- DL manuals

- Octagon

- Burner

- bio 3

- User Manual

Octagon bio 3 User Manual

Summary of bio 3

Page 1

Octagon v2.16 page 1 octagon user guide pellet burner series octagon model bio 3 – fbio 3 3’’.

Page 2

Octagon v2.16 page 2.

Page 3

Octagon v2.16 page 3 contents section contents page 1 letter of thanks 3 2 instructions for use 4 3 burner’s operating principles 5 4 burning phases 7 5 choosing the right burner 8 6 safety rules 9 6.1 safety installation instructions to licensed technicians 9 7 package 10 7.1 package contents 11 7....

Page 4

Octagon v2.16 page 4.

Page 5

Octagon v2.16 page 5 1. Letter of thanks thank you for choosing the pellet burner of octagon. We would like to reassure you for the high quality of our product which we trust will fully satisfy your requirements. Octagon will always be at your service maximizing the value of your purchase. For a bet...

Page 6

Octagon v2.16 page 6 2. Instructions for use the device can be used by persons over eighteen (18) years of age with full physical, neurological and mental capabilities and persons with no previous experience and skill or persons being trained for the use of the device but always under the supervisio...

Page 7

Octagon v2.16 page 7 3. Burner’s operating principles first start the pellet burner has predetermined configurations of maximum and minimum power rating by the manufacturer. The authorized trained technician who will fire up the burner has the option – if necessary – to reduce the maximum power of t...

Page 8

Octagon v2.16 page 8 the innovation of octagon pellet burner bio lies with two crucial elements relating to combustion: a. The operation of the burner is totally proportional, within the predefined parameters, subject to automatic adjustment of the level of power (self adjustment). In this way the p...

Page 9

Octagon v2.16 page 9 4. Burning phases everything described in the previous chapter, operating principles, is outlined in the cycle below which is divided in four sections: a. Fire up, yellow colour the burner checks whether there is flame in the burning chamber, in case of a keep fire status, so as...

Page 10

Octagon v2.16 page 10 5. Choosing the right burner in order to make to right choice of burner - both technically and practically - you need to take under consideration certain basic parameters: 1. The burner is designed to burn wood pellets only. The use of any other type of pellet such as agro-pell...

Page 11

Octagon v2.16 page 11 6. Safety rules the pellet burner is an electric/electronic device that operates with 230 v – 50 hz. According to applicable legislation its installation, connection, regulation, operation and service should be done by trained personnel authorized by the local authorities. It i...

Page 12

Octagon v2.16 page 12 7. Package the pellet burner will be packed in hard cardboard box of dimensions 60 cm x 40 cm x 40 cm (length / width / height) and will bear an adhesive label showing the model of the burner as follows: model special care is given to the packing of the burner to make sure that...

Page 13

Octagon v2.16 page 13 7.1 package contents each package contains: o a user guide manual with information in respect of installation, operation and maintenance. O a burner with its metal casing and the display screen, connected with its stainless steel burning chamber. O a stainless steel pipe 2” for...

Page 14

Octagon v2.16 page 14 7.2 pellet burner parts the pellet burner consists of the following parts: 1) a steel metallic casing electrostatically painted (green). 2) an electronic display and programming touch screen. 3) a connection cable of the screen to the central control unit. 4) a stainless steel ...

Page 15

Octagon v2.16 page 15 8. Spare parts the table herebelow contains a list of spare parts of a pellet burner by octagon hellas including relevant reference numbers. The reference number should be quoted when an order is placed. Reference number description of spare part Μ001-1001-1 steel casing of pel...

Page 16

Octagon v2.16 page 16 s100-1001-1 flame sensor brahma , fc 8r s100-1010-1 electric heating element 250 w s100-1020-1 boiler water temperature sensor s100-1030-1 exhaust flue gas temperature sensor 1,5 m (length) s100-1030-2 exhaust flue gas temperature sensor 3 m (length) s100-1050-1 bimetallic cont...

Page 17

Octagon v2.16 page 17 9. Burner fuel the pellet burners of octagon, are designed to burn wood pellets. The pellets are very small chips of wood along with other logging residues which are compressed mechanically in order to take a cylindrical shape of around 6 - 8 mm diameter and less than 40 mm of ...

