements choose a place for printer installation follo...

Page 10: 1.2 Dimensions

Cs9200 low solvent series printers 10 ap-40301 – rev. 2.0 – 02/05/2008 1.2 dimensions 1.2.1 cs9265 1.2.2 cs9290

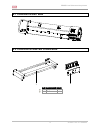

Page 11: 1.3 Required Space

Cs9200 low solvent series printers 11 ap-40301 – rev. 2.0 – 02/05/2008 1.3 required space 1.3.1 necessary free space a = 1,5 m b = 1,5 m c = 2,5 m d = 0,6 m e = 1,3 m distance c and d are interchangeable. Just ensure to have at one side of the printer at least 2,5 m. This to be sure that you can pas...

Page 12

Cs9200 low solvent series printers 12 ap-40301 – rev. 2.0 – 02/05/2008.

Page 13

Cs9200 low solvent series printers 13 ap-40301 – rev. 2.0 – 02/05/2008 2 verification of packaged items after unpacking the packaging box, inspect if the printer is not damaged and verify that all necessary parts are present. N otes t he contents of the packages may be different depending on the mar...

Page 14: 2.1 Contents Unit Box

Cs9200 low solvent series printers 14 ap-40301 – rev. 2.0 – 02/05/2008 2.1 contents unit box 2.2 contents printer stand box 1 2 nr description qty 1 stay 1 2 foot 2.

Page 15

Cs9200 low solvent series printers 15 ap-40301 – rev. 2.0 – 02/05/2008 2.3 contents installation kit 13 14 15 16 17 1 2 3 4 5 6 7 8 9 10 11 12 nr description qty 1 screwdriver philips p2 1 2 hexagon wrench 4 mm 1 3 hexagon wrench 5 mm 1 4 plain washer m6 16 5 spring washer m6 16 6 hexagon bolt m6x30...

Page 16: 2.4 Contents Starter Kit

Cs9200 low solvent series printers 16 ap-40301 – rev. 2.0 – 02/05/2008 2.4 contents starter kit 1 2 3 4 5 6 nr description qty 1 starter kit 1 2 commercial kit 1 3 user and good shape kit 1 4 + 5 + 6 ink starter set 1 2.4.1 commercial kit 1 2 3 4 5 nr description qty 1 user’s guide cs9200 low solven...

Page 17

Cs9200 low solvent series printers 17 ap-40301 – rev. 2.0 – 02/05/2008 2.4.2 user and good shape kit order number: 29801288 kit content: nr description qty 1 sponge plate 6 2 wipers 24 3 spitting box sponge 12 4 cleaning liquid 250 ml 3 5 instruction sheet 1 6 good shape kit 1 ▼ ▼ ▼ * good shape kit...

Page 18

Cs9200 low solvent series printers 18 ap-40301 – rev. 2.0 – 02/05/2008 2.4.3 océ ijc920 hs low solvent setup cleaning nr description qty part number 1 océ ijc920 hs low solvent setup cleaning 8 29952256 2.4.4 océ ijc920 hs low solvent cleaning nr description qty part number 1 océ ijc920 hs low solve...

Page 19

Cs9200 low solvent series printers 19 ap-40301 – rev. 2.0 – 02/05/2008 2.5 contents unwinder/winder 100 notes p lease refer to the user ’ s guide of the unwinder winder 100 for the complete in - the - box configuration ..

Page 20

Cs9200 low solvent series printers 20 ap-40301 – rev. 2.0 – 02/05/2008.

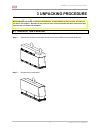

Page 21: 3 Unpacking Procedure

Cs9200 low solvent series printers 21 ap-40301 – rev. 2.0 – 02/05/2008 3 unpacking procedure caution w hen removing this product from the packaging box , always remove the vinyl plastic , and hold on the side of the product . H olding the unit over the vinyl plastic wrapping can result in slippage a...

Page 22

Cs9200 low solvent series printers 22 ap-40301 – rev. 2.0 – 02/05/2008 step 3 : remove the 2 boxes (stand and installation kit). Step 4 : remove the top card board of the printer body. Step 5 : remove the 3 buffers..

Page 23

Cs9200 low solvent series printers 23 ap-40301 – rev. 2.0 – 02/05/2008 step 6 : remove the covering plastic. Step 7 : prepare the printer to be installed on the stand. Please refer to chapter 5 for all necessary information. ► flip open the box when using a forklift. ► cut away the complete box when...

