Summary of SPRINT 5000

Page 1

Sprint 5000 bookletmaker operation manual.

Page 2

Sprint5000hcs-usa.Doc3.Doc page 1 01/05/2002 contents 1. Introduction. 2 2. Specification. 2 3. Initial setting up. 3 4. Operation. 4 4.1 loading staples. 5 4.2 staple out system. 7 4.3 staple jam. 7 4.4 paper width settings. 8 4.5 stapling / folding positions. 9 4.6 changing stapling head positions...

Page 3

Sprint5000hcs-usa.Doc3.Doc page 2 01/05/2002 1 introduction • the sprint 5000 bookletmaker centre staples and folds to make booklets between 4” x 5½“ and 8½“ x 11” with up to 80 pages. On each cycle of the machine one set of sheets is stapled and the preceding set is folded and stacked on the convey...

Page 4

Sprint5000hcs-usa.Doc3.Doc page 3 01/05/2002 3. Initial setting up 1. Remove the bolts holding the machine to the pallet. 2. Castors are already fitted to the machine, lift from the pallet on to an even surface. 3. Remove packing from stapling section and from under fold stop beneath the conveyor. 4...

Page 5

Sprint5000hcs-usa.Doc3.Doc page 4 01/05/2002 4. Operation 4 4 4 0 3 8 3 6 3 4 3 2 2 8 2 6 2 4 2 2 2 0 1 8 1 6 1 4 1 2 1 0 a 4 a 5 a 3 8 7 14 5 4 3 2 1 9 10 4 11 12 13 figure 2 - control layout 1 fold stop lock thumbscrew 8 staple position fine adjustment screw 2 stapling head position arm 9 on / off...

Page 6

Sprint5000hcs-usa.Doc3.Doc page 5 01/05/2002 4.1 loading staples : 1. Only those staples sold or recommended by your supplier should be used in the sprint 5000 bookletmaker. Use of non recommended staples may damage the stapling heads and they are not covered by any warranty. 2. Raise the top cover....

Page 7

Sprint5000hcs-usa.Doc3.Doc page 6 01/05/2002 figure 3 - staple out reset/indicators..

Page 8

Sprint5000hcs-usa.Doc3.Doc page 7 01/05/2002 4.2 staple out system : this is switched on and off using a three-way toggle switch located on the inside left-hand side wall underneath the shelf. Select the switch position as follows. 1. With the toggle switch is in the central position the staple out ...

Page 9

Sprint5000hcs-usa.Doc3.Doc page 8 01/05/2002 4.4 paper width settings: 1. Both sides guides should be adjusted for a given size of paper. Loosen the thumbscrews and move the side guides until their outside edges are level with the marking on the scale corresponding to the width of the paper, and the...

Page 10

Sprint5000hcs-usa.Doc3.Doc page 9 01/05/2002 4.5 stapling / folding positions : 1. The stapling and the folding positions are adjusted as one. Loosen fold stop lock thumbscrew, figure 5. 2. Turn the fold stop adjustment wheel until the staple stop aligns with the appropriate calibration on the scale...

Page 11

Sprint5000hcs-usa.Doc3.Doc page 10 01/05/2002 4. If fold line is not perpendicular to booklet edges, this can be corrected by adjusting the fold stop tilt thumbscrew, figure 6, on the left-hand side of the fold stop adjusting shaft. Loosen the locking nut and turn the thumbscrew clockwise to raise t...

Page 12

Sprint5000hcs-usa.Doc3.Doc page 11 01/05/2002 4.6 changing stapling head positions. 1. To move the stapling heads to the alternative positions, lift the stapling head position arm, figure 7, then slide the entire stapling unit to the new position. 2. When moving the stapling head, hold the slide bra...

Page 13

Sprint5000hcs-usa.Doc3.Doc page 12 01/05/2002 5. Booklet making. 1. The machine will not operate with the top safety cover in the raised position. After closing the top safety cover it is necessary to press the circuit reset button, located in the left hand inside side wall. This is an added safety ...

Page 14

Sprint5000hcs-usa.Doc3.Doc page 13 01/05/2002.

Page 15

Sprint5000hcs-usa.Doc3.Doc page 14 01/05/2002 4. When paper is placed in the machine it breaks the light beam between the photocell emitter (part no. 2.83) and the photocell receiver (part no. 2.71). On the interruption of the beam the time set by the timer expires and the machine will operate for o...

