- DL manuals

- Oerlikon

- Water Pump

- RUVAC WA

- Installation and operating instructions manual

Oerlikon RUVAC WA Installation and operating instructions manual

Summary of RUVAC WA

Page 1

Part numbers 112 17/54 113 22/42 117 20/21/24/30/31/34/40/41/44 /50/51 118 31/41/51 128 38 155 008/011v 167 004/022 ruvac wa / wau 251/501/1001/2001 roots vacuum pumps atex categories 3 i and 3 i/o installation and operating instructions ga03107_002_a4.

Page 2

Contents 2 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum page 0 important safety information 5 0.1 mechanical hazards 5 0.2 electrical hazards 6 0.3 thermal hazards 7 0.4 hazards caused by materials and substances 7 0.5 ignition risk 8 0.6 noise hazard 8 0.7 danger of pump damage 9 ruvac root...

Page 3

Contents 3 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum original installation and operating instructions. 3.5 connecting the atex-motor 44 3.5.1 general installation information 45 3.5.2 fitting the coupling 46 3.5.3 fitting the motor 47 3.5.4 electrical connection 47 4 operation 48 4.1 star...

Page 4

Safety information 4 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum obligation to provide information before installing and commissioning the pumps, carefully read these operating instructions and follow the information so as to ensure optimum and safe working right from the start. The oerliko...

Page 5

Safety information 5 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 0 important safety information 0.1 mechanical hazards 1 avoid exposing any part of the human body to the vacuum. 2 even during standstill of the ruvac it is dangerous to grasp into the pump casing. Fingers can easily be squeez...

Page 6

Safety information 6 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 13 the pumps must only be operated at the permitted speeds. Especially when using frequency converters which have not been specifically approved by oerlikon leybold vacuum, you need to ensure an effec- tive protection against ...

Page 7

Safety information 7 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 0.3 thermal hazards 1 hot surfaces, risk of suffering burns. Under certain ambient conditions the pump may attain temperatures over 80° c. There then exists the risk of suffering burns. Note the dan- ger symbols on the pump an...

Page 8

Safety information 8 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 4 the user has to ensure that all appropriate safety codes and all safety procedures are applied in case of pumping toxic, chemically reactive, corrosive gases and/or pyrophoric substances. Before using the ruvac pumps with to...

Page 9

Safety information 9 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 0.7 danger of pump damage 1 do not use the pump for applications that produce abrasive or adhe- sive powders or condensable vapors that can leave adhesive or high viscosity deposits. Please contact oerlikon leybold vacuum sale...

Page 10

Atex 10 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum ruvac roots pumps wa/wau atex category 3 (inside) category 3 (inside) and (outside) important information for operating the ruvac wa/wau 251/501/1001/2001 atex category 3 roots pumps in potentially explosive atmospheres the roots pumps ruv...

Page 11

Atex 11 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum explanation of the symbols ii equipment group ii applies to all equipment for use in areas which can be endangered by an explosive atmosphere except in underground mining oper- ations and their related above ground systems which can be end...

Page 12

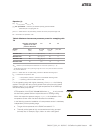

Atex 12 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum tx (temperature class 1 - 6) temperature class: classification of equipment in classes depending on their maximum surface temperature corresponding to the following table: temperature class maximum surface temperature (°c) t1 450 t2 300 t3...

Page 13

Atex 13 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum ignition protection type and marking of the electrical compo- nents of the ruvac wa/wau atex kat. 3 (i) and 3 (i) / 3 (o) a) motor: ex e iic t3 (200 °c) bzw. Ex de iic t4 (135 °c) b) temperature sensor (only permissible for t3 operation) i...

Page 14

Atex 14 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum operation keeping below limit temperatures basic diagram: kompr ession k ef f verdichtungsdruck p v am druckstutzen (mbar) p const, t3 0,01 0,1 1 10 100 1000 p const, t4 t4 - einsatzgrenze t3 - einsatzgrenze k 0: maximal mögliche kompressi...

Page 15

Atex 15 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum equation (1) (1) p a, max. Permissible = p const, tx / k th p a, max. Permissible = maximum permissible operating pressure ruvac (intake side) for complying with tx p const, tx = table value for tx (see table), pressure at roots pump disch...

Page 16

Atex 16 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum equation (2): (2) p a, max. Permissible ≤ p v / k eff, permissible ≤ ∆p max / (k th -1) if k eff cannot be reliably determined, here too k th must be applied. Generally the following applies to atex applications: p e (cut-in pressure, see ...

Page 17

Atex 17 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum through the installation position and the measurement tolerances of the pt 100, the shutdown temperatures listed in the table needed to be taken into account. Proper operation of the monitoring facilities must be checked before commissioni...

