- DL manuals

- OHAUS

- Scales

- Catapult 1000

- Service Manual

OHAUS Catapult 1000 Service Manual - Service Manual

SERVICE MANUAL

Catapult™ 1000 Scales

The information contained in this manual is believed to be accurate at the time of publication, but Ohaus

Corporation assumes no liability arising from the use or misuse of this material. Reproduction of this

material is strictly prohibited.

Material in this manual is subject to change.

© Copyright 2008 Ohaus Corporation, all rights reserved.

TM Registered trademark of Ohaus Corporation.

Summary of Catapult 1000

Page 1

Service manual catapult™ 1000 scales 99 washington street melrose, ma 02176 phone 781-665-1400 toll free 1-800-517-8431 visit us at www.Testequipmentdepot.Com.

Page 3: Service Manual

Service manual catapult™ 1000 scales the information contained in this manual is believed to be accurate at the time of publication, but ohaus corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material is strictly prohibited. Material in this manu...

Page 5

Table of contents page no. Chapter 1 getting started 1.1 introduction ................................................................................................................1-1 1.2 service facilities...............................................................................................

Page 6

Table of contents list of tables table no. Title page no. 1-1 specifications ........................................................................................................1-2 2-1 diagnostic guide table ...........................................................................................

Page 7

Chapter 1 getting started 1.1 introduction this service manual contains the information needed to perform routine maintenance and service on the ohaus catapult™ 1000 scales. The contents of this manual are contained in five chapters: chapter 1 getting started – contains information regarding service...

Page 8

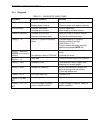

Chapter 1 getting started 1.3 tools and test equipment required the service shop should contain the following equipment: 1. Standard hand tools. 2. Digital voltmeter (dvm). 3. Load cell simulator optional. 1.4 specifications table 1-1. Specifications specification c11p9 c11p20 c11p75 capacity x read...

Page 9

Chapter 1 getting started 1.5 operation this section contains information on the basic operation of the catapult™ 1000 scale. Exploded view drawings in chapter 5 identify all components. 1.5.1 power supply power to the scale is supplied by a 9 v dc, 100ma power adapter, or by 3 “c” size (lr 14) alka...

Page 10

Chapter 1 getting started 1.5.3 basic functions power up test: when on/zero offbutton is pressed the scale turns on, all display segments appear, followed by the software version. The display then resets to zero. Zero function: by pressing on/zero off, the display returns to zero. When adding additi...

Page 11

Chapter 1 getting started 1.6 calibration for best results, calibrate the scale at regular intervals. Correct calibration weights must be available before starting calibration. (see specification table). Multiple weights may be used to equal the required calibration weight. Calibration is unavailabl...

Page 12

Chapter 1 getting started.

Page 13

Chapter 2 troubleshooting 2.1 introduction this section of the manual covers visual inspection, troubleshooting, and a diagnostic guide, table 2-1. Follow all directions step by step. Make certain that the work area is clean and use care when handling components of the scale. 2.2 visual inspection c...

Page 14

Chapter 2 troubleshooting 2.3.1 diagnosis table 2-1. Diagnostic guide table symptom possible cause(s) remedy scale will not turn on no power to scale battery power used up verify connections and voltage. Connect power and replace batteries. Poor accuracy improper calibration unstable environment per...

Page 15

Chapter 2 troubleshooting 2.4 checking the load cell’s signal remove the pcb cover to gain access to the pcb and wiring. 2.4.1 output voltage test measure the no load, 50% load and full load output. The reading should meet the load cell specifications. The load cell output should be very close to li...

Page 16

Chapter 2 troubleshooting 2.4.1 output voltage test 3. Measure the voltages on +sig and –sig wires, disconnected from pcb. Note: measurements must be made with these wires disconnected from the pcb. These measurements represent the output of the load cell. Record measurements at zero load, 50% and f...

Page 17

Chapter 2 troubleshooting 2.5 testing the printed circuit board (pcb) the pcb can be tested by measuring voltages and by using a simulator. The simulator replaces the load cell during testing and is a useful tool for diagnosing problems. 2.5.1 pcb voltage measurements note: prior to the voltage meas...

