- DL manuals

- OHAUS

- Scales

- EB15

- Service Manual

OHAUS EB15 Service Manual - Eb Series Scales

The information contained in this manual is believed to be accurate at the time of publication,

but Ohaus Corporation assumes no liability arising from the use or misuse of this material.

Reproduction of this material is strictly prohibited.

Material in this manual is subject to change.

© Copyright 2006 Ohaus Corporation, all rights reserved.

® Registered trademark of Ohaus Corporation.

EB SERIES SCALES

SERVICE MANUAL

Summary of EB15

Page 1

Eb series scales service manual 99 washington street melrose, ma 02176 phone 781-665-1400 toll free 1-800-517-8431 visit us at www.Testequipmentdepot.Com.

Page 3: Eb Series Scales

The information contained in this manual is believed to be accurate at the time of publication, but ohaus corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material is strictly prohibited. Material in this manual is subject to change. © copyright ...

Page 5

I table of contents chapter 1 introduction page 1. Introduction ...................................................................................................... 1-1 1.1 service facilities ................................................................................................. 1-1 1.2 ...

Page 6

Ii table of contents (cont.) chapter 4 repair procedures 4. Repair procedures ............................................................................................... 4-1 4.1 removing top housing ....................................................................................... 4-1 4.2 r...

Page 7

1-1 chapter 1 introduction 1. Introduction this service manual contains instructions for the diagnosis and repair work to be performed by ohaus dealers or ohaus authorized service centers. Knowledge of the operation of the eb scale is assumed. Instruction manuals may be required with this service ma...

Page 8

1-2 chapter 1 introduction 1.2 tools and equipment 1.2.1 standard tools and test equipment the service shop should contain the following equipment: 1. Digital voltmeter (dvm). 2. Standard electronics tool kit. 3. Desk magnifier on a stand. 4. Grounding mat and clip. 5. Razor blades. 1.2.2 special to...

Page 9

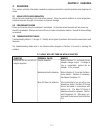

2-1 chapter 2 diagnosis 2. Diagnosis this section contains information needed to properly evaluate the reported problem and diagnose its cause. 2.1 scale setup and examination set up the scale according to the instruction manual. Allow the scale to stabilize to room temperature. Examine the scale fo...

Page 10

2-2 chapter 2 diagnosis remedy refer to section 3.5 and test the battery. Replace if necessary. See repair proce- dure 4.6. Refer to section 4.1 and open the scale. Check voltage at battery contacts first. Check dc voltage at the battery connector on the main pc board. Voltage should read approximat...

Page 11

2-3 chapter 2 diagnosis symptom scale does not respond to front panel controls. Table 2-3 scale does not respond to front panel controls. Probable cause membrane switch is defec- tive. Remedy refer to section 3.2 and test the mem- brane switch. Replace if necessary. See repair procedure 4.2. If memb...

Page 12

2-4 chapter 2 diagnosis table 2-5 scale reading incorrect or unstable. Table 2-6 cannot calibrate the scale. Symptom scale reads incorrectly. Scale reading unstable. Probable cause needs calibration. Load cell is damaged. Main pc board defective. Remedy perform service calibration in appen- dix a. I...

Page 13

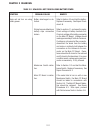

2-5 chapter 2 diagnosis 2.4 eb series scales error code table the eb series scales is equipped with software which will display an error condition when it occurs. Review the listed codes and follow instructions to correct the problem. Table 2-7. Eb series scales error codes error code e1, e2, e3 dis...

Page 14

2-6 chapter 2 diagnosis.

Page 15

3-1 chapter 3 scale testing and calibration 3. Testing and calibration this section of the manual contains testing procedures of the individual replaceable components and the scale. Before and after servicing the eb series scales, an operational test and various performance tests should be made to a...

Page 16

3-2 chapter 3 scale testing and calibration 3.3 testing the load cell assembly this section contains two methods of testing the load cell. 3.3.1 resistance test 1. Refer to section 4.1 and remove the top housing. 2. Refer to figure 3-2 and record color code and position of the wires from the load ce...

Page 17

3-3 chapter 3 scale testing and calibration 3.3.2 excitation and output voltage test (cont.) 4. Refer to figure 3-2 and measure the voltages on points 3 and 4, +sig and –sig points. These measurements represent the output of the load cell. Repeat measurements at 50% and full scale capacities. See ta...

Page 18

3-4 chapter 3 scale testing and calibration 3.4 testing the main pc board the main pc board can be tested by measuring voltages and by using a simulator. The simulator replaces the load cell during testing and is a useful tool for diagnosing problems. 3.4.1 main pc board voltage measurements prior t...

