- DL manuals

- Oce

- Printer

- VarioPrint 6180

- User Manual

Oce VarioPrint 6180 User Manual

Summary of VarioPrint 6180

Page 1

User guide océ varioprint® 6000 line varioprint 6180, 6220, 6270, 6330

Page 2

Copyright and trademarks copyright copyright 2006-2017 océ. Illustrations and specifications do not necessarily apply to products and services offered in each local market. No part of this publication may be reproduced, copied, adapted or transmitted, transcribed, stored in a retrieval system, or tr...

Page 3: Contents

Contents chapter 1 introduction.........................................................................................................................9 notes for the reader.................................................................................................................................

Page 4

Use hotfolders................................................................................................................................................ 64 introduction to hotfolders...................................................................................................................

Page 5

Description of the print job settings that you can change on the control panel.............................. 130 change the [output] settings................................................................................................................ 143 change [2-sided] into [1-sided] and vice v...

Page 6

Introduction...................................................................................................................................................204 introduction to the media handling......................................................................................................2...

Page 7

Get access to the staplers............................................................................................................... 270 add staples.......................................................................................................................................271 close th...

Page 8

Contents 8 océ varioprint 6000 line.

Page 9

Chapter 1 introduction.

Page 10: Notes For The Reader

Notes for the reader typography this manual uses the following typography to indicate elements that are part of the user interface. Typography indicates [text between square brackets] name of a button, tile, setting, value, or other option of the user interface • name of a key on a keyboard • name o...

Page 11

Symbol type of symbol indicates caution laser beam indicates a caution concerning operations that may lead to in- jury to persons if not performed correctly. To use the ma- chine safely, always pay attention to these cautions. Important indicates operational requirements and restrictions. Be sure to...

Page 12: Users of The Print System

Users of the print system the océ varioprint® 6000 line enables to set up a flexible and efficient print environment. Default user groups the océ varioprint® 6000 line knows five default customer user groups, each with their default access rights. Users can be member of one or more user groups: defa...

Page 13

Information in this operation guide contents of this guide read this operation guide to learn what the océ varioprint® 6000 line product can do for you, how to operate and maintain the print system, and how to use it in a safe way. The guide starts with basic information on the print system (chapter...

Page 14: Available Documentation

Available documentation introduction this machine is delivered with the following items: • a 'documentation and driver notice' • a 'safety information sheet'. Main content of the user manuals note please check downloads.Oce.Com for the latest version of the documentation. The following table provide...

Page 15

Chapter 2 explore the print system.

Page 16

Introduction to the océ varioprint® 6000 line introduction the océ varioprint® 6000 line is a series of high-volume, cut-sheet printers. The printers are intended both for document printing and stream printing. The key feature of the machine is the océ gemini instant duplex technology. This technolo...

Page 17

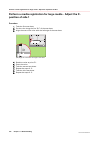

Introduction to the main system components introduction the following illustrations show the main system components. The table describes the main components. Please follow the links in the table for comprehensive information. 5 3 4 1 2 6 5 7 3 4 the main system components component function 1 contro...

Page 18

Component function 4 engine module the engine module contains the components that print the media. Access to the engine module is only required when a paper jam occurs or when maintenance is re- quired. The doors at the left-hand side and right-hand side of the engine module give access to the toner...

Page 19: The Paper Modules

The paper modules introduction the paper trays contain the media that are required for the print jobs. The default configuration of the machine contains 1 paper module with 4 paper trays. • two standard trays with a capacity of 600 sheets each. • two bulk trays with a capacity of 1,700 sheets each (...

Page 20

The parts of the control panel number description 1 the leds indicate the current amount of sheets in the corresponding paper tray. Each lit-up led indicates the presence of about 100 sheets (based on media of 80 g/m 2 or 20 lb bond). 2 press the button to open the corresponding paper tray. You can ...

Page 21: The Output Locations

The output locations introduction the machine supports several output locations for the printed jobs. The default configuration of your machine contains a stacker and the system output. The finisher is an optional output location. Furthermore, you can connect several optional external finishers to t...

Page 22

Component description 3 [finisher] (op- tional) the optional finisher contains the following output trays. • 3 output trays • 1 upper output (see no. 4 below) the finisher contains 2 staple cartridges to staple the jobs. The 3 output trays can receive a4, letter and similar media sizes. Stapled jobs...

Page 23: Form Assist Module

Optional finishers and other devices form assist module introduction the printer allows you to print on special media with irregular thickness. Examples of such media are media with glued-on (membership or bank) passes, folded media, or media with a slip attached. When you load a stack of special me...

Page 24: Easylift

Easylift introduction the easylift is a device that helps you to lift stacks of paper out of the stacker more easily. The easylift is delivered with an 'information sheet'. Caution the maximum lifting weight is 15 kg / 33 lb. Caution: this is only a guideline, the amount may be lower/higher dependin...

Page 25

7" x 10" statement size support introduction the smallest media size that this machine supports is 203 x 203 mm / 7.9 x 7.9 inch. The 7" x 10" statement size support device enables you to print on media with a size of 7 x 10 inches / 178 x 254 mm and on jis b5. You can insert this device in your bul...

Page 26

Action illustration 4 flip the metal plates over to the left-hand side over the media. 5 close the paper tray 7" x 10" statement size support 26 chapter 2 - explore the print system océ varioprint 6000 line.

Page 27: Dual Paper Tray

Dual paper tray introduction the dual paper tray enables you to load 2 stacks of the same media in one paper tray. When the first stack of media becomes empty, the printing stops. The second stack is moved to the left- hand side and printing continues. A dual paper tray replaces a bulk tray. Contact...

Page 28

Icon description the left-hand stack of the dual paper tray is partly filled. Note each line of the left-hand stack indicates the presence of about 100 sheets. The right-hand stack of the dual paper tray is partially or completely fil- led. Note the right-hand part of the dual paper tray is assumed ...

Page 29: Flex-Xl Paper Input Module

Flex-xl paper input module the flex-xl pim paper input module is the same as the standard paper module. The only difference is that the two bulk trays are replaced by flex-xl trays. A flex-xl tray can contain media until media size 350 mm x 500 mm. The minimum media size 208 mm x 203 mm. You can ins...

Page 30

Integrated camera mounting unit icmu the integrated camera mounting unit icmu is a unit that can contain a camera system. With the camera system you can compare the actual printed sheets with the digital original. When the printed image and the original do not match the print job is aborted. Interfa...

Page 31

Chapter 3 explore the ease of operation.

Page 32

What the print system can do for you the océ varioprint® 6000 line is an easy-to-use multitasking print system that offers many useful functions. You can define the same job properties from several locations : in remote printer driver, the control panel, and remote manager. Across the whole print wo...

Page 33: Control Panel

Control panel the control panel is the location on the print system to manage print jobs, copy jobs, and scan jobs. The control panel provides you full system control. 1 11 2 3 4 5 7 8 10 6 9 the following table describes the main parts of the control panel and their functions. The main components o...

Page 34

Component function 8 [system] button access the [system] section to do the following, for example: • check the status of the toner, staples and other supplies. • get information of the finishers. • read counters. • start maintenance. • set up the preferred workflows. • change a number of default sys...

Page 35

The access to the control panel can be secured to protect the contents of the documents and print quality settings. When the access to the control panel is secured, you need to log in to the print system. The system administrator is responsible for user authorization and for providing your credentia...

Page 36: Settings Editor

Settings editor introduction the settings editor is a web-based application and therefore accessible via an internet browser. The settings editor enables you to manage settings or to display information in the following areas. Prismasync offers the web-based settings editor to configure the print sy...