Page 18

Atex 18 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum example for t3 without temperature monitoring a ruvac wa 501 atex kat. 3 (i) / (o) is being operated together with a liquid ring pump and a steam ejector pump. The liquid ring pump and the steam ejec- tor pump generate a pumping speed of a...

Page 19

Atex 19 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum example for calculating p e and p a for a t2 application a ruvac wa 501 is being operated together with a backing pump at a pump- ing speed of approximately 150 m 3 / h. Compliance with temperature classifica- tion t2 is required. This wil...

Page 20

Atex 20 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum if only the inside of the pump (process side) has been certified for use in explosive atmospheres, then the pump itself must not be installed and operated within explosion hazard areas. Outside of the pump: zone definitions areas in which ...

Page 21

Atex 21 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum additional installation requirements “x” in addition to the installation information provided in the main operating instructions, the following needs to be ensured: the pump must exclusively be filled and operated with the oil lvo 100 or l...

Page 22

Atex 22 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum potential ignition sources an assessment of the ignition hazard was performed in accordance with the european standard en 13463-1 (en 13463-1 non-electrical equipment for potentially explosive atmospheres - part 1: basic method and require...

Page 23

Atex 23 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum mechanical sparks during normal operation no sparks due to mechanical causes will occur. The fan and the fan cowl are so designed that a sufficient clearance is maintained thereby excluding the possibility of a contact. The ingress of part...

Page 24

Atex 24 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum how must the temperature sensor be connected electrically? Oerlikon leybold vacuum describes here a recommended circuit for the elec- trical connection. The circuit shown (fig. 0.3) represents one possibility of processing the signal, othe...

Page 25

Description 25 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1 description 1.1 design and function the ruvac wa and ruvac wau are roots vacuum pumps which are driv- en directly by an electric motor. The wau types have a pressure balance line between the discharge and intake flange. Standard r...

Page 26

Description 26 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum in practice, the maximum attainable pressure differential is significant only in the rough vacuum range (p > 10 mbar), whereas for pressures in the fine vacuum range (p ruvac wa/wau pumps have been specifically designed for operatio...

Page 27

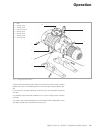

Description 27 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1.1.2 design ruvac roots pumps can pump gas in the vertical or horizontal direction. Although the pumping chamber of roots pumps is free of sealing agents and lubricants, the two gearwheels of the synchromesh gearing and the bearing...

Page 28

Description 28 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum the motor of the ruvac wa/wau is directly flanged to the coupling hous- ing. One shaft of the pump is linked to the shaft of the motor by an elastic coupling. The shaft of the other impeller is driven via the synchromesh gear. With ...

Page 29

Description 29 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1.1.4 lubricants the standard ruvac wa/wau pumps are ready for operation with mineral oil or synthetic oil. In case of operation with mineral oil we recommend our vacuum pump oil lvo 100, in case of operation with synthetic oil we r...

Page 30

Description 30 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1.3 technical data for atex applications, only the values for 50 hz apply. Ruvac wa/wau 251 501 1001 2001 nominal pumping speed at 50 hz 1) m 3 . H -1 253 505 1000 2050 max. Pumping speed at 50 hz m 3 . H -1 210 410 800 1850 nominal...

Page 31

Description 31 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum a a 1 a 2 a 5 a 4 a 3 h 7 h 1 b 7 b b 1 b 2 b 6 h h 2 b 6 b 5 b 4 b 3 h 3 h 4 h 5 b 8 dn dn dn dn d b 9 b 9 typ b b 1 b 2 b 3 b 4 b 5 b 6 b 7 1) b 8 1) wa/wau 251 250 270 210 280 230 170 24 305 285 wa/wau 501 310 299 229 320 271 201...

Page 32

Description 32 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1.3.1 motor data wa(u) 251 wa(u) 501 wa(u) 1001 wa(u) 2001 motor type amh 80z ba2 amh 90l ba2 amh 112m aa2 amh 1325 ta2 motor power 50/60hz 1.1 kw 2.2 kw 4 kw 7.5 kw number of phases 3 number of pole pairs 1 nominal frequency 50/60 ...

Page 33

Description 33 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1.4 ordering data roots vacuum pump wa/wau 251 wa/wau(h) 501 wa/wau(h) 1001 wa/wau(h) 2001 ruvac wa 117 20 117 30 117 40 117 50 wa with horizontal flow – 128 38 – 113 42 ruvac wau 117 21 117 31 117 41 117 51 wau with horizontal flow...