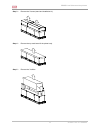

Page 24: 3.2 Unpack The Stand

Cs9200 low solvent series printers 24 ap-40301 – rev. 2.0 – 02/05/2008 3.2 unpack the stand step 1 : move the stand box to the location to unpack. Step 2 : open the package. Step 3 : remove the following items consecutively: 1. Buffers 2. Stand 3. Box with feet 4. Feet 1 2 1 1 1 3 4.

Page 25: 4 Assembling The Unit

Cs9200 low solvent series printers 25 ap-40301 – rev. 2.0 – 02/05/2008 4 assembling the unit caution w hen assembling this product , always work with at least 4 people or more 4.1 assembling the stand assemble the stand according to the following procedure. Step 1 : unpack the stand assembly as desc...

Page 26

Cs9200 low solvent series printers 26 ap-40301 – rev. 2.0 – 02/05/2008 4.2 installing the printer on the stand install the stand to the main unit according to the following procedure: step 1 : position the stand correctly (with the pcb box screw holes to the right). Front step 2 : insert the lifting...

Page 27

Cs9200 low solvent series printers 27 ap-40301 – rev. 2.0 – 02/05/2008 step 5 : fix the body to the stand using each time (8x) a hexagon screw (m6x16) + spring washer (m6) + plain washer (m6). Do not fix the screws tightly yet. Step 6 : check if there is no gap between the body and the stand. ► if t...

Page 28

Cs9200 low solvent series printers 28 ap-40301 – rev. 2.0 – 02/05/2008 4.3 remove protective materials. To ensure that nothing can be damaged during transport, temporary buffers and brackets are installed on the printer. Remove them before powering on the printer. 1 2 3 4 step 1 : remove the protect...

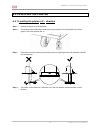

Page 29: 4.4 Levelling The Printer

Cs9200 low solvent series printers 29 ap-40301 – rev. 2.0 – 02/05/2008 4.4 levelling the printer 4.4.1 levelling the printer in x – direction step 1 : position the printer on its final position. Step 2 : turn down all feet of the printer stand with an equal pressure until the wheels come off the gro...

Page 30

Cs9200 low solvent series printers 30 ap-40301 – rev. 2.0 – 02/05/2008 4.4.2 levelling the printer in y – direction step 1 : open the front cover. Step 2 : place the level on the print platform. Step 3 : adjust the levelling feet until the printer is completely level. As for the example below ► high...

Page 31

Cs9200 low solvent series printers 31 ap-40301 – rev. 2.0 – 02/05/2008 4.5 install the unwinder/winder 100 notes • please refer to the user’s guide of the unwinder/winder 100 for the proper installation..

Page 32

Cs9200 low solvent series printers 32 ap-40301 – rev. 2.0 – 02/05/2008 4.6 install the waste bottle step 1 : hook the waste bottle assembly over the four pre-mounted screws and push it downwards. Step 2 : tighten the four screws. Step 3 : loosen the 2 waste tubes attached to the printer with some ta...

Page 33: 5 Connecting The Cables

Cs9200 low solvent series printers 33 ap-40301 – rev. 2.0 – 02/05/2008 5 connecting the cables 5.1 connecting the foot switch if the pressure rollers need to be raised or lowered, it is possible to do this by way of the foot switch, instead of doing so at the operation panel. Caution • w hen handlin...

Page 34

Cs9200 low solvent series printers 34 ap-40301 – rev. 2.0 – 02/05/2008 5.2 connecting the power cable the connection procedure for the power cable is explained below. Important • m ake sure that the enclosed power cable is used . U se of a different cable may result in electric shock or fire . • d o...

Page 35

Cs9200 low solvent series printers 35 ap-40301 – rev. 2.0 – 02/05/2008 step 1 : plug in the power cable to the inlet at the back of the printer. Step 2 : plug it in the power cable to the outlet important • d o not attempt to plug in electrical plugs with wet hands . D oing so may result in electric...

Page 36

Cs9200 low solvent series printers 36 ap-40301 – rev. 2.0 – 02/05/2008 5.3 connecting the printer to the pc 5.3.1 system requirements to use the printer with rip software, you need the following minimum requirements. System os windows 2000 professional cpu pentium iii 1 ghz or higher memory (ram) 51...