Page 37

You can now make the required changes. Settings editor chapter 3 - explore the ease of operation 37 océ varioprint 6000 line.

Page 38: Remote Manager

Remote manager the web-based remote manager provides workload planning on the configured prismasync print systems. Workload planning helps to achieve an optimal print production and an efficient job handling. When you work with remote manager, you can access the queues of the connected print systems...

Page 39: Media-Based Workflow

Media-based workflow the media catalog is the backbone of the media-based workflow. The media catalog contains the media that the print system supports. The prepress staff select the media for the job from the media catalog. The control panel shows the operator the media the job needs. The operator ...

Page 40: Document Printing Workflow

Document printing workflow the document printing workflow describes the route from the job preparation to the finishing and delivery of the printed output. The document printing workflow has four phases: 1. Job preparation prepress staff defines the print document and job settings, and submits the p...

Page 41

Transaction printing workflow when there is a license for transaction printing (ipds or pcl), you can operate the print system in the transaction printing mode. An ipds or pcl host sends a streaming job to a dedicated port in the print system. The transaction printing mode fits print environments wi...

Page 42

• tray-to-tray mapping you specify which logical tray (indicated by a number) corresponds to a physical paper tray. The print system will use the media that are loaded in the physical paper tray to which the job refers via a logical tray. Also other paper trays that contain these media are used when...

Page 43

Chapter 4 start the print system.

Page 44

The power buttons and power modes the power buttons the printer has the following button to control the power supply. Button name description sleep button the sleep button is located at the right-hand side of the control panel. Using the sleep button puts the printer in- to sleep mode, wakes the pri...

Page 45

Power mode control panel description sleep mode off once the printer has been idle for the time defined in the [sleep mode timer] setting in the settings editor, the printer goes into sleep mode automatically. Compared to the low power mode, the printer uses less energy. Possible values: 16 - 240 mi...

Page 46: Turn On The System

Turn on the system procedure 1. Press the sleep button at the right-hand side of the control panel. The power switch must be turned on. Turn on the system 46 chapter 4 - start the print system océ varioprint 6000 line.

Page 47: Shut Down The System

Shut down the system illustration [8] shut down the system procedure 1. Touch [system] -> [setup] -> [shut down system]. The control panel displays the message [are you sure you want to shut down?]. 2. Touch [yes]. A message indicates when the shut down will begin. When the shut down is complete, th...

Page 48: Restart The System

Restart the system introduction you can restart the system via the settings editor (under [support] -> [troubleshooting]) or via the printer control panel. Illustration [9] restart the system procedure 1. Touch [system] -> [setup] -> [shut down system]. The control panel displays the message [are yo...

Page 49

Chapter 5 prepare the print system.

Page 50: Adjust The Control Panel

Adjust the control panel you can change several settings to adjust the control panel according to your needs or workflow. Change the display language of the control panel 1. Touch [system] -> [setup] -> [language]. 2. Select the language. 3. Touch [ok] adjust the warning time the dashboard and the o...

Page 51

[11] job name truncation 1. Touch [system] -> [setup] -> [job name truncation]. 2. Indicate how you want to shorten the job name. 3. Touch [ok]. Adjust the readability of the control panel you can adjust the brightness and contrast of the control panel screen. Use the automatic or manual adjustment....

Page 52

[12] control panel adjustments 1. Touch [system] -> [setup] -> [control panel settings]. 2. Choose the automatic adjustment method or touch the + and - buttons to adjust the brightness and contrast manually. 3. Touch [ok]. Use pinch zoom gestures when you want to use pinch-in and pinch-out gestures ...

Page 53

[13] multi-touch function 1. Touch [system] -> [setup] -> [control panel settings]. 2. Enable the multi-touch function. 3. Touch [ok]. 4. Restart the system. Adjust the control panel chapter 5 - prepare the print system 53 océ varioprint 6000 line.

Page 54

Work with the workflow profiles introduction the machine is used in different printing environments. Each environment requires other settings to optimize the workflow or to meet your personal workflow preferences. The machine contains a number of default workflow profiles to help you optimize your w...

Page 55

Job by job workflow profile [job by job] docbox scheduled jobs finishing and delivery printing media loading waiting jobs print production job planning [15] job by job workflow profile • the job-by-job workflow profile fits a workflow in which every job needs attention. • all jobs come in the list o...

Page 56

Manual planning workflow profile [manual planning] print production job planning docbox scheduled jobs finishing and delivery printing media loading waiting jobs [17] manual planning workflow profile • the manual planning workflow fits a workflow in which you want to determine the print priority of ...

Page 57

The default settings for [print] the default [print] settings workflow profile [print] settings [confirm start of job] [check first set] [standard] [off] [as in job] [job by job] [on] [as in job] [check and print] [off] [on] [manual planning] [off] [as in job] [unattended] [off] [off] the default se...

Page 58

Setting values effect [confirm start of job] [on] the machine always stops before the next scheduled job. Touch [resume] in the dashboard to start each job. [off] the machine keeps printing all the jobs. The machine does not stop before the next scheduled job, unless there is a reason to stop. For e...

Page 59: Editor)

Automated workflows (access through the settings editor) introduction to automated workflows definition the settings editor enables you to set up separate automated workflows. Automated workflows are print queues that you can program to perform a range of operations. Automated workflows are mostly u...

Page 60: Add An Automated Workflow

Add an automated workflow introduction the settings editor contains 1 factory default automated workflow. However, it can be beneficial for your productivity to add more automated workflows. Note it is not compulsory to define all the settings. When you put a check mark in front of a setting, that s...

Page 61: Edit An Automated Workflow

Edit an automated workflow introduction you can change the attributes of an existing automated workflow. Note it is not compulsory to define all the settings. When you put a check mark in front of a setting, that setting and its values become enabled. Procedure 1. Go to [workflow] -> [automated work...

Page 62: Delete An Automated Workflow

Delete an automated workflow introduction when you no longer need a certain automated workflow, you can delete that workflow. Note you cannot delete the factory default automated workflow. Procedure 1. Go to [workflow] -> [automated workflows]. 2. Put a check mark in front of the workflow you want t...

Page 63

Restore the factory default workflow introduction you can restore the factory default automated workflow. This has the following consequences. • all the automated workflows you added will be removed • all the changes in the default workflow will be lost. Procedure 1. Go to [workflow] -> [automated w...

Page 64: Use Hotfolders

Use hotfolders introduction to hotfolders introduction technically, a hotfolder is a mapped network drive on a workstation that is linked to a shared folder on the prismasync controller. For an operator, a hotfolder is a folder on a workstation where printable files can be dropped for printing. Hotf...

Page 65

Activate the hotfolder function introduction the information in this section is intended for system administrators. Note • by factory default, the hotfolder function is disabled. To use the hotfolder function, the system administrator must activate this function once. • for this procedure, the syste...

Page 66: Create A Hotfolder

Create a hotfolder introduction the information in this section is intended for system administrator. Before you begin the hotfolder function must be activated. Otherwise, the system administrator must activate the hotfolder function first. Procedure note for this procedure, the system administrator...

Page 67

Create a shared network folder on a workstation introduction the information in this section is intended for key operators. Before creating a shared network folder on a workstation, the following actions must be carried out first: • enable the hotfolder function. • create an automated workflow (opti...

Page 68

Create a hotfolder default ticket ('default_ticket.Jdf') introduction hotfolders are primarily aimed at recurring workflows. In these workflows identical printable files with identical settings are printed on a regular basis. A hotfolder default ticket (' default_ticket.Jdf') in the hotfolder determ...

