- DL manuals

- Oilon

- Heat Pump

- RE 35

- Installation And Operation Manual

Oilon RE 35 Installation And Operation Manual

Summary of RE 35

Page 1

Re01 1445en installation and operation manual oilon re 35 – re 85 read these instructions carefully before installation, use, or maintenance.

Page 3: Contents

Re01 1445en 1 (67) contents 1. Introduction 1.1. Overview of this manual...............................................................................3 1.2. Transportation and storage.......................................................................... 3 1.3. Delivery content, optional equipme...

Page 4: 6. Technical Data

2 (67) re01 1445en 6. Technical data 6.1. Heat pump technical data...........................................................................51 6.2. Condenser and ground circuit flow and pumps..........................................52 6.3. Spare parts..................................................

Page 5: 1. Introduction

Re01 1445en 3 (67) 1. Introduction 1.1. Overview of this manual keep the instructions near the device. Read these instructions carefully before installing, adjusting or maintenance of the device. Follow the given instructions. Remember to ask the hvac technician to fill in the installation record, w...

Page 6

4 (67) re01 1445en be careful when lifting the heat pump. Use appropriate lifting tools. The heat pump can be tilted to a maximum angle of 45 degrees for short periods of time (1–2 minutes). Always use a pallet truck when lifting the re 55, re 70, and re 85 heat pumps. The smaller models re 35 and r...

Page 7: 1.4. Control System

Re01 1445en 5 (67) ● humidity sensors for cooling applications ● diverting valve ● connection hose package 2” 1000 mm (4 steel cord hoses + gaskets) accessories when installing the heat pump, depending on the installation site, few additional accessories and devices may be needed. Among other things...

Page 8: 1.5. Operating Principle

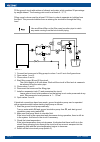

6 (67) re01 1445en 1.5. Operating principle a b c re15 ver. 2 1. Evaporator 2. Compressor 3. Condenser 4. Expansion valve a. Brine circuit b. Refrigerant circuit c. Heating circuit there are three closed circuits running within, or through, the heat pump: ● brine circuit ● refrigerant circuit ● heat...

Page 9: 1.6. Main Features

Re01 1445en 7 (67) next, the high-pressure gaseous refrigerant is led into the condenser, where it releases its heat energy into the water that circulates between the heat pump and the buffer tank. As the refrigerant releases its heat energy and its temperature drops, it becomes liquid again. The li...

Page 10: 1.8. Collecting Heat

8 (67) re01 1445en when using the heat pump as a water chiller (clean water circulates in the evaporator instead of frost-proof solution), the evaporator must be protected from freezing. Usage of flow switch on the evaporator side is highly recommended. When maintaining the heat pump, note that addi...

Page 11: 2. Installation

Re01 1445en 9 (67) 2. Installation 2.1. Installation site requirements installation, commissioning or service of equipment must be carried out by authorized personnel only, adhering to all local regulations and requirements. General site requirements when installing the heat pump, note the following...

Page 12

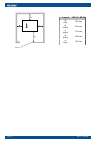

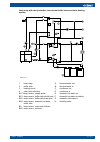

10 (67) re01 1445en re01 ver. 2 legend re 35 – re 85 a (left) 500 mm b (back) 500 mm c (right) 100 mm d (front) 1000 mm e (top) 500 mm.

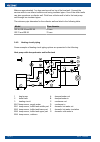

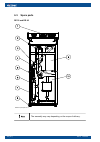

Page 13: 2.2. Main Components

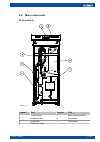

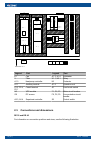

Re01 1445en 11 (67) 2.2. Main components re 35 and re 42 re35-42 ver. 1 legend part legend part 1 control panel 5 main electrical switch 2 desuperheater 6 condenser 3 evaporator 7 compressor 4 expansion valve.

Page 14

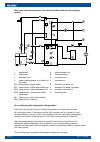

12 (67) re01 1445en 40 40 40 re35-42cp ver. 1 legend part legend part a1.0 heat pump controller f1 auxiliary contact a1.1 auxiliary module f3 motor circuit breaker a1.3 softstarter f5, f6, f9, f10 line protection circuit breaker a1.5 operation unit s3 control switch k1.1 relay q1 load break switch k...

