- DL manuals

- Oki

- Printer

- B412dn

- Maintenance Manual

Oki B412dn Maintenance Manual

OEL

Maintenance Manual

B412/B432/B512

ES4132/ES5112

Revision 1

31 Oct 2014

This document is “OKI DATA – CONFIDENTIAL”

Only persons and parties authorised by OKI DATA have

permissions to access this document.

This document should not be accessed by any parties

without the approval of OKI DATA.

Anyone who is found to be contradicting the above may be subject to legal action.

Summary of B412dn

Page 1

Oel maintenance manual b412/b432/b512 es4132/es5112 revision 1 31 oct 2014 this document is “oki data – confidential” only persons and parties authorised by oki data have permissions to access this document. This document should not be accessed by any parties without the approval of oki data. Anyone...

Page 2

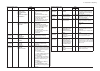

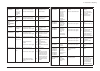

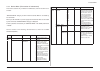

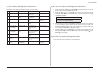

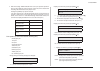

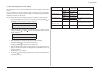

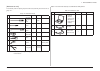

Document revision history rev.No date corrected items person in charge no. Page description of change 1 2014-10-31 issue p1e18 h.Hayashi rev.No date corrected items person in charge no. Page description of change 2.

Page 3

Preface 3 this manual provides an overview of method for maintaining the b412dn/ b432dn/b512dn/es4132dn/es5112dn. This manual is intended for maintenance staff. For more information about how to operate the b412dn/b432dn/b512dn/es4132dn/es5112dn, please refer to user 's manual. Note! • manual may be...

Page 4: Index

Contents 1. Configuration ................................................................. 1-1 1.1 system configuration .........................................................................................1-2 1.2 structure of printer ................................................................

Page 5

Contents 4.2.14 stacker cover ..........................................................................................4-16 4.2.15 fuser assy ...............................................................................................4-17 4.2.16 mpt assy ............................................

Page 6

1. Configuration 1.1 system configuration ...................................................................1-2 1.2 structure of printer ......................................................................1-3 1.3 offer of options ......................................................................

Page 7

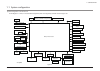

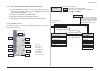

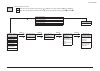

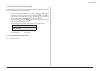

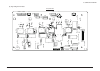

System configuration of the printer unit as the diagram 1.1 shows, for the standard configuration printer is configured by controller unit and engine unit. Main print circuit board lcd operator panel board led head toner cartridge board image drum unit fuse relay terminal high voltage power supply u...

Page 8

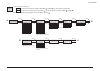

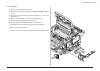

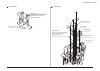

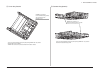

B412dn/b432dn/es4132dn the printer main unit includes the following hardware parts. • electrophotographic processing part • paper feeding part • controller • operational part • power supply unit note! • fuser-assy has to be replaced by assy unit. • it is forbidden to disassemble fuser-assy or reuse ...

Page 9

B512dn/es5112dn figure1-3 1-4 1. Configuration.

Page 10

This product can be installed with the following option. (1) second tray unit 1.3 offer of options (2) wireless lan 1-5 1. Configuration.

Page 11

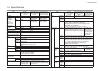

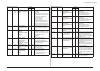

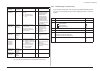

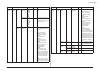

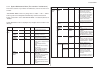

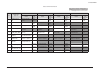

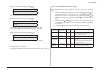

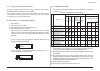

Item b412dn (dt low speed model) b432dn/es4132dn (dt high speed model) b512dn/es5112dn (dt high speed, 530 sheet model) segment dt print speed (simplex) (*) fusibility spec. For this mode is different with other mode. A4 33ppm 40ppm (nn) 38ppm (ll/hh) 45.5ppm (nn) (*) 38ppm (ll/hh) letter 35ppm 42pp...

Page 12

Item b412dn (dt low speed model) b432dn/es4132dn (dt high speed model) b512dn/es5112dn (dt high speed, 530 sheet model) paper input paper capacity 1st tray 250 sheets (80g/m 2 ) 530 sheets (80g/m 2 ) 2nd tray (option) 530 sheets (80g/m 2 ) mpt 100 sheets (80g/m 2 ) paper output paper size facedown t...

Page 13

Item b412dn (dt low speed model) b432dn/es4132dn (dt high speed model) b512dn/es5112dn (dt high speed, 530 sheet model) transfer roller life equal to printer life fuser life equal to printer life print function quiet mode yes toner save mode yes override a4/letter yes airprint yes google cloud print...

Page 14

1.5 interface specifications 1.5.1 usb interface specification 1.5.1.1 outline of usb interface (1) basic specification usb (2) transmission mode hi speed (480mbps±0.05% max.) (3) power control self power device 1.5.1.2 usb interface connector and cable (1) connector • printer side: b receptacle (fe...

Page 15

1.5.2 network interface specification 1.5.2.1 network interface basic specification network protocol ・tcp/ip related 1.5.2.2 network interface connector and cable (1) connector 100 base-tx/10 base-t (auto switch and simultaneous use are not available) 1 8 connector pin arrangement (2) cable unshield...