Page 69: Accounting

Accounting general information the basics of accounting introduction note accounting requires a license. Contact your local authorized dealer for more information. The accounting function is meant to charge the costs for jobs to customers or users. Below, the basics of accounting are described. Deta...

Page 70

The accounting related settings in the settings editor description note accounting requires a license. Contact your local authorized dealer for more information. The table below describes the available accounting related settings in the settings editor (navigate to [configuration] -> [accounting]). ...

Page 71: The Account Log File

The account log file the account log file the name of an account log file note accounting requires a license. Contact your local authorized dealer for more information. An account log file has the following name format: , for example 012345678920120115.Csv. Item description the serial number of the ...

Page 72

Field name specification description a text string with a max- imum length of 40 char- acters a unique identification for a job or document, which is supplied by the submitter of the job. The document id is extracted from the print data, for ex- ample the attribute 'documentid' in an ojt. This field...

Page 73

Field name specification description :: note when you open the file in microsoft® excel, the time format changes into the time for- mat that is de- fined in micro- soft® excel the time on which the printer started printing the job. Typically, this is the first moment that a job can be interrupted or...

Page 74

Field name specification description a text string with a max- imum length of 40 char- acters the account id as defined in the [account id] field of the [account] tab of the printer driver, or on the control panel, or in the attribute 'accountid' in an ojt, for example. This field is empty when the ...

Page 75

Field name specification description plex>(1-16)* a number the number of 1-sided sheets of a certain paper type used in a job. Plex>(1-16)* a number the number of 2-sided sheets of a certain paper type used in a job. Mat>(1-16)* a text string with a max- imum length of 255 characters the media size ...

Page 76

Field name specification description a number the number of booklets in a job. A number the number of bound sets in a job. Note * all fields that contain (1-16) will be included 16 times in an account log file. Each number refers to the type of media (1 up to 16) that is used. The media characterist...

Page 77

Save an account log file procedure note accounting requires a license. Contact your local authorized dealer for more information. 1. In the settings editor, click [configuration] -> [accounting]. 2. Click [download account log file]. 3. Click the link to the required file, then click [save]. 4. Brow...

Page 78

Learn about user authentication the océ varioprint® 6000 line offers many security features because the printer often needs to handle sensitive documents and information. If settings and functions are not secure, someone can change jobs, re-route jobs, or change important system settings. The user a...

Page 79

Default user group only per‐ sonal jobs all jobs remote tools mainte‐ nance tasks configura‐ tion set‐ tings it settings operators central op- erators key opera- tors mainte- nance oper- ators system ad- ministrators default user accounts after installation of the printer, each default user group ha...

Page 80

Learn about user authentication 80 chapter 5 - prepare the print system océ varioprint 6000 line.

Page 81

Chapter 6 prepare the print jobs.

Page 82

Where to define print job settings introduction print jobs can vary from straightforward jobs with only a few settings to complex jobs with extended settings. Therefore, there are several possibilities to define the settings for your print jobs. For straightforward jobs, the use of the printer drive...

Page 83

Item description control panel after a print job has arrived on the prismasync controller, the print job becomes visible on the control panel. There you can change a number of job settings or combine print jobs, for exam- ple. It is best to change the print job settings in the list of [waiting jobs]...

Page 84

Print a job using océ prismaprepare (optional) introduction océ prismaprepare enables you to prepare the print job completely on page level. You can preview the result per page. Océ prismaprepare is an optional application. This procedure describes the most important settings for daily use. Procedur...

Page 85

3. Define the required finishing options. Note see the online help of océ prismaprepare for detailed information. Print a job using océ prismaprepare (optional) chapter 6 - prepare the print jobs 85 océ varioprint 6000 line.

Page 86

Print a file from a usb drive introduction you can print documents (*.Pdf, *.Ps, *.Prn files) on a usb drive. You can disable / enable this function in the settings editor. Illustration [21] example of a folder structure on the usb drive print a file from a usb drive 86 chapter 6 - prepare the print...

Page 87

[22] save a file to a different location procedure 1. Insert the usb drive into the usb port at the left-hand side of the control panel. 2. On the control panel, touch [jobs] -> [usb]. 3. Touch to browse through the directories on the usb drive. 4. Touch the file or files you want to print, or touch...

Page 88

Print a page number via prismasync introduction you can print a page number on each page for pdf print jobs. Per job you can specify the position and alignment of the page number, the prefix, and the suffix of the page number. You can also add a page number via prismaprepare. In prismaprepare you ca...

Page 89

Chapter 7 plan the workload remotely.

Page 90

Prismasync remote manager (option) with prismasync remote manager you can monitor printers, operate printers remotely and send jobs and ready-to-print documents to the printer queues of all configured printers. You must enable and configure prismasync remote manager in the settings editor. Refer to ...

Page 91

Use the remote control app to monitor printing the prismasync remote control app helps you to stay informed about the print production on the available prismasync printers. Even at a distance. With prismasync remote control on your smartphone, you see the status of your prismasync driven printers at...

Page 92

Set up the remote control app 1. Download the prismasync remote control app from google play or the apple app store . 2. Start the app and log in with your google or microsoft account. 3. Change the default settings, if required. Use the remote control app to monitor printing 92 chapter 7 - plan the...

Page 93

Chapter 8 plan the jobs.

Page 94: Manage The Jobs In The Queue

Manage the jobs in the queue schedule a waiting job for printing introduction the destination of jobs is determined by the selected workflow profile. When jobs go to the list of [waiting jobs], you must manually send the jobs to the print queue (list of [scheduled jobs]). This enables you to keep fu...

Page 95

Print an urgent job immediately introduction when a job must be printed urgently, you can give that print job priority over all other print jobs. The [print now] button allows you to print a job immediately. When you use the [print now] button, the active print job will be paused as soon as the curr...

Page 96: Give Priority to A Print Job

Give priority to a print job introduction when you want to print a job as soon as possible, but not necessarily immediately, you must use the [to top] function. The [to top] function moves the selected job to the second position in the list of [scheduled jobs], below the active print job . The job w...

Page 97: Print A Scheduled Job Later

Print a scheduled job later introduction the machine prints the jobs that are present in the list of [scheduled jobs] jobs. However, you can decide to print a job later, for example because: • the required media are out of stock, or • you first want to make a proof. Then you must move the job back t...

Page 98

Send a job to another printer you can send jobs with their settings to another prismasync printer from the following locations: • list of scheduled jobs • list of waiting jobs • a docbox • list of printed jobs note when one or more settings or finishing options for the job are not available on the s...

Page 99

Bundle jobs in the list of [waiting jobs] introduction the bundle function allows you to combine two or more jobs into one new job. For example, this can be convenient when the participants of a meeting need several documents in a specific order. Often, the required documents are sent from several w...

Page 100

2. Touch the jobs you want to combine, or use an option from the [select] menu to select multiple jobs at once. 3. Touch [bundle]. A [create bundle] window appears that allows you to make some changes. 4. If necessary, use the [up] and [down] buttons to change the job order. 5. If necessary, change ...

Page 101: Add Extra Sheets to A Job

Add extra sheets to a job introduction you can add extra sheets to print and copy jobs to get more information on your printed jobs. Include banner and trailer pages to see the beginning and end of a job. Use separator sheets to separate the sets in jobs. Print job information is printed on banner a...

Page 102: Use The Docbox (Option)

Use the docbox (option) the docbox function introduction to the docbox function introduction docbox is short for document box. The docbox function, which is available through the control panel, creates a buffer between the preparation of a job and the printing of the job. The docbox supports the ope...

