- DL manuals

- Oerlikon

- Water Pump

- Sogevac SV40 BI

- Operating Instructions Manual

Oerlikon Sogevac SV40 BI Operating Instructions Manual

Summary of Sogevac SV40 BI

Page 1

Sogevac ® sv40 bi single-stage, oil-sealed rotary vane pump operating instructions ga02329_002_03 waters corporation ref.: 960331v3007 document y26/300270034/002/03.

Page 2

2 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum contents page important safety information 3 1 description 5 1.1 principle of operation 5 1.2 technical characteristics 6 1.3 accessories 8 1.4 lubricants 8 2 transport and storing 9 2.1 transport and packaging 9 2.2 mounting orientation 9 2.3 s...

Page 3

3 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum important safety information indicates procedures that must be strictly observed to prevent hazards to persons. Indicates procedures that must be strictly observed to prevent damage to, or destruction of the product. Emphasizes additional applic...

Page 4

4 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum these installation and operating instructions are valid for waters use of the sogevac ® pumps, model sv40 bi. The sogevac ® vacuum pumps have been manufactured according to the latest technical standards and safety regulations. If not installed ...

Page 5

5 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum 1 description sogevac ® pumps are designed for pumping of inert gases in the range of rough vacuum, between atmospheric pressure and ultimate pressure of the pump. When removing condensable vapors, periodic opening of the gas ballast valve is re...

Page 6

6 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum 1.2 technical characteristics sv40 b technical data 50 hz 60 hz nominal pumping speed m 3 /h 42 50 pumping speed (according to pneurop) m 3 /h at 2 mbar > 35 > 45 ultimate partial pressure without gas ballast mbar ≤ 0,25 ≤ 0,25 ultimate total pr...

Page 7

7 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum description pumping speeds curves sv40 b - sv65 b fig. 1 sv40 bi pumping speeds curves sv40 bi p umping speed p umping speed.

Page 8

8 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum description 1.3 accessories sv40 bi specification cat. Nr. Oil level switch 711 19 110 temperature switch 9 714 32 820 exhaust filter over 9 714 25 890 pressure switch exhaust filter over 951 94 pressure manometer oil drain tap 711 30 114 1.4 lu...

Page 9

9 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum transport and storing 2 transport and storing 2.1 transport and packaging sogevac ® vacuum pumps pass a rigorous operating test in our factory and are packaged to avoid transport damages. Please check packaging on delivery for transport damages....

Page 10

10 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum 3 installation it is essential to observe the following instructions step by step to ensure safe start-up. Start-up may only be conducted by trained specialists. The standard pump is not suitable for installation in explosion hazard atex areas....

Page 11

11 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum the electrical installation may only be conducted by a specialist. Local regulations have to be followed. Electrical connection work must only be carried out by a qualified electrician in accordance with the applicable safety rules, see iec 602...

Page 12

12 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum the motor connection box integrates an on/off 24 vdc relay. The pump operation is commanded with a 24 vdc signal lead through a dedicated cable. The final end product must provide a 24 vdc signal (protected by a 3 a fuse) for the remote control...

Page 13

13 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum operation 4 operation 4.1 operation to avoid overloading the motor, do not start the pump more than 6 times within one hour. If more than 6 starts per hour are necessary keep the pump running and mount a valve which opens and closes into the in...

Page 14

14 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum 4.2 working in cycles in / out we recommend strongly to limit starting of the pump to 5 or 6 per hour. If the process need it, we recommend utilization of a pneumatic or electromagnetic valve and to let the pump run continously. 4.3 switching o...

Page 15

15 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum maintenance 5 maintenance 5.1 safety information observe all safety regulations. All work must be done by suitably trained personnel. Maintenance or repairs carried out incorrectly will affect the life and performance of the pump and may cause ...

Page 16

16 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum 5.3 oerlikon leybold vacuum service whenever you send us in equipment, indicate whether the equipment is contaminated or is free of substances which could pose a health hazard. If it is contaminated, specify exactly which substances are involve...

Page 17

17 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum maintenance to flush the pump, for clean oil up to the minimum level, let the pump run for a few minutes and drain the oil. Install a full charge of oil, 1 liter. C. Replacing the exhaust filters oil mist escaping from the exhaust during operat...

Page 18

18 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum troubleshooting 6 troubleshooting fault possible cause remedy reference section * pump does not pump is connected incorrectly. Connect the pump correctly. 3.3 start. Motor protection switch incorrectly set. Set motor protection switch properly....

Page 19

19 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum troubleshooting fault possible cause remedy reference section * oil in intake line oil comes from the vacuum system. Check the vacuum system. Or in vacuum anti-suckback valve is obstructed. Clean or repair the valve. 5.4-f vessel. Sealing surfa...

Page 20

20 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum spare parts 7 spare parts to guarantee safe operation of the oerlikon leybold vacuum pump, only original spare parts and accessories should be used. When ordering spare parts and accessories, always state pump type and serial number. You can fi...

Page 21

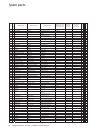

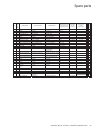

21 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum spare parts fig. 3 sv40 bi modifie par : freissinet le : 08.12.2008 num : é fé é 08 12 2008 2 3 5 6 7 11 8 9 10 11a 13 14 16 15 18 19 22 23d 23i 23b 27 28 29 30 31 32 5 33 34 36 37 38 35 42 43 44 48a 48 58a 58 52 40 53 55 54 57b 57a 57 59 46 17...

Page 22

22 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum spare parts pos. Stüc k. Qty qté benennung specification designation abmessungen (mm) dimensions (mm) dimensions (mm) bestell-nr ref, no, n° de réf bemerkungen notes remarques 971 45 21 50 971 44 31 50 971 45 46 00 971 42 76 60 1 1 gehÄusedecke...

Page 23

23 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum pos. Stüc k. Qty qté benennung specification designation abmessungen (mm) dimensions (mm) dimensions (mm) bestell-nr ref, no, n° de réf bemerkungen notes remarques 97 14 52 15 0 97 14 43 15 0 97 14 54 60 0 97 14 27 66 0 39 8 mutter nut ecrou h ...

Page 24

24 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum.

Page 25

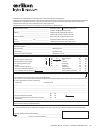

25 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum declaration of contamination of compressors, vacuum pumps and components the repair and / or servicing of compressors, vacuum pumps and components will be carried out only if a correctly completed declaration has been submitted. Non-completion ...

Page 26

26 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum notes.

Page 27

27 ga02329_002_03 - 01/2010 - © oerlikon leybold vacuum notes.

Page 28

Oerlikon leybold vacuum gmbh bonner strasse 498 d-50968 cologne phone: +49-(0)221-347 0 fax: +49-(0)221-347 1250 info.Vacuum@oerlikon.Com p.R. China oerlikon leybold vacuum (tianjin) international trade co., ltd. Beichen economic development area (beda), shanghai road tianjin 300400 china sales and ...