Page 16

1.5.3 wireless lan interface (option) 1.5.3.1 outline of wireless lan (1) specification ieee 802.11a/b/g/n (2.4ghz/5ghz) (2) power supply voltage 5v (3) printer side interfaces usb usb port note! In using wireless lan, don't connect a lan cable to this product. 1-11 1. Configuration.

Page 17: Procedures For Repairing

2.1 troubleshooting .........................................................................2-2 2.2 points to be checked before modifying printing problems .........2-2 2.3 points to be checked when the printing problems are modified ...2-2 2.4 preparation for troubleshooting .........................

Page 18: 2.1 Troubleshooting

2-2 (1) check “troubleshooting” of the user’s manual. (2) collect the information of the status at the failure as much as possible. (3) inspect the device in the status similar to the status at the failure occurrence. 2.1 troubleshooting 2.2 points to be checked before modifying printing problems (1...

Page 19

2-3 2. Procedures for repairing 2.4 preparation for troubleshooting (1) display of the operator panel the failure status of the printer is displayed don the lcd of the operator panel. Take an appropriate action as instructed by the messages displayed on lcd. B412dn/b432dn/b512dn/es4132dn/es5112dn on...

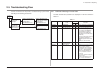

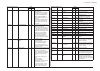

Page 20: 2.5 Troubleshooting Flow

2-4 2. Procedures for repairing troubles troubles displayed on the lcd message printing troubles (and troubles displayed on the lcd message) perform troubleshooting from the lcd status message table. See the section 2.5.1 perform detailed trouble- shooting from the trouble- shooting chart. See the s...

Page 21

2-5 status level error code lcd led function ready atten initializing flash format off off displays that flash memory is being formatted. It is displayed it when resident flash memory not fomented are detected, or "maintenance menu"-"flash format" of a factory maintenance menu is performed. The func...

Page 22

2-6 status level error code lcd led function ready atten normal canceling job (user denied) blink varies indicates a job being cancelled due to no print permit. (related to jobaccount) 1. A job received from a user who is denied printing. 2. A color job received from a user who is denied color print...

Page 23

2-7 status level error code lcd led function ready atten warning toner empty varies on the thing that the toner empties is shown. This status (warning) is displayed to open/close the cover or turn on the power supply again after the error of no toner occurs. Warning toner sensor varies on the thing ...

Page 24

2-8 status level error code lcd led function ready atten warning %info% varies varies indicates that the new consumable (toner). This status should be appeared at detecting the new consumable (toner), and be disappeared automatically after 3 seconds. %info% is contained in the consumable tag.[oki or...

Page 25

2-9 status level error code lcd led function ready atten warning press online sw invalid data varies varies invalid data was received. Press the on-line switch and eliminate the warning.. Warning press online sw accounting log writing error varies varies the job accounting log is not registered corr...

Page 26

2-10 status level error code lcd led function ready atten error 460 load %media_size%/ %media_type% and press online switch %errcode%:%tray% size mismatch off blink the size of paper or media type in the tray does not match the print data. Load paper in tray (it takes a while until the status disapp...

Page 27

2-11 status level error code lcd led function ready atten error 490 491 492 load %media_size% %errcode%:%tray% empty off blink printing request is issued to an empty tray. Load paper. (it takes a while until the status disappears after you have closed the tray and the lever lifted.) error 490 : mp t...

Page 28

2-12 status level error code lcd led function ready atten error 391 392 open upper cover %errcode%:paper jam off blink paper jam occurred during paper feeding from tray. Error 391 : tray1 error 392 : tray2 error 380 381 382 389 open upper cover %errcode%:paper jam off blink jam has occurred in paper...

Page 29

2-13 2.5.2 service call list display cause error details measure power off/on 002:error 003:error 005:error fff:error cpu exception is the error display provided again? Yes turn off and on the sfp. Replace the cu/ pu board. Service call 030:error cu ram check error is the error display provided agai...

Page 30

2-14 display cause error details measure service call 123:error ambient humidity error or non connection of humidity sensor is the cable from the cu/pu board to the toner sensor board connected properly? No yes re-connect it properly. Replace the toner sensor board. Service call 124:error ambient te...

Page 31

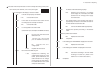

2-15 2.5.3 lcd message troubleshooting if you still have trouble even after using the lcd status message/ trouble list, follow the troubleshooting flowchart displayed below to solve the trouble. No. Trouble flowchart no. 1. The printer does not work normally after tuning on the power. 2. Jam alert p...

Page 32

2-16 the case where the printer does not work normally after tuning on the power • turn off the power and then, turn on the power again. • are messages in the display of lcd all in black? • no is the ac cord properly connected? • no connect the ac cord. • yes is the cable to connect the main board w...

Page 33

2-17 [jam error] -1 paper feed jam (error 390)(error 391)(error 392) • does a jam error occur when turning on the power? • yes is there any paper in the entrance sensor? • yes remove the paper • no does the entrance sensor lever work normally? (it moves freely by touching.) • no replace the entrance...

Page 34

2-18 [jam error] -2 running jam (error 380)(error 381) • does a jam error occur when turning on the power? • yes is there any paper in the write sensor? • yes remove the paper. • no does the write sensor lever work normally? (it moves freely by touching.) • no replace the paper sensor plate. • yes r...