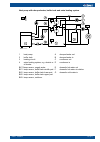

Page 15

Re01 1445en 13 (67) re 55, re 70, and re 85 re55-85002 ver. 1 legend part legend part 1 control panel 6 compressor 2 2 dryer-filter 7 desuperheater 3 evaporator 8 main electrical switch 4 el. Expansion valve 9 condenser 5 compressor 1.

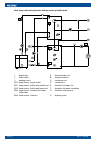

Page 16

14 (67) re01 1445en q1 -f6.1 n f3 f1 f2 f5 f6 s3 f9 60 60 60 x1 x0 x2 pe 40 -k2.1 60 -a1.9 60 -a1.1 -a1.0 40 -a2.3 -a2.4 psr25 psr37 -a1.4 -a1.3 -k1.1 -k3 x4 x5 40 -u6 40 -g6 -f2.3 -f2.4 60 pe x4 -a1.5 -e1 re55-85cp ver. 1 legend part legend part e1 fan a1.3, a1.4 softstarter 2 filter k1.1, k2.1 rel...

Page 17

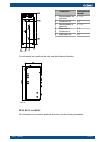

Re01 1445en 15 (67) re07 ver. 3 connection size (external thread) 1 desuperheater out (optional) g 1 1/4 2 condenser out g 2 3 desuperheater in (optional) g 1 1/4 4 evaporator in g 2 5 condenser in g 2 6 evaporator out g 2 for information on sizes from the side, see the following illustration. Re08 ...

Page 18

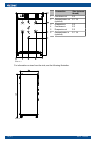

16 (67) re01 1445en re02 ver. 2 connection size (external thread) 1 condenser out g 2 2 desuperheater out (optional) g 1 1/4 3 evaporator in g 2 4 condenser in g 2 5 evaporator out g 2 6 desuperheater in (optional) g 1 1/4 for information on sizes from the side, see the following illustration. Re03 ...

Page 19: 2.4. Piping Diagrams

Re01 1445en 17 (67) 2.4. Piping diagrams a filter should always be installed on both the heating circuit return line and the brine circuit return line before the heat pump. Install a shut-off valve on both sides of the filter to facilitate easy cleaning and replacing of the filter element. 2.4.1. Gr...

Page 20

18 (67) re01 1445en make an approximately 1 m deep service well on top of the heat well. Connect the service wells to one shared collector well using insulated pipes. One of the drilled wells can also operate as a collector well. Fluid from collector well is led to the heat pump well through two ins...

Page 21

Re01 1445en 19 (67) heat pump with desuperheater, buffer tank and extra heating system pi re 1 ver. 6 1 heat pump a desuperheater out 2 buffer tank b desuperheater in 3 heating circuit c condenser out 4 extra heating system, e.G. Electric or oil heater d condenser in bx11temp.Sensor, supply water e ...

Page 22

20 (67) re01 1445en heat pump with desuperheater and two external buffer tanks pi re 2 ver. 7 1 heat pump a desuperheater out 2 buffer tanks b desuperheater in 3 heating circuit c condenser out bx11temp.Sensor, supply water d condenser in bx1 temp.Sensor, buffer tank middle part e domestic hot water...

Page 23

Re01 1445en 21 (67) heat pump with desuperheater, two external buffer tanks and solar heating system pi re 3 ver. 5 1 heat pump a desuperheater out 2 buffer tank b desuperheater in 3 heating circuit c condenser out 4 solar heat collectors d condenser in bx11temp.Sensor, supply water e domestic hot w...

Page 24

22 (67) re01 1445en heat pump with desuperheater, two external buffer tanks and extra heating system pi re 4 ver. 1 1 heat pump a desuperheater out 2 buffer tank b desuperheater in 3 heating circuit c condenser out 4 extra heating system, e.G. Electric or oil heater d condenser in bx11temp.Sensor, s...

Page 25: 2.5. Electrical Connections

Re01 1445en 23 (67) gshp26 ver. 4 a fan b cooling radiator c filter d circulation pump e regulating valve f non-return valve g ground circuit return line h shut-off valves for more detailed information in connecting to an air conditioner, refer to the manufacturer’s instructions. 2.5. Electrical con...