Page 37

Cs9200 low solvent series printers 37 ap-40301 – rev. 2.0 – 02/05/2008 5.3.3 connecting the centronics interface 5.3.3.1 installation the procedure for connecting the centronics interface is explained below. To connect the printer to your computer, follow the steps below. Step 1 : power off the prin...

Page 38

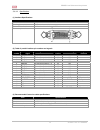

Cs9200 low solvent series printers 38 ap-40301 – rev. 2.0 – 02/05/2008 5.3.3.2 specifications (1) interface specifications item specifications transmission modes compatible , nibble , ecp mode data length 8 bits transmission direction unidirectional (receiving only), bidirectional connector pin numb...

Page 39

Cs9200 low solvent series printers 39 ap-40301 – rev. 2.0 – 02/05/2008 5.3.4 connecting the network interface 5.3.4.1 installation the procedure for connecting the network interface is explained below. To connect the printer to the network environment, follow the steps below. Caution • f ollow the i...

Page 40

Cs9200 low solvent series printers 40 ap-40301 – rev. 2.0 – 02/05/2008.

Page 41: 6.1 Parts Needed

Cs9200 low solvent series printers 41 ap-40301 – rev. 2.0 – 02/05/2008 6 loading ink for first time read these cautions first, before powering on the printer and installing ink cassettes for the first time. Caution • b efore using the ink and cleaning cassettes , be sure to read and understand the m...

Page 42

Cs9200 low solvent series printers 42 ap-40301 – rev. 2.0 – 02/05/2008 6.2 first ink load procedure step 1 : power on the unit. Step 2 : the carriage will automatically move to the left side of the machine. Open the front cover and moisten the rubber sides of the caps with solvent cleaning liquid wh...

Page 43

Cs9200 low solvent series printers 43 ap-40301 – rev. 2.0 – 02/05/2008 step 8 : the printer will automatically start pumping cleaning fluid. Step 9 : empty the waste bottle when asked and confirm later on with enter. Step 10 : at this time, we want to make sure that the ink tube system is completely...

Page 44

Cs9200 low solvent series printers 44 ap-40301 – rev. 2.0 – 02/05/2008 step 11 : please wait while the printer is sucking air. Step 12 : insert 8 new cassettes with low solvent cleaning when following message is displayed: step 13 : the printer will automatically start pumping cleaning fluid when al...

Page 45

Cs9200 low solvent series printers 45 ap-40301 – rev. 2.0 – 02/05/2008 d. Repeat this for all eight cassettes. E. When finished, remove all cleaning cassettes. Step 16 : please wait while printer is sucking air step 17 : insert 8 new cassettes with low solvent ink in the correct order when following...

Page 46

Cs9200 low solvent series printers 46 ap-40301 – rev. 2.0 – 02/05/2008.

Page 47: 7 Loading Media

Cs9200 low solvent series printers 47 ap-40301 – rev. 2.0 – 02/05/2008 7 loading media 7.1 loading roll media please refer to the user’s guide of the unwinder/winder 100 to know how to load roll media properly. 7.2 loading sheet media to load sheet media, follow the steps below. Step 1 : power on th...

Page 48

Cs9200 low solvent series printers 48 ap-40301 – rev. 2.0 – 02/05/2008 step 7 : make measurement settings in following menu: setupmenu (1/7) ► mediaset [f4] ► sheetsize menu choice description f1 auto media measurement sequence ► rear – right – left – top f2 length media measurement sequence ► right...

Page 49

Cs9200 low solvent series printers 49 ap-40301 – rev. 2.0 – 02/05/2008 8 head adjustments verification when the printer leaves the company, the heads are already adjusted. During transportation, the heads can be moved slightly. Therefore, it is recommended to verify the different head adjustments. T...

Page 50: 8.1 Head Slant Check

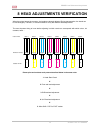

Cs9200 low solvent series printers 50 ap-40301 – rev. 2.0 – 02/05/2008 8.1 head slant check purpose of this check ► check if the heads are positioned straightly. How to print the file ► power on the printer in diagnostics mode ►adjustment [f2] ►headslant [f4] ►slant [f1] pattern 8b 8a 7b 7a 6b 6a 5b...