Page 35

2-19 [jam error] -3 ejection jam (error 382) • does an ejection jam error occur when turning on the power? • yes is there paper in the ejection sensor lever? • yes remove the paper. • no does the ejection sensor lever work normally? (it moves freely by touching.) • no replace the ejection sensor lev...

Page 36

2-20 fuser unit assy (error 170) (error 171) (error 172) (error 173) • is the thermistor connector inserted into the therm connector of the main board normally? • no insert the thermistor connector correctly. • yes is the heater connector normally inserted in the cn2 connector of the low-voltage pow...

Page 37

2-21 -1 fuser fan error (error 127) • is the exhaust fan rotating? • yes replace the main board. • no is the cn2 connector of the high-voltage power supply unit connected to the board properly? •no connect the cn2 connector appropriately. • yes replace the exhaust fan or main board. -2 drum fan erro...

Page 38

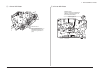

2-22 2.5.4 print troubleshooting the troubleshooting procedure of abnormal printing is described as follows. The typical abnormal printing is shown in the following figure 2-2. Trouble flowchart number pale printing or the whole printing is faded. (fig.2-2 ) the white section is dirty. (fig.2-2 ) wh...

Page 39

2-23 • has the trouble been solved? • yes completed • no replace the image drum cartridge. • has the trouble been solved? • yes completed • no is the surface elasticity of the back-up roller normal? • no replace the fuser assy. • yes replace the main board or high-voltage power supply unit. Pale pri...

Page 40

2-24 the white section is dirty • is the image drum exposed by the external light? • yes install the image drum in the printer and wait 30 minutes. • no from [maintenance menu], select [paper black set] - [smr setting] and set a larger value for adjustment. • has the trouble been solved? • yes compl...

Page 41

2-25 in case of error printing • does the contact plate of the transfer roller contact the tr terminal of the high-voltage power supply unit properly? (see figure 2-4 , section 6.2(6)) • no adjust the contact plate so that it contacts the tr terminal of the high-voltage power supply unit properly. •...

Page 42

2-26 in case of inefficient fusing (if touch by hand the character or image that are printed on paper will be faded or unstuck.) • is the specified paper used? • no use the specified paper. • yes is the backup roller surface normal? • no replace the fuser assy. • yes does the contact plate of the fu...

Page 43

2-27 figure 2-3 e d c a fuse e d c a charging roller earth (dr um) de veloping roller toner supply roller fuse charging roller earth (drum) developing roller toner supply roller frame-assy-tr transfer roller contact plate for transfer contact plate for transfer high voltage power supply board tr ter...

Page 44

2-28 fuser assy contact plate figure 2-5 2. Procedures for repairing.

Page 45: Adjustment

3.1 category and function of maintenance mode ............................3-2 3.2 adjustment at part replacement ..............................................3-23 3. Adjustment this chapter provides explains relating to the adjustment that is necessary while replacing part. Adjustment is performed ...

Page 46

3-2 3. Adjustment •maintenance mode includes the following. - "admin menu" and "boot menu" which is shown by an end user. - "service menu" , "system maintenance menu" and "engine maintenance mode" for the member of maintenance that is not shown by an end user. - "factory maintenance menu" to use in ...

Page 47

3-3 category item value default function / notes admin setup others setup ram setup receive buf size auto 0.1 mb 0.2 mb 0.5 mb 1 mb 2 mb 4 mb * sets the size of receive buffer resource save auto off 0.1 mb 0.2 mb 0.5 mb 1 mb 2 mb 4 mb * sets the size of resource saving area. This item does not appea...

Page 48

3-4 category item value default function / notes admin setup others setup language setup lang initialize execute initialize the message file loaded in flash. The following message for confirmation will appear by pressing ok key. Are you sure? Yes / no if no is selected, it will go back to the source...

Page 49

3-5 category item value default function / notes admin setup settings restore menu execute – changes to the menu setting saved. When the enter switch is pressed, the following confirmation message appears. Are you sure? Yes/no if no is selected, the previous menu display resumes. If yes is selected,...

Page 50

3-6 3.1.2 boot menu to enter boot menu,you should holding on the "ok" button as the same time as the power is turned on. A password the same as admin menu is necessary for "boot menu". Boot menu is displayed only in english. Show a function in the following. Category item value default function / no...

Page 51

3-7 3.1.3 service menu (the member of maintenance) this menu is used for only a member of maintenance, and it is not shown to an end user. "service menu" category is shown when the service menu is set enable by pjl command. When you did off/on of a power supply after the service menu is set enable b...

Page 52

3-8 3.1.4 system maintenance menu (the member of maintenance) this menu is used for only a member of maintenance, and it is not shown to an end user. "sys mainte menu" enters it by doing hold of a "back" + "ok" + "online" button by push from a ready state simultaneously more than five seconds. Enter...

Page 53

3-9 3.1.5 factory maintenance menu (for a factory) this menu is used for a factory, and it is not shown to an end user. "fac mainte menu" is only shown in factory mode, and is not shown in shipping mode. This menu enters it by doing hold of a "back" + "ok" + "cancel" button by push from a ready stat...

Page 54

3-10 power on normal operation mode eng diag level0 diagnositc mode xx.Xx.Xx -mode engine status display switch scan respective voltages display during print motor clutch test toner sensor monitor test print toner pulse count monitor consumable status toner tag noise test monitor printer status moni...

