- DL manuals

- Oki

- Printer

- B930 Series

- Service Manual

Oki B930 Series Service Manual

Summary of B930 Series

Page 1

B930 maintenance manual revision 1 the information contained in this manual is the property of oki printing solutions and is to be used solely in conjunction with servicing of said product..

Page 2: B930

B930 laser printer base engine service manual fi01001a1.

Page 3: Contents

Toc-1 contents chapter 1 introduction.................................................................................................... 1-1 conventions...............................................................................................................................................1-1 ...

Page 4

Toc-2 hcf......................................................................................................................................................... 2-33 overview ..............................................................................................................................

Page 5

Toc-3 compile tray ...........................................................................................................................................2-68 outline of operation .......................................................................................................................

Page 6

Toc-4 general wiring diagram ........................................................................................................................... 4-1 engine............................................................................................................................................

Page 7

Toc-5 notes on using the wiring diagram between parts ...................................................................4-61 1 switch.............................................................................................................................................4-62 2 sensor...............

Page 8: Chapter 1

Chapter 1 introduction this manual is a standard service manual containing information required for maintenance of this laser printer (standard specifications). This manual is intended for use by oems when they provide maintenance services for this laser printer or when they prepare maintenance data...

Page 9: Laser Beams

1-2 occasionally procedures not covered by this manual may be required in actual operation, which laser beams this laser printer has a switch (interlock s/w 5v) which removes power to the laser beam output circuit, preventing operation of the laser beam output unit (ros assy-12). The switch automati...

Page 10: Chapter 2

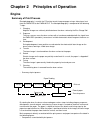

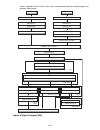

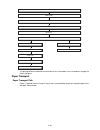

Chapter 2 principles of operation engine summary of print process electrophotography is used in the fio printer to print image on paper using a video signal sent from the pwba ess to the pwba mcu f. The electrophotography is composed of the following 7 steps. 1. Charging negative charges are uniform...

Page 11

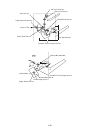

• components associated with paper transportation fi61002a1 fuser assy cru 1. Charging 3. Development 4. Transfer 5. Detack 6. Fusing 2. Exposure 7. Cleaning.

Page 12

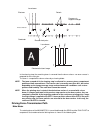

2-3 in the exposure step, the negatively charged drum surface is scanned by a laser beam. The laser diode of the ros (raster output scanner) passes through a rotating polygon mirror (6 facets) and lens scanning the drum from one end to the other. The radiation of the laser beam varies according to a...

Page 13

2-4 in the cleaning step, the remaining toner is removed from the drum surface. The drum surface is prepared for the next cycle. The toner is scraped off the drum surface by a cleaning blade. Note the toner scraped off in the cleaning step is collected in a recovery toner compartment partitioned fro...

Page 14: Paper Transport

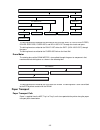

2-5 the driving force transmitted to the gear drives the roller assy-ta, roller assy-feed, roller assy regi, fuser assy, and roll assy oct through the clutch and gears. The driving force transmitted to the pulley 25t drives the exit1 (roll assy-oct) through the gears. The driving force transmitted t...

Page 15

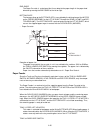

2-6 layout of paper transport path the following is a cross section of the fio laser printer, showing main components directly asso- ciated with the paper path and transport. • main components associated with transport of paper fi61007a2 roller assy roller assy print exit roller assy regi roller ass...

Page 16: Functions of Main Components

2-7 functions of main components this chapter describes the functions of the main components of the fio laser printer. 4.1 paper cassette 4.2 paper feeder 4.3 mpf 4.4 xero 4.5 fuser 4.6 drive 4.7 electrical components and rollers paper cassette it is necessary to adjust the front side guide assy, re...

Page 17

2-8 the force pushing up the bottom plate is transmitted by the driving force of the motor on the feeder assembly to the lift up shaft through the gear (13t/60t) and sec- tor gear (60t). The bottom plate is pushed up by the rotation of the lift up shaft, which causes the supplied paper to get in con...

Page 18

2-9 of the sensor is transmitted. When the sensing area is blocked (paper is present), the signal becomes off. Level sensor this sensor detects, by the actuator position, whether paper in the paper cassette is lifted. When the flag of the actuator leaves the level sensor sensing area, the sen- sor d...