Page 103

• to store jobs that must be reprinted regularly, for examples reports or books. Introduction to the docbox function chapter 8 - plan the jobs 103 océ varioprint 6000 line.

Page 104

Create a new docbox illustration [27] create a docbox procedure note only the system administrator is allowed to create a new docbox in the settings editor. 1. Open your web browser and enter the host name or ip address of the prismasync controller. 2. Log on to the settings editor as system adminis...

Page 105: Handle The Jobs In A Docbox

Handle the jobs in a docbox overview of the available settings for docbox jobs introduction when you select a job in a docbox and touch [properties], the current settings of the selected job are displayed. Below, the available settings are described. Note depending on the type of job you want to edi...

Page 106

Change the job settings 1 2 4 5 3 number pane description 1 [original] the [original] pane shows general job information 2 [output] the [output] pane shows the output settings you can define for the whole job 3 [jobs] the [jobs] pane shows the general settings you can define for the job 4 preview th...

Page 107

[binding edge] setting values description [binding edge] [portrait left] • the original has a vertical format (height > width). • the binding edge is at the left-hand side. • when you turn a sheet over the binding edge, the image or text on the back of the sheet is in readable form. [portrait top] •...

Page 108

[cover] setting values description [cover] [front] touch the button to toggle between [on] and [off]. When [front] is [on] then the [media] setting below [front] becomes enabled. [media] when [front] is [on], you can select a media from the media catalog to use as front cover. [print sides] when [fr...

Page 109

[layout] setting values description [layout] [normal] the machine prints the pages with no special lay- out settings. [booklet] the machine prints the pages in booklet order. The pages one and four are printed on the front side of a sheet. The pages two and three are printed on the back side of a sh...

Page 110

[align] setting values description [align] [top left] an image on a sheet may be smaller than the media size of the output, for example because you scaled the image to 70% of its original size. The [align] setting allows you to indicate the position of the image on the sheet. [top left] moves the im...

Page 111

[shift] setting values description [shift] [margin shift] use this setting to increase or decrease the margin. By default, the values of the front side and the back side are interlocked. This means that the values for the front side and the back side remain identical. Widening the margin can be usef...

Page 112

[print delivery] setting values description [print delivery] 1 [output location] select the output location for the job. Depend- ing on the settings for your copy job, the ma- chine automatically suggests the preferred output location for your job. However, you can manually overrule this suggestion....

Page 113

Setting values description [print delivery] 2 [sheet order] [face up] deliver the prints face up, first sheet on top. [face up reverse] deliver the prints face up, last sheet on top. [face down] deliver the prints face down, first sheet on top. [face down reverse] deliver the prints face down, last ...

Page 114

Setting values description [print delivery] 3 [print order] • [front/back] default value. The front page on the front, the back page on the back. • [back/front] puts the front page on the back and the back page on the front. [rotation] • [0 degrees] • [180 degrees] rotates the prints 180 degrees. [m...

Page 115

[print quality] setting values description [print quality] [brightness] (default 0) when your prints are too dark or too light, changing the brightness can correct this prob- lem. -1 to -3 creates darker prints. +1 to +3 creates lighter prints. [contrast] (default 0) when the difference between ligh...

Page 116

Setting values description [print quality] [color profile] (default [normal]) you can use color profiles when you print col- or images on a b&w printer. The selected col- or profile determines how a color image is re- produced in black and white. • [enhanced] is a color profile developed by océ that...

Page 117

[number of sets] setting values description [number of sets] [check first set] when the [check first set] setting is enabled, the printer stops after the first set of a job has been printed. You can check the quality of the output. Note this setting is only available when in the workflow profile [ch...

Page 118

[page numbering] this setting is only available for pdf jobs. Setting values description [page numbering] [on] print a page number on each page of the job. [off] no page number on each page of the job. [position] [top left] [top center] [top right] [bottom left] [bottom center] [bottom right] the po...

Page 119

Edit a job in a docbox procedure 1. On the control panel, touch [jobs] -> [docbox]. 2. Touch the docbox that contains the job you want to edit. 3. Touch the job you want to edit. 4. Touch [properties], or double-tap the job to open the [properties] window. 5. Change the required settings. 6. Touch [...

Page 120

Combine jobs in a docbox (build function) introduction you can combine a job in a docbox with other jobs from the same docbox. The system creates a new job from the selected jobs. The icon indicates a built job. Note you cannot combine pdf jobs with non-pdf jobs. Illustration [28] the [create build]...

Page 121

Split a combined job in the docbox introduction you can split a combined job in the docbox into the original separate jobs. Then the system restores the jobs with their original settings and status. You cannot split a combined job in the list of waiting jobs. Note you can only split a job when the j...

Page 122

Lock a job in a docbox introduction the docbox allows you to lock the settings of your jobs. Advantages: • settings cannot be changed accidentally. • the job is always printed exactly the same. Illustration [29] select [lock]. Procedure 1. On the control panel, touch [jobs] -> [docbox]. 2. Touch the...

Page 123

Unlock a job in a docbox introduction unlocking a job can be required if you want to split a locked, combined job into the original jobs, for example. Illustration [30] select [unlock]. Procedure 1. On the control panel, touch [jobs] -> [docbox]. 2. Touch the docbox that contains the job you want to...

Page 124

Move a job from one docbox to another illustration [31] move a docbox job procedure 1. On the control panel, touch [jobs] -> [docbox]. 2. Touch the docbox button that contains the job you want to move. 3. Touch the job you want to move. 4. Touch the [move] button, or select [move] from the drop-down...

Page 125: Print The Jobs In A Docbox

Print the jobs in a docbox print a non-urgent job from the docbox introduction you can print jobs from the docbox in two ways: • without urgency the system sends the print job to the bottom of the list of [scheduled jobs]. • with urgency (immediately) the system sends the print job to the top of the...

Page 126

Print an urgent job from the docbox immediately introduction you can print jobs from the docbox in two ways: • without urgency the system sends the print job to the bottom of the list of [scheduled jobs]. • with urgency (immediately) the system sends the print job to the top of the list of [schedule...

Page 127

Select and print multiple jobs from the docbox introduction when you want to print one job in a docbox, select and print that job. However, you can also select multiple jobs at a time. The table below shows the available options. Select multiple jobs jobs description [all] select all the jobs from t...

Page 128

Procedure 1. On the control panel, touch [jobs] -> [docbox]. 2. Touch the docbox that contains the jobs you want to print. 3. Touch the [select] button. 4. From the drop-down menu, select the required option. 5. Touch [print]. Select and print multiple jobs from the docbox 128 chapter 8 - plan the j...

Page 129

Chapter 9 carry out print jobs.

Page 130: Control Panel

Change the print job settings on the control panel description of the print job settings that you can change on the control panel introduction usually, the settings for a print job is defined in pdls, applications, printer drivers, automated workflows, or hotfolder default tickets. However, when a j...

Page 131

4. Use the zoom function to view specific details. Change the job settings 1 2 4 5 3 number pane description 1 [original] the [original] pane shows general job information 2 [output] the [output] pane shows the output settings you can define for the whole job 3 [jobs] the [jobs] pane shows the gener...

Page 132

[binding edge] setting values description [binding edge] [portrait left] • the original has a vertical format (height > width). • the binding edge is at the left-hand side. • when you turn a sheet over the binding edge, the image or text on the back of the sheet is in readable form. [portrait top] •...

Page 133

[cover] setting values description [cover] [front] touch the button to toggle between [on] and [off]. When [front] is [on] then the [media] setting below [front] becomes enabled. [media] when [front] is [on], you can select a media from the media catalog to use as front cover. [print sides] when [fr...