Page 55

3-11 engine status display long pressing of [ ] (2 sec) heater information long pressing of [online] (2 sec) environment information fuser, ch, db setup table number error details tr setup table number error code display and others tr off setup table number [menu ] [menu ] [menu ] [menu ] respective...

Page 56

3-12 [menu ] [menu ] [menu ] [menu ] [menu ] [menu ] a diagnositc mode xx.Xx.Xx -mode switch scan motor clutch test test print consumable status printer status b [menu ] paper route : pu [menu ] main motor print execute k-id unit [menu ] k-total drum cnt [menu ] toner sens exit motor fwd [menu ] tes...

Page 57

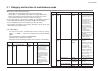

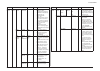

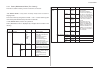

3-13 3.1.6.2 ordinary self-diagnostic mode (level 1) menu items of the ordinary self-diagnostic mode are shown below. Item self-diagnostic menu adjustment contents maintenance utilities 1 switch scan test switch scan entry sensor check and switch check refer to 2.4.1.5.1 2 motor clutch test motor&cl...

Page 58

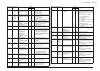

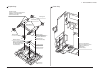

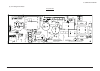

3-14 : paper level indicator lever : driven roller : driving roller (continuous rotation) : driving roller (control rotation) : paper conveying route : indicating lever : photo sensor : micro switch : magnetic clutch : micro switch front back face up stacker eject assy opening -closing sensor 2nd ho...

Page 59

3-15 table 3-3 switch scan details no display area, upper row 1 2 3 4 details display area, lower row details display area, lower row details display area, lower row details display area, lower row 1 paper route : pu entrance cassette sns(in1) h:off l:on in sns h:off l:on write sns h:off l:on exit s...

Page 60

3-16 : paper level indicator lever : driven roller : driving roller (continuous rotation) : driving roller (control rotation) : paper conveying route : indicating lever : photo sensor : micro switch : magnetic clutch : micro switch front back face up stacker 1st eject roller 2nd eject roller heat ro...

Page 61

3-17 3.1.6.5 test print this self-diagnostic menu is used to print the test pattern that is built inside pu. Other test patterns are stored in the controller. This test print cannot be used to check the print quality. Diagnosis for the abnormal print image should be performed in accordance with sect...

Page 62

3-18 4. While the message "print execute" that is set by the operation specified in step 2 is being displayed, press the [ok] key and the test print is executed with the setting value that has been set by steps 2 and 3. Pressing the [cancel] key stops the test print. If any alarm that is shown in th...

Page 63

3-19 • displays are switched by pressing the [menu ] key. Db:k** db : develop voltage setting table id number [unit: hex] • displays are switched by pressing the [menu ] key. Tr1:k** tr2:k** trl : transfer voltage parameter vtr1 table id number [unit: hex) tr2 : transfer voltage parameter vtr2 table...

Page 64

3-20 3.1.6.7 number of print copies counter display this self-diagnostic menu is used to display status of the number of copies of a printer. 1. Enter the self-diagnostic mode (level 1), press the [menu ] or [menu ] key repeatedly ,and press the [ok] key when the "printer status" is displayed in the...

Page 65

3-21 3.1.6.9 self-diagnostic function setting this self-diagnostic menu is used to set valid/invalid of the error detection by the various sensors. The error detection can be made invalid or valid for locating source of abnormality. However, this menu item requires expert knowledge to set among the ...

Page 66

3-22 3.1.6.10 led head serial number display this self-diagnostic menu item is used to check whether the downloaded led head data matches the serial number of the actual led head. 1. Enter the self-diagnostic mode (level 1), press the [menu ] or [menu ] key repeatedly ,and press the [ok] key when th...

Page 67

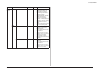

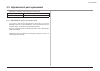

3-23 3.1.8 eeprom initialization the treatment for eeprom initialization at each phenomenon is displayed as diagram 3-1. Diagram 3-1 eeprom initial setting range no phenomenon cu eeprom area pu eeprom area factory default area user menu area op menu area administrator menu/ system maintenance menu a...

Page 68

3-24 3. Adjustment adjustment is necessary while replacing the following part. Replacing part adjustment main pcb board eeprom data upload / download 3.2.1 eeprom data upload / download method in the case of replacing the print board of controller, copy the old eeprom content to the new eeprom of ne...

Page 69: Replacement of Parts

4. Replacement of parts 4.1 preparation for parts replacement .............................................4-2 4.2 parts replacement procedure ....................................................4-4 4.3 lubricating points ....................................................................4-30 this ...

Page 70: Warning

This section explains the replacement procedure of part, assembly, and unit in the working place. Disassembling procedure relating to reassembling is conducted conversely. (1) be sure to unplug the ac cord and interface cable before starting to replace parts. (a) unplugging the ac cord by the follow...

Page 71

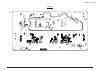

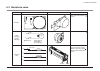

[maintenance tools] the necessary tools for replacing the print circuit board, assembly, and unit is shown as graph 4-1-1. Graph 4-1-1 maintenance tools no. Maintenance tools quantity use remark 1 no.2-200 + magnetic driver 1 3~5mm screw 2 no.3-100 driver 1 3 no.5-200 driver 1 4 digital multi-meter ...