Page 51: 8.2 Front and Back

Cs9200 low solvent series printers 51 ap-40301 – rev. 2.0 – 02/05/2008 8.2 front and back purpose of this check ► to check if the heads are all positioned in one line. Notes please note that heads 1 to 4 has been shifted in production 1/720 of an inch (as explained in chapter 8.5) compared to heads ...

Page 52: 8.3 Bi-Directional

Cs9200 low solvent series printers 52 ap-40301 – rev. 2.0 – 02/05/2008 8.3 bi-directional purpose of this check ► to check if each head fires the ink at the same position when printing from right to left and left to right. ► the check will be done for all head heights # 1 = low # 2 = middle # 3 = hi...

Page 53

Cs9200 low solvent series printers 53 ap-40301 – rev. 2.0 – 02/05/2008 adjustment procedure please follow the instructions below to adjust the printer. Step 1 : print the first file ► [bi-d] ► [f1] – key. Step 2 : set the thickness of the media and press enter. Step 3 : confirm with enter to start p...

Page 54

Cs9200 low solvent series printers 54 ap-40301 – rev. 2.0 – 02/05/2008 step 5 : the first printed blocks are the reference and the blocks printed secondly should be aligned with the reference blocks. Refer to the image below to know in which direction. Second blocks are printed too much to the right...

Page 55: 8.4 Uni-Directional

Cs9200 low solvent series printers 55 ap-40301 – rev. 2.0 – 02/05/2008 8.4 uni-directional purpose of this check ► to check if each head fires at the same time compared with the reference head 1. How to print the files ► power on the printer in diagnostics mode ►adjustment [f2] ►menu 2/4 ► uni-d [f2...

Page 56

Cs9200 low solvent series printers 56 ap-40301 – rev. 2.0 – 02/05/2008 8.5 micro shift 1/720” for fast modes purpose of this check ► when all heads are in one line, and you want to print in one of the fast modes (fast 720, fast 540 or fast 360), head 5-8 (headset 2) have to be shifted 1 / 720 of an ...

Page 57

Cs9200 low solvent series printers 57 ap-40301 – rev. 2.0 – 02/05/2008 step 1 : copy the files to your computer’s hard disk. Step 2 : power on the printer in user mode (no diagnostics mode needed). Step 3 : turn off all heaters and make sure head height is low in user 1. Step 4 : load media. In orde...

Page 58

Cs9200 low solvent series printers 58 ap-40301 – rev. 2.0 – 02/05/2008 adjustment procedure please follow the instructions below to perform the micro shift. Step 1 : loosen the screws (1) fixing head 5-8. These heads have to be shifted 1 / 720 inch. In general, the µ-shift can be accomplished by tur...

Page 59: 9 Test Printing

Cs9200 low solvent series printers 59 ap-40301 – rev. 2.0 – 02/05/2008 9 test printing follow the steps below to do a test print and confirm if your printer operates correctly. Step 1 : power on the printer. Step 2 : load media. Step 3 : make sure that your printer is in normal [ready to print] - st...

Page 60

Cs9200 low solvent series printers 60 ap-40301 – rev. 2.0 – 02/05/2008 prints the bi directional test pattern at 300 cps. The purpose of this print is to check if the heads are still well adjusted. If necessary, adjust the heads. Please refer to the maintenance manual for all necessary information. ...

Page 61

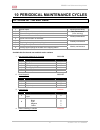

Cs9200 low solvent series printers 61 ap-40301 – rev. 2.0 – 02/05/2008 10 periodical maintenance cycles 10.1 done by the end user no° action frequency 1 clean wipers morning and evening 2 flush caps in maintenance station 3 clean the edges of the caps in maintenance station daily maintenance (in the...

Page 62

Cs9200 low solvent series printers 62 ap-40301 – rev. 2.0 – 02/05/2008 10.2 done by an authorized technician no° action frequency 1 changing the dampers 2 changing the spitting box + tube + l connection 3 applying grease on the head up-down cams when needed 4 applying grease on the y-motor belt if n...

Page 63

63 ap-40301 – rev. 2.0 – 02/05/2008 feedback sheet first ink load procedure dear customer, during the first few months after the cs9065-cs9090 launch, we want to collect data of all installations. During installation, the transition from water-based state to low solvent state is a key procedure, whi...