- DL manuals

- OHAUS

- Scales

- Scout Pro Series

- Service Manual

OHAUS Scout Pro Series Service Manual

Summary of Scout Pro Series

Page 1

Service manual scout ® pro balances ohaus corporation 19a chapin road, p.O. Box 2033, pine brook, nj 07058-2033 (973) 377-9000

Page 2

Www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 3

Service manual scout ® pro balances the information contained in this manual is believed to be accurate at the time of publication, but ohaus corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material is strictly prohibited. Material in this manua...

Page 4

Www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 5

I table of contents chapter 1 introduction 1.1 introduction .............................................................................................................1-1 1.2 service facilities .....................................................................................................1-1...

Page 6

Ii list of tables table no. Title 1-1 calibration points .................................................................................................1-2 1-2 specifications .......................................................................................................1-3 2-1 diagnostic g...

Page 7

1-1 chapter 1 introduction 1.1 introduction this service manual contains the information needed to perform routine maintenance and service on the ohaus scout ® pro balances. The contents of this manual is contained in five chapters and are listed as follows: chapter 1 introduction - contains informa...

Page 8

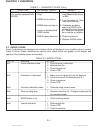

1-2 chapter 1 introduction 1.4 test masses required the masses required to test the scout pro balances must meet or exceed the requirements of astm class 4 tolerance. The calibration points are listed in table 1-1. Table 1-1. Calibration points capacity span cal point linearity cal points 200g 200g ...

Page 9

1-3 chapter 1 introduction 1.5 specifications specifications for the scout pro balances are listed in table 1-2. When a balance has been serviced, it must meet the specifications listed in the table. Before servicing the balance, determine what specifications are not met. Table 1-2. Specifications c...

Page 10

1-4 chapter 1 introduction www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 11

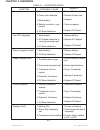

2-1 chapter 2 diagnosis 2.1 troubleshooting this section of the manual specifies problem areas of the balance which can occur. Information is contained to isolate specific problems using table 2-1, diagnostic guide, and table 2-2, error codes. Follow all directions step by step. Make certain that th...

Page 12

2-2 chapter 2 diagnosis remedy 1. Check ac adapter. 2. Replace power jack. 3. Replace. 4. Clean or replace. 5. Replace pc board. 1. Replace battery. 2. Replace ac adapter. 3. Replace pc board. 1. Replace battery. 2. Replace pc board. 1. Perform linearity calibra- tion. 2. Set per specifications. 3. ...

Page 13

2-3 chapter 2 diagnosis table 2-1. Diagnostic guide (cont.) symptom displays (err2) (cont.). Exceeds off center load limit. Inaccurate readings. Fluctuating readings. Drifting display. Error code (err#) on display. Probable cause 4. Defective transducer. 5. Pc board defective. 1. Defective transduce...

Page 14

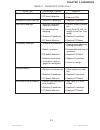

2-4 chapter 2 diagnosis 2.3 error codes scout pro balances are equipped with software which will display an error condition when it occurs. Table 2-2 error codes, describes the various error codes which can appear on the display and specifies the probable reason and remedy. Table 2-2. Error codes di...

Page 15

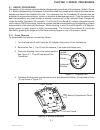

3-1 chapter 3 repair procedures 3.1 repair procedures this section of the manual contains detailed disassembly procedures of the balance. Refer to figure 5-1. Before disassembling the balance, it should be noted that components inside of the balance are delicate and need to be handled with care. It ...

Page 16

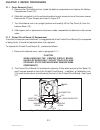

3-2 chapter 3 repair procedures 3.1.1 cover removal (cont.) 5. Remove the 4 aa batteries from inside the battery compartment and replace the battery compartment cover (12). 6. Slide the lockswitch to to the unlocked position to gain access to one of the cover screws. Remove the 3 cover screws as sho...

Page 17

3-3 chapter 3 repair procedures 3.1.2 printed circuit board (9) replacement (cont.) 3. When an rs232 option is installed, remove the rs232 connector from j11on the printed circuit board (9). 4. Disconnect the transducer cable from connector j6 on the printed circuit board (9). 5. Disconnect the batt...

Page 18

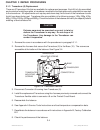

3-4 chapter 3 repair procedures 3.1.3 transducer (8) replacement there are 8 transducer kits that are available for replacement purposes. Each kit is fully assembled and consists of metal base plate, a transducer mounted to the base plate and a subplatform mounted to the transducer. All adjustments ...

Page 19

4-1 chapter 4 testing 4.1 testing before servicing the balance, an operational test and various performance tests should be made to ascertain whether or not the balance meets specifications. Turn the balance on and allow it warm up for at least five minutes before performing these tests. Make sure t...

Page 20

4-2 chapter 4 testing 4.2 performance tests (cont.) the following performance tests are used to evaluate the balance operation before and after repairs. Each balance tested must meet the requirements specified in each test as well as the specifications listed in table 1-2. Tolerance values are expre...

Page 21

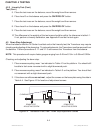

4-3 chapter 4 testing 4.2.2 off-center load test the off-center load test is used to determine whether displayed weight values are affected by moving the sample to different areas of the pan (6). Test 1. Place 1/2 of the balance capacity in the center of the pan (1). 2. Note the reading. 3. Move the...

Page 22

4-4 chapter 4 testing . 4.2.3 linearity test (cont.) test (cont.) 5. Place the test mass on the balance, record the weight and then remove. 6. Place load 3 on the balance and press the on/zero/off button. 7. Place the test mass on the balance, record the weight and then remove. 8. Place load 4 on th...

Page 23

4-5 chapter 4 testing table 4-3. Test mass values model mass 1 mass 2 spx202 250 350 spx402 500 700 spx401 500 900 spx601 700 900 spx2001 3000 7000 spx4001 5000 7000 spx6000 7000 9000 table 4-4. Transducer adjustment tolerances model min(mm/in) max(mm/in) spx123 0.40/0.016 0.45/0/018 spx202 0.60/0.0...

Page 24

4-6 chapter 4 testing www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 25

5-1 chapter 5 drawings and parts lists 5.1 drawings this section of the manual contains an exploded view and parts lists. The exploded view drawing is designed to identify the parts which can be serviced on the balance in the field. Note: in all cases where a part is replaced, the balance must be th...

Page 26

Www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 27

5-3 chapter 5 drawings and parts lists 5.2 parts lists this section of the manual contains the replaceable parts for the scout pro balances. Table 5-1. Replacement parts list key no. Part no. Description 1 71160314 square pan, 6.5" x 5.5" ss, scout pro, spx01, spxx01, spxx00, spxx01, spxxx01, spxxx0...

Page 28

5-4 chapter 5 drawings and parts lists table 5-1. Replacement parts list (cont.) 10 71164070 base w/threaded inserts, scout pro, spgxxx, spsxxx, spxxxn 10 71160301 base, scout pro, all with fixed feet 11 71160412 adjustable feet, with rubber pad, scout pro, spgxxx, spsxxx, spxxxn 11 71160305 foot, n...

Page 29

A-1 appendix a service tool instructions a.Service tools instructions this tool is required when either a main pc board or a transducer is replaced in a scout pro balance. It is used to re-configure the balance to its old parameters in the case of a board replacement or new parameters in the case o...

Page 30

A-2 appendix a service tool instructions a.3 hardware installation note: the optional interface must be modified so that the eeprom may be written to. 1. Remove the screw and the housing as shown in figure a-1. 2. Locate j3 on the interface board. See figure a-2. Figure a-1. Screw and housing remova...

Page 31

A-3 appendix a service tool instructions a.4 special instructions for usb interface after installing the interface using the instructions that come with the kit, the com port will have to be changed. The interface uses com 5 as a default. Config tool only recognizes com 1 to com 4. 1. Enter the wind...

Page 32

A-4 appendix a service tool instructions 2. If the communications parameters have to be set, click on the com port tab and the screen shown in figure a-5 will appear. Adjust the parameters as required to match the balance. Figure a-5. A.5 using configtool.Exe. (cont.) 3. When the communications para...

Page 33

A-5 appendix a service tool instructions 5. When communications are reliable return to the config tab. Press the read button (a) and the data will be read from the balance. See figure a-7. Figure a-7. B c d e a f g a.5 using configtool.Exe. (cont.) 6. If the pc board has been replaced, refer to a.6....

Page 34

A-6 appendix a service tool instructions a.6 using config tool after replacing the main pc board (cont.) 5. The balance displays err 9. 6. Start the configtool software, see a.5 7. An error message will be displayed user enable units & user variable check sum verify error, click on ok. 8. Set rs23...

Page 35

B-1 a ppendix b factory calibrations b.Factory linearity calibrations the scout pro service and factory linearity calibrations use three calibration points; zero, mid-scale and full scale. B.1 service calibration this calibration is used when an error 2 has been displayed by the balance. The calibra...

Page 36

B-2 appendix b factory calibrations 3. You may need to use some kind of draft shield since the top cover has to be left off. 4. Apply power to the balance. 5. Start with the unit off. 6. Press and hold both the on/zero off and the print unit buttons until the display reads ramp. 7. Press and release...

Page 37

B-3 a ppendix b factory calibrations 13. Repeatedly press and release the print unit button until the display shows end. 14. Press and release the on/zero off button. The balance will return to the weighing mode. 15. Press and hold the on/zero off button until the display shows off. 16. Remove power...

Page 38

B-4 appendix b factory calibrations www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 39

Www.Mirvesov.Ru Тел.: (495) 921-44-57.

Page 40

P/n 80250973 service manual scout pro electronic balances *80250973* Официальный представитель: Компания "Мир Весов" 115409, Москва, ул. Москворечье 47, корп. 2 Тел./ факс: (495) 921-44-57 http://www.Mirvesov.Ru e-mail: mv@mirvesov.Ru.