Page 134

[layout] name of the setting available options description [layout] [normal] the printer prints the pages with no special layout settings. [booklet] the printer prints the pages in booklet order. The pages 1 and 4 are printed on the front side of a sheet. The pages 2 and 3 are printed on the back si...

Page 135

[align] setting values description [align] [top left] an image on a sheet may be smaller than the media size of the output, for example because you scaled the image to 70% of its original size. The [align] setting allows you to indicate the position of the image on the sheet. [top left] moves the im...

Page 136

[shift] setting values description [shift] [margin shift] use this setting to increase or decrease the margin. By default, the values of the front side and the back side are interlocked. This means that the values for the front side and the back side remain identical. Widening the margin can be usef...

Page 137

[print delivery] setting values description [print delivery] 1 [output location] select the output location for the job. Depend- ing on the settings for your copy job, the ma- chine automatically suggests the preferred output location for your job. However, you can manually overrule this suggestion....

Page 138

Setting values description [print delivery] 2 [sheet order] [face up] deliver the prints face up, first sheet on top. [face up reverse] deliver the prints face up, last sheet on top. [face down] deliver the prints face down, first sheet on top. [face down reverse] deliver the prints face down, last ...

Page 139

Setting values description [print delivery] 3 [print order] • [front/back] default value. The front page on the front, the back page on the back. • [back/front] puts the front page on the back and the back page on the front. [rotation] • [0 degrees] • [180 degrees] rotates the prints 180 degrees. [p...

Page 140

Setting values description [print quality] 2 [rip resolution] (de- fault [600x2400] dpi) the rip resolution can improve the readability of fine details. When you print very thin, slan- ted lines, for example in chinese characters, 1200x1200 gives the best result. 600x2400 is best suited for mainly h...

Page 141

[number of sets] setting values description [number of sets] [check first set] when the [check first set] setting is enabled, the printer stops after the first set of a job has been printed. You can check the quality of the output. Note this setting is only available when in the workflow profile [ch...

Page 142

[page numbering] this setting is only available for pdf jobs. Setting values description [page numbering] [on] print a page number on each page of the job. [off] no page number on each page of the job. [position] [top left] [top center] [top right] [bottom left] [bottom center] [bottom right] the po...

Page 143

Change the [output] settings change [2-sided] into [1-sided] and vice versa introduction jobs for which [1-sided] or [2-sided] printing was defined, will be printed on either 1 side or both sides of a sheet. If required, you can change this setting. When a job contains mixed settings ([1-sided] and ...

Page 144

Change the binding edge introduction the binding edge determines whether the binding position is along the long edge or the short edge of the media. The binding edge is usually set via the printer driver, for example. However, you can view and change the binding edge via the control panel. The bindi...

Page 145

Select a different media for a job introduction if you want to print a job on other media than originally defined for that job, you can select a different media via the control panel. Requirements regarding the new media: • the media must be available in the media catalog. • the media must have the ...

Page 146

Change the settings for covers introduction when front covers or back covers are required, the settings are usually set in the printer driver, for example. However, you can view and change the settings for the covers via the control panel. You can change the following settings for both the front cov...

Page 147

Shift the image roughly to create binding space introduction if you want to create space for staples or punch holes, for example, you can use the [align] function. The preview in the right-hand pane of the control panel displays the consequences of your changes. You can also shift the image or margi...

Page 148

Shift the image precisely to create binding space or correct the layout introduction if you want to create space for staples or punch holes, for example, you can use the [align] function. However, when the [align] function is not precise enough, you can use the [margin shift] and [image shift] funct...

Page 149

Change the print delivery settings introduction usually the print delivery settings have been defined in the printer driver. Overview of the print delivery settings setting description [output location] change the output location for the job. The list shows all the out- put locations that are availa...

Page 150

Setting description [sheet orientation] [header up lef] deliver the prints with the header on top side and in portrait posi- tion (vertical). [header up sef] deliver the prints with the header on top side and in landscape po- sition (horizontal). [header down lef] deliver the prints with the header ...

Page 151

Change the stacking method per job introduction the [offset stacking] function creates a visible distinction between sets or jobs in an output location. The active workflow profile or the active automated workflow determines the default type of offset stacking. You can only change the type of [offse...

Page 152

Change the number of staples introduction when a job is sent to the machine, a desired number of staples for that job can be indicated. However, you can change the number of staples on the control panel. This section describes how to change the number of staples for a specific job. Note there must b...

Page 153

Define the finishing for print jobs introduction the required finishing method is usually set in the printer driver. However, you can change the finishing method on the control panel. Depending on the configuration of your system you can change the following finishing methods, for example. • number ...

Page 154: Change The [Job] Settings

Change the [job] settings change the number of sets introduction follow the procedure below to change the number of sets for a job that is present in the list of [waiting jobs] or [scheduled jobs], or in a docbox. Note you cannot change this setting for the active print job . Procedure 1. On the con...

Page 155

Check the first set introduction when you have a large print job and you want to check whether the job is printed correctly, it is advised to check the first set before printing all other sets. When a job is sent to the printer, the submitter can indicate in the job submission application that the f...

Page 156

Change the page range you want to print introduction usually, in the printer driver is defined whether all pages or only a range of pages must be printed. However, you can also change this setting through the control panel. Note you cannot change this setting for the active print job . Procedure 1. ...

Page 157

Rename a job introduction when you print a job, the job name is created in the application. The job name is displayed in the [job name] field. However, you can rename the job. Procedure 1. In the job window, touch [job name]. A keyboard appears. 2. Touch 'backspace' until the current name is deleted...

Page 158

Change the use of separator sheets introduction separator sheets are empty sheets that are automatically inserted before each new set or job to separate two sets or jobs. In the settings editor you can define the media that must be used as separator sheets. You can also specify after how many sets y...

Page 159: The Print Function

The print function print a job using the printer driver - how to print a job using a windows ® driver main features of the printer drivers feature description settings you can define a large number of settings for layout, paper, finish- ing and image. Templates when you want to use a number of print...

Page 160: Contradiction Handling

Contradiction handling be aware that if you change settings you might make contradicting settings. If you make contradicting settings, the preview pane informs you how to solve the contradictions. The contradicting settings are marked. The system indicates, with a green check mark, which setting you...

Page 161: Stop The Printer

Stop the printer introduction the printer can be stopped in 2 ways. • manually use the stop button or the [stop after job] button to stop the printer. • automatically define a corresponding setting in the workflow profiles. Stop the printer manually manual stop when to stop action description after ...

Page 162

When to stop action description after a job touch the [stop after job] button • in [jobs] -> [queues] -> [scheduled jobs] you must se- lect the job after which the printer must stop. Then touch the [stop after job] button. • a horizontal, red and white stop bar indicates that the stop-after-job func...

Page 163: Delete Print Jobs

Delete print jobs locations from which jobs can be deleted you can delete jobs from the following locations. • list of [printed jobs] (if this function is enabled in the settings editor). • list of [scheduled jobs]. • list of [waiting jobs]. Note you can only delete the active print job in the list ...

Page 164

Print your jobs using the control panel introduction to the [jobs] view introduction the [jobs] view enables you to manage the print jobs on the machine locally. The [jobs] view is divided in the [queues] and [printed jobs] views. This section describes the items of both views. Note whether a button...

Page 165

Item function more information [to top] button give priority to a scheduled job. The job is printed when the active print job is ready. The button is only en- abled when you select 1 job. Give priority to a sched- uled job on page 96 [stop after job] button stop the machine after a selected job. The...