Page 19

3-5 chapter 3 scale testing and calibration 3.4.2 simulator testing to perform these tests, the use of a simulator is required. The basic function of a simulator is to simulate the output of a full bridge load cell allowing the scale to be separated from the load cell for the purposes of troubleshoo...

Page 20

3-6 chapter 3 scale testing and calibration calibration test (cont.) 3. Upon completion of calibration, the main pc board can be further checked using the simulator to simulate various weight values. If simulator settings and weight reading on the scale agree, the main pc board is functional. If the...

Page 21

3-7 chapter 3 scale testing and calibration 3.5.2 battery tests (cont.) 3. With the ac adapter connected, measure the battery voltage at the battery terminals; the voltage should be approximately 6 to 7 volts dc when charging. The voltage should be above 6.0 volts dc ten minutes after charging stops...

Page 22

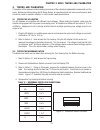

3-8 chapter 3 scale testing and calibration 3.6 performance tests figure 3-3. Segment display. 3.6.2 repeatability test repeatability is the standard deviation of a set of similar weight readings. Requirements: to perform this test a single mass must be used for all readings. The test mass should be...

Page 23

3-9 chapter 3 scale testing and calibration 3.6.2 repeatability test (cont.) test procedure: 1. Zero the scale. 2. Using a test mass approximately 1/2 the capacity of the scale, place the mass on the center of platform. Record the reading on the worksheet provided. 3. Remove the mass from the platfo...

Page 24

3-10 chapter 3 scale testing and calibration 3.6.3 off-center load test the off-center load test is used to determine whether displayed weight values will be affected by moving the sample to different areas of the weighing surface. See figure 3-4. This test must be performed using a single mass or t...

Page 25

3-11 chapter 3 scale testing and calibration 3.6.4 linearity test the linearity test is used to determine the linearity of the scale throughout its operating range. The results should be in accordance with the specifications shown above. The reference mass should be approxi- mately 1/8 of the full-c...

Page 26

3-12 chapter 3 scale testing and calibration 3.6.4 linearity test (cont.) record readings reading 1 reference weight added to zero ________________ reading 2 reference weight added at 1/4 full-scale capacity ________________ reading 3 reference weight added at 1/2 full-scale capacity _______________...

Page 27

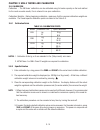

3-13 chapter 3 scale testing and calibration model eb3 eb6 eb15 eb30 capacity x readability 3 kg x 0.0001 kg 6 kg x 0.0002 kg 15 kg x 0.0005 kg 30 kg x 0.001 kg 3000 g x 0.1 g 6000 g x 0.2 g 15000 g x 0.5 g 30000 g x 1 g 6.6 lb x 0.0002 lb 13 lb x 0.0005 lb 33 lb x 0.001 lb 66 lb x 0.002 lb 105 x 0....

Page 28

3-14 chapter 3 scale testing and calibration 3.8 calibration calibration – the eb series’ calibration can be calibrated using full scale capacity as the best method for the most accurate results, this is referred to as span calibration. Calibration weights – before beginning calibration, make sure t...

Page 29

3-15 chapter 3 scale testing and calibration 3.9 scale settings the eb scale contains four user-selectable scale settings (setup mode). These are as follows: scale increment, backlight, zero tracking range and filtering. A description of each setting is explained below. 1. To enter the setup mode, p...

Page 30

3-16 chapter 3 scale testing and calibration.

Page 31

4-1 chapter 4 repair procedures 4. Repair procedures this section describes how to change individual components of the eb series scales. When doing this, please refer to the drawings and parts lists in section 5. Important: after replacing components, an operational test of the scale must always be ...

Page 32

4-2 chapter 4 repair procedures 4.2 replacing the membrane switch the membrane switch is affixed to the top housing of the scale. To replace the membrane switch, the scale must be disassembled to gain access to the switch connections. 1. Refer to section 4.1 and remove top housing. Caution use care ...

Page 33

4-3 chapter 4 repair procedures 4. Disconnect the membrane switch cable from the display pcb as shown in figure 4-4. 4.2 replacing the membrane switch (cont.) 5. On the top housing, lift up the defective membrane switch (if necessary carefully prying it up with a knife) and gently peel it off the to...

Page 34

4-4 chapter 4 repair procedures 4.3 main pc board the main pc board is located in the bottom housing. To replace the main pc board, it is necessary to disassemble the scale. 4.3.1 main pc board replacement 1. Refer to section 4.1 and remove the top housing. 2. At the rear of the bottom housing, disc...

Page 35

4-5 chapter 4 repair procedures 7. Unsolder the load cell wiring from the main pc board. Note the position and color coding of the wires on the main pc board. These will have to be soldered on the new pc board in the same positions. 8. On the replacement main pc board, install the battery and switch...

