- DL manuals

- OHAUS

- Scales

- FD Series

- Service Manual

OHAUS FD Series Service Manual - Fd Series Scales

The information contained in this manual is believed to be accurate at the time of publication,

but Ohaus Corporation assumes no liability arising from the use or misuse of this material.

Reproduction of this material is strictly prohibited.

Material in this manual is subject to change.

© Copyright 2004 Ohaus Corporation, all rights reserved.

® Registered trademark of Ohaus Corporation.

FD SERIES SCALES

SERVICE MANUAL

Summary of FD Series

Page 1

Fd series scales service manual 99 washington street melrose, ma 02176 phone 781-665-1400 toll free 1-800-517-8431 visit us at www.Testequipmentdepot.Com.

Page 3: Fd Series Scales

The information contained in this manual is believed to be accurate at the time of publication, but ohaus corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material is strictly prohibited. Material in this manual is subject to change. © copyright ...

Page 5

I table of contents chapter 1 introduction page 1. Introduction ......................................................... ................................................. .1-1 1.1 service facilities .......................................................................................................

Page 6

Ii chapter 4 repair procedures 4. Repair procedures .................................................................................................... .4-1 4.1 removing top housing ............................................................................................ .4-1 4.2 replacing the m...

Page 7

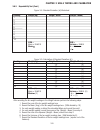

Iii table of contents (cont.) list of tables table no. Title page 1-1 calibration masses ............................................................................. 1-2 2-1 scale will not turn on with ac adapter................................................. 2-1 2-2 scale will not turn on using ...

Page 8

Iv.

Page 9

1-1 chapter 1 introduction 1. Introduction this service manual contains instructions for the diagnosis and repair work to be performed by ohaus dealers or ohaus authorized service centers. Knowledge of the operation of the scale is assumed. Instruction manuals may be required with this service manua...

Page 10

1-2 chapter 1 introduction 1.2 tools and equipment 1.2.1 standard tools and test equipment the service shop should contain the following equipment: 1. Digital voltmeter (dvm). 2. Standard electronics tool kit. 3. Desk magnifier on a stand. 4. Grounding mat and clip. 5. Razor blades. 1.2.2 special to...

Page 11

2-1 chapter 2 diagnosis 2. Diagnosis this section contains information needed to properly evaluate the reported problem and diagnose its cause. 2.1 scale setup and examination set up the scale according to the instruction manual. Allow the scale to stabilize to room temperature. Examine the scale fo...

Page 12

2-2 chapter 2 diagnosis remedy refer to section 3.5 and test the battery. Replace if necessary. See repair proce- dure 4.6. Refer to section 4.1 and open the scale. Check voltage at battery contacts first. Check dc voltage at pins 1 and 3 of battery connector on the main pc board. See figure 3-2. Vo...

Page 13

2-3 chapter 2 diagnosis symptom scale does not respond to front panel controls. Table 2-3 scale does not respond to front panel controls. Probable cause membrane switch is defec- tive. Remedy refer to section 3.2 and test the mem- brane switch. Replace if necessary. See repair procedure 4.2. If memb...

Page 14

2-4 chapter 2 diagnosis table 2-5 balance reading incorrect or unstable. Table 2-6 cannot calibrate the scale. Symptom balance reads incorrectly. Balance reading unstable. Probable cause needs calibration. Load cell is damaged. Main pc board defective. Remedy perform service calibration in appen- di...

Page 15

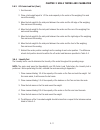

2-5 chapter 2 diagnosis 2.4 fd series scales error code table the fd series scales is equipped with software which will display an error condition when it occurs. Review the listed codes and follow instructions to correct the problem. Table 2-7. Fd series scales error codes error code error 1 error ...

Page 16

2-6 chapter 2 diagnosis 2.4 fd series scales error code table (cont.) the fd series scales is equipped with software which will display an error condition when it occurs. Review the listed codes and follow instructions to correct the problem. Table 2-7. Fd series scales error codes error code error ...

Page 17

3-1 chapter 3 scale testing and calibration 3. Testing and calibration this section of the manual contains testing procedures of the individual replaceable components and the scale. Before and after servicing the fd series scales, an operational test and various performance tests should be made to a...