Page 19

2-10 the roller assy-drive feeds paper into the printer. Solenoid pick up the solenoid pick up transmits the driving force from the main motor to the roller assy-feed. Sensor-photo in the sensor-photo in detects whether paper is present on the mpf. Sensor assy-mpf the sensor assy-mpf detects the wid...

Page 20

2-11 xero cru the cru is made up of the following main six components. • drum the drum is composed of a photoconductive surface layer (an insulator in the dark but becomes conductor when receiving light) and a conductive inner layer (aluminum cylinder). The drum retains electric charges on the surfa...

Page 21

2-12 ros assy the ros assy-12 scans the drum surface with a laser beam. It consists of four main com- ponents: ld (laser diode) pwb, ros motor, polygon mirror, and sos pwb. (1) ld pwb the ld pwb generates a laser beam with the two lds of ld1 and ld2. The beam is turned on or off according to a print...

Page 22

2-13 fuser heat roll the heat roll is a hollow metal tube with its surface coated. This tube is heated by the inner heater rod. The heat is applied to the paper passing between the heat roll and pressure roll, fusing and fixing the toner on the paper. Pressure roll the pressure roll is a metal shaft...

Page 23

2-14 center thermistor the center thermistor monitors the surface temperature of the paper-feed portion of the heat roll to control on/off of the main heater rod and sub heater rods 1 and 2. Rear thermistor the rear thermistor monitors the surface temperature at rear side of the heat roll to switch ...

Page 24: Drive

2-15 the sensor-photo in detects exit1 face down tray full by moving the actuator up and down. Gate-exit 1 the gate-exit 1 switches the paper transport path. When the gate-exit 1 is lifted, paper is fed to the exit1 face down tray. When it is lowered, paper is fed to the exit2 face down tray. Drive ...

Page 25

2-16 electrical components and controller switch-power turning on/off the switch-power supplies/cuts off the main power of the printer. Outlet mn the outlet mn supplies the power to the finisher directly from the main power unit. Switch (24v interlock switch) the switch (24v interlock switch) is a s...

Page 26: Control

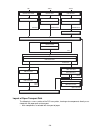

2-17 the pwba ess connected to the pwba mcu f controls the entire system. Roller assy-ta the roller assy-ta feeds paper from the tray2 or an optional tray to the cru or fuser. Roller assy regi the roller assy regi feeds paper from the tray2, optional tray or mpf to the cru or fuser. Control paper si...

Page 27

2-18 ros control rotation of ros motor the on/off control of the ros motor is performed according to the mode of operation as shown below. Determination of ros ready the ros goes into ready state after the specified period passes since the reception of the ros mpa start signal and the sos cycle exce...

Page 28: 1000 Sheet Feeder

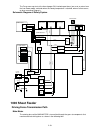

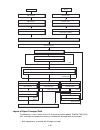

2-19 the fuser warm-up starts at the time of power on, interlock open/close, jam reset, or return from the low power mode, and ends when the ready temperature is attained, when a failure occurs, or when executing diagnosis. Schematic diagram of safety system 1000 sheet feeder driving force transmiss...

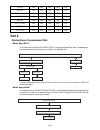

Page 29: Paper Transport

2-20 paper transport paper transport path main motor gear (22t/40t) gear (38t) gear (126t) clutch gear (60t) gear (37t) takeaway roll assembly gear (32t).

Page 30

2-21 paper is supplied from the tray3 or tray4, and is transported to the printer along the paper trans- port path shown below. Layout of paper transport path the following is a cross section of the fio laser printer and the optional 2 tray module, show- ing main components directly associated with ...

Page 31: Paper Transport

2-22 • main components associated with the paper transport paper transport paper transport path heat roll roll assy-oct msi hsg assy-btr drum option 2 tray module tray 1 tray 2 tray 3 tray 4 rlr-pinch exit roller assy-feed roller assy-pinch roll assy-drive roller-ta pinch roller assy-ta pinch roll r...

Page 32

2-23 paper is supplied from the tray3 or tray4, and is transported to the printer along the paper trans- port path shown below. Layout of paper transport path fi6k004a1 print exit tray 3 roller assy roller assy roller assy roller assy-ta roller assy regi hsg assy-btr drum fuser assy roller assy roll...