Page 18

Chapter 2 troubleshooting 2.5 testing the printed circuit board (pcb) 2.5.4 calibration test this test calibrates the scale using the simulator and can verify that the main pc board is functioning properly or improperly. 1. With the scale on, press and hold units cal to perform a calibration. (see s...

Page 19

Chapter 3 maintenance procedures 3.1 preventive maintenance ohaus scales should be carefully handled, stored in a clean, dry area, and cleaned periodically. Follow these precautionary steps: – when a scale has had chemicals or liquids spilled on it, all exterior surfaces should be cleaned as soon as...

Page 20

Chapter 3 maintenance procedures 3.2.1 replacing load cells repairs are not recommended on the catapult 1000 scale. Some component parts may be replaced. Replacement is recommended rather than repairing. Load cells may need to be replaced because of scale instability, or because the scale does not c...

Page 21

Chapter 3 maintenance procedures 3.2.2 printed circuit board (pcb) replacement replace the printed circuit board (pcb) for any of the following reasons: – display is defective; characters missing or partial display. – scale fails to calibrate properly. – display is erratic or unstable. – scale does ...

Page 22

Chapter 3 maintenance procedures 3.2.3 battery replacement 1. To replace the type c (lr14) batteries, press the inset latch lever in the middle of the bottom housing. 2. Note the proper direction for inserting new batteries, printed on the inside of the battery compartment door. 3. After placing the...

Page 23

Chapter 4 testing 4.1 testing before and after servicing the scale, operational and performance tests should be made to determine if it meets specifications. Turn the scale on and allow it to warm up for at least 20 minutes before performing these checks. The masses used for calibration should be as...

Page 24

Chapter 4 testing 4.5 repeatability test repeatability is the standard deviation of a set of similar weight readings. Requirements: – to perform this test a single mass must be used for all readings. – the test mass should be approximately ½ of the capacity of the scale. Before starting a repeatabil...

Page 25

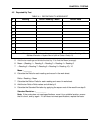

Chapter 4 testing 4.5 repeatability test table 4-1. Repeatability worksheet n reading delta = reading – mean delta x delta 1 2 3 4 5 6 7 8 9 10 n = number of reading mean = sum of readings / 10 delta = reading – mean standard deviation = square root of (sum of (delta x delta) / 9) 5. Add the ten rea...

Page 26

Chapter 4 testing 4.6 off-center load test the off-center load test is used to determine whether displayed weight values are affected by moving the sample to different areas of the pan. 1. Place half of the scale’s capacity in the center of the pan. 2. Note the reading. 3. Move the mass halfway (bet...

Page 27

Chapter 4 testing 4.7 adjusting off center load on strain gauge load cells if the off center load (ocl) is excessive, perform adjustment as follows: top view of load cell side view of load cell 2 3 weighing pan’s center, with points a – d indicated 1 4 figure 4-1. Scale drawing of catapult 1000 load...

Page 28

Chapter 4 testing 4.8 linearity test this test is used to determine the linearity of the unit throughout its operating range. The masses used to perform this test can be utility masses. Note: the scale must pass the repeatability and off center load tests, and be calibrated, before the linearity tes...

Page 29

Chapter 5 parts lists & diagrams this section of the manual contains exploded views for the catapult 1000 scales. The exploded view drawings are designed to identify the parts which can be serviced in the field. Note: in all cases where a part is replaced, the scale must be thoroughly checked after ...

Page 30

Chapter 5 parts lists & diagrams 5.1 catapult 1000 scale: parts catapult 1000 1 2 3 4 5 6 7 6 10 3 9 80b 6 81 82 80a figure 5-1. Catapult 1000 scale: parts..

Page 31

Chapter 5 parts lists & diagrams 5.1 catapult 1000 scale: parts table 5-1. Catapult 1000 scale: parts drawing item description 1 pan, stainless steel (optional) 2 pan, plastic 3 load cell set 4 function label 5 main pcb with lcd 6 hardware kit 7 pcb cover 9 battery cover 10 rubber feet (4) 80a adapt...

Page 32

Chapter 5 parts lists & diagrams.

Page 34

*80252209* p/n 80252209 service manual: catapult™ 1000 scales test equipment depot - 800.517.8431 - 99 washington street melrose, ma 02176 - testequipmentdepot.Com.