- DL manuals

- OEM

- Printer

- KPM216HII

- User Manual

OEM KPM216HII User Manual

Summary of KPM216HII

Page 1

Oem commands manual 77200000002000 kpm216hii kpm216hii user manual.

Page 3

The format used for this manual improves use of natural resources reducing the quantity of necessary paper to print this copy. Custom engineering s.P.A. Str. Berettine 2 43010 fontevivo (parma) - italy tel. : +39 0521-680111 fax : +39 0521-610701 http: www.Custom.Biz customer service department: ema...

Page 5: Index

1 introduction .................................................................................................................................................... 7 1.1 document structure ..................................................................................................................

Page 6: 6 Kpm216Hii

10 alignment ........................................................................................................................................................ 81 10.1 enable alignment ................................................................................................................

Page 7: 1 Introduction

1 introduction 1.1 document structure this document includes the following chapters: 1 introduction information about this document 2 description general description of device 3 installation information required for a correct installation of the device 4 operation information required to make the de...

Page 8: 8 Kpm216Hii

1. Introduction 8 kpm216hii user manual.

Page 9: 2 Description

2 description 2.1 unpacking the device remove the printer from its carton being careful not to damage the packing material so that it may be re-used if the printer is to be transported in the future. Make sure that all the components illustrated below are present and that there are no signs of damag...

Page 10: 10 Kpm216Hii

2.2 device components external view 1. Motorization cover 2. Lock/unlock button of mo- torization cover 3. Printing head set 4. Opening lever of head set 5. Roller cover 6. Paper out adjustable in two positions 7. Adjustable cursor for paper in 8. Paper in 9. Tilting paper holder 10. Paper ejector r...

Page 11: Kpm216Hii 11

Internal view 1. ‘paper in presence’ sensor 2. Printing head 3. ‘printing head open’ sensor 4. ‘paper under the cutter’ sensor 5. Cutter 6. ‘paper out presence’ sensor 7. Sensor for notch detection 2 1 3 4 5 6 7 2. Description user manual kpm216hii 11.

Page 12: 12 Kpm216Hii

2.3 device components: connectors view 1. Rs232 connector 2. Usb connector 3. Power supply connector 1 2 3 2. Description 12 kpm216hii user manual.

Page 13: Kpm216Hii 13

2.4 key functions the following fi gures show the functions of printer’s keys according to the operating condition of the device. Lf ff lf ff modify selected parameter fast push next parameter fast push lf ff lf ff lf ff lf ff printing font test power up hold down hold down printing setup report ski...

Page 14: 14 Kpm216Hii

Lf ff lf ff advance the paper (preset length) standby fast push fast push hardware reset (power off/ power on) lf ff reset is the “notch alignment” parameter set on “disabled”? (see setup) perform the ticket alignment printing demo ticket yes no 2. Description 14 kpm216hii user manual.

Page 15: Kpm216Hii 15

2.5 status led fl ashes the status led indicates hardware status of device. Given in the table below are the various led signals and the cor- responding printer status. Status led description - off printer off green on printer on: no error green communication status 1 x receive data 2 x reception er...

Page 16: 16 Kpm216Hii

2. Description 16 kpm216hii user manual.

Page 17: 3 Installation

3 installation 3.1 mounting speci fi cations the printer is designed for the following positions: warning respect the mounting specifications to guar- antee the right ticket emission. 0° 0° 90° 90° 0° 0° -90° -90° disable the parameter ‘automatic ejecting’ (see par.5.4) 45° 45° 45° 45° horizontal pa...

Page 18: 18 Kpm216Hii

3.2 fastening the printer is provided with three fi xing holes on the bottom of device (see following fi gure). To fasten the printer on a panel, use three m4 screws 11 5 220 15 4 x m4 a a it’s very important to consider the screws length to not damage the internal components placed near the fi xing...

Page 19: Kpm216Hii 19

3.3 fixing brackets the printer includes a kit for the assembly of two additional fi xing brackets (see following fi gure). The kit contains: 1. Two fi xing brackets; 2. No.4 fi xing screws. 1 1 2 for the assembly procedure, proceed as follows: 1 remove the side cover by rotating the lock/unlock. Bu...