Page 33: Functions of Main Components

2-24 the following is a cross section of the fio laser printer and the optional 2 tray module, show- ing main components directly associated with the paper path and transport. • main components associated with the paper transport functions of main components when the optional 2 tray module is instal...

Page 34

2-25 end guide the paper cassette is so designed that it can adapt to the paper length in the paper feed direction by moving the end guide to the left or right. Bottom plate the force pushing up the bottom plate is transmitted by the driving force of the motor on the feeder assembly to the lift up s...

Page 35

2-26 this tray 3/4 paper size switch switches for setting the size of paper supplied from each paper cassette. A signal indicating the set size is transmitted as a voltage to the pwba mcu f. No paper sensor if paper runs out in the paper cassette, the actuator lowers and the flag of the actua- tor t...

Page 36

2-27 main components left cover interlock switch the left cover interlock switch detects open/close of the left cover assem- bly. Tray 3 feed out sensor the tray 3 feed out sensor detects paper fed from the tray 3 or tray 4. Tray 4 feed out sensor the tray 4 feed out sensor detects paper fed from th...

Page 37: Control

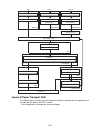

2-28 control paper size control paper cassette feeding the following table gives on/off states of the switches on the tray 3/4 paper size switch, corresponding to the paper sizes on the paper cassette. Notethe switches on the tray 3/4 paper size switch are denoted by “s/w2”, “s/w4”, “s/w3”, “s/w5”, ...

Page 38: Exit 2

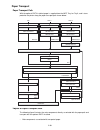

2-29 exit 2 driving force transmission path motor assy exit 2 the rotating force of the motor assy exit2 is transmitted through the gears to components that need mechanical driving force as shown in the following flow. The transmitted driving force drives the roll assy-fu, roll assy-inv and roll ass...

Page 39: Paper Transport

2-30 paper transport paper transport path with the optional exit2 installed, paper is supplied from the mpf, tray1 or tray2, and is trans- ported to the printer along the paper transport path shown below. Layout of paper transport path the following figure illustrates the main components directly as...

Page 40: Functions of Main Components

2-31 functions of main components when the optional exit2 is installed on the top of the printer, offset transfer of paper is available with the fio laser printer. This chapter outlines the functions of the main components of the exit2. Motor assy exit 2 the motor assy exit 2 is a stepping motor to ...

Page 41

2-32 the pwba exit that contains a cpu controls paper feed in the exit2 upon receiving a command from the pwba mcu f and sensor/switch information. Switch-i/l,cab the switch-i/l,cab detects open/close of the chute lh high. Sensor-photo in the sensor-photo in detects whether paper is remaining in the...

Page 42: Hcf

2-33 hcf overview the hcf, a paper feeder connected to the printer, has a function to feed up to 2,000 sheets of paper. The following outlines the operation of the hcf. Configuration the hcf is composed of the following three blocks. - tray block: contains paper. - feeder block: feeds paper from the...

Page 43: Paper Feeding

2-34 main functions in addition to the paper feed feature, the hcf has functions to: - m/c status monitoring - paper size detection - no-paper detection - tray lifting - remaining paper volume detection - paper jam detection see the items below for details of each function. Paper capacity paper volu...

Page 44

2-35 this block comprises roll assy nudger (called “nudger roll” hereafter) to feed paper from the tray, roll assy feed (“feed roll” hereafter) and roll assy retard (“retard roll” herein- after) to feed paper from the nudger roll to the transport block. These rollers are driven by the feed motor (st...

Page 45

2-36 feeder block operation upon receiving the feed start signal from the controller, the hcf activates the nudger solenoid after a preset time has passed to press the nudger roll against the paper in the tray. Further, after a preset time has passed after receiving the feed start signal, the hcf ro...

Page 46

2-37 transport block operation upon receiving the feed start signal from the controller, the hcf activates the t/a motor at a high speed after a preset time has passed. This rotating power of the t/a motor is transmitted to the take away roll, and the paper from the feeder block is transferred to th...

Page 47: M/c Status Monitoring

2-38 (1) feed motor the feed motor is a stepping motor that rotates forward the nudger roll and feed roll to feed paper from the tray to the transport block. The motor also lifts the tray by reverse rotation. (for details, see sections 5 and 7.) (2) nudger solenoid the nudger solenoid raises or lowe...