Page 18

3-2 chapter 3 scale testing and calibration 3.3 testing the load cell assembly this section contains three methods of testing the load cell. 3.3.1 ramp test refer to appendix a and perform the ramp test. If the ramp test passes, continue with the rest of this procedure. 3.3.2 resistance test 1. Refe...

Page 19

3-3 chapter 3 scale testing and calibration 3.3.3 excitation and output voltage test (cont.) 4. Measure the voltages on j1 across pins 2 and 3, +sig and –sig points. These measurements represent the direct output of the load cell. Repeat measurements at 50% and full scale capacities. See table 3-2 f...

Page 20

3-4 chapter 3 scale testing and calibration 3.4 testing the main pc board the main pc board can be tested by measuring voltages and by using a simulator. The simulator replaces the load cell during testing and is a useful tool for diagnosing problems. 3.4.1 main pc board voltage measurements prior t...

Page 21

3-5 chapter 3 scale testing and calibration 3.4.2 simulator testing to perform these tests, the use of a simulator is required. The basic function of a simulator is to simulate the output of a full bridge load cell allowing the scale to be separated from the load cell for the purposes of troubleshoo...

Page 22

3-6 chapter 3 scale testing and calibration calibration test (cont.) 3. Upon completion of calibration, the main pc board can be further checked using the simulator to simulate various weight values. If simulator settings and weight reading on the scale agree, the main pc board is functional. If the...

Page 23

3-7 chapter 3 scale testing and calibration 3.5.2 battery tests (cont.) 3. With the ac adapter connected, measure the battery voltage at the battery terminals; the voltage should be approximately 6 to 7 volts dc when charging. The voltage should be approximately 6.4 volts dc ten minutes after chargi...

Page 24

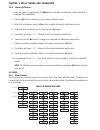

3-8 chapter 3 scale testing and calibration 3.6 performance tests 3.6.1 segment display test connect the ac adapter into a suitable power source and connect it to the scale. Turn the scale on, all segments are enabled and displayed briefly followed by a software revision number. This is a segment di...

Page 25

3-9 chapter 3 scale testing and calibration reading weight (kg) weight - mean (weight – mean) 2 1 2 3 4 5 6 7 8 9 10 sum = sum = mean = sum/10 variance = sum/9 mean = = = = = = variance = = = = = figure 3-5. Calculation of standard deviation ( ). Reading weight (kg) weight - mean (weight – mean) 2 1...

Page 26

3-10 chapter 3 scale testing and calibration figure 3-6. Sample calculation of standard deviation ( ) for fd3 scale. Reading weight (kg) weight - mean (weight – mean) 2 1 3000.5 0.4 0.16 2 3000.0 -0.1 0.01 3 3000.5 0.4 0.16 4 3000.0 -0.1 0.01 5 3000.5 0.4 0.16 6 3000.0 -0.1 0.01 7 2999.5 -0.6 0.36 8...

Page 27

3-11 chapter 3 scale testing and calibration 1. Zero the scale. 2. Place a test weight equal to 1/2 the scale capacity in the center of the weighing pan and record the reading. 3. Move the test weight to the mid-point between the center and the left edge of the weighing pan and record the reading. 4...

Page 28

3-12 chapter 3 scale testing and calibration 3.7 specifications table 3-4. Specifications. Note: product specifications are subject to change without any obligation on the manufacturer. Maximum displayed resolution 1:6000 1:7500 1:7500 model fd3 fd6 fd15 capacity x readability (max x d non-approved)...

Page 29

3-13 chapter 3 scale testing and calibration 3.8 calibration n n n n note: before calibrating the scale, make sure it is not set for legal for trade operation. Calibration types – the fd series’ calibration can be adjusted in two ways, span and linearity. Span calibration uses two calibration points...

Page 30

3-14 chapter 3 scale testing and calibration 3.8.3 linearity calibration 1. Enter the menu by holding down the menu button until menu is displayed. When the button is released, cal is displayed. 2. Press the no button to advance to the linearity calibration menu. 3. When lin is displayed, press the ...

Page 31

4-1 chapter 4 repair procedures 4. Repair procedures this section describes how to change individual components of the fd series scales. When doing this, please refer to the exploded view drawings and parts lists in section 5. Important: after replacing components, an operational test of the scale m...