Page 26

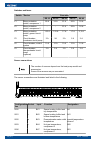

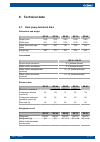

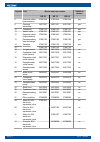

24 (67) re01 1445en switches and fuses fuse size switch device re 35 re 42 re 55 re 70 re 85 f1 motor protection switch, compressor 1 25 a 32 a 21 a 25 a 32 a f2 motor protection switch, compressor 2 - - 21 a 25 a 32 a f3 motor protection switch, ground circuit pump 1.33 a 1.33 a 1.7 a 1.7 a 3.,3 a ...

Page 27: 2.6. Filling Brine Circuit

Re01 1445en 25 (67) configuration line socket input function designation 5937 h bx8 domestic hot water buffer tank top temperature b3 5938 k bx9 outside temperature b9 5939 n bx10 condenser outlet temperature b21 5940 p bx11 heating circuit 1 flow temperature b1 5941 q bx12 condenser inlet temperatu...

Page 28

26 (67) re01 1445en fill the ground circuit with mixture of ethanol and water, which contains 28 percentage by weight ethanol. The freezing point must be at least of −17 °c. Filling vessel volume must be at least 100 litres in order to separate air bubbles from the liquid. This prevents bubbles from...

Page 29

Re01 1445en 27 (67) make sure there is no air in the system, vent if necessary. Check the ground circuit filters. 2.7. Filling heating network at renovation sites, flush and clean the existing heating system. Fill and vent the buffer tank before starting the heat pump. Make sure that shut-off valves...

Page 30: 3. Commissioning

28 (67) re01 1445en 3. Commissioning 3.1. Fuses and switches switch/ fuse device q1 main power s2 brine pump f1 compressor 1 f2 compressor 2 (not in re 35 or re 42) f3 brine pump f5 condenser circuit pump f6 control system f9 desuperheater circulation pump (optional) 3.2. Prerequisites for commissio...

Page 31: 3.4. Testing Relay

Re01 1445en 29 (67) 5. Check that the circulation pumps are working and carry out the relay test. For more instructions, see section testing relay . Do not continue and start the heat pump compressor if the buffer tank temperature is below 20° c. 6. Switch on the compressor over-current protection f...

Page 32

30 (67) re01 1445en 3.5. Adding heating circuits by default, there is one heating circuit configured to the heat pump’s control system. If there are more controllable heating circuits in the heating system, it is possible to configure the heat pump to control two heating circuits. 1. Connect the tem...

Page 33

Re01 1445en 31 (67) flow temperature (room temperature set point 24 °c) hc1 ver. 1 flow temperature (room temperature set point 14 °c) hc2 ver. 1.

Page 34

32 (67) re01 1445en flow temperature (room temperature set point 18 °c) hc3 ver. 1 flow temperature (room temperature set point 20 °c, parallel displacement 2 °c) hc4 ver. 1.

Page 35

Re01 1445en 33 (67) flow temperature (room temperature set point 20 °c) hc5 ver. 1 flow temperature (room temperature set point 22 °c, flow temperature maximum limitation 45 °c) hc6 ver. 1.

Page 36

34 (67) re01 1445en flow temperature (room temperature set point 22 °c) hc7 ver. 1 6. Select flow temperature set point minimum and press ok . 7. Set the correct value and press ok . 8. Select flow temperature set point maximum and press ok . 9. Set the correct value and press ok . The heating curve...

Page 37

Re01 1445en 35 (67) ● select the relay output where the solar heat collector’s circulation pump was connected (operating lines 5890 – 5903) and set its value to collector pump q5 . ● select the sensor input where the temperature sensor of the solar heat collector was connected (operating lines 5930-...

Page 38: 4. Operation

36 (67) re01 1445en 4. Operation 4.1. Control panel control panel remote controller (optional extra) 1 4 5 6 8 7 2 3 control panel ver. 3 gshp01 ver. 3 control panel buttons 1 domestic hot water heating on/off 6 ok 2 heating mode 7 cooling 3 information 8 reset 4 back/esc 9 occupancy button 5 settin...

Page 39

Re01 1445en 37 (67) domestic hot water when this function is on, the heat pump heats domestic hot water automatically according to the defined settings. When the function is off, the heat pump does not generate any domestic hot water. Pressing and holding the button for five seconds or longer activa...

Page 40: 4.2. Changing Settings

38 (67) re01 1445en cooling mode if you have a separate air conditioning unit, you can connect the heat pump to it and use the button to change the heat pump’s operation from heating to cooling. By default, this button is not in use. Reset use the button to acknowledge and reset possible error notif...