Page 48

2-39 interlock detection checks the “open” state of the transport cover interlock switch and the home position switch. This checking is constantly carried out while the power is on. When “open” of the transport cover interlock switch is detected, printing operation is inhibited, and the 24 v supply ...

Page 49: Paper Size Detection

2-40 (2) home position switch detects the coupling of the hcf with the iot. The off state of this switch indicates that the hcf is separated from the iot. In this case, transfer of paper is inhibited. (3) tray in sensor detects insertion of the tray into the hcf. This sensor turns on when the tray i...

Page 50: Tray Lifting

2-41 there are two size sensors: hcf size sensor r and hcf size sensor l. By moving the guide assy side r to turn on/off these sensors, and by using the resulting sensor level patterns, paper size can be determined. Tray lifting tray lift operation starts automatically when the tray is inserted with...

Page 51: No-Paper Detection

2-42 no-paper detection this function checks whether paper is loaded or not in the tray. When paper is present, the actuator in the middle of the hcf is raised by the lifting of paper and leaves the sensing area of the no paper sensor (photo-sensor), which makes the sensor light- receivable. Thus, p...

Page 52: Tandem Tray

2-43 when a fault occurs, determination of remaining paper volume is carried out as shown below. - when the interlock becomes open during lifting operation remaining paper volume is determined based on the total of the time until interlock open + the time from the feed motor forward/reverse rotation...

Page 53: Paper Transport

2-44 the driving force transmitted to the gear drives the takeaway roll assembly through the clutch and gears. Paper transport paper transport path paper is supplied from the tray3 or tray4, and is transported to the printer along the paper trans- port path shown below. Main motor gear (22/40) takea...

Page 54

2-45 layout of paper transport path the following is a cross section of the fio laser printer and the optional tandem tray mod- ule, showing main components directly associated with the paper path and transport. • main components associated with the paper transport fi6l010a1 print exit tray 3 roller...

Page 55: Functions of Main Components

2-46 functions of main components when the optional tandem tray module is installed under the printer, additional trays are available. The following chapters outline the functions of the main components of the tandem tray module. 24.1 paper cassette 24.2 paper feeder 24.3 main components paper casse...

Page 56

2-47 the gear assembly (tray 3). The bottom plate is pushed up via the tray cable, f/r cable and f/l cable by the rotation of the lift shaft assembly, which causes the supplied paper to get in contact with the roller assy (nudger). Regarding the tray4, the force pushing up the bottom plate is transm...

Page 57

2-48 • tray4 paper cassette detection of paper size the paper size to which the cassette is set is transmitted to the switches s/w1 and s/w3 on the tray 3/4 paper size switch by moving these guides. The paper size is detected by the on/off information of these switches. Paper sizes that can be autom...

Page 58

2-49 no paper sensor if paper runs out in the paper cassette, the actuator (support assembly) lowers and the flag of the actuator (support assembly) that has stayed in the no paper sensor sensing area leaves there. Thus, the light of the sensor is transmitted. When the sensing area is blocked (paper...

Page 59

2-50 the tray 3 feed out sensor detects paper fed from the tray 3 or tray 4. Tray 4 feed out sensor the tray 4 feed out sensor detects paper fed from the tray 4. Takeaway roll assembly the takeaway roll assembly feeds paper from the tray 3 or tray 4 to the printer. Tray module pwb the tray module pw...

Page 60: Duplex

2-51 duplex driving force transmission path motor assy dup the rotating force of the motor assy dup is transmitted through the gears to components that need mechanical driving force as shown in the following flow. The transmitted driving force drives the roller dup a3l (upper), roller assy dup and r...

Page 61

2-52 layout of paper transport path the following figure illustrates the main components directly associated with the paper path and transport with the optional duplex installed. • main components associated with transport of paper fi61007a2 roller assy roller assy print exit roller assy regi roller...

Page 62: Functions of Main Components

2-53 functions of main components when the optional duplex is installed to the left of the printer, duplex (double-sided) printing is available with the fio laser printer. The following outlines the functions of the main components of the duplex. Switch-i/l,cab the switch-i/l,cab detects open/close ...

Page 63: Finisher

2-54 the motor assy dup transmits driving force to the roller dup a3l (upper), roll assy dup and roller dup a3l (lower) that feed paper. Finisher overview the finisher performs post-processing, such as stapling, punching, and stacking paper trans- ferred from the iot, and ejects paper to the top tra...