Page 16

Sprint5000hcs-usa.Doc3.Doc page 15 01/05/2002 6. Corner and edge stapling refer to figure 10. 1. Open the top perspex cover. Move the paper width guides to the position where they will side jog the set of paper without impeding its path through the machine. For 8½“ x 11” paper, set the guides to the...

Page 17

Sprint5000hcs-usa.Doc3.Doc page 16 01/05/2002 4. Push the divert plate (part no. 3.71) back against the top front plate (part no. 3.42), figure 11. This will divert the set of paper away from the folding section and out of the machine. Figure 11 - conveyor setup 1. 5. Fit the deflector plate, by fit...

Page 18

Sprint5000hcs-usa.Doc3.Doc page 17 01/05/2002 figure 12 - conveyor setup 2. 7. Place the conveyor wheel spindle (part no. 6.17) into the slots provided in the conveyor wheel support brackets. 8. As a set exits the machine down the exit plate it should first come to a stop so that approximately 1” of...

Page 19

Sprint5000hcs-usa.Doc3.Doc page 18 01/05/2002 7. Counter the counter can be reset to '0000' by pressing the rectangular black button below the number window. 8. Replacing stapling heads should it become necessary to remove either or both of the stapling heads follow the procedure below. 1. Pull the ...

Page 20

Sprint5000hcs-usa.Doc3.Doc page 19 01/05/2002 4. Locate pip on adjustment guide into small hole at front of anvil and then retighten hex screws. The stapling head should now be in a position to carry on stapling after removing adjustment guide..

Page 21

Sprint5000hcs-usa.Doc3.Doc page 20 01/05/2002 10. Problem solving. Problem possible causes remedy motor will not start blown fuse switch off and unplug machine. Check and replace fuses as necessary machine will not start when paper is inserted powerful light source from above shield safety cover fro...

Page 22

Sprint5000hcs-usa.Doc3.Doc page 21 01/05/2002 spare parts drawings for the sprint 5000 bookletmaker appendix a c5003-fc 4.97.

Page 23

Rhs 1 2 3 4 10 11 12 1. Panels lhs c5000-1a 5.97 9 8 5 7 6 240v 3 a 14 15.

Page 24

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 1.00 panels 1.01 side cover 1 1.02 bottom front plate 1 1.03 top front plate 1 1.04 counter (not in view). State 240vac or 24vdc 1 1.05 fuse holder 2 1.06 fuse 2 1.07 switch - staple count 1 1.08 staple delay knob 1 1.09 reset switch 1 1.10 power switch ...

Page 25

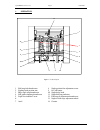

16 47 46 1 2 109,107 6 7 8 9 10 11 12 14 88 18 2. Staple section lhs rhs 108 19 20 93 26 28 29 30 31 32 33 34 134 36 37 35 39 40 41 42 43 50 51 54 55 48 57 61 62 58 60 65 63 68 69 104 105 70 71 135 77 78 131 80 81 82 83 138 133 85 87 56 98 101 103 99 100 102 94 95 96 91 13 24 90 17 89 64 122,67 59 1...

Page 26

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 2.00 staple section 2.01 stapling head actuator bar 1 2.02 top takeaway wheel - corner stapler 1 2.03 2.04 2.05 2.06 corner/edge stop adjust thumbscrew 1 2.07 side guide rhs 1 2.08 scale rhs 1 2.09 paper table 1 2.10 scale lhs 1 2.11 bearing housing 1 2....

Page 27

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 2.58 collar 1 2.59 center bearing block 1 2.60 bottom takeaway wheel 1 2.61 side guide extension lhs 1 2.62 side guide lhs 1 2.63 paper deflector lhs 1 2.64 second paper table 1 2.65 side guide clamping thumbscrew 2 2.66 anvil 2 2.67 anvil bar 1 2.68 sta...

Page 28

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 2.117 block 2 2.118 collar 2 2.119 cup bearing 2 2.120 clinchers 4 2.121 clinch spacer plate 2 2.122 anvil bar for clinchers (replaces 2.67) 1 2.130 2.131 centre guide (replaces 2.79) 1 2.132 stapling head universal bar (replaces 2.74) 1 2.133 slide brac...

