- DL manuals

- Oerlikon

- Water Pump

- SCROLLVAC SC 15 D

- Operating Instructions Manual

Oerlikon SCROLLVAC SC 15 D Operating Instructions Manual

Summary of SCROLLVAC SC 15 D

Page 1

Oil-free vacuum pump scrollvac sc 5 d sc 15 d sc 30 d sc 60 d operating instructions ga01423_002_a2 part nos. 133 000 133 001 133 002 133 003 133 004 133 008 133 100 133 101 133 102.

Page 2: Table of Contents

General safety information 3 1 description 7 1.1 design and operation 7 1.2 component designations of the individual pump types 9 1.2.1 ordering information 9 1.3 technical data 10 1.3.1 motor data 11 1.3.2 dimensions 14 2 transport and storage 17 3 installation 18 3.1 checking the product 18 3.2 am...

Page 3: Safety Information

Safety information 3 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum general safety information indicates procedures that must be strictly observed to prevent hazards to persons. Indicates procedures that must be strictly observed to prevent damage to, or destruction of the appliance. The oerli...

Page 4: Safety Information

Ensure proper grounding of the pump. Otherwise there exists the risk of suffering an electric shock or igniting a fire. Never put fingers or foreign matter into the pump's inlet or the clearance of fan blades. If done, it can cause injury. Install in an area which is not exposed to moisture such as ...

Page 5: Safety Information

Safety information fig. 0.1 placement of the warning stickers electric shock terminal cover capacitor cover sc 5 d single-phase sc 15 d single-phase sc 15 d three-phase always keep warning stickers clean. If they become dirty or lost, replace them with new ones. If you need stickers, contact oerliko...

Page 6: Safety Information

6 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum safety information sc 30 d single-phase sc 30 d three-phase electric shock terminal cover cover for operating hours counter capacitor cover electric shock terminal cover cover for operating hours counter fig. 0.2 placement of the warning sticker...

Page 7: Description

7 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 1 description 1.1 design and operation the scrollvac vacuum pumps are oil-free vacuum pumps. Each scrollvac consists of two archimedes spirals offset within each other by 180 °. Thus several crescent-shaped pockets of different sizes are created...

Page 8: Description

8 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum description fig. 1.2 component designations (sc 15 d/30 d) sc 15 d sc 30 d motor direction indicating arrow direction indicating arrow motor motor terminal box motor terminal box operating hours counter operating hours counter fan cover fan cove...

Page 9: Description

9 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 1.2 component designations of the individual pump types 1.2.1 ordering information part no. Sc 5 d, single-phase motor, cable with schuko plug 133 000 sc 15 d, single-phase motor, cable with schuko plug 133 001 sc 30 d, single-phase motor, cable...

Page 10: Description

10 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum description 1.3 technical data model sc 5 d sc 15 d sc 30 d sc 60 d 50 hz 60 hz 50 hz 60 hz 50 hz 60 hz 50 hz 60 hz displacement l · min -1 90 108 250 300 500 600 1000 1200 (swept volume) m 3 · h -1 5 6,48 15 18 30 36 60 72 cfm 3.1 3.8 8.8 10.6...

Page 11: Description

11 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 1.3.1 motor data motor data sc 5 d type single-phase induction motor / motor 4p / totally enclosed insulation class b ip 44 thermal protector tp 212 - automatic reset type power consumption w 150 voltage v 100 115 200 230 rated current 50 hz a ...

Page 12: Description

12 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum description motor data sc 30 d type single-phase induction motor 4p three-phase induction motor 5 4p totally enclosed totally enclosed insulation class b / ip 44 insulation class b / ip 44 thermal protector tp 212 automatic reset type power con...

Page 13: Description

13 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum fig. 1.4 pumping speed curves of the scrollvac sc 5 d to sc 60 d 0,10 1,00 10,00 100,00 0,001 0,010 0,100 1,000 10,000 100,000 1000,000 50 hz with and without purge 60 hz with and without purge sc5d sc15d sc30d sc60d p u m p in g s p e e d pres...