Page 64

2-55 paper size and weight the following shows paper sizes and weight that the finisher can handle, as well as applicable functions for each paper size. The iot and the finisher handle different paper sizes and weights. For this reason, if the iot has printed paper that the finisher cannot handle, t...

Page 65: Paper Transfer

2-56 note: *1: numbers (2, 3, 4) mean 2 holes, 3 holes, and 4 holes, respectively. *2: applicable within the following range: paper width: 203.2 - 297 mm paper length: 182 - 431.8 mm paper wight - for punching: 52 - 176 gsm - for stapling:52 - 226 gsm (*1) - for ejecting in the stacker tray:52 - 226...

Page 66

2-57 from iot fi6p030a1 belt h-x’port exit sensor h-x’port entrance sensor to finisher top tray stacker tray compile tray stapler puncher fi6p029a2 from h-tra.

Page 67

2-58 top tray exit sensor compile exit sensor compile tray no paper sensor top tray full sensor buffer path sensor gate sensor x’port entrance sensor fi6p027a2 see figure below from h-tra staple motor staple home sensor low staple sensor self priming sensor compile tray no paper sensor sub paddle so...

Page 68

2-59 h-tra when the finisher is designated by the command of iot, the exit gate in the iot opens and paper is fed from exit 1 on the h-tra. The h-x’port motor is activated by the trigger of iot’s regi clutch on to drive the feed belts in the h-tra. The motor power is transmitted to the two belts bet...

Page 69

2-60 the paper is further fed in the finisher by the roll assy-transfers or the buffer roll that are driven by the regi motor, and passes through the puncher. The x’port entrance sensor becomes “low” upon detecting paper. After a certain time has passed from the level transition to “h”, the regi mot...

Page 70

2-61 when printing multiple sets, while stapling the first set on the compile tray or ejecting it to the stacker tray, the first paper of the second set shall not be fed to the compile tray. To this end, when the first paper of the second set reaches the finisher, the buffer gate solenoid is activat...

Page 71

2-62 from compile tray to stacker tray stapled paper on the compile tray (stapling mode) or aligned paper (non-stapling mode) are held between the eject clamp (lowered by the eject clamp motor) and the shaft assy-eject roll. The shaft assy-eject roll is driven by the eject motor to transferred paper...

Page 72

2-63 functions of sensors along the paper path h-tra 1. H-x’port entrance sensor a photo-interrupter to detect whether paper is fed from the iot to the h-tra it turns “h” (+5 v) (light receiving) when paper enters the h-tra. 2. H-x’port exit sensor a photo-interrupter to detect whether paper passes ...

Page 73: Puncher

2-64 3. Compile exit sensor a photo-interrupter to detect whether paper passes through the compile exit sensor it turns “h” (+5 v) (light receiving) when the actuator is driven out of the sensing area by the paper. When the level tunes “h”, activates the front tamper motor and the rear tamper motor ...

Page 74: Adjusting Punching Positions

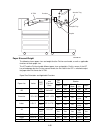

2-65 adjusting punching positions the punching positions from the paper edge in the direction of feed are determined by gently pressing the paper against the guide assy (see section 2.2). While the punching positions from the paper edge in the direction of paper width are deter- mined by the followi...

Page 75: Detecting Punch Dust Full

2-66 detecting punch dust full punch dust is stored in the punch dust box. A sensor is provided to detect punch dust full. When punch dust full is detected, it is notified to the operator only once. Even if punch dust is not removed, the finisher can still punch paper. However it can spread punch du...

Page 76

2-67 1. Side regi sensor 1 a reflective photo-sensor to detect the side edge of large paper paper side edge is detected by on/off of this sensor while shifting the puncher (containing this sensor) in the direction of paper width. The sensor remains at “h” (+5 v) while paper is present, and turns “l”...

Page 77: Compile Tray

2-68 compile tray this section describes the operation of the compile tray that aligns the paper edge transferred from the puncher. Outline of operation when paper is fed onto the compile tray, tamping operation is performed to align the paper edge in the paper width direction. When ejecting stapled...

Page 78: Tamping

2-69 when feeding large paper in the non-staple mode, there may be a misalignment depending on paper characteristics. For this reason, the default paper capacity is set to a smaller value. Compile tray paper capacity compile tray operation with multiple paper sizes when two or more paper sizes are u...