Page 20: 20 Kpm216Hii

2 fix the brackets as shown in fig. Observe the orientation of the slot a. A a the following fi gure shows the printer overall dimensions with the two additional brackets (dimensions in mm). 269 11 5 10 10 4 x 10 (no.4) 3. Installation 20 kpm216hii user manual.

Page 21: Kpm216Hii 21

3.4 near paper end sensor the printer includes a near paper end sensor with wiring (see following fi gure). To fi x the sensor use two m3 screws not supplied. Npe sensor npe sensor board npe wiring fixing screws m3 material included material not included for the assembly procedure, proceed as follow...

Page 22: 22 Kpm216Hii

2 connect the wiring coming from the near paper end sensor board at the connector shown in figure npe wiring 3. Installation 22 kpm216hii user manual.

Page 23: Kpm216Hii 23

3.5 connections the following fi gure shows the possible connections for device. Rs232 seriale standard cable usb usb standard cable power supply power supply cable (supplied) attention: in some using conditions, we recommend the installation of a ferrite core on the power supply cable. 3. Installat...

Page 24: 24 Kpm216Hii

3.6 pinout 1 4 3 6 power supply male molex connector vertical (no. 39-30-0060) j14 1 +24 vdc 2 +24 vdc 3 +24 vdc 4 gnd 5 gnd 6 gnd attention: respect power supply polarity. Nota : power supply cable the following fi gure shows the connector pinout of the power supply cable for the device: power supp...

Page 25: Kpm216Hii 25

1 1 5 5 6 6 9 9 rs232 serial interface female db9 connector j8 1 dtr 2 tx during transmission, takes the values “0” and “1” depending on data. 3 rx during reception, takes the values “0” and “1” depending on data. 4 n.C. 5 gnd 6 dtr when “1”, printer is power on. 7 cts 8 rts when “1”, printer is rea...

Page 26: 26 Kpm216Hii

3.7 driver the drivers are available for the following operating system: operating system driver installation procedure windows windows xp from the start menu, press enter and key-in the path where the sw was saved on your pc, then click ok. Follow the instructions that appear on the screen to insta...

Page 27: 4 Operation

4 operation 4.1 adjusting paper width paper width may be adjusted from 194mm to 216mm by moving the mobile paper guides as shown in the following fi gure. 4. Operation user manual kpm216hii 27.

Page 28: 28 Kpm216Hii

4.2 turning on the device cavo di alimentazione (in dotazione) 2 connect the power supply cable to the connector of the printer (see par.3.6). 1 connect the power supply cable (supplied) to an external power supply unit (optional). 3 the green led turns on and the printer is ready. Power supply cabl...

Page 29: Kpm216Hii 29

4.3 paper insertion each time you change the paper, check inside the printer. To change the paper proceed as follows: 1 adjust the paper width (see previous paragraphs). 2 place the paper roll, so that it unrolls in the direction shown in figure. Attention: make sure the cut is straight. 4. Operatio...

Page 30: Room

3 insert the paper into the paper infeed opening and wait for it to load automatically. V room paper out in horizontal position paper out in vertical position the following fi gure gives the limit positions of the paper roll related to the printer for a correct paper loading without a paper roll hol...

Page 31: Kpm216Hii 31

4.4 issuing ticket the printer allows you to choose between different operating modes for the issuance of printed tickets. The operating modes shown in the following images, depend on the settings of the con fi guration parameters and commands sent to the printer. Note: for further information, refe...

Page 32: 32 Kpm216Hii

4 the user withdraw the ticket from the paper mouth 3 when printing ends, the device cuts the ticket and presents a portion of the ticket printed on the paper mouth paper out in vertical position ticket presented paper cut ejector rollers paper out in horizontal position ticket presented paper out i...

Page 33: Kpm216Hii 33

“eject” mode 1 the device starts the ticket printing 2 the ticket advances ahead to the ejector and is caught between the ejector rollers. The printed part of ticket is collected while the device continues printing paper input printing head printing head paper caught between rollers ejector rollers ...