Page 166

[36] the [waiting jobs] view the items of the [waiting jobs] view of the [jobs] view description of the [waiting jobs] view item function more information [waiting jobs] display the jobs that are not yet scheduled for printing. [properties] button check or change the properties of a job. The button ...

Page 167

Item function more information [select] button select a number of jobs at the same time. You can use one of the follow- ing: • [all]: select all the jobs in the list. • [none]: deselect all the jobs in the list. • [invert selection]: turn the selected jobs into deselected jobs, and the other way rou...

Page 168

[37] the [printed jobs] view the items of the [printed jobs] view of the [jobs] view description of the [printed jobs] view item function more information [printed jobs] display the jobs that were printed successfully. The system only moves the printed jobs to the [printed jobs] list when you enable...

Page 169

Item function more information [ticket] button print an overview of the main job settings and job parameters. The button is only enabled when you se- lect 1 job. Print the job parameters on page 172 [select] button select a number of jobs at the same time. You can use one of the follow- ing: • [all]...

Page 170: Reprint A Job

Reprint a job introduction note the following description is only applicable when you enable the [store printed jobs] setting in the [printed jobs] section in the settings editor. Print jobs that have been completed are moved from the list of [scheduled jobs] list to the list of [printed jobs]. The ...

Page 171

Select more than one job for printing introduction the table below describes the possibilities to select more than one job for printing. Select more jobs options description select two or more jobs manually touch the jobs you want to print one by one. [select] button - [all] all jobs in the list of ...

Page 172: Print A Job Ticket

Print a job ticket introduction job tickets are used to transfer settings from an application to the printer. It can be convenient to print a job ticket before printing a job, to get an overview of the main job characteristics. Job tickets can contain the following information, for example. • job na...

Page 173: Make A Proof

Make a proof introduction you can make a proof to check whether the quality and the layout of the output meet your expectations. When you use the [proof] function, the machine prints 1 copy of the job. You can only make a proof for a job in the list of [waiting jobs]. This section describes how to m...

Page 174: Variable Data Printing

Variable data printing variable data printing introduction printing variable data (vdp or variable document printing) is a print method that uses variable text and graphics, for example names and addresses. A vdp job has records to distinguish the different sets. Vdp is used for direct marketing, ad...

Page 175

Convert a job to a variable data job if you print a large document that has the structure of a variable data document, you can instruct the print system to handle this job as a variable data job. To indicate how the job is composed, you enter either the number of records or the pages per record. The...

Page 176

The transaction section (optional) introduction to the [transaction] section introduction note transaction printing requires a license. The [system] view on the control panel displays the [transaction] section only when transaction printing is licensed. Transaction printing enables you to print typi...

Page 177

The items of the [transaction] section description of the [transaction] section num‐ ber item function 1 dashboard the dashboard displays the following information for transaction printing. • the connection status • the ip address of the host that sends the jobs • the name of the active transaction ...

Page 178

Step actions on the print‐ er actions on the host remarks 3 change the active pdl when currently the wrong pdl is ac- tive. This is only pos- sible when you have licenses for more than 1 pdl. Via the settings editor: [transac- tion printing] -> [setups] -> [re- quested active pdl]. 4 load the requir...

Page 179

Output recovery in case of an error introduction the océ varioprint® 6000 line is equipped with an efficient, reliable output recovery in case of an error. By factory default, the output recovery is set to [normal]. After the error is solved, the job continues at the page where the error occurred au...

Page 180

Job job progress states normal output recov‐ ery end up in the output location after error re‐ covery sheets jammed in the machine. The control panel dis- plays instructions on how to solve the pa- per jam. The operator has to remove these jammed sheets man- ually. These sheets stay in the memory of...

Page 181

Job job progress states suppressed output re‐ covery end up in the output location after error re‐ covery sheets copied to con- troller memory (in- cluding error pages). Are deleted complete- ly. These sheets are not delivered to the out- put location. Sheets jammed in the machine. The control panel...

Page 182

Activate transaction printing before you begin make sure that the list of [scheduled jobs] is empty. Procedure 1. On the control panel, touch [system] -> [transaction] -> [transaction printing mode]. The text on the button changes from [off] to [on]. 2. If required, touch [active transaction setup] ...

Page 183

Deactivate transaction printing before you begin make sure that the list of [scheduled jobs] is empty. Procedure 1. On the control panel, touch [system] -> [transaction] -> [transaction online] to put the printer offline. The text on the button changes from [on] to [off]. Note that you can only swit...

Page 184

Shift the image in the transaction printing mode introduction when a misalignment occurs you can shift the image to correct the problem. You can shift the image on the front side and back side horizontally and vertically. Examples of possible misalignments: • a name or address is not placed correctl...

Page 185: In The Tray-to-Tray Mode

Handle the media messages - how to handle the [media message] in the tray-to-tray mode introduction the media catalog • contains a list of predefined media and their attributes • is an essential part of the system behavior of the océ varioprint® 6000 line • helps you to print your jobs more easily w...

Page 186

Continue with step 2 when you select this option. • press [continue]. The controller will use the pcl default media and continue the print job. Note that this might be an incorrect media. • press [cancel stream]. The print job is stopped. You can now solve the problem. It is most likely that you can...

Page 187

Create a transaction setup - how to create a new transaction setup introduction when you want to use transaction printing, you have to create the necessary transaction setups. You can create these setups in the settings editor. Note when the settings editor does not display the correct language, you...

Page 188

4. For [ipds tray to media for media 1] assign the [media catalog item] from the list. The list displays all the media in the media catalog. The system copies the media attributes from the selected media to the transaction setup. When you assign a3/ledger-like media or want to use short-edge feed fo...

Page 189

Create a transaction setup - how to change the pcl parameters procedure 1. Go to [transaction printing] - [pcl setup]. 2. Make sure that the tray selection mechanism is set to tray to media. This is the preferred setting. This printer is a media-based machine. The tray-to-media method supports this ...

Page 190

Create a transaction setup - how to modify a transaction setup note when you have more than one printer, you can exchange transaction setups. Go to [transaction printing] - [setups] and use the [import] and [export] functions. Procedure 1. Go to [transaction printing] - [setups]. 2. Put a checkmark ...

Page 191

Exchange all setups between printers introduction if you have more than one printer, you can exchange the transaction setups between the printers, provided that the printer type and software version are identical. You can then use identical transaction setups on two or more printers. Procedure 1. In...

Page 192

Make an intermediate check print introduction the machine has a function that enables you to make a check print while a job is printed. This function is called the intermediate check print. When you use this function, the machine prints a copy of the sheet that is printed at the moment you press the...

Page 193

Chapter 10 keep the system printing.

Page 194: Use The Schedule

Use the schedule introduction to the [schedule] view introduction the [schedule] is your daily planning board for print jobs. The [schedule] helps you to keep the machine running. This section shows and describes the main parts of the [schedule]. Note the descriptions of the colors of the bars and t...

Page 195

2. The [required media] pane the [required media] pane displays the media that are required for each scheduled job. For each required media, the media properties are displayed (see list of references below). The bars show the availability of the media. The bars can be the following colors. The color...

Page 196

Icon description the list of [required media] shows the required media for the sched- uled jobs. When a paper tray is highlighted in blue, the highlighted pa- per tray contains the media that is also highlighted in blue in the list of [required media]. 4. The output locations pane the output locatio...

Page 197

Load media via the [schedule] view introduction when the [schedule] view is available on your printer, you can load and assign the required media directly in the [schedule] section. Note when you load a different media size, you must also set the paper guides inside the paper tray to the correct dim...