Page 79

2-70 1. Front tamper home position (front tamper home sensor position) 2. Front tamper size position 3. Front tamper offset position 4. Rear tamper home position (rear tamper home sensor position) 5. Rear tamper standby position 6. Rear tamper tamping position 7. Rear tamper offset position rear tam...

Page 80: Offsetting

2-71 the tamper positions during center tamping are shown below: 1. Front tamper home position (front tamper home sensor position) 2. Front tamper standby position 3. Front tamper tamping position 4. Front tamper offset position 5. Rear tamper home position (rear tamper home sensor position) 6. Rear...

Page 81: Stapler

2-72 during dual stapling shifts stapled sheets using the front tamper by 9 mm to the rear side before ejecting them to the stacker tray. Offsetting is not executed (0 mm) for small paper. Functions of compile tray sensors/motors 1. Compile tray no paper sensor a photo-interrupter to detect whether ...

Page 82

2-73 there are the following four stapling modes. Front staple (corner) [front corner] the stapler staples a set of paper obliquely (45 degrees) after the rear tamper aligns the paper to the front side. Rear staple (corner) [rear corner] this type of stapling is applied for paper with a width of 216...

Page 83: 0.1 Stapling One Sheet

2-74 yes: applicable no: not applicable 0.1 stapling one sheet upon receiving the stapling command from the iot with one sheet remaining on the compile tray, the finisher ejects the paper to the stacker tray without stapling it. 0.2 stapling multi-size paper when sheets with different sizes and same...

Page 84: 0.4 Stapler Operation

2-75 upper limit of compile tray paper capacity when stapling: default: 50 (variable (10 to 100) by the non-volatile memory), 0.4 stapler operation the stapler stays at the front home position, that is, at the front staple (corner) position when the power is turned on. The stapler starts stapling wh...

Page 85

2-76 stapling operation is executed by closing the stapler head. The stapler head, containing the staple motor, the staple home sensor, the self priming sen- sor, and the low staple sensor, is activated by the staple motor. Forward (clockwise) rotation of the motor drives the stapler to staple a set...

Page 86: Operation

2-77 operation the top tray contains the top tray full sensor to detect the paper stack volume in the top tray. Once the sensor detects “full stack” (500 sheets) of the top tray, ejection of paper to the top tray is inhibited until “full stack” is reset. Functions of top tray sensors 1. Top tray exi...

Page 87

2-78 sors turn “h”. The height of paper or the stacker tray is detected based on the levels of these sensors. This sensor information is used to control the elevator motor. The motor is activated to move the stacker tray while the stacker height sensor 1 turns into the light blocking state to the li...

Page 88: Full Stack Detection

2-79 full stack detection “full stack” is detected when paper in the stacker tray becomes full to prevent paper jam or fall- ing of paper to the floor. The stacker tray can stack up to approx. 3000 sheets. The paper volume in the stacker tray is detected at every 10% (approx. 300 sheets) and notifie...

Page 89

2-80 • a sheet of paper of less than 11 inches is stacked in the stacker tray with the staple mode changed. • an operator put a sheet (or sheets) when no paper is remaining in the stacker tray. The size and condition of paper stacked in the tray are not identified.) • paper was present in the stacke...

Page 90: Power Supply and Interlock

2-81 a dc motor to elevate or lower the eject clamp when feeding paper from the puncher to the compile tray or from the compile tray to the stacker tray 9. Set clamp home sensor a photo-interrupter to detect the set clamp home position. This sensor functions as a trigger to control on/off of the set...

Page 91

2-82 fi6p024a1 eject cover switch finisher front door switch ac lvps-c pwb main-c sensor motor +24 vdc +24 vdc +5 vdc eject cover switch finisher front cover switch interlock +24 vdc on/off iot fi6p025a1.

Page 92: Chapter 3

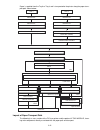

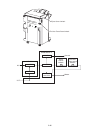

Chapter 3 wiring general wiring diagram the following describes the legend of the general wiring diagram shown on the next page. Symbols description denotes a connection between parts with harnesses and wires. A frame not having parts name inside denotes the connector (p/j). Numeric value inside imp...