Page 36

4-6 chapter 4 repair procedures 4.3.1 main pc board replacement (cont.) 11. Install the main pc board into position in the slots on the bottom housing and secure with the screws and washers previously removed. 12. Connect the battery connector to the battery. Note : when a replacement main pc board ...

Page 37

4-7 chapter 4 repair procedures 4.3.2 display pc board replacement 1. Refer to section 4.1 and remove the top housing. 2. Disconnect the ribbon cable from the display pc board. See figure 4-10. Figure 4-11. Disconnecting the membrane switch cable from the display pc board. 3. Disconnect the membrane...

Page 38

4-8 chapter 4 repair procedures 4.3.2 display pc board replacement (cont.) 6. Install the replacement display pc board with the screws previously removed. 7. Connect the membrane switch cable from the top housing to the display pc board and the ribbon cable from the main pc board to the display pc b...

Page 39

4-9 chapter 4 repair procedures figure 4-14. Load cell retaining screw locations. 4.4 replacing the load cell assembly (with frame) the load cell assembly is centrally located inside the scale. The load cell is factory assembled and the overload protection stops are installed. The overload protectio...

Page 40

4-10 chapter 4 repair procedures 5. Refer to section 4.5.1 and check overload stops on the new assembly. 6. Lift the load cell assembly out of the bottom housing and replace with the new one. Install screws. 7. Refer to figure 3-2 and the label on the replacement load cell. 8. Solder the load cell w...

Page 41

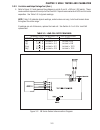

4-11 chapter 4 repair procedures 4.5 replacing the load cell component this procedure is used when it is desired to keep the existing load cell frame and replace only the load cell. The load cell assembly is centrally located inside the scale. When the new load cell is mounted to the existing frame,...

Page 42

4-12 chapter 4 repair procedures 4.5 replacing the load cell component (cont.) 7. Position the load cell and frame in the bottom housing and install the four retaining screws through the frame into the bottom housing. See figure 4-17. 4.5.1 overload protection stop adjustment when a load cell has be...

Page 43

4-13 chapter 4 repair procedures 4. Tighten the nut on the down stop screws so they will not move and recheck. Table 4-2. Load cell overload protection stop gap settings scale capacity overload gap setting mass 3 kg 0.6mm 4.5kg 6 kg 0.8mm 9kg 15 kg 1.0mm 22.5kg 30kg 1.6mm 45kg 5. Reassemble the scal...

Page 44

4-14 chapter 4 repair procedures 3. Remove the battery from the bottom housing. 4. Install a replacement battery into the same position as the original battery. The positive terminal (red) should be facing up. 5. Connect the wires to the battery. Make sure the red wire is attached to the positive te...

Page 45

5-1 chapter 5 parts lists 5. Parts lists this section of the manual contains exploded views, and parts lists for the eb series scales. The exploded view drawings identify the replaceable parts. Note: in all cases where a part is replaced, the scale must be thoroughly checked after the replacement is...

Page 46

5-2 chapter 5 parts lists figure 5-1. Major components of eb series scales. 5.1 eb series scales components platform (p/n 80120009) platform support (p/n 80120007) top housing (p/n 80104205) eb scale fully assembled top housing open membrane switch (p/n 80251386) (p/n 80251391 ebjp) display pcb (p/n...

Page 47

5-3 chapter 5 parts lists 5.1 eb series scales components (cont.) loadcell (p/n 80120013, ec3) (p/n 80120014, ec6) (p/n 80120015, ec15) (p/n 80120016, ec30) main pcb (p/n 80104190) bottom housing open figure 5-2. Components in bottom housing of eb series scales. Battery (p/n 80120026) display cable ...

Page 48

5-4 chapter 5 parts lists table 5-1. Eb series scales parts list. Part no. Description 80120000 adapter, us, 120v, 80120001 adapter, eu, 230v, 80120002 adapter, gb, 230v, 80120003 adapter, au, 240v, 80120004 adapter, jp, 100v, 80251386 switch, membrane 80251391 switch, membrane, ebjp 80120007 platfo...

Page 49

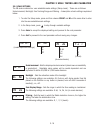

A-1 appendix a eb service modes/service calibration a. Eb service modes figure a-1. Main pc board jumper positions. This appendix describes the service menu and sub-menus, which allow authorized service personnel to configure the eb scale. Configuration settings include setting the capacity and reso...

Page 50

A-2 appendix a eb service modes/service calibration a.2 service calibration (cont.) 3. Add the displayed weight and wait until the display shows the third weight to add (full capacity). 4. After accepting the weight, the scale will restart the scale check process. Remove the weight while the self-ch...

Page 52

Pn 80251392 a service manual - eb series scales *80251392* test equipment depot - 800.517.8431 - 99 washington street melrose, ma 02176 - testequipmentdepot.Com.