Page 32

4-2 chapter 4 repair procedures 4.2 replacing the membrane switch the membrane switch is affixed to the top housing of the scale. To replace the membrane switch, the scale must be disassembled to gain access to the switch connections. 1. Refer to section 4.1 and remove top housing. Caution use care ...

Page 33

4-3 chapter 4 repair procedures 4.3 main pc board / lcd replacement the main pc board is located inside the scale towards the front. To replace the main pc board, it is necessary to disassemble the scale. The lcd may also be replaced as a separate item if cracked or partial displays are shown. 4.3.1...

Page 34

4-4 chapter 4 repair procedures 4.3.1 main pc board replacement (cont.) 11. Set the capacity, see appendix a.3. 12. Calibrate the scale according to the instructions in appendix a 13. Turn the scale off then on. It will go through all the self-testing. 14. Reassemble the scale. 15. Replace the pan s...

Page 35

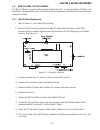

4-5 chapter 4 repair procedures figure 4-3. Load cell retaining screws. 4.4 replacing the load cell assembly (with frame) the load cell assembly is centrally located inside the scale. The load cell is factory assembled and the overload protection stops are pre-adjusted. There are no adjustments to b...

Page 36

4-6 chapter 4 repair procedures 4.5 replacing the load cell component this procedure is used when it is desired to keep the existing load cell frame and just replace the load cell. The load cell assembly is centrally located inside the scale. When the new load cell is mounted to the existing frame, ...

Page 37

4-7 chapter 4 repair procedures 3. Repeat this procedure for all of the overload protection stops using the appropriate feeler gauges. 4. When the initial gap setting have been made, recheck all gap settings and adjust as required. 5. Using a thread locking solution, coat all down stop screws so the...

Page 38

4-8 chapter 4 repair procedures 6. Place the battery holder in place over the battery and secure with the two screws previously removed. 7. Attach the two battery wires with clips to the battery. Make sure the red wire is attached to the positive terminal on the battery and the black wire is attache...

Page 39

5-1 chapter 5 parts lists 5. Parts lists this section of the manual contains exploded views, and parts lists for the fd series scales. The exploded view drawings identifies the replaceable parts. Note: in all cases where a part is replaced, the scale must be thoroughly checked after the replacement ...

Page 40

5-2 chapter 5 parts lists figure 5-1. Exploded view of fd series scales. 5.1 fd series scales exploded view.

Page 41

5-3 chapter 5 parts lists table 5-1. Fd series scales parts list. Item no. Part no. Description quantity 1 71172937 seal, adapter & foot switch socket, fd 1 2 80500435 ac adapter, us 120 volts, 60 hz 1 2 80500521 ac adapter, us 220 volts, 60 hz 1 2 80500437 ac adapter, uk 230 volts, 50 hz 1 2 805004...

Page 42

5-4 chapter 5 parts lists.

Page 43

A-1 appendix a service menu a. Introduction this section describes the service menu and sub-menus, which allow authorized service personnel to perform factory settings and calibration as well as setting the geo code. There is also a ramp display used to indicate the condition of the load cell. Pleas...

Page 44

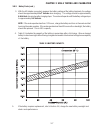

A-2 appendix a service menu a.4 geographical adjustment factor this menu item is used to allow entry of values from 0 to 31 and is used to compensate for slight variations in gravity at different geographical locations around the world. (complete geographical adjustment (complete geographical adjust...

Page 45

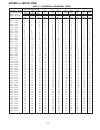

A-3 appendix a service menu a.6 ramp ramp is used to primarily determine if the load cell is damaged from causes including abuse, heavy weights dropped on the pan, or dropping the scale. The ramp function displays the duty cycle of the a/d converter output to within one tenth of a percent. When in t...

Page 46

A-4 appendix a service menu elevation above sea level in meters 0 325 650 975 1300 1625 1950 2275 2600 2925 3250 325 650 975 1300 1625 1950 2275 2600 2925 3250 3575 elevation above sea level in feet 0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 1060 2130 3200 4260 5330 6400 7460 8530 9600 106...

Page 48

Pn 80250906 service manual - fd series scales *80250906* test equipment depot - 800.517.8431 - 99 washington street melrose, ma 02176 - testequipmentdepot.Com.