Page 29

1 2 3 4 6 9 40 41 42 44 45 46 51 52 53 54 55 56 57 59 61 62 63 64 65 69 71 75 76 77 78 73 72 79 80 81 82 83 84 85 3 . F o ld s e c tio n rear rhs c 5 0 0 2 -3 a 1 1 .9 8 47 48, 49 66 86 87, 88 89 7 8 11 50 74 43 front 60 25 26 27 29 30 37 31 32 33 34 38 35 36 lhs 39 14 12 15 18 28 23 24 16 17 19 13 ...

Page 30

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 3.00 fold section 3.01 staple & fold stops adjust wheel 1 3.02 bearing housing 1 3.03 fold stop tape wheel 1 3.04 fold stop tilt thumbscrew 1 3.05 3.06 spacer 1 3.07 fold stop tilt block 1 3.08 fold stop shaft 1 3.09 collar 1 3.10 knife crank assembly bo...

Page 31

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 3.58 3.59 fold roll stub shaft 2 3.60 fold stop retainer 2 3.61 conveyor wheel assembly mount shaft 1 3.62 fold stop guide retaining shaft 1 3.63 fold roll 2 3.64 fold roll stub shaft - bottom 1 3.65 fold roll stub shaft - top 1 3.66 bearing housing 1 3....

Page 32

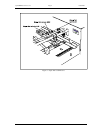

62 11 12 13 14 16 17 19 18 20 21 22 24 25 26 27 28,29 32 43 1 2 3 4 5 8 9 33 34 35 36 37 38 39 40 42 44 45 46 47 51 52 53 49 50 4 . L e ft h a n d s id e 55 c 5 0 0 2 -4 a 1 0 .9 9 61 31 48 57,58 30 41 23 15 59 54 10

Page 33

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 4.00 left hand side 4.01 bearing housing 1 4.02 sprocket 1 4.03 chain 1 4.04 sprocket 1 4.05 sprocket 1 4.06 4.07 4.08 ball race 1 4.09 nylatron runner 1 4.10 actuating lever 1 4.11 shoulder screw 1 4.12 block 1 4.13 plate 1 4.14 bar 1 4.15 chain link 4....

Page 34

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 4.58 relay base 1 4.59 transformer 1 4.60 4.61 spring retaining plate 1 4.62 actuating lever return spring 1 please quote machine model and serial number, with part number, on order..

Page 35

21 26 27 28 30 32 33 1 2 3 5 6 9 8 11 12 17 10 13 14 15 24 25 18 23 16 22 19 44 57 35 36 38 39 40 41 42 45 47 48 49 50 51 53 5. Right hand side c5002-5 10.99 4 29 56 31 43 54 37 34 60 61 59 55 on newer machines, parts 59, 60 & 61 have replaced parts 29, 30 & 31. The two sets do not exist on any one ...

Page 36

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 5.00 right hand side 5.01 bearing housing 1 5.02 washer 1 5.03 bearing block 1 5.04 side jog fork plate 1 5.05 timing pulley 1 5.06 bearing housing 1 5.07 5.08 pressure plate 1 5.09 bearing housing 1 5.10 compression spring 1 5.11 fold roll tension sprin...

Page 37

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 5.58 5.59 clutch bracket (replaces item 5.31 on 240v ac m/c's) 1 5.60 clutch drive collar (replaces item 5.57 on 240v ac m/c's) 1 5.61 clutch assembly (replaces item 5.29 & 5.30 on 240v ac m/c's) 1 nb:240v ac m/c's pcb have prefix 'pskf'. 24v dc m/c's pc...

Page 38

C 5 0 0 1 -6 4 .9 9 20 2 3 4 5 6 7 8 10 9 11 12 17 16 1 6 . O u tf e e d c o n v e y o r 18 19 21 23 24.

Page 39

Kf_5002.Xls 01/05/2002 5000hcs/ part quantity 6.00 outfeed conveyor 6.01 deflector plate 1 6.02 conveyor mounting bracket 2 6.03 conveyor drive shaft 1 6.04 conveyor belt drive rolls 1 6.05 conveyor belt 1 6.06 support bar 2 6.07 plate 2 6.08 cup bearing 2 6.09 conveyor belt drive rolls 1 6.10 conve...