Page 34: 34 Kpm216Hii

4 the device ejects the ticket (horizontally or vertically depending on the model used) 3 when printing ends, the device cuts the ticket and presents a portion of the ticket printed on the paper mouth 4 the ticket is waiting on the paper mouth for a preset period of time paper out in vertical positi...

Page 35: Kpm216Hii 35

“retract” mode 1 the device starts the ticket printing 2 the ticket advances ahead to the ejector and is caught between the ejector rollers. The printed part of ticket is collected while the device continues printing paper input printing head printing head paper caught between rollers ejector roller...

Page 36: 36 Kpm216Hii

4 the device retracts and collects the ticket from the mouth paper 3 when printing ends, the device cuts the ticket and presents a portion of the ticket printed on the paper mouth 4 the ticket is waiting on the paper mouth for a preset period of time paper out in vertical position paper out in horiz...

Page 37: 5 Configuration

5 configuration 5.1 con fi guration mode to enter the con fi guration mode and print a setup report with the operating parameters of the printer, proceed as follows. 1 during power-up, hold down the form feed key while the wiring is plugged into the power supply connector of the printer. 2 the devic...

Page 38: 38 Kpm216Hii

4 proceed with the configuration by using the keys according the functions printed on paper. For description and values of setup parameters, see the following paragraphs. 3 press the form feed key to enter the configuration mode lf ff form feed key [ff] to modify parameter [lf] for next parameter [ ...

Page 39: Kpm216Hii 39

5.2 setup report the following fi gures show the setup reports of the printer. The shown values for parameters are sample values; for the list and the description of printer and ethernet parameters see the following paragraphs. Printer setup interface ......................................... Rs232 ...

Page 40: 40 Kpm216Hii

5.3 printer status printer operating status is indicated in the con fi guration print-out in which, next to the name of the components dis- played, the following information is given: interface is given the interface present. Program memory test the message ok appears if functioning and not ok if fa...

Page 41: Kpm216Hii 41

5.4 printer parameters this printer allows the con fi guration of the parameters listed in the following table. The parameters marked with the symbol d are the default values. Settings remain active even after the printer has been turned off and they are stored in non-volatile memory. Rs232 baud rat...

Page 42: 42 Kpm216Hii

Autofeed setting of the carriage return character: cr disabled d = carriage return disabled cr enabled = carriage return enabled print mode printing mode: normal d = enables printing in normal writing way reverse = enables printing rotated 180 degrees chars / inch font selection: 200dpi models 300dp...

Page 43: Kpm216Hii 43

Notch threshold threshold value (in percent) for the recognition of the presence of notch by the notch sensor: 0.5v 2.0v d 3.5v 1.0v 2.5v 4.0v 1.5v 3.0v 4.5v note: if the “notch alignment” parameter is disabled, this parameter is not printed. Notch distance “notch distance” is the minimum distance (...

Page 44: 44 Kpm216Hii

5.5 hexadecimal dump this function is used to diagnose the characters received through the communication port; the characters are printed out both as hexadecimal codes and ascii codes. Once the self-test routine has fi nished, the printer enters hexadecimal dump mode. The printer remains in standby ...

Page 45: 6 Maintenance

6 maintenance 6.1 ejector paper jam in case of paper jam proceed as follows: a 1 lift up the print head using the opening slot (a) located on the cover, lift up the rollers cover 2 remove the damaged paper from the ejector rollers and check the presence for paper scraps inside the printer; carefully...

Page 46: 46 Kpm216Hii

3 remove the damaged paper by pulling it in the direction shown in figure. 4 insert the new paper (see previous paragraphs). Attention: do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and...

Page 47: Kpm216Hii 47

6.2 autocutter paper jam in case of paper jam proceed as follows: a 2 lift up the print head using the opening slot (a) located on the cover 1 remove the side cover by rotating the lock/unlock. Button in unlocked position button in locked position 6. Maintenance user manual kpm216hii 47.

Page 48: 48 Kpm216Hii

3 lift up the autocutter. 4 remove the damaged paper from the autocutter and check the presence for paper scraps inside the printer; carefully remove all scraps of paper. If necessary, use tweezers. Attention: do not touch the head heating line with bare hands or metal objects. Do not perform any op...