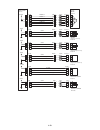

Page 93: Engine

4-2 engine ld pwb ros assy-12 pl5.1.14 fuser assy pl6.1.7 switch (front cover) pl1.1.5 sensor-photo in (oct home sensor) pl6.2.5 pwb a mcu f pl8.1.5 p/j117 10 1 power unit pl8.1.8 pwb a exit pl8.1.4 p/j613 pwba ess pl8.1.25 p/j521 p/j300 p/j301 p/j402 p/j421 p/j431 p/j432 sensor-photo in (full stack...

Page 94: Wiring Diagram Between Parts

4-3 wiring diagram between parts configuration the wiring diagram is separated into 11 sections to show detailed connection between parts. 1 power supply - connection between power unit and pwba ess - connection between power unit and pwb a exit - connection between power unit and pwb a mcu f - conn...

Page 95

4-4 tray2 - connection between pwb a mcu f and tray2 feed lift up motor - connection between pwb a mcu f and sensor (tray2 level sensor) - connection between pwb a mcu f and sensor (tray2 no paper sensor) - connection between pwb a mcu f and sensor (tray2 pre feed sensor) - connection between pwb a ...

Page 96

4-5 denotes the parts. Pl x.Y.Z implies the item "z" of plate (pl) "x.Y" in chapter 5. Parts list. Denotes functional parts attached with functional parts name. Denotes the control and its outline in pwb. Denotes a connection between parts with harnesses or wires, attached with signal name/contents....

Page 97: 1 Power Supply

4-6 1 power supply pwb a mcu f pl8.1.5 power unit pl8.1.8 pwb a exit pl8.1.4 pwba ess pl8.1.25 switch-power pl8.1.2 switch (front cover) pl1.1.5 switch (lh cover) pl4.2.4 switch assy xero intlk pl5.1.4 choke coil pl8.1.9 outlet mn pl8.1.16 p/j405 2 p/j120 b1 a1 +24vdc 1 p/j405 4 p/j121 b1 a1 3 i/l +...

Page 98: 2 Fuser

4-7 • short protection (over-current protection) & over-voltage protection of power unit - each output has the short protection and over-voltage protection functions as shown on the table below: in the case of short protection (over-current protection) cut off: after the clearance of the shortage, p...

Page 99: 3 Paper Feed

4-8 3 paper feed signal line name description main heater on(h)+5vdc on/off control signal of main heater in fuser assy sub heater1 on(h)+5vdc on/off control signal of sub heater1 in fuser assy sub heater2 on(h)+5vdc on/off control signal of sub heater2 in fuser assy relay on(l)+24vdc on/off control...

Page 100: 4 Xero / Deve

4-9 4 xero / deve signal line name description regi clutch on(l)+24vdc clutch asy regi h(regi clutch) on/off control signal regi sensor paper sensed(l)+5vdc, paper detection signal by snr assy regi in regis- tration l/h lower cover open(h)+5vdc l/h lower cover open/close detection signal by switch-i...

Page 101

4-10 pwb a mcu f pl8.1.5 p/j403 a1 a2 pshv-y2 pl7.1.7 p/j500 15 14 i/l +24vdc i/l +24vdc a3 a4 13 12 rtn rtn a5 a6 a7 a8 a9 a10 a11 a12 a13 a14 a15 11 10 9 8 7 6 5 4 3 2 1 dts on btr monitor agnd btr sel btr remote bcr ac clock bcr ac on bcr dc remote deve bias dc remote deve bias dc on cru pl5.1.15...

Page 102: 5 Drive / Crum

4-11 5 drive / crum signal line name description dts on on/off control signal of dts output btr monitor voltage monitor signal of btr output (analog value) btr sel polarity switching signal of btr output btr remote current control signal of btr dc output (analog value) bcr ac clock clock signal od b...

Page 103

4-12 pwb a mcu f pl8.1.5 p/j408 14 13 12 11 10 2 1 9 8 3 7 6 5 4 motor assy 242 pl7.1.7 p/j214 1 2 3 4 5 13 14 6 7 12 8 9 10 11 i/l +24vdc i/l +24vdc rtn rtn +5vdc fuser fan on fuser fan fail m/c clock main motor ref clock main motor on(l)+5vdc drum motor fail(h)+5vdc drum motor ref clock drum motor...