Page 14: Description

14 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum description 1.3.2 dimensions fig. 1.5 dimensional drawing of the sc 5 d sc 5 d ( dimensions in mm).

Page 15: Description

15 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum fig. 1.6 dimensional drawing of the sc 15 d 3-phasig 1-phasig sc 15 d description ( dimensions in mm) t th hrre ee e--p ph ha as se e s siin ng glle e--p ph ha as se e.

Page 16: Description

16 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum description fig. 1.7 dimensional drawing of the sc 30 d 3-phasig 1-phasig sc 30 d ( dimensions in mm) t th hrre ee e--p ph ha as se e s siin ng glle e--p ph ha as se e.

Page 17: Description

17 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 2 transport and storage lift the pump only at the provided handles, respectively crane eyelets. Exclusively use lifting facilities with sufficient lifting capability. Never stand under the hanging pump when it is being moved. Avoid any other or...

Page 18: Installation

18 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation 3 installation 3.1 checking the product check that the package is right-side-up and then open it. Check that model of the product is one that you ordered. Check that there is no damage. If there is any damage, file a damage claim w...

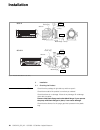

Page 19: Installation

19 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum fig. 3.2 product check (sc 30 d / sc 60 d) blank flange o-ring clamp inlet outlet sc 60 d installation sc 30 d plastic bag silencer clamp blank flange o-ring clamp blank flange o-ring inlet outlet plastic bag 60 d 60 72 8 1,4.

Page 20: Installation

20 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation 3.2 ambient conditions danger of electric shock. Install in an area which is not exposed to moisture such as rain or steam. Moisture on electric power connections can cause bodily injury by short circuit or electric shock. Danger o...

Page 21: Installation

21 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 3.3 setting up the pump the sc 5 d and sc 15 d are equipped with a carrying handle for transporting. The sc 30 d and sc 60 d are provided with a crane eyelet for transporting and place- ment. Use lifting devices with sufficient carrying capacit...

Page 22: Installation

22 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation 3.4 electrical connections wiring must be done by a qualified electrician. Otherwise, electric shock or fire may occur. Turn off the incoming main electrical power before wiring the pump. Failure to do so can cause injury from elec...

Page 23: Installation

23 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation involving different mains voltages this vacuum pump must be equipped with a mains circuit breaker in accor- dance with requirements of en 60204-1. It is recommended to use a circuit breaker as main breaker which is suitable for iso...

Page 24: Installation

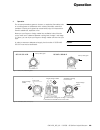

24 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation fig. 3.5 checking the direction of rotation after having provided the wiring viewed from the motor side, clockwise direction of rotation direction of rotation direction indicating arrow motor fig. 3.6 prevent foreign matter from en...

Page 25: Installation

25 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 3.4.2 three-phase motors for sc 15 d / 30 d / 60 d only be sure to install a reliable main disconnect switch (or breaker) which meets the iec standard for emergency stop. Failure to do so can cause damage or fire. Ce requirements the 3-phase mo...

Page 26: Installation

26 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation table 2: three-phase connection v hz rated current for mains power circuit breaker - a sc 15 d sc 30 d sc 60 d 200 50 1.8 3.1 5.9 200 60 2.2 3,2 6.2 208 60 2.2 3.0 6.2 230 60 2.2 2.9 6.1 380 50 1.1 1.8 3.7 415 50 1.2 1.9 4.0 460 60...

Page 27: Installation

27 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum operate the pump with inlet open, and check that air comes out from outlet. If you plan to switch the pump on-off with remote control, check the pump's rotation direction before connecting it to the vacuum system. When checking rotation, avoid ...

Page 28: Installation

28 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum installation 3.5 connection to the vacuum system ■ inlet of the sc 5 d is dn 25 and the exhaust is dn 16. ■ inlet of the sc 15 d is dn 25 and the exhaust is dn 16. ■ inlet of the sc 30 d is dn 40 and the exhaust is dn 25. ■ inlet of the sc 60 d...