Page 41

Re01 1445en 39 (67) in case the basic display is not visible, press back/esc as many times as necessary until the display does not change any more. The display reverts back to the basic display if nothing is done on the control panel for eight minutes. The following procedure describes how to select...

Page 42: 4.3. Changing User Level

40 (67) re01 1445en 4.3. Changing user level 1. To access the menu system, press ok . 2. Press and hold the information button for three seconds or longer. A list of available user levels is displayed on screen. The user levels are: ● end user ● commissioning ● expert (to enter this level, you need ...

Page 43: 4.7. Operating Lines

Re01 1445en 41 (67) 1. To access the menu system, press ok . A menu list opens on the screen. 2. Select domestic hot water and press ok . A list of available operating lines opens on the screen. 3. Select the 1610: nominal setpoint operating line and press ok . 4. Set the correct value and press ok ...

Page 44

42 (67) re01 1445en operating line number (heating circuit 1 / heating circuit 2) function 721 / 1021 heating curve displacement if the curve slope is suitable for heating circuit but the room temperature is constantly too low or high in comparison to the set value, the temperature can be changed fr...

Page 45

Re01 1445en 43 (67) heat pump operating line number function 2880 use electric flow setting for switching on electric heater. Options: ● substitute: electric heater is used only in failure mode. ● complem operation hc: if heat pump cannot produce required capacity for heating circuit, electric heate...

Page 46

44 (67) re01 1445en fault operating line number function 6710 reset alarm relay relay can be reset through relay output qx, if heat pump has failure data for external system. Failure data at pump remains active. 6711 reset hp reset the heat pump, if the failure is not active. Service/special operati...

Page 47

Re01 1445en 45 (67) operating line number function 8410 return temp hp displays temperature of the return water to the heat pump. 8412 flow temp hp displays condenser outlet temperature. 8415 hot-gas temp hp 8427 source inlet temp displays collector circuit inlet temperature. 8429 source outlet temp...

Page 48

46 (67) re01 1445en operating line number function 8980 buffer temp 1 buffer tank middle part temperature. 8982 buffer temp 2 buffer tank middle part temperature. 9031 relay output qx1.

Page 49: 5. Maintenance

Re01 1445en 47 (67) 5. Maintenance 5.1. Annual maintenance installation, commissioning or service of equipment must be carried out by authorized personnel only, adhering to all local regulations and requirements. Heat pumps containing more than 3000 g of refrigerant must be annually checked and main...

Page 50

48 (67) re01 1445en no. Definition sensor cause action 10 outside sensor bx9 no outside sensor check outside sensor connection. 30 flow sensor 1 bx11 no measurement from outgoing water check heating circuit 1 flow sensor connection. 32 flow sensor 2 bx21 no measurement from outgoing water check heat...

Page 51

Re01 1445en 49 (67) no. Definition sensor cause action 324 bx same sensors bx outputs connected using same address change sensor addresses. 325 bx/e', same sensors bx/e'module same sensors change sensor addresses. 327 e’module same funct. Same function for additional modules check added module opera...

Page 52

50 (67) re01 1445en led 3 (yellow status led) status always on shc is disabled or (due to any error or alarm condition) control is absent (which automatically disables the shc) always off shc is running without eev movement single blink the eev is opening, closing, or synchronizing. A single blink (...

Page 53: 6. Technical Data

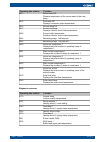

Re01 1445en 51 (67) 6. Technical data 6.1. Heat pump technical data dimensions and weight re 35 re 42 re 55 re 70 re 85 height (mm) 1502 1502 1680 1680 1680 width (mm) 601 601 1030 1030 1030 depth (mm) (with pipe inlets) 693 693 720 720 720 weight (kg) 256 277 450 530 530 connections re 35 – re 85 g...

Page 54

52 (67) re01 1445en the amount of the refrigerant varies depending on the optional equipment integrated into the heat pump. Always when carrying out maintenance tasks check the exact amount of the refrigerant from the heat pump’s identification plate. Performance performance presented is according t...

Page 55

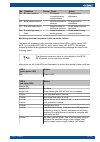

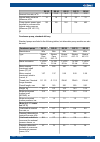

Re01 1445en 53 (67) re 35 re 42 re 55 re 70 re 85 nominal flow rate, m 3 /h 8.8 10.8 14.0 17.5 21.5 internal static pressure difference, kpa 14 14 26 22 31 pump electric power input required to overcome the internal static pressure difference (en 14511-3), w 153 180 326 334 483 condenser pump, stand...