Page 198

Related information introduction to the schedule view on page 194 load media via the [schedule] view 198 chapter 10 - keep the system printing océ varioprint 6000 line.

Page 199: The Dashboard

The dashboard introduction the dashboard is the upper blue part of the control panel. The dashboard is always visible, irrespective of the current view. The dashboard shows the following. • the status of the system • the current process • instructions for the operator • the status of the supplies • ...

Page 200

Number function 2 display the file name of the current job (for document printing) or cur- rent stream (for stream printing). Furthermore, the progress of the cur- rent job is displayed. For document printing, the counter can display the following informa- tion. • set x of y • sheet x of y or sheet ...

Page 201: The Operator Attention Light

The operator attention light introduction the operator attention light informs you about the status of the machine. To improve the productivity, the operator attention light can warn you some time before the machine stops. You can set the warning time on the control panel. The colors of the lights m...

Page 202

The operator attention light 202 chapter 10 - keep the system printing océ varioprint 6000 line.

Page 203

Chapter 11 media handling.

Page 204: Introduction

Introduction introduction to the media handling introduction the machine supports a wide range of media, including tabs and inserts. The supported media sizes range from 203 mm x 203 mm (minimum) to 320 mm x 488 mm (maximum). When the flex- xl paper input module is installed the media sizes range to...

Page 205

Introduction to the trays view introduction the [trays] view has the following functions. • display the current content and filling level of the paper trays. • open the paper trays and assign the required media for the print jobs. • change the media that is currently assigned to a paper tray. • assi...

Page 206

Item function [open] button open the selected paper tray to load the media ( load the media on page 211 ). [registration] perform a media registration for the selected media ( perform a media registration for standard-size media - print the test sheets and create the ruler on page 222 , perform a me...

Page 207

Icon description the paper tray contains media that are fed over the short edge (sef) introduction to the trays view chapter 11 - media handling 207 océ varioprint 6000 line.

Page 208

Introduction to the [media] section introduction the [system] view gives access to system settings, system information, media information and maintenance tasks. This section gives an overview of the [media] section in the [system] view. Overview of the [media] section the print system uses a central...

Page 209

Num‐ ber item function more information 3 add temporary media to the media catalogue . Add temporary media to the media catalog on page 214 4 [registration] button print test sheets and per- form the registration for in- dividual media. You can do a media registration for standard-size media and lar...

Page 210

Num‐ ber item function more information 2 media management manage the media catalog: • add (new, copy) • edit • delete • optimize • [to catalog] (only for temporary media) • add add media to the media catalog on page 213 • optimize perform a media regis- tration for standard-size media - print the t...

Page 211: Media Related Actions

Media related actions load the media introduction this section describes how to load the media into a paper tray. When you load the media via the [load] button in the [schedule], the paper tray is automatically assigned to the correct media. When you load and assign the media via the [assign] button...

Page 212: Paper Tray

Assign the media to a paper tray - load and assign the media to a paper tray introduction the [trays] view has several functions (see introduction to the trays view on page 205 ). This section describes how to open the paper trays and assign the media in the [trays] view. Note the preferred way to l...

Page 213

Add media to the media catalog when enabled in the settings editor, you can add new media to the media catalog via the control panel. [50] media management via the control panel procedure 1. Touch [system] -> [media]. 2. Use one of the following methods to add new media. • touch [copy] to use one of...

Page 214

Add temporary media to the [media catalog] introduction when a job is submitted that requires media that are not included in the [media catalog], these media become temporary media. The control panel displays the temporary media in the following places. • in the list of [required media] in the [sche...

Page 215

Media indicators black & white media is displayed on several locations of the control panel. Extra information about the media is displayed by icons. Icon description the media is required for a job in the list of scheduled jobs or list of waiting jobs. The media is loaded into a paper tray. The med...

Page 216

Change the advanced media settings introduction the advanced media settings enables you to print on certain special media. When all the advanced media settings have their default value, the button for [advanced media settings] displays the word [default]. After you changed one or more settings, this...

Page 217

Changing the value of the [paper quality] setting to [low] or even [lower]. However, this affects the productivity by almost 5 and 10% respectively. Please refer to the troubleshooting chapter for more information (see troubleshooting on page 278 ). [paper quality test] this test helps you to check ...

Page 218

Change the advanced media settings - disable the double-sheet detection procedure 1. Touch the [double-sheet detection] button. The text on the button changes from [on] to [off]. Note each time you touch the button, the setting changes from [on] to [off] and the other way round. 2. Press [ok]. Chang...

Page 219

Change the advanced media settings - enable the enhanced media mode important this setting is only available on machines that are equipped with an optional finisher. Procedure 1. Touch the [enhanced media mode] button. The text on the button changes from [off] to [on]. Note each time you touch the b...

Page 220

Change the advanced media settings - change the [paper quality] procedure 1. Touch the [paper quality] button. A drop-down list appears. 2. Touch the desired value. 3. Press [ok]. Change the advanced media settings - change the [paper quality] 220 chapter 11 - media handling océ varioprint 6000 line.

Page 221

Change the advanced media settings - start the [paper quality test] procedure 1. Touch the [paper quality test] button to start the test. Note when the test is started, the progress of the test is displayed on the button and the text on the button changes from [start] to [stop]. Note the test stops ...

Page 222

Perform a media registration for standard-size media - print the test sheets and create the ruler introduction the different properties of media can influence the alignment of images when the media are printed. To ensure a correct alignment, you can perform a media registration for each individual m...

Page 223: Z-Position of Side 1

3. Fold the sheet along the line 'b-h' on side 1. Te st bitm ap: reg is t rat ion siz e: 210 x 297 mm 2006-10- 09 / 14: 08: 36 pa g e 1 1 pr ima ry i m age a g 0 5 - 0 0 5 + 3 w e k s t e e h s - b h d c i f [51] fold the sheet to create a ruler this is your ruler. Test bi tmap: reg is tration si ze...

Page 224

4. Enter the value. 5. Take the second test sheet. 6. Repeat the steps 2 - 4. 7. Take the third test sheet. 8. Repeat the steps 2 - 4. Perform a media registration for standard-size media - adjust the z-position of side 1 224 chapter 11 - media handling océ varioprint 6000 line.

Page 225: X-Length of Side 1

Perform a media registration for standard-size media - adjust the x-length of side 1 procedure 1. Take the first test sheet. 2. Put the ruler along the line 'd-f' of the test sheet. 3. Align the start of the ruler with point 'd' of the test sheet. Test bitmap: registration size: 210 x 297 mm 2006-10...

Page 226: Z-Position of Side 2

Perform a media registration for standard-size media - adjust the z-position of side 2 procedure 1. Take the first test sheet. 2. Align the start of the ruler with point 'k' of the test sheet. Tes t b it map: r egistr ation siz e: 2 1 0 x 297 mm 2006- 10- 09 / 1 4: 08: 36 pag e 2 2 sec ondary i mage...

Page 227: X-Position of Side 1

Perform a media registration for standard-size media - adjust the x-position of side 1 procedure 1. Take the first test sheet. 2. Put the ruler along the line 'd-f' of the test sheet. 3. Align the start of the ruler with the left edge of the test sheet. Test bitmap: registration size: 210 x 297 mm 2...

Page 228: X-Position of Side 2

Perform a media registration for standard-size media - adjust the x-position of side 2 procedure 1. Take the first test sheet. 2. Align the start of the ruler with point 'n' of the test sheet. Test bitmap: registration size: 210 x 297 mm 2006-10-09 / 14:08:36 page 2 2 secondary image 0 5- 0 0 5 + 2 ...