Page 49: Kpm216Hii 49

5 insert the new paper (see previous paragraphs). 6. Maintenance user manual kpm216hii 49.

Page 50: 50 Kpm216Hii

6.3 planning of cleaning operations the regular cleaning of the device keeps the print quality and extends its life. The following table shows the recom- mended planning for the cleaning operations. Every paper change printing head use isopropyl alcohol rollers use isopropyl alcohol every 5 paper ch...

Page 51: Kpm216Hii 51

6.4 cleaning for periodic cleaning of the printer, see the instructions below sensors 1 disconnect the power supply cable. 3 lift up the print head using the opening slot (a) located on the cover 2 remove the side cover by rotating the lock/unlock. 4 lift up the autocutter. A attention: do not touch...

Page 52: 52 Kpm216Hii

5 clean the printer sensors by using compressed air. Paper path 1 disconnect the power supply cable. 2 clean the paper output area by using compressed air. Attention: do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. On alcohol, solvent cohol, s...

Page 53: Kpm216Hii 53

A 3 clean the paper input area by using compressed air. 3 clean the printing head by using a non-abrasive cloth moistened with isopropyl. Printing head 1 disconnect the power supply cable. 2 lift up the print head using the opening slot (a) located on the cover isopropyl alcohol attention: do not us...

Page 54: 54 Kpm216Hii

Printing roll 1 disconnect the power supply cable. 3 lift up the print head using the opening slot (a) located on the cover 2 remove the side cover by rotating the lock/unlock. Button in unlocked position button in locked position a 4 clean the dragging roller by using a soft cloth moistened with is...

Page 55: Kpm216Hii 55

Cutter 1 disconnect the power supply cable. 2 remove the side cover by rotating the lock/unlock. 4 lift up the autocutter. Button in unlocked position button in locked position 3 lift up the print head using the opening slot (a) located on the cover a attention: do not touch the head heating line wi...

Page 56: 56 Kpm216Hii

5 remove any scraps of paper and the accumulated paper dust on the cutter input by using compressed air. Case 1 disconnect the power supply cable. 2 to clean the machine, use compressed air or a soft cloth. Attention: do not use alcohol, solvents, or hard brushes. Do not let water or other liquids g...

Page 57: Kpm216Hii 57

A 4 clean the ejector roller by using a soft cloth moistened with isopropyl. Ejector 1 disconnect the power supply cable. 2 lift up the ejector cover (a). 3 lift up the guide and remove any scraps of paper and the accumulated paper dust inside the ejector. Isopropyl alcohol attention: do not use alc...

Page 58: 58 Kpm216Hii

6.5 upgrade fi rmware warning: during communication between pc/ printer for the fi rmware update it is strictly forbidden to disconnect the communication cable or to remove the power supply of the devices not to endanger the proper functioning of the printer. Note: the latest fi rmware of the printe...

Page 59: Kpm216Hii 59

3. Connect the printer to the pc using a usb cable (see paragraph 3.5). 4. Switch on the printer. 5. Start the software upgceprn. 6. Select the update fi le .Psw location : 7. Select item usb and then select the usb device among those proposed (ex. Kpm216h): c:\vkp80iii.Psw custom kpm216h2 custom kp...

Page 60: 60 Kpm216Hii

6. Maintenance 60 kpm216hii user manual.

Page 61: 7 Specifications

7 specifications 7.1 hardware speci fi cations general sensors head temperature, ‘paper in presence’ sensor, detector for black mark, ‘paper out presence’ sensor, ‘paper under the cutter’ sensor, ‘printing head open’ sensor external near paper end emulations esc/pos tm printing driver windows xp, vi...

Page 62: 62 Kpm216Hii

Esc/pos™ emulation (models with simplified chinese font) pc437, pc850, pc860, pc863, pc865, pc858 (euro), gb2312 printable barcode upca, upce, ean13, ean8, code39, itf, codabar, code93, code128, code32 printing speed (1) (2) 200 dpi models high speed = 125 mm/sec normal = 100 mm/sec high quality = 5...

Page 63: Kpm216Hii 63

Electrical specifications power supply cod.964ge010000350 (optional) power supply voltage from 100 vac to 240 vac frequence from 47 hz to 63 hz current (output) max. 9,6 a power 230w environmental conditions operating temperature from 0°c to +50°c relative humidity from 10% rh to 85% rh storage temp...

Page 64: 64 Kpm216Hii

7.2 character speci fi cations in esc/pos tm emulation modelli a 200 dpi character set 3 character density 11 cpi 15 cpi 20 cpi number of columns 88 123 160 chars / sec 1760 2480 3200 lines / sec 20 20 20 characters (l x h mm)-normal 2,25 x 3 1,625 x 3 1,25 x 3 modelli a 300 dpi character set 3 char...

Page 65: Kpm216Hii 65

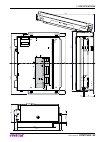

127 140.5 140.5 147.4 248 83 35.5 196 2.5 164 2.5 1.75 48 1.6 16.5 16.5 8 12 270 7. Specifications user manual kpm216hii 65.

Page 66: 66 Kpm216Hii

7.4 power supply dimensions cod.964ge010000350 (optional) length 198 mm height 50 mm width 99 mm 49.5 49.5 63.0 2xm4 65.0 70.0 176.5 10.0 11.5 50.0 21.0 12.5 25.0 12.5 29.0 25.0 25.0 25.0 117.0 56.0 99.0 198.0 +v +v -v -v pe n l 7. Specifications 66 kpm216hii user manual.

Page 67: Kpm216Hii 67

7.5 speci fi cations for ticket with black mark printer is provided with a sensor for the notch detection as described in chapter 10. The following fi gure shows an example of paper roll with black mark, where: dmin. = minimum notch to notch distance: min. 160mm (if the “short ticket” parameter is d...

Page 68: 68 Kpm216Hii

7.6 character sets in esc/pos ™ emulation the printer has 3 embedded fonts of varying width: 11, 15, 20 cpi for the 200dpi models and 16, 23, 60 cpi for the 300dpi models. Each of these fonts offers the following code tables: pc437, pc850, pc860, pc863, pc865, pc858. Pc437 code table (usa, standard ...

Page 69: Kpm216Hii 69

Pc850 code table (multilingual) char sp ! “ # $ % & ‘ ( ) * + , - . / hex 0020 0021 0022 0023 0024 0025 0026 0027 0028 0029 002a 002b 002c 002d 002e 002f dec 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 char 0 1 2 3 4 5 6 7 8 9 : ; = > ? Hex 0030 0031 0032 0033 0034 0035 0036 0037 0038 0039 003a ...

Page 70: 70 Kpm216Hii

Pc860 code table (portuguese) char sp ! “ # $ % & ‘ ( ) * + , - . / hex 0020 0021 0022 0023 0024 0025 0026 0027 0028 0029 002a 002b 002c 002d 002e 002f dec 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 char 0 1 2 3 4 5 6 7 8 9 : ; = > ? Hex 0030 0031 0032 0033 0034 0035 0036 0037 0038 0039 003a 00...

Page 71: Kpm216Hii 71

Pc863 code table (canadian, french) char sp ! “ # $ % & ‘ ( ) * + , - . / hex 0020 0021 0022 0023 0024 0025 0026 0027 0028 0029 002a 002b 002c 002d 002e 002f dec 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 char 0 1 2 3 4 5 6 7 8 9 : ; = > ? Hex 0030 0031 0032 0033 0034 0035 0036 0037 0038 0039 0...

Page 72: 72 Kpm216Hii

Pc865 code table (nordic) char sp ! “ # $ % & ‘ ( ) * + , - . / hex 0020 0021 0022 0023 0024 0025 0026 0027 0028 0029 002a 002b 002c 002d 002e 002f dec 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 char 0 1 2 3 4 5 6 7 8 9 : ; = > ? Hex 0030 0031 0032 0033 0034 0035 0036 0037 0038 0039 003a 003b 0...

Page 73: Kpm216Hii 73

Pc858 code table (euro symbol) char sp ! “ # $ % & ‘ ( ) * + , - . / hex 0020 0021 0022 0023 0024 0025 0026 0027 0028 0029 002a 002b 002c 002d 002e 002f dec 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 char 0 1 2 3 4 5 6 7 8 9 : ; = > ? Hex 0030 0031 0032 0033 0034 0035 0036 0037 0038 0039 003a 0...

Page 74: 74 Kpm216Hii

7. Specifications 74 kpm216hii user manual.

Page 75: 8 Consumables

8 consumables the following table shows the list of available consumables for device: description code thermal paper roll weight = 70g/m 2 width = 210mm Ø external = 140mm Ø core = 25mm 67300000000321 thermal paper roll weight = 70g/m 2 width = 216mm Ø external = 140mm Ø core = 25mm 67300000000327 8...

Page 76: 76 Kpm216Hii

8. Consumables 76 kpm216hii user manual.

Page 77: 9 Accessories

9 accessories the following table shows the list of available accessories for device: description code power supply (for technical speci fi cations, see the paragraph 7.1) 964ge010000350 paper roll holder (see paragraph 9.1) 974as010000303 kit for near paper end (see paragraph 9.2) 26300000000602 9....

Page 78: 78 Kpm216Hii

9.1 external paper roll holder for the device is available an external paper roll holder kit (cod.974as010000303) supplied as an accessory. The kit makes it possible to use paper rolls with larger diameter (Øext.180mm max). The kit includes: 1. Paper holder support 2. Paper roll pin 3. Paper roll 21...

Page 79: Kpm216Hii 79

2 place the paper roll holder behind the printer. To load paper refer to the instructions indicated in par. 4.3 of this manual side without holes paper roll holder dimensions and paper roll specifications (in mm) Ø max 180 max 216 160 80 4 x ø4.5 note: for external rolls diameter higher to 100mm it’...

Page 80: 80 Kpm216Hii

9.2 kit for near paper end for the device is available a kit of wirings with near paper end sensor 26300000000602 (supplied as an accessory). The kit includes: 1. Wiring assembled with near paper end sensors board 2. Plastic spacer 3. Fixing screw 4. Shield 1 2 3 4 to assemble the near paper end sen...

Page 81: 10 Alignment

10 alignment device is provided with a sensor for the use of alignment notch in order to handle: • roll of tickets with pre-printed fi elds and a fi xed length; the alignment notch may be formed by • black mark printed on paper (see par.7.5); all alignment sensor is a “re fl ection” sensor: this kin...

Page 82: 82 Kpm216Hii

The following fi gure shows an example of paper with the non-thermal paper printed with black marks: the outgoing voltage is constant while passing the white paper between two notches and presents a peak at each black mark. In this case, the optimal value for the “notch threshold” parameter is place...

Page 83: Kpm216Hii 83

If the maximum value of “noise” read by the sensor is very close to the peak value, it might be dif fi cult to place the value of the “notch threshold” at an intermediate point. In these cases, it is mandatory that the portion of paper be- tween the point of printing end and the front notch is compl...

Page 84: 84 Kpm216Hii

The following fi gure shows a section of the device with the paper path and the distances (in mm) between the align- ment sensors, the printing head and the cutter (cutting line). Printing head notch sensor 25.5 autocutter 30 esc/pos tm emulation to de fi ne the alignment point you need to set the p...

Page 85: Kpm216Hii 85

10.4 printing area in order to print ticket containing only one notch and to not overlay printing to a notch (that will make it useless for the next alignment), it is important to well calibrate: • the height of the printing area of ticket according to the inter-notch distance • the value for the pa...

Page 86: 86 Kpm216Hii

10. Alignment 86 kpm216hii user manual.

Page 87: 11 Technical

11 technical service in case of failure, contact the technical service by sending an e-mail to support@custom.It detailing: 1. Product code 2. Serial number 3. Hardware release 4. Firmware release to get the necessary data, proceed as follows: product label 5 send an e-mail to the technical service,...

Page 88: Www.Custom.Biz

Part number : 76200000002400 rev . 1.00 www.Custom.Biz custom engineering s.P.A. W orld headquarters via berettine, 2 - 43010 fontevivo, parma italy tel. +39 0521 680111 - fax +39 0521 610701 info@custom.Biz - www.Custom.Biz all rights reserved.