Page 72

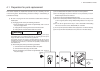

① hook ffc cable holder-head ① 4.2 parts replacement procedure this section describes the procedure for replacing the parts and assemblies shown in the disassembly diagrams below. 4.2.1 led head (1) open the stacker cover. (2) remove the id unit. (3) disengage the tab of the holder-head from the sta...

Page 73

Frame-assy-tr spring spring latch ③ ② ② ① ① ① 4.2.2 roller-transfer (1) open the stacker cover. (2) remove the id unit. (3) take the frame-assy-tr out of the printer. (4) disengage the latches of bearing-tr ① on both ends. (5) hold the bearing-tr ① on the both side, and then lift up the roller- tran...

Page 74

Shaft-dup-clutch ① ④ ⑤ ② ③ ④ ⑥ ⑤ 4.2.3 duplex belt (1) take out the frame-assy-tr. (refer to 4.2.2) (2) remove the cassette and place the printer unit with its right side down. (3) remove the e-ring ① and slide the shaft-dup-clutch in the direction of the arrow. (4) raise the printer unit and remove...

Page 75

Hole b ④ tab 4.2.4 cover-side-r / cover-lower-r (b512 only) (1) remove the cassette. (2) open mpt, the cover-assy-stacker and the cover-assy-rear. (3) remove the cover-wlan ① . (4) remove the screw (silver) ② . (5) insert the minus driver into the hole a of guide-cassette-r. (b512 only) (6) push the...

Page 76

① a b e d c hole a 4.2.5 cover-side-l / cover-lower-l (b512 only) (1) remove the cassette. (2) open mpt, the cover-assy-stacker and the cover-assy-rear. (3) insert the minus driver into the hole a of guide-cassette-l. (4) disengage the two tabs (d,e) and remove the three tabs(a,b,c) while cover-side...

Page 77

③ ⑥ ⑦ ⑥ ④ ④ ④ ⑤ 4.2.6 cu-board (1) remove the cover-side-r. (refer to 4.2.4) (2) remove the seven screws (silver) ① . Remove the plate-shield ② . ① ① ① ② (3) disconnect the all cables. (4) remove the screw (silver : small) ③ , remove the two screw (silver) ④ and remove the cu-board ⑤ . (5) remove th...

Page 78: Warning

③ ① ⑤ ⑦ ⑥ ① ② ④ warning risk of electric shock there is a risk of electric shock during replacement of the low voltage power supply. Use insulating gloves or avoid direct contact with any conducting part of the power supply, and caution should be exercised during replacement. The capacitor may take ...

Page 79

③ ⑤ ① ② ④ ⑥ ×3 4.2.8 dc motor (1) remove the plate-shield. (refer to 4.2.6) (2) remove the power supply unit ( board ) and sheet-insulation-lv.(refer to 4.2.7) (3) disconnect the cable and remove the screw(silver) ① , remove the switch-assy ② . (4) remove the screw(silver) ③ , remove the duct-fan-po...

Page 80

④ ③ ① ⑤ ④ ⑨ ⑩ ⑪ ⑭ ⑦ ⑥ ⑬ ⑫ ⑧ ② ② 4.2.9 hopping / mpt / regist clutch (1) remove the cu-board. (refer to 4.2.6) (2) remove the power-supply unit ( board ). (refer to 4.2.7) (3) remove the dc motor. (refer to 4.2.8) (4) remove the sheet-insulation-cu ① . (5) remove the two screws (silver) ② ,remove the...

Page 81

① ② ⑤ ④ ×5 ② a b c d ⑤ ③ air projection of plate side l assy notch of fan view a view a impeller 4.2.10 hv-board / motor-fan (1) remove the cover-side-l. (refer to 4.2.5) (2) remove the screw (black) ① and the four screws (silver) ② , disengage the two tabs (a and b), and remove hv-board ③ . Be care...

Page 82

① ① ② ③ ② ① ① 4.2.11 cover assy ope (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the plate-shield. (refer to 4.2.6) (3) remove the ffc cable from the cu-board. (4) remove the two screws (black) ① . Remove the cover-assy-ope ② . (5) assembling is performed by the ...

Page 83

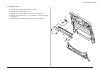

Closed the cover assy stacker ④ ③ ② ① ② ⑤ release lever ⑥ ⑦ ⑧ 4.2.13 cover assy stacker (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the plate-shield. (refer to 4.2.6) (3) remove the screw ① and disconnect ffc cable from board. (4) remove the two screws (silver) ...

Page 84

① ⑤ ④ ① ② ③ 4.2.14 stacker cover (1) remove the cover assy stacker. (refer to 4.2.13) (2) remove the led head. (refer to 4.2.1) (3) remove the four screws (black) ② , remove the cover-lever ③ . (4) remove the lever-lock-top ④ , lever-lock-button ⑤ . Remove the spring- lever-top ⑥ . (5) assembling is...

Page 85

Thick cable thin cable a square hole to draw the thick cable ① ① ② ③ ③ ⑤ ⑤ ④ ④ view a view a 4.2.15 fuser assy note! Replace the fuser-assy by assy unit. It is forbidden for disassembling the fuser-assy, also, reusing the disassembled fuser-assy. (1) take out the frame-assy-tr. (refer to 4.2.2) (2) ...