Page 56

54 (67) re01 1445en evaporator pump, standard delivery evaporator pump re 35 re 42 re 55 re 70 re 85 manufacturer wilo wilo wilo wilo wilo type ipl 40 / 115-0.55/2 ipl 40 / 115-0.55/2 ipl 50 / 115-0.75/2 ipl 50 / 115-0.75/2 ipl 50 / 120-1.5/2 mains connection 3 x 400 v 50 hz 3 x 400 v 50 hz 3 x 400 ...

Page 57

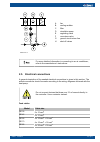

Re01 1445en 55 (67) wiring diagram ver. 1 ∆: connection diagram delta connection y: connection diagram star connection desuperheater pump, standard delivery desuperheater pump re 35 re 42 re 55 re 70 re 85 manufacturer wilo wilo wilo wilo wilo type stratos para 25/1-7 stratos para 25/1-7 stratos par...

Page 58

56 (67) re01 1445en wilo stratos para 25/1–12 wsp01 ver. 1.

Page 59

Re01 1445en 57 (67) wilo stratos 40/1–12 wsp02a ver. 1 wsp02b ver. 1.

Page 60

58 (67) re01 1445en wilo ipl 40/115 - 0.55/2 wipl03 ver. 1.

Page 61

Re01 1445en 59 (67) wilo ipl 50/115 - 0,75/2 wipl02 ver. 1.

Page 62

60 (67) re01 1445en wilo ipl 50/120 - 1,5/2 and wilo ipl 50/130 - 2,2/2 wipl01 ver. 1.

Page 63

Re01 1445en 61 (67) wilo stratos para 25/1–7 wsp03 ver. 1.

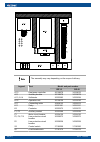

Page 64: 6.3. Spare Parts

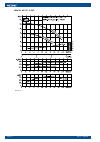

62 (67) re01 1445en 6.3. Spare parts re 35 and re 42 re35-42 spareparts ver. 1 the assembly may vary depending on the scope of delivery..

Page 65

Re01 1445en 63 (67) legend part model and part number visible in picture re 35 re 42 1 control panel 36108126 36108126 yes 2 desuperheating heat exchanger 37881182 37881182 yes 3 pressure switch (low pressure) 37881044 37881044 yes 4 vibration eliminator 37881122 37881122 yes 5 evaporator 37881644 3...

Page 66

64 (67) re01 1445en 40 40 40 re35-42cp ver. 1 the assembly may vary depending on the scope of delivery. Model and part number legend part re 35 re 42 a1.0 heat pump controller 36108076 36108076 a1.1 auxiliary module 36108078 36108078 a1.3, a1.4 softstarter 36323083 36323084 a1.5 operation unit 36108...

Page 67

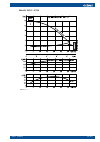

Re01 1445en 65 (67) re 55, re 70, and re 85 re55-85002 spare parts ver. 1 the assembly may vary depending on the scope of delivery. Legend part model and part number visible in picture re 55 re 70 re 85 1 control panel 36108126 36108126 36108126 yes 2 dryer-filter 31476325 31476325 31476325 yes 3 ev...

Page 68

66 (67) re01 1445en legend part model and part number visible in picture re 55 re 70 re 85 8 pressure switch (low pressure) 37881044 37881044 37881044 yes 9 pressure transmitter 36217221 36217221 36217221 yes 10 condenser 37881130 37881133 37881133 yes 11 needle valve 37881031 37881031 37881031 yes ...

Page 69

Re01 1445en 67 (67) q1 -f6.1 n f3 f1 f2 f5 f6 s3 f9 60 60 60 x1 x0 x2 pe 40 -k2.1 60 -a1.9 60 -a1.1 -a1.0 40 -a2.3 -a2.4 psr25 psr37 -a1.4 -a1.3 -k1.1 -k3 x4 x5 40 -u6 40 -g6 -f2.3 -f2.4 60 pe x4 -a1.5 -e1 re55-85cp ver. 1 the assembly may vary depending on the scope of delivery. Model and part numb...

Page 70

68 (67) re01 1445en.

Page 72

Tarmontie 4 fi-15860 hollola finland tel: +358 3 85 761 fax: +358 3 857 6239 email: info@oilon.Com www.Oilon.Com.