Page 29: Operation

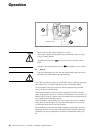

Operation 4 operation do not pump hazardous gases to humans, or explosive, flammable, toxic or corrosive gases or substances which contain chemicals, solvents or powders. Pumping such gases can cause bodily injury from exposure to harmful substances, explosion or fire. Never put your fingers or fore...

Page 30: Operation

30 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum operation never remove or alter safety equipment or covers. Removing or altering this equipment can cause electric shock or bodily injury by rotating objects. Operate at the pump only w wiitth h the fan cover and the terminal cover in place. Op...

Page 31: Operation

31 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum proceed as follows to start the pump: 1. Close the isolation valve to prevent drawback of debris from the vacuum pump into vacuum chamber (open the purge gas valve if one is installed). 2. Switch the vacuum pump on. 3. Open the isolation valve ...

Page 32: Operation

32 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum operation never change the purge gas conditions during operation (on/off) open or close the purge gas valve port only after shutting down the pump. Opening or closing the purge gas valve during operation can cause the pump to fail and cause bod...

Page 33: Operation

33 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 4.4 shutdown after vapour has been pumped, continue to operate the pump with the purge gas valve open for over one hour. If you close the purge gas valve port or stop the pump soon after vapour has been pumped, condensed moisture remains in the...

Page 34: Maintenance

34 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum maintenance 5 maintenance neglecting maintenance and inspection can cause poor performance and pump failure. To remove debris accumulated in the vacuum pump, operate the pump several times for 3-5 seconds (once a day) with its inlet open to atm...

Page 35: Maintenance

35 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum fan cover fan electric shock! During inspection and maintenance work keep the power supply switched off. Sc 30 d / sc 60 d sc 5 d / sc 15 d fig. 5.2 during inspection and maintenance work keep the power supp- ly switched off. Electric shock! Fa...

Page 36: Maintenance

36 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum maintenance 5.1 table - maintenance when the maintenance interval has been reached, contact oerlikon leybold vacuum to arrange the required maintenance. Never disassemble, reassem- ble or alter the pump yourself. We are not responsible for any ...

Page 37: Maintenance

37 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 5.2 oerlikon leybold vacuum service whenever you send us equipment, indicate whether the equipment is conta- minated or is free of substances which could pose a health hazard. If it is contaminated, specify exactly which substances are involved...

Page 38: Troubleshooting

38 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 6 troubleshooting if the pump malfunctions, please refer to the following chart for help in solving the problems. If you cannot solve the problem, please contact oerlikon leybold vacuum. Troubleshooting fault possible cause remedy pump does not...

Page 39: Spare Parts

Spare parts 39 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum 7 spare parts scrollvac sc 5 d sc 15 d sc 30 d sc 60 d maintenance kits small maintenance kit (after 8,000 h) minor kit large maintenance kit (after 16,000 h) major kit toolkit scroll profiled seal (tip seal) shaft installation kit ...

Page 40

40 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum.

Page 41

41 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum ec declaration of conformity we, oerlikon leybold vacuum gmbh, hereby declare that the products specified and listed below which we have placed on the market, comply with the applicable ec council directives. This declaration becomes invalid if...

Page 42

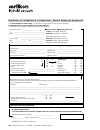

42 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum declaration of contamination of compressors, vacuum pumps and components the repair and / or servicing of compressors, vacuum pumps and components will be carried out only if a correctly completed declaration has been sub- mitted. Non-completio...

Page 43: Notes

43 ga01423_002_a2 - 10/2008 - © oerlikon leybold vacuum notes.

Page 44

Oerlikon leybold vacuum gmbh bonner strasse 498 d-50968 cologne phone: +49-(0)221-347 0 fax: +49-(0)221-347 1250 info.Vacuum@oerlikon.Com p.R. China oerlikon leybold vacuum (tianjin) international trade co. Ltd. Beichen economic development area (beda), no.8 western shuangchen road tianjin 300400 ch...