Page 34

Description 34 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum accessories for all ruvac wa/wau part nos temperature sensor (pt 100) 155 010 oil drain facility (m 16 x 1.5) ■ with straight drain coupling 190 02 ■ with right-angled drain coupling 200 14 271 pressure switch ps 115 (stainless stee...

Page 35

Transport and storage 35 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 2 transport and storage roots pumps are heavy machines made of cast iron and thus should only be lifted using suitable lifting equipment tied to the eyes provided for this pur- pose, see fig. 2.1. When the pump is removed ...

Page 36

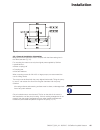

Installation 36 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 1 2 4 5 6 7 8 9 10 11 12 3 14 13 3 installation only fill in the oil after having installed the pump. 3.1 installation install ruvac wa/wau pumps on a flat, horizontal surface (1° max. Tilt). If the pump is not level, lubricant may...

Page 37

Installation 37 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum secure the pump. Four bores in the feet are provided for this purpose. When bolting the feet down, make certain that there is no stress or twist on the pump casing. Stress on the pump can change the close tolerances between the imp...

Page 38

Installation 38 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.2 conforming utilisation the ruvac pumps are vacuum pumps which in connection with suitable backing pumps are capable of pumping gases and vapours. They are employed to increase the pumping speed of backing pumps below 10-100 mba...

Page 39

Installation 39 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.2.1 non-conforming utilisation non-conforming utilisations for the pump are among others: ■ pumping of gases and vapours for which the materials of the pump are not suited. ■ pumping of condensable vapours without adequately cont...

Page 40

Installation 40 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.3 electrical connection for pumps without a motor, first fit a suitable motor, see section 3.5. Notice safety information 0.2. Always provide an uninterrupted connection for the protective ground conductor connecting it in a prof...

Page 41

Installation 41 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum the electric motor must be protected with a motor protection switch. The local connection conditions will possibly necessitate means for the pur- pose of reducing the surge currents upon switching the pump on. Star-delta start-up i...

Page 42

Installation 42 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum after connecting the motor and every time you alter the wiring, check the direction of rotation. Wear protective goggles for protection against particles which may be forced out of the flange opening. Keep your hands away from the ...

Page 43

Installation 43 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.4 connecting the flanges already small quantities of liquids (from the vacuum chamber or the piping) can lead to liquid damages within the pump. These may lead to a defor- mation of the impellers and may entirely destroy the pump...

Page 44

Installation 44 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.5 connecting the atex-motor the ruvac wa pump can also be ordered without a connected motor (see ordering data). When motor is fitted by the customer, the operator will be responsible for selecting and operating the motor. Mounti...

Page 45

Installation 45 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 3.5.1 general installation information make sure that the respective motor complies with the information given in the table (see also fig. 3.5). For mounting the motors use only the original parts supplied by oerlikon leybold vacuu...

Page 46

Installation 46 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum fig. 3.7 mounting the coupling half at the motor fig. 3.6 pump with preassembled coupling half 3.5.2 fitting the coupling the ruvac wa is supplied by olv with the coupling (fig. 3.6) preassembled on the pump’s shaft. The coupling h...

Page 47

Installation 47 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum fig. 3.8 checking the axial distance dimension for the coupling l1 fig. 3.9 view of the fitted motor washer (4x) wa 251 / 501: Ø 11 wa 1001 / 2001: Ø 13 nut (4x) wa 251/501: m10 / torque 40 nm wa 1001/2001: m12 / torque 40 nm l1 3....

Page 48

Operation 48 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 4 operation 4.1 start-up check the pump motor’s direction of rotation and the oil level in the oiler and the bearing chambers (see section 3.1.1). Ruvac wau the ruvac wau can be started together with the backing pump at atmos- pheric ...

Page 49

Operation 49 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum with small vacuum vessels, the maximum permissible pressure differential can be briefly exceeded (max. 3 min) upon start-up. If a pressure switch has been installed, do not set it to this higher pressure because it will fail to pro- t...

Page 50

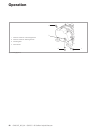

Operation 50 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum never open the oil-fill or oil-drain screw in the presence of a vacuum or while the pump is running. There is the danger that oil may squirt out. The oil level for the shaft seal housing must always be visible in the oiler (see fig. 4...

Page 51

Operation 51 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum unscrew oiler and sealing screw. Screw in the oiler from the top using a perfect gasket and screw in the sealing screw from the side also using a perfect gas- ket. Fill in the oil for the side chambers at and the oil for the shaft sea...

