- DL manuals

- Officezone

- Laminator

- MightyLam 2700

- Operating Instructions Manual

Officezone MightyLam 2700 Operating Instructions Manual

Summary of MightyLam 2700

Page 1

Operating instructions mightylam 2700 roll laminator 1-800-543-5454 www.Officezone.Com officezone.

Page 2

1-800-543-5454 www.Officezone.Com officezone.

Page 3: Table of Contents

Safety messages and electrical safeguards ..............................1-2 introduction .................................................................................2-3 laminator features .................................................................3 specifications ............................

Page 4

1-800-543-5454 www.Officezone.Com officezone.

Page 5: Electrical Safeguards

Important safety messages and electrical safeguards for your protection, do not connect the laminator to electrical power or attempt to operate it until you read these instructions completely. Keep these instructions in a convenient loca- tion for future reference. This instruction manual and labels...

Page 6: Introduction

Unplug the laminator before moving it or when it is not in use for an extended period of time as a precaution against the possibility of an internal malfunction that could create a fire hazard. Do not operate the laminator with a damaged power supply cord or plug, or after it malfunctions or has bee...

Page 7

Your ml27 is preset at the factory for most applications so any adjustments should be mi- nor. A lcd readout provides continual indication of the heat shoe temperature which may be adjusted as needed. Laminator standard features... Preset laminating roller pressure and speed require no adjustment. F...

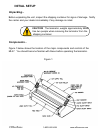

Page 8: Initial Setup

Initial setup unpacking... Before unpacking the unit, inspect the shipping container for signs of damage. Notify the carrier and your dealer immediately if any damage is noted. Caution! The laminator, weighs approximately 98lbs. Use two people when removing the laminator from the shipping container....

Page 9: Operation

Motor switch: this switch controls power to the laminating rollers. If the switch is pressed to the fwd (light will come on) position the rollers move forward, pulling the plastic film and laminated material past the heat shoes. Reverse switch: this toggle switch is found on the back of the machine....

Page 10

Threading laminating film... These instructions apply to poly-in film rolls (shiny side out, dull side in). 1. For the top supply roll place the mandrel ends into the slots in the top of the laminator. If you are facing the front of the laminator the film should unwind toward you from the bottom of ...

Page 11

5. Turn the motor switch on to start the laminating and pull rollers. 6. Feed a piece of thin cardboard about 10” x 25” against the film so that it is centered between the two heat shoes. Push the cardboard and film into the laminating rollers. See figure 5. Watch cardboard pass through the back (pu...

Page 12

The laminator temperature should be adjusted according to the film thickness and the item being laminated. See table 1 below for recommended temperature settings. Keep in mind that the temperatures listed are approximate and different brands of laminating film and heavy paper stocks may require diff...

Page 13: Laminating

Caution! If the blade release knobs are turned too far, the slitter blade may fall out of its guide and come in contact with the rubber rollers. If this happens, the rollers could be damaged. Never turn the blade release knobs more than one turn to position the blades. To adjust the slitter blades: ...

Page 14: Note:

10 note: you may want to run a test lamination first as any item that passes between the heat shoes will be laminated and cannot be recovered until it exits the rear of the laminator 5. Additional items may be fed in sequence, keeping enough distance between sheets for trim ming. 6. After the last i...

Page 15

Mounting & laminating the ml27 is capable of simultaneously mounting and laminating a print on up to 3/16” mount board. Mounting your print: 1. Be sure all laminator parts (i.E. Safety shield, feed table, etc.) are in their proper positions and the laminating film is loaded correctly on top and bott...

Page 16

Trouble shooting the following guide will assist you with most problems that may be encountered when laminating. Problem: laminator is inoperative. Motor does not run, indicator lights are out. Action: unit may be unplugged. Connect power supply. Ensure that your circuit breaker has not tripped. Fus...

Page 17: Maintenance

Problem: blistering of the film appears over the item or along the edge. Action: reduce temperature on one or both heat shoes. If the indicator light remains on after the adjustment is made, disconnect the power supply and contact your dealer. Clean laminating rollers. See maintenance section for cl...

Page 18

14 6. Use a soft cloth moisentened with alcohol to remove any residue from the teflon surface of the heat shoes and laminating rollers. 7. Allow the heat shoes and laminating rollers to dry before re-threading the film. Removing wrap-arounds... When laminating with thinner gauges of film, there is t...

Page 19

Parts list and illustrations this section contains reference drawings and a parts list to assist you when ordering parts for your laminator. The drawings show only those parts that may be replaced by the dealer. Item part number description qty 1 10091 c-clip, 15/16” dia 2 2 10092 bushing, 5/8 x 3/4...

Page 20

36 1170 feet, rubber, large 4 37 1182 fuse, 15amp, mda-15 1 38 10509 heater, 120v, 290w, mightylam 6 39 8288 relay, solid state, 25a, dc 1 40 10500 sprocket, motor, mightylam 1 41 10505 sprocket, front, mightylam 1 42 10504 sprocket, rear, mightylam 1 44 10232 switch, motor reverse ezii 1 45 10393 c...

Page 21

79 10354 spring, thermometer, ezii 1 80 10355 screw, cover, ezii 10 81 10357 block, terminal, 10 sta 1 82 547 terminal ring blue 8 83 1459 screw, set, 10-24 x 1/4” 4 84 10359 screw, 6-32 x 1”” phil. 2 85 2501 screw, 6-32 x 3/4” 2 86 700562 nut, 6-32 w/nylon insert 8 87 2661 screw, 1/4-20 x 3/4” p.H....

Page 22

116 589 wire, 18 gauge, black 6.917 117 598 wire, 18 awg, white/red 3.917 118 7125 wire, 18 awg, white/violet 4.417 119 596 wire, 18 awg, white w/blue 1.292 120 1326 wire, 18 awg, white/black 3.833 121 597 wire, 18 gauge, white 2 122 593 wire, 18 gauge, red 1.875 123 10392 housing, fan, bottom 1 124...

Page 23

19 1-800-543-5454 www.Officezone.Com officezone.

Page 24

20 1-800-543-5454 www.Officezone.Com officezone.

Page 25

21 1-800-543-5454 www.Officezone.Com officezone.

Page 26

1-800-543-5454 www.Officezone.Com officezone.