Page 18

Octagon v2.16 page 18 9.1 technical characteristics of wood pellet according ΕΝ 14961-1 the european standard ΕΝ 14961-1, which specifies the technical characteristics of wood pellets, has not yet been finalized. Upon completion it will become mandatory to all european union member states. As at tod...

Page 19

Octagon v2.16 page 19 10. Fuel feeding - auger the feeding of the pellet burner is achieved using a metal auger which rotates via a motor and transfers pellet from the fuel tank to the burner. Between the feeder and the inox feeding tube of the burner, a polyurethane flex hose is used. Relevant hose...

Page 20

Octagon v2.16 page 20 11. Fuel tank the fuel tank plays an important role in the proper and undisturbed feeding of the burner. Octagon has designed a fuel tank - with special interior - that fully meets the requirements of the burner by ensuring steady and safe operation of the auger and allowing ma...

Page 21

Octagon v2.16 page 21 12. Burner installation 12.1 installation steps 1. Ensure that the boiler room is in line with local regulations paying special attention to ventilation. 2. Ensure that the boiler is connected to the hydraulic network and that the exhaust flue gas system is tightly connected. 3...

Page 22

Octagon v2.16 page 22 13. Electrical installation – sensors the electrical connections of the burner as well as the adjustment of the burner are only allowed to trained licensed technicians for safety reasons. The safety electric connector of the burner has twelve (12) numbered connections. As soon ...

Page 23

Octagon v2.16 page 23 14. Burner display screen keyboard buttons and display symbols alarm servicing indicator timer fuel temperature alarm ir sensor fan time cleaning power alarm no fuel set up cancel increase / decrease + _ light signal of operation power on /off enter menu buttons >.

Page 24

Octagon v2.16 page 24 15. 1 st level - configuration of the burner the 1 st level of configuration is user friendly and easily accessible to the end user of the burner. This configuration mainly introduces the end user to basic information of the device and allows him to modify settings such as time...

Page 25

Octagon v2.16 page 25 time is displayed by a “clock” symbol and the screen indicates the current time in hours and minutes i.E. 13:12. Programming is displayed by a “gear” symbol and the screen indicates off. The programming belongs to the 2 nd level of configuration of the pellet. Description of ke...

Page 26

Octagon v2.16 page 26 15.2 basic configuration of burner after the electric connection is made you may proceed with the installation of the burner. By keeping the button on / off pressed for one (1) second the indication on will be displayed on the screen and the burner will automatically begin oper...

Page 27

Octagon v2.16 page 27 15.2.2 boiler water temperature navigate through the menu button to the temperature (thermometer symbol). Press enter. The screen will show the predefined boiler water temperature. Press the edit buttons +, - to choose the desired boiler water temperature. Press enter to set th...

Page 28

Octagon v2.16 page 28 15.2.4 time navigate through the menu button to the time (clock symbol). Press enter. The indication 00:00 will appear on the screen. The first part will be blinking. Press the edit buttons +, - to insert the time in hours (0 to 24). Press the menu button to move to the second ...

Page 29

Octagon v2.16 page 29 15.2.6 filling the auger the filling of the auger is performed after you have first disconnected the flex hose from the stainless steel tube of the burner and place a bucket to its end to collect the outgoing pellets. Those pellets can be placed back to the fuel tank once you h...

Page 30

Octagon v2.16 page 30 16. 2 nd level - configuration of the burner the 2 nd level of configuration of the burner is only allowable to trained licensed technicians. Access to this level of configuration is strictly forbidden to end users as there is a serious risk of deregulation of the burner. 16.1 ...

Page 31

Octagon v2.16 page 31 16.1.2. Display of individual parameters of combustion regulation the screen provides us with information on the current values of the various parameters. It is particularly useful during the first fire up and when you wish to perform a system check. Repeat steps detailed in pr...

Page 32

Octagon v2.16 page 32 17. Power adjustment of burner before you change the maximum power of the burner you should first understand its analog function and as an example we will look into the operation of model bio 2 of maximum power (Ρ5), nominal power 35 kw/h and minimum power (Ρ1) of 8 kw/h. In an...

Page 33

Octagon v2.16 page 33 the values of the fan in table 1 (see §19.1) are indicative and may need to be revised by you. Each system “burner -boiler-chimney” has its own characteristics and it might require new adjustments of fan values. The shortage of air fan may cause - in addition to poor combustion...

Page 34

Octagon v2.16 page 34 18. Troubleshooting the keyboard of the burner provides notifications and warnings for alerts and errors, which can occur during operation. The alarm icons indicate a problem. An alert notification is indicated with the blinking icons, errors are indicated with continuously lit...

Page 35

Octagon v2.16 page 35 18.1 additional error notifications indication: icon service is on the combustion system malfunctioned and is not operational. This can be due to: code e001: keyboard error code e002: ir communication error code e003: rf communication error code e004: mb communication error cod...

Page 36

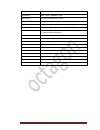

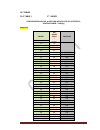

Octagon v2.16 page 36 19. Tables 19.1 table 1 3’’ auger configuration values, auger-fan with pellets of category 2, heating power = 5 kw/kg 400 gr/min power on auger value fan value 5 kw/h kw*h/kg bio3 8 8 9 9 10 10 11 11 12 12 104 13 13 105 14 14 107 15 15 108 16 16 110 17 17 111 18 18 112 19 19 11...

Page 37

Octagon v2.16 page 37 42 42 146 43 43 147 44 44 149 45 45 150 46 46 151 47 47 153 48 48 154 49 49 156 50 50 157 51 51 158 52 52 160 53 53 161 54 54 163 55 55 164 56 56 165 57 57 167 58 58 168 59 59 170 60 60 171 61 61 172 62 62 174 63 63 175 64 64 177 65 65 178 66 66 179 67 67 181 68 68 182 69 69 18...

Page 38

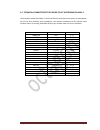

Octagon v2.16 page 38 19.2. Table 2 table of parameters in so far as the 2 nd level of configuration is concerned access to the parameters included in the table below is allowed. The remaining parameters belong to 3 rd level of configuration and can be modified only in liaison with and subject to ag...

Page 39

Octagon v2.16 page 39 20. Maintenance and checks to be performed by end user as with all electronic devices, the burner also requires maintenance and cleaning service annually in order to ensure long term operability as well as optimum fuel economy. Do not neglect the annual service, it is possible ...

Page 40

Octagon v2.16 page 40

Page 41

Octagon v2.16 page 41 21. Warranty of pellet burner octagon the european directive 99/44/ce, sets out the specific responsibilities and obligations of the ultimate seller of the product to the ultimate buyer for any possible defects. The european directive can be found on the website at: http://euro...

Page 42

Octagon v2.16 page 42.

Page 43

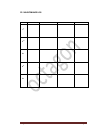

Octagon v2.16 page 43 22. Maintenance log section date name of technician remarks signature 1 st 2 nd 3 rd 4 th 5 th.

Page 44

Octagon v2.16 page 44 23. Brief instructions for initial adjustment and operation 1. Electrical connection connection 1 power supply - phase 230 v ac – 50 hz (live). The polarity of the current is very important and this connection should be connected with the phase of the current otherwise there wi...

Page 45

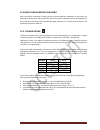

Octagon v2.16 page 45 5. Modification of the maximum power of the burner in two steps 5.1. Adjustment of fan speed, 2 nd configuration level the speed levels per power rating are subject to the following parameters: fan speed parameter fan speed during phase fire stop 19 fan speed during phase test ...

Page 46: Cє12

Octagon v2.16 page 46 24. Certificates declaration of conformity manufacturer : octagon address : koumoundourou 53 – 182 33 attiki – hellas declares that this unit is complies with the : • en 60335-1:2012 , en 60335-2-102:2006 +a1:2010 harmonized to the lvd european directive 2006/95/ec (low voltage...

Page 47

Octagon v2.16 page 47 25. Quality control checklist we herby confirm that the burner passed successfully all manufacturing steps and quality control tests and is delivered to you ready to use. Model of burner ……………………………………………… power rating kw/h Ρ5…….. Ρ4…….. Ρ3…….. Ρ2…….. Ρ1…….. Electronic controll...