Page 229

Perform a media registration for large media - print the test sheets and create the ruler introduction the different properties of media can influence the alignment of images when the media are printed. To ensure a correct alignment, you can perform a media registration for each individual media in ...

Page 230: Position of Side 1

3. Fold the sheet along the line 'b-h' on side 1. Te st bitm ap: reg is t rat ion siz e: 210 x 297 mm 2006-10- 09 / 14: 08: 36 pa g e 1 1 pr ima ry i m age a g 0 5 - 0 0 5 + 3 w e k s t e e h s - b h d c i f [58] fold the sheet to create a ruler this is your ruler. Test bi tmap: reg is tration si ze...

Page 231

4. Enter the value. 5. Take the second test sheet. 6. Repeat the steps 2 - 4. 7. Take the third test sheet. 8. Repeat the steps 2 - 4. Perform a media registration for large media - adjust the z-position of side 1 chapter 11 - media handling 231 océ varioprint 6000 line.

Page 232: Of Side 1

Perform a media registration for large media - adjust the x-length of side 1 procedure 1. Take the first test sheet. 2. Align the start of the ruler with point 'd' and read the value at point 'e'. Test bitmap: registration size: 420 x 297 mm 2006-10-09 / 14:08:22 page 1 1 primary image -50 0 +50 3 -...

Page 233: Position of Side 2

Perform a media registration for large media - adjust the z- position of side 2 procedure 1. Take the first test sheet. 2. Align the start of the ruler with point 'k' of the test sheet. Test bitm ap: re g is t ra t io n siz e: 420 x 297 m m 2006-10- 09 / 14:08: 22 page 2 2 secondary i mag e k p m l ...

Page 234: Position of Side 1

Perform a media registration for large media - adjust the x- position of side 1 procedure 1. Take the first test sheet. 2. Put the ruler along the line 'd-f' of the test sheet. 3. Align the start of the ruler with the left edge of the test sheet. Test bitmap: registration size: 420 x 297 mm 2006-10-...

Page 235: Position of Side 2

Perform a media registration for large media - adjust the x- position of side 2 procedure 1. Take the first test sheet. 2. Align the start of the ruler with point 'n' of the test sheet. Test bitmap: registration size: 420 x 297 mm 2006-10-09 / 14:08:22 page 2 2 secondary image k p m l n 100 0 105 0 ...

Page 236: Light-Weight Media

Light-weight media introduction light-weight media is media with a weight less than 50 g/m². You must handle light-weight media with extra care because light-weight media can be damaged very easily. Even minor irregularities of the light-weight media will lead to a significant reduced reliability an...

Page 237

Load light-weight media into the paper module introduction important • before you load media into the paper trays, it is important to unpack and carefully check the stack and sheets. Unpack light-weight media on page 241 • load the media carefully because light-weight media is fragile, especially at...

Page 238

• do not use media that is not wrapped, or not wrapped well. • unpack one ream and load the media before you load another ream. • load media as soon as possible after unpacking. Do not use media that was stored outside the printer for more than 2 hours. • make sure that the correct media is assigned...

Page 239

Action 4 move the sliders carefully to the stack. Slowly turn the knob clockwise until the side sliders touch the stack without dam- aging it. Squeeze the green handle of the front slider to move the trailer-edge sliders carefully against the stack without dam- aging it. 5 unpack the following ream ...

Page 240

Action 7 gently push the paper tray back until it clicks into place. Load light-weight media into the paper module 240 chapter 11 - media handling océ varioprint 6000 line.

Page 241: Unpack Light-Weight Media

Unpack light-weight media introduction before you load media in the paper trays, unpack the media and check the stack. Before you begin only unpack media just before you load the stack into the paper trays. When you leave the media unpacked for a long period, tight edges or waviness can occur. Proce...

Page 242

Action 5 loosen the stack carefully a few times at the four sides and the four corners. Make sure that all sheets are loose. Unpack light-weight media 242 chapter 11 - media handling océ varioprint 6000 line.

Page 243

Determine the grain direction of light-weight media introduction for optimal runnability the grain direction is important. When the grain direction of a certain media is unknown, you must determine the grain direction according to the following procedure. Procedure action 1 draw rectangles with the ...

Page 244

Action 4 • when rectangle a bends the least, the grain direction is in the direction of the ar- rows, see picture a. • when rectangle b bends the least, the grain direction is perpendicular to the di- rection of the arrows, see picture b. Picture a picture b determine the grain direction of light-we...

Page 245

Chapter 12 maintain the print system.

Page 246: System Configuration

System configuration system configuration and maintenance your organization and print environment can ask for a system configuration that meets production and workflow requirements. In addition, authorization, security and sustainability guidelines are important when you establish a print system. Th...

Page 247

Maintenance tasks for maintenance operators maintenance operators can perform procedures to clean machine parts or improve the image quality. Furthermore, they are responsible for mechanical maintenance tasks and maintenance procedures via the control panel. For some procedures you must have the rig...

Page 248: Panel

Change a number of settings in the settings editor via the control panel introduction note the information contained in this section is primarily intended for key operators and system administrators. The settings editor application on the prismasync controller is a web based application that allows ...

Page 249

Group of settings available settings short description [software updates] • [download auto- matically] • [upgrade from usb drive] • [upgrade from server] • [prismasync downgrade] • [install windows update] • [uninstall windows update] • [install software from usb installa- tion drive] you can upgrad...

Page 250

Group of settings available settings short description [logging] • [save data dump file] • [save trace file] • [print configuration report] when an error occurs, the help desk of your printer supplier can ask you to create and send a trace file and a datadump file. The datadump file is a .Zip file t...

Page 251

Group of settings available settings short description [remote connection] (optional) • [remote connection status] (read-only) • [erds connection] (read-only) • [remote connection enabled] • [remote service country code] • [remote service custom country code] • [service organiza- tion id] • [test re...

Page 252

Introduction to the [setup] section introduction the [system] view gives access to system settings, system information, media information and maintenance tasks. This section gives an overview of the [setup] section in the [system] view. Overview of the [setup] section [68] overview of the [setup] se...

Page 253

Item function [shut down system] button shut down the system in a controlled way. [advanced media settings] button define a number of special media-related settings. Change the advanced media settings on page 217 [intermediate check print] button print a test sheet of a running job to check the qual...

Page 254: Backup and Restore

Backup and restore introduction the system administrator can make a backup of the configuration of the print system. The system administrator can use this backup a/o to restore the configuration. • after a hardware failure, for example a crash of the hard disk. • after installation of a new version ...

Page 255: Counters

Counters introduction to the [maintenance] section introduction the [system] view gives access to system settings, system information, media information and maintenance tasks. This section gives an overview of the [maintenance] section in the [system] view. Overview of the [maintenance] section [69]...

Page 256

Item function more information [toner counters] indicates the amount of toner that has been used since the printer was installed. You cannot reset the toner counter. [go to maintenance tasks] open the list of the suggested or re- quired maintenance tasks. Note only a trained and certified operator i...

Page 257: Introduction to The Counters

Introduction to the counters introduction the [maintenance] section of the [system] view displays 3 types of counters. 2 of these counters provide information about the number of sheets that have been printed. The other counter provides information about the amount of toner that has been used. Gener...

Page 258: Reset The Day Counters

Reset the day counters procedure 1. On the control panel, touch [system] -> [maintenance] -> [reset day counters]. A dialog box will ask you to confirm that you really want to reset the day counters. 2. Touch [yes] to reset the day counters to 0. Reset the day counters 258 chapter 12 - maintain the ...

Page 259