Page 104: 6 Tray1

4-13 6 tray1 signal line name description fuser fan on high speed / low speed switching signal of fan fuser fuser fan fail(h)+5vdc fail detection signal of fan fuser m/c clock clock signal from main motor in motor assy 242 main motor ref clock reference clock signal to main motor in motor assy 242 m...

Page 105: 7 Tray2

4-14 • paper size detection - the on/off pattern of each switch (s1-s5) of switch assy p s and the relation of paper size and the output voltage of tray1 size switch signal are as follows. 7 tray2 signal line name description fmot1 a, fmot1 b, fmot1 /a, fmot1 /b tray1 feed lift up motor exciting sig...

Page 106

4-15 pwb a mcu f pl8.1.5 p/j409 b1 p602 15 j602 1 p/j202 6 tray2 feed lift up motor pl2.3.2 fmot2 /b 5 4 3 2 1 b2 b3 b4 b5 b6 m 14 2 13 3 12 4 11 5 10 6 fmot2 /a +24vdc +24vdc fmot2 b fmot2 a +24vdc sensor (tray2 level sensor) pl2.3.14 p/j102 3 2 1 p602 9 j602 7 8 8 7 9 p/j409 b7 b8 b9 +5vdc tray2 l...

Page 107: 8 Mpf

4-16 • paper size detection - the on/off pattern of each switch (s1-s5) of switch assy p s and the relation of paper size and the output voltage of tray2 size switch signal are as follows. 8 mpf signal line name description fmot2 a, fmot2 b, fmot2 /a, fmot2 /b tray2 feed lift up motor exciting signa...

Page 108

4-17 pwb a mcu f pl8.1.5 p/j411 4 +24vdc 5 pick up solenoid on(l)+24vdc p205 2 1 1 2 solenoid pick up pl3.2.15 j411 1 2 3 j107 1 2 3 sensor assy-msi pl3.3.10 msi size sensor signal sg +5vdc p605 8 j605 1 7 2 6 3 +5vdc +24vdc p609 3 j609 1 2 2 1 3 p605 5 j605 4 4 5 p/j108 3 2 1 p605 3 j605 6 2 7 1 8 ...

Page 109

4-18 ◆ mpf paper size detection in the main scan direction the paper guide of mpf is interlocked with, variable resistance of sensor assy-mpf changes, and the output voltage of mpf size sensor signal changes. The relation between the output voltage of mpf size sensor signal and paper size is shown b...

Page 110: 9 Ros

4-19 9 ros 10 exit signal line name description /xdata1, xdata1, /xdata2, xdata2 pixel data signals to make ld (laser diodes) in ros assy-12 emit the light ros valid compulsive putting-out-lights signal of ld in ros assy- 12 ld+5vdc power supply voltage for ld in ros assy-12 sos signal scanning star...

Page 111

4-20 signal line name description oct home sensed(l)+5vdc oct home position detection signal by sensor- photo in (oct home sensor) full stack sensed(l)+5vdc stacker tray paper full detection signal by sensor- photo in (full stack sensor) offset motor a, offset motor b, offset motor /a, offset motor ...

Page 112: 11 Controller

4-21 11 controller signal line name description command (ess to engine) communication signal of pwba ess (ess) and pwb a mcu f (engine) status (engine to ess) status ready command ready sclock fwe top bd start pred engine ready ess ready ready pwba ess pl8.1.25 pwb a mcu f pl8.1.5 p/j402 1 2 3 4 5 6...

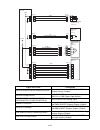

Page 113: 1000 Sheet Feeder

4-22 1000 sheet feeder general wiring diagram wiring diagram between parts configuration the wiring diagram is separated into 3 sections to show detailed connection between parts. 1 drive - connection between tray module pwb and clutch (takeaway clutch) - connection between tray module pwb and main ...

Page 114

4-23 - connection between tray module pwb and pwb a mcu f 2 tray3 - connection between tray module pwb and tray3 feed lift up motor - connection between tray module pwb and sensor (tray3 level sensor) - connection between tray module pwb and sensor (tray3 no paper sensor) - connection between tray m...

Page 115: 1 Drive

4-24 1 drive denotes the control and its outline in pwb. Denotes a connection between parts with harnesses or wires, attached with signal name/contents. Denotes the function, and logic value of the signal to operate the function (low: l, high: h). The given voltage is for signal in high status. The ...

Page 116

4-25 tