- DL manuals

- Oilon

- Heat Pump

- RE 110

- Installation And Operation Manual

Oilon RE 110 Installation And Operation Manual

Summary of RE 110

Page 1

Re03 1406 en installation and operation manual oilon re 110 - re 170 read these instructions carefully before installation, use, or maintenance.

Page 3: Contents

Re03 1406 en 1 (48) contents 1. Introduction 1.1. Warnings....................................................................................................... 3 1.2. Transportation and storage.......................................................................... 3 1.3. Delivery content, optio...

Page 4

2 (48) re03 1406 en 5.4. Compressor protection device....................................................................37 6. Technical data 6.1. Technical data.............................................................................................39 6.2. Condenser and evaporator circuit flow ...

Page 5: 1. Introduction

Re03 1406 en 3 (48) 1. Introduction 1.1. Warnings read these instructions carefully before installing, adjusting or maintenance of the device. Follow the given instructions. Throughout this manual, the following warnings are used to point out information: be careful. The symbol indicates a possible ...

Page 6

4 (48) re03 1406 en 1.3. Delivery content, optional equipment and accessories standard delivery content heat pump standard delivery includes the following: ● heat pump ● condenser pump ● ground circuit pump ● temperature sensor for outdoors ● temperature sensor for supply water ● 3 temperature senso...

Page 7

Re03 1406 en 5 (48) a remote control unit (option) can also be used for browsing and changing system data and error notifications. The remote control unit can also be used as a remote temperature sensor, providing the control system with room temperature data. The system settings have been organised...

Page 8

6 (48) re03 1406 en when the refrigerant is in the condenser, it is colder than the brine, so the heat energy transfer from brine into refrigerant can take place. The heat transfer raises the temperature of the refrigerant up to the point where it becomes gaseous. The gaseous refrigerant is then led...

Page 9

Re03 1406 en 7 (48) the re heat pump is always connected to separate buffer tank or buffer tanks. Domestic hot water is warmed up in hot water loops inside buffer tank. Preheating loop can be located in the middle of the same buffer tank or in another buffer tank. Rest of the heating is carried out ...

Page 10

8 (48) re03 1406 en 1.9. Collecting heat oilon re heat pump’s heat source is usually a drilled well. The number and depth of wells depend on heating demand. Soil or water can also be used as heat source. Heat is collected from soil using horizontal piping in 1–1.5 m depth. When using water the pipin...

Page 11: 2. Installation

Re03 1406 en 9 (48) 2. Installation 2.1. Installation site requirements general site requirements follow local construction rules and regulations when installing the heat pump. In addition, make sure that the following requirements are met: ● the installation site must have a floor drain. ● maximum ...

Page 12

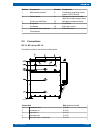

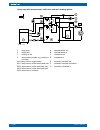

10 (48) re03 1406 en re01 ver. 2 model/ dimension re 110, re 140 and re 170 a (left) 800 mm (100 mm, if electric switchboard attached to the right side.) b (back) 300 mm c (right) 100 mm (1200 mm, if electric switchboard attached to the right side.) d (front) 800 mm e (top) 100 mm 2.2. Main componen...

Page 13

Re03 1406 en 11 (48) number component number component 1 main electrical switch 8 compressor operating control system (ocs) devices 2 control panel 9 refrigerant pressure double relief valves with change valves 3 cooling fan with filters 10 refrigerant expansion tanks 4 evaporator 11 dryer-filters 5...

Page 14

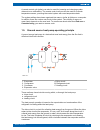

12 (48) re03 1406 en 6 desuperheater out (optional) g 1 1/4 7 and 8 plugged, do not connect - 9 and 10 holes for piping out refrigerant pressure relief valves - 2.4. Piping diagrams 2.4.1. Ground circuit piping it is recommended to install line regulation valves with flow meters, shut-off valves and...

Page 15

Re03 1406 en 13 (48) make approx. 1 m deep service well on top of heat well. Connect service wells to one shared collector well using insulated pipes. One of the drilled wells can also operate as a collector well. Fluid from collector well is led to heat pump well through two insulated pipes. 2.4.2....

Page 16

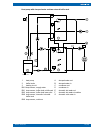

14 (48) re03 1406 en heat pump with desuperheater, buffer tank and extra heating system pi re 1 ver. 6 1 heat pump a desuperheater out 2 buffer tank b desuperheater in 3 heating circuit c condenser out 4 extra heating system, e.G. Electric or oil heater d condenser in bx11temp.Sensor, supply water e...

Page 17

Re03 1406 en 15 (48) heat pump with desuperheater and two external buffer tank pi re 2 ver. 6 1 heat pump a desuperheater out 2 buffer tanks b desuperheater in 3 heating circuit c condenser out bx11temp.Sensor, supply water d condenser in bx1 temp.Sensor, buffer tank middle part e domestic hot water...

Page 18

16 (48) re03 1406 en heat pump with desuperheater, two external buffer tank and solar heating system pi re 3 ver. 4 1 heat pump a desuperheater out 2 buffer tank b desuperheater in 3 heating circuit c condenser out 4 solar heat collectors d condenser in bx11temp.Sensor, supply water e domestic hot w...

Page 19

Re03 1406 en 17 (48) 2.5. Installing filters at renovation sites, flush and clean the existing heating system. A filter should always be installed on both the heating circuit return line and the brine circuit return line before the heat pump. Install a shut-off valve on both sides of the filter to f...

Page 20

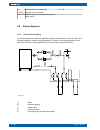

18 (48) re03 1406 en 2.7. Electrical connections a general description of the needed electrical connections is given in this section. The actual connections should be made according to the wiring diagrams delivered with the heat pump. Do not connect devices that draw over 2 a of current directly to ...

Page 21

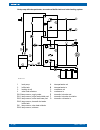

Re03 1406 en 19 (48) connection legend temperature sensor x bx4 hot gas, compressor 2 w bx3 desuperheater sensor u bx2 buffer tank lower part t bx1 buffer tank middle part s bx14 brine out r bx13 brine in q bx12 return water, heating circuit p p bx11 supply water, heating circuit 1 n bx10 supply wat...

Page 22: 3. Commissioning

20 (48) re03 1406 en 3. Commissioning 3.1. Fuses and switches switch/fuse device q1 main power s3 ground circulation pump f1 compressor 1 f2 compressor 2 (not in re 35 or re 42) f3 ground circulation pump f4 condenser pump f5 domestic hot water circulation pump f6 desuperheater circulation pump (opt...

Page 23

Re03 1406 en 21 (48) read carefully the commissioning instructions given in the next chapter and plan the commissioning phases and timetables for the site before starting the actual commissioning. Especially note that before starting the heatpump’s compressors, you have to preheat them at least 6 ho...

Page 24

22 (48) re03 1406 en 4. After the ground circuit and heating circuits are filled and vented, start and test all circulation pumps with relay test to check that the circulations are working. ● set circuit breakers of all used circulation pumps ( f3 , f4 and f5 ) to 1. ● test circulation pumps with re...

Page 25

Re03 1406 en 23 (48) a. Press the ok button to access the menu system. B. Press the information (i) button for 5 seconds, select commissioning user level and press ok button. 3. Take the heating circuit into use. A. Select configuration menu and press ok button. B. Select free heating circuit ( 5710...

Page 26

24 (48) re03 1406 en heating curve can be adjusted using heating curve displacement. Then curve slope is according to curve control, but set value raises or decreases. + raises setting and – decreases setting. Adjust curve on operating lines 721: heating curve displacement (heating circuit 1) and 10...

Page 27: 4. Operation

Re03 1406 en 25 (48) 4. Operation 4.1. Control panel control panel remote controller (optional extra) 1 4 5 6 8 7 2 3 control panel ver. 3 gshp01 ver. 3 control panel buttons 1 domestic hot water 6 ok 2 heating mode 7 cooling 3 information 8 reset 4 back/esc 9 occupancy button 5 settings knob.

Page 28

26 (48) re03 1406 en domestic hot water button when this function is on, the heat pump generates domestic hot water automatically according to set settings. When the function is off, the heat pump does not generate any domestic hot water. Pressing and holding the button for five seconds or longer ac...

Page 29

Re03 1406 en 27 (48) cooling mode button if you have a separate air conditioning unit, you can connect the heat pump to it and use the cooling mode button to change the heat pump’s operation from heating to cooling. By default, this button is not in use. Reset button use the reset button to acknowle...

Page 30

28 (48) re03 1406 en if the feature is sued, note following issues for locating remote control unit. ● locate the remote control unit to the main living area. ● choose the location so that sensor can measure room temperature as accurately as possible. Place the remote control unit ideally on a light...

Page 31

Re03 1406 en 29 (48) 5. Press the ok button to select the operating line and edit its setting. 6. Adjust the setting. Use the settings knob to change the operating line setting. 7. Confirm the change. Press the ok button to confirm your changes. If you mistakenly entered a different menu than you in...

Page 32

30 (48) re03 1406 en a list of available operating lines appears on screen. 3. Select hours / minutes and press the ok button. The setting for hours starts blinking on screen. 4. Set current time in hours and press the ok button. The setting for minutes starts blinking on screen. 5. Set current time...

Page 33

Re03 1406 en 31 (48) wireless remote control (optional extra) operating line number function 120 connection 121 test mode heating circuit 1 / heating circuit 2 operating line number (heating circuit 1 / heating circuit 2) function 710 / 1010 comfort setpoint set room temperature that heating circuit...

Page 34

32 (48) re03 1406 en heat pump operating line number function 2880 use electric flow setting for switching on electric heater. Options: ● substitute: electric heater is used only in failure mode. ● complem operation hc: if heat pump cannot produce required capacity for heating circuit, electric heat...

Page 35

Re03 1406 en 33 (48) fault operating line number function 6710 reset alarm relay relay can be reset through relay output qx, if heat pump has failure data for external system. Failure data at pump remains active. 6711 reset hp reset heat pump, if failure is not active. Service/special operation oper...

Page 36

34 (48) re03 1406 en 8410 return temp hp displays temperature of the return water to the heat pump. 8412 flow temp hp displays condenser outlet temperature. 8415 hot-gas temp hp 8427 source inlet temp displays collector circuit inlet temperature. 8429 source outlet temperature displays collector cir...

Page 37: 5. Maintenance

Re03 1406 en 35 (48) 5. Maintenance 5.1. Annual maintenance heat pumps containing more than 3000 g of refrigerant must be annually checked and maintained by a professional service provider. Annual maintenance includes cleaning, and if necessary replacing, the circuit filters. In addition, all circul...

Page 38

36 (48) re03 1406 en 32 flow sensor 2 bx21 no measurement from outgoing water check heating circuit 2 flow sensor connection. 33 flow sensor hp bx10 no measurement from outgoing water check heating circuit p flow sensor connection. 35 source inlet sensor bx13 no measurement from source inlet sensor ...

Page 39

Re03 1406 en 37 (48) 225 low pressure e9 compressor intake pressure is below low pressure minimum limit check that ground circulation pump is rotating. Check ground circuit and well, vent if necessary. Check that ground circulation pump rotation speed is at maximum. 226 compressor 1 overloaded e11 c...

Page 40

38 (48) re03 1406 en the ocs device has two led lights to indicate status and possible faults in the system. In the following tables, information on how to interpret the lights are given. Led 1 (red) status action continuous on ocs powered and stable no need. Slow blinking 1,5 s on / 1 s off warning...

Page 41: 6. Technical Data

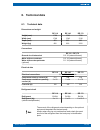

Re03 1406 en 39 (48) 6. Technical data 6.1. Technical data dimensions and weight re 110 re 140 re 170 height (mm) 1798 1798 1798 width (mm) 1746 1746 1746 depth (mm) 863 863 863 weight (kg) 800 900 1000 connections re 110 – re 170 ground circuit return/out g 2 1/2 (external thread) water to/from con...

Page 42

40 (48) re03 1406 en performance performance presented is according to en 14511: ● brine 0/35, performance without circulation pumps ● water temperature from the condenser: 35 ºc ● brine in temperature: 0 ºc. Re 110 re 140 re 170 heat from ground (kw) 78 101 125,2 compressor power (kw) 29 36,5 43,2 ...

Page 43

Re03 1406 en 41 (48) motor nominal (maximum) electric current, a 1,7 1,7 1,7 thread size / nominal flange diameter dn 50 dn 50 dn 50 overall lenght, mm 280 280 280 weight, kg 27,2 27,2 27,2 minimum required suction head (npshr), m 5,0 5,0 5,0 minimum required suction pressure, bar 0,5 0,5 0,5 (brine...

Page 44

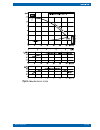

42 (48) re03 1406 en pressure differential at nominal flow rate, kpa 120 143 124 total head available to overcome the external pressure losses, m 9,5 11,9 9,9 pressure differential available to overcome the external pressure losses, kpa 90 113 94 desuperheater pump, standard delivery desuperheater p...

Page 45

Re03 1406 en 43 (48) wipl02 ver. 1 figure1. Wilo ipl 50/115 - 0,75/2.

Page 46

44 (48) re03 1406 en wipl01 ver. 1 figure2. Wilo ipl 50/120 - 1,5/2 and wilo ipl 50/130 - 2,2/2.

Page 47

Re03 1406 en 45 (48) wsp03 ver. 1 figure3. Wilo stratos para 25/1–7.

Page 48

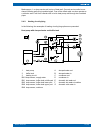

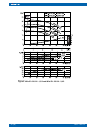

46 (48) re03 1406 en 6.3. Spare parts d036009 ver. 2 the assembly may vary depending on the scope of delivery. Model and part number nbr part re 110 re 150 re 170 visible in picture 1 user panel 36108126 36108126 36108126 yes 2 main switch 37181091 37181091 37181091 yes 3 filter ventilator 37289255 ...

Page 49

Re03 1406 en 47 (48) 11 crankcase heater 34791142 34791142 34791142 yes 12 bellow compensator 37881198 37881199 37881199 yes 13 service nippel 5/16" 37881204 37881204 37881204 yes pressure transmitter, low pressure (plain) 36217186 36217186 36217186 14 pressure transmitter, low pressure (inc. Cable ...

Page 50

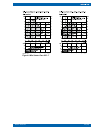

48 (48) re03 1406 en rexcp ver. 1 the assembly may vary depending on the scope of delivery. Model legend part re 110 re 150 re 170 a.1.0 heat pump controller 36108076 36108076 36108076 a1.1 auxiliary module 36108078 36108078 36108078 a1.3, a1.4 soft starter 36323102 36323103 36323104 f1, f2 circuit ...

Page 52

Www.Oilon.Com.