Page 52

Operation 52 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum fig. 4.2 changing the oil 1 oil-drain screw for horizontal gas flow 2 oil-drain screw for vertical gas flow 3 oil level glass 4 oil-fill screw 1 2 3 4.

Page 53

Maintenance 53 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5 maintenance 5.1 safety information the safety information given in the following applies to all maintenance work. Notice safety information 0.1 to 0.3. Disconnect the electrical power before disassembling the pump. Make absolutely...

Page 54

Maintenance 54 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.2 exchanging the oil / bearing chambers observe all safety information provided in sections 0.3 to 0.5. Before pumping oxygen (or other highly reactive gases) at concentrations exceeding the concentration in the atmosphere (> 21 %...

Page 55

Maintenance 55 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum please consult us if you intend to run the pump with other oils or special lubricants. The oil filling levels stated in fig. 3.2 to 3.3 - which apply to the shutdown (standing still) pump - must be observed. The filling level visibl...

Page 56

Maintenance 56 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.4 cleaning the fan cowl and the cooling fins observe all safety information provided in sections 0.3 to 0.5 and 5.1. The slits in the fan cowl as well as the fins on the motor and on the pump may be contaminated depending on humid...

Page 57

Maintenance 57 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum the loosened deposits must not remain in the pump. After cleaning, check the pump by slowly turning the impellers by hand. They should move freely and without any resistance. Generally, the roots pump does not need to be disassemble...

Page 58

Maintenance 58 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.8 exchanging the shaft seals observe all safety information provided in sections 0.3 to 0.5 and 5.1. The shaft feedthrough of the ruvac wa/wau is sealed with two shaft seals. In order to reduce wear on the shaft these shaft seals ...

Page 59

Maintenance 59 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.8.1 preparations unscrew sealing screw with the gasket, drain the oil out from the shaft seal housing and screw the sealing screw back in using a gasket which is in perfect condition. Support the motor so that it can not drop. Uns...

Page 60

Maintenance 60 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum fig. 5.3 exchanging the shaft seal 1 oiler 15 coupling element 2 o-ring 16 protection tube 3 bushing 17 motor with coupling piece (other half) 4 o-ring 18 nuts 5 o-ring 19 screw 6 securing ring 20 screw 7 shaft seal 21 sealing screw...

Page 61

Maintenance 61 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.8.3 ruvac wa/wau 1001, 2001 (see figs. 5.2 and 5.3). Use a puller to pull out shaft seal housing and bushing together. Remove o-rings. Pull the bushing out of the housing. Take the o-ring out of the housing. Remove securing ring. ...

Page 62

Maintenance 62 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.9 exchanging the bearings for atex applications the pump must be completely refurbished every 15,000 operating hours or every three years, including replacement of the bearings and the coupling as well as inspecting the toothed wh...

Page 63

Maintenance 63 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 5.11 maintenance schedule process meas./test quantity maintenance intervall remark check oil level min./max. Oil level in oil level glass before switching on and daily check oil level with the pump at stand- still, see section 3.1.1...

Page 64

Troubleshooting 64 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 6 troubleshooting malfunction likely cause remedy repair pump does not start up. Motor incorrectly connected. Pressure switch is defective. Oil is too thick. Motor defective. Pump has seized: defective impellers, bearings or too...

Page 65

Troubleshooting 65 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum malfunction likely cause remedy repair pump is losing oil. Oil leak is apparent: oil drain plug is leaky. Oil level glasses leaky. Gear cover is leaky. Leaky coupling flange no oil leak is apparent: see malfunction „oil in the p...

Page 66

Disposal 66 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 7 wearing and original spare parts original spare parts are available from the oerlikon leybold vacuum service facilities. 8 waste disposal the pump may have been contaminated by the process or by environmental influences. In this case...

Page 67

Notes 67 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum.

Page 68

68 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum ec declaration of conformity.

Page 69

69 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum ec incorporation declaration.

Page 70

70 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum 17200001_002_a1 © oerlikon leybold vacuum safety information on contamination of compressors, vacuum pumps and components. Scope every employer (user) is held responsible for the health and safety of his employees. This also applies to service ...

Page 71

Index 71 ga03107_002_a4 - 09/2015 - © oerlikon leybold vacuum.

Page 72

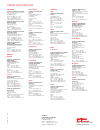

Oerlikon leybold vacuum gmbh bonner strasse 498 d-50968 cologne phone: +49-(0)221-347 0 fax: +49-(0)221-347 1250 info.Vacuum@oerlikon.Com w w w . O e r l i k o n . C o m / l e y b o l d v a c u u m germany oerlikon leybold vacuum gmbh sales, service, support center (3sc) bonner strasse 498 d-50968 c...