Page 86

View a ① ② ③ ④ ① ③ ⑤ ⑥ view a 4.2.16 mpt assy (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the switch-assy.(refer to 4.2.8) (3) remove the cover-assy-ope. (refer to 4.2.11) (4) remove the two screws (silver) ① . Remove the plate-front ② . (5) remove the two screw...

Page 87

4.2.17 cover assy rear (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the cu-board. (refer to 4.2.6) (3) remove the sheet-insulation-cu. (refer to 4.2.9) (4) remove the spacer ① . (5) slide cover assy rear ② and pull it out of the hole on the right of the printer. ...

Page 88

4.3.18 guide eject lower assy (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the cu-board. (refer to 4.2.6) (3) remove the sheet-insulation-cu. (refer to 4.2.9) (4) remove the cover-eject. (refer to 4.2.13) (5) remove the two screws (silver : 8mm) ① . Remove the co...

Page 89

4.2.19 eject motor (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the cu-board. (refer to 4.2.6) (3) remove the cover assy stacker. (refer to 4.2.13) (4) remove the fuser assy. (refer to 4.2.15) (5) remove the cover assy rear. (refer to 4.2.17) (6) remove the guide...

Page 90

① ② plate side l assy plate side r assy front assy ③ ⑥ ⑥ ⑤ ⑤ ④ 4.2.20 plate side r assy / plate side l assy / front assy (1) remove the cover-side-r and cover–side-l. (refer to 4.2.4 / 4.2.5) (2) remove the cu-board. (refer to 4.2.6) (3) remove the power supply unit. (refer to 4.2.7) (4) remove the ...

Page 91

① ⑤ ④ ② ③ ⑥ ⑧ ⑨ ⑩ ⑦ a b 4.2.21 plate side l assy (1) separate the plate side l assy. (refer to 4.2.20) (2) remove the four screws (silver) ① . Remove the guide-cassette-l ② and spring-lock-cassette ③ . (3) remove lever-sensor cassette ④ and spring-sensor ⑤ from the guide- cassette-l ② . (4) remove t...

Page 92

① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩ ⑳ ⑪ ⑫ ⑫ ⑭ ⑯ ⑰ ⑮ ⑬ ⑱ ⑲ ⑭ ⑮ view a view a projection notch impeller 4.2.22 plate side r assy (1) separate the plate side r assy. (refer to 4.2.20) (2) remove the two screws (silver) ① . Remove the guide-cassette-r ② . (3) remove the two screws (black) ③ . Remove the connector ④ . (...

Page 93

① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩ ⑩ ⑪ ⑪ ⑫ ⑬ ① ② ③ ③ ④ ⑤ ⑥ ⑦ ⑧ ⑧ regist assy 4.2.23 roller regist (1) separate the front assy. (refer to 4.2.20) (2) remove the two screws (black) ① and plate-feed-b ② . (be careful not to lose the gear that is removed with the plate.) (3) remove the gear-idle-mpt ③ .Remove the gear...

Page 94

⑦ ① ① ② ③ ④ ⑤ ⑥ b a 4.2.25 lever in sensor / lever wr sensor / photo interrupter (1) separate the front assy. (refer to 4.2.20) (2) separate the roller-pressure and roller regist. (refer to 4.2.23) (3) remove the two screws (black) ① . Remove the holder-sensor ② . (4) remove the lever-in-sensor ③ . ...

Page 95

① tab cover tab ② ② 4.2.26 paper feeding roller (roller-pick-up,roller-feed-now) • in the case of tray 1 (1) turn off the printer and pull out the paper cassette tray. (2) remove the feed roller ① as pushing its tab outward. (3) as pushing the tab downward, open the cover (black) that is on the left...

Page 96

❶ ❷ ③ ⑤ ④ 4.2.27 paper feeding roller(roller-assy-mpt)/paper feeding sub roller (1) turn off the printer. (2) open the multipurpose tray. (3) open the lever-link ① and feed roller cover ② . (4) remove the feed sub roller ③ by rotating it toward you. (5) open the feed roller cover ④ by pushing its ta...

Page 97

Retard-cover tab ① ② 4.2.28 frame-assy-retard , spring-retard (1) remove the cassette. (2) open the retard-cover by pushing two tabs in the directions of the arrows. (3) remove frame-assy-retard ① by pushing it in the direction of the arrow. (spring-retard ② is removed together.) (4 ) assembling is ...

Page 98: 4.3 Lubricating Points

This subsection indicates the lubricating points of the printer. Conversely, it means that any other parts than the specified lubricating points must not be lubricated. There is no need to lubricate in the midst of a disassembling job. However, if lubricating oil has been wiped off, supply the speci...

Page 99

Plate-assy-side-l c-9300 or c-5005 class a apply a normal amount of tetra (c-9310 or c-5005) to the hatched areas. (contact surface) -1 plate-assy-side-r em-30lp class c apply a normal amount of molykote (em-30lp) to the hatched areas. (shaft end surface side) plate-id-gear (caulking) 4-31 4. Replac...

Page 100

-2 plate-assy-side-r frame-assy-hopping em-30lp class c apply a normal amount of molykote (em-30lp) to the hatched areas. (shaft end surface side) em-30lp class d apply a normal amount of molykote (em-30lp) to the hatched areas. (gear tooth surface) gear-reduction-z14-z70 plate-gear-eject_caulking p...

Page 101

-1 frame assy-regist -2 frame assy-regist roller-pressure roller-regist grease prohibition em-30lp class c apply a normal amount of molykote (em-30lp) to the hatching areas (shaft end surface side) em-30lp class c apply a normal amount of molykote (em-30lp) to the hatching areas (shaft end surface s...

Page 102

-1 front-assy -2 front-assy plate-feed-b_caulking em-30lp class c apply a normal amount of molykote (em-30lp) to the hatching areas (shaft end surface side) frame assy.-regist gear-idle-mpt-z35 plate-feed-b_caulking gear-idle-z35 gear-reduction-mpt-z37-20 em-30lp class c apply a normal amount of mol...

Page 103

-1 frame-assy-mpt roller-pinch shaft-idle-dup em-30lp class b apply a normal amount of molykote (em-30lp) to the hatched areas. (center of shaft) em-30lp class a apply a normal amount of molykote (em-30lp) to the hatched areas. (side of roller and ditch of shaft) (the other side is also the same. : ...

Page 104

-1 guide-assy –eject-u gear-idle_exit (z38) em-30lp class c x2 apply a normal amount of molykote (em-30lp) to the whole circle of gear teeth. Of 2 places. Em-30lp class c apply a normal amount of molykote (em-30lp) to surface of the post (bearing portion), the flange portions. -2 frame-assy-mpt boss...

Page 105

-2 guide-assy –eject-u -1 frame-assy-tr note1) please wipe the amount that grease began to see the sliding area off. Gear-exit (z19) bearing-eject_r see note 1) see note 1) bearing-feeder see note 1) em-30lp class c apply a normal amount of molykote (em-30lp) to bearing surface of the shaft. Em-30lp...

Page 106

-2 frame-assy-tr -3 frame-assy-tr bearing roller-transfer bearing geartr-z23 frame-guide-tr em-30lp class c apply a normal amount of molykote (em-30lp) to the hatching areas (bearing sliding surface) em-30lp class c apply a normal amount of molykote (em-30lp) to the hatched areas. (gear tooth surfac...

Page 107

Duplex-assy bearing-dup roller-tensioner grease prohibition frame-dup bearing-dup mxl87-belt-dup roller-feed_dup em-30lp class b apply a normal amount of molykote (em-30lp) to the hatched areas. (shaft end surface side) em-30lp class a apply a normal amount of molykote (em-30lp) to the hatched areas...

Page 108

⑪ -1 printer nip-pn307 ⑪ -2 printer nip-pn307 plate-assy-side-r em-30lp class b apply a normal amount of molykote (em-30lp) to the sliding surface with drum shaft. (hatched areas) em-30lp class f apply a normal amount of molykote (em-30lp) to the whole circle of gear teeth of 1 place. 4-40 4. Replac...

Page 109

⑫ cover-assy-stacker ⑬ cassette-assy(250sht) hanarl sf-133 class c lever-lock-button sliding surface (all circumference of the hatching portion) *leave it for about 30minutes (drying time) after painting hanarl sf-133, and then assemble the lever-lock-button. *hanarl sf-133 should not protrude outsi...

Page 110: Periodic Maintenance

5.1 cleaning ....................................................................................5-2 5.2 cleaning of led lens array ........................................................5-3 5.3 cleaning the feed rollers and the retard roller ........................5-4 5.4 cleaning the mpt feed ro...

Page 111: 5.1 Cleaning

5-2 5. Periodic maintenance 5.1 cleaning remove toner powder and dust in the printer inner section. Clean the inside of and the periphery of the printer with the cloth as needed. Clean the printer inner section with the handy cleaner (maintenance tool). Note! Do not touch the image drum, led lens ar...

Page 112

5-3 5. Periodic maintenance if the vertical white lines, and white belt (white spot, pale printing) occur in printing as shown below, the led lens array should be cleaned or the toner cartridge should be replaced. Note! As for the led lens array, clean it with soft tissues or soft cloth after elimin...

Page 113

5-4 5. Periodic maintenance feed roller 5.3 cleaning the feed rollers and the retard roller (3) wipe two paper feed rollers inside the printer with a soft cloth that has been slightly moistened with water and then squeezed well. Note! Use water only. (1) power off the printer. (2) pull the tray out..

Page 114

5-5 retard roller (4) wipe two paper feed rollers in the tray with a soft cloth that has been slightly moistened with water and then squeezed well. Note! Use water only. (5) push the tray back into the printer. 5. Periodic maintenance.

Page 115

5-6 5. Periodic maintenance 5.4 cleaning the mpt feed rollers (1) power off the printer. (2) open the mpt. (3) close the mpt gently to a position where the left and right tabs fit the arm grooves. Tab arm (4) separate the tabs on the roller guide from the left and right arms by opening the arms outs...

Page 116

5-7 (5) raise the roller guide until it comes in contact with the printer. (6) wipe the two feed rollers with a tightly wrung cloth soaked in water through the opening for mpt. Note! Use water only. Roller guide (7) close the mpt is performed by the inverse procedure with opening. 5. Periodic mainte...

Page 117: Connection Diagram

6.1 connection diagram ..................................................................6-2 6.2 board layout .............................................................................6-3 6.3 resistance value .....................................................................6-11 6. Connection ...

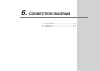

Page 118: 6.1 Connection Diagram

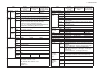

6-2 ffc cable core main control board board mrm pr-cable15 3p cn1 3p wr sensor 3p in sensor 3p 8p 11p 16p 8p 9p 9p 6p 6p pap therm power 2p 16p 4p 3p 3p pwfan2 cn1 cn3 pwsw wlan il 2p in_wr 2nd dm dfan1 2p return fuse cut ch db sb 3p cn2 tr 6p 2p tag_gnd tagrw hvif ope 16p 28p cn1 28p wr (blue) in (...

Page 119: 6.2 Board Layout

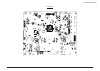

6-3 (1) main control board component side 6.2 board layout 457249 6 6 45554699 mrm rc lt board-mrm 2 3 4 1 usb1 1 4 exitm 1 2 9 12 7 8 lan 6 1 pap 1 3 df an1 1 8 2nd 3 1 rco 1 14 13 2 za38 za39 za40 za41 1 9 2 1 1 3 4 1 toner 2 1 2 1 mc lt 2 1 hc lt 1 4 pwsw 3 1 pwf an2 2 1 idthrm 1 3 exit 1 6 in̲wr...

Page 120

6-4 soldering side 6 6 45554699 r540 1 3 4 6 7 8 9 11 12 13 14 16 17 18 19 21 22 23 24 26 27 28 29 31 32 34 35 39 36 37 43 40 41 46 44 45 50 49 48 47 1 2 3 5 6 8 9 10 11 12 1 2 3 4 5 6 7 8 r527 c586 c587 c583 q510 c672 c674 c600 q506 c510 c680 c682 c686 c688 c689 c687 c683 c580 c575 c585 r675 c597 q...

Page 121

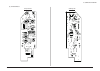

6-5 (2) op panel board component side jp30 jp21 jp4 jp2 jp22 jp12 jp6 jp29 jp26 jp16 jp28 jp27 jp24 jp23 jp18 jp17 jp15 jp14 jp13 jp11 jp10 jp9 jp8 jp7 jp1 jp25 jp20 jp19 jp5 jp3 led3 led2 led1 sw7 sw6 sw5 sw4 sw3 sw2 sw1 11 1 cn2 cn1 16 2 15 1 37c 1 1 45709999 board-37c back online cancel [online] ...

Page 122

6-6 (3) soft power switch board component side 1 4 44711699 22 p6a cn1 (4) toner sensor board component side sns cn 1 c e k a 3 1 1 44413799 97t 6. Connection diagram.

Page 123

6-7 (5) low-voltage power board component side 45674799 board-30l 5 5 for continued protection against risk of fire. Replace only with same type and rating of fuse. Avertissement advertencia heatsink and transformer core present risk of electric shock. Test before touching. Primary secondary 250v 25...

Page 124

6-8 soldering side 45674799 5 5 c522 c501 r547 r507 r508 r510 r545 r546 r544 r550 r549 r548 r553 r552 r551 r541 r542 r538 c507 r528 r531 r561 r562 r563 rj503 rj504 rj505 r573 zd506 r543 r537 r513 c528 c529 r572 r574 r570 r569 c535 bf501 r576 zd512 zd511 zd513 za501 6. Connection diagram.

Page 125

6-9 (6) high-voltage power board component side t6 t5 t4 t3 t2 t1 sns1 s14 s13 s12 s11 s10 s9 s8 s7 s6 s5 s4 s3 s2 s1 q7 q6 q5 q4 q3 q2 q1 ps1 led1 jp44 jp43 jp42 jp41 jp40 jp39 jp38 jp37 jp36 jp35 jp34 jp33 jp32 jp31 jp30 jp29 jp28 jp27 jp26 jp25 jp24 jp23 jp22 jp21 jp20 jp19 jp18 jp17 jp16 jp15 jp...

Page 126

6-10 soldering side r648 r647 r646 r645 r643 r642 r641 r640 r639 r638 r637 r636 r631 r626 r625 r623 r620 r619 r616 r615 r614 r612 r611 r609 r608 r602 r600 r598 r596 r595 r593 r590 r589 r587 r586 r585 r584 r583 r580 r579 r578 r577 r553 r542 r541 r539 r513 r512 r511 r510 r503 q508 q501 d517 d516 d513 ...

Page 127: 6.3 Resistance Value

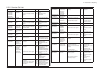

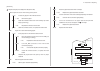

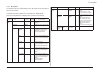

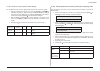

6-11 unit circuit diagram and configuration part diagram resistance value dc motor both ends of ip2 and ip3: 1 or less clutch (hopping) (regist) (mp tray) cable cable cable color : black (hopping) : blue (regist) : yellow (mp tray) 1 2 c between pin1 and pin2 : 240 fuser unit assy 1 2 3 4 thermostat...

Page 128

6-12 unit circuit diagram part diagram resistance value fan motor ( fuser ) red black +24 v 1 fanalm-n 3 0 v 2 m fan motor ( drum) fan motor ( power ) red black +5 v 1 fanalm-n 3 0 v 2 m red black +5 v 1 fanalm-n 3 0 v 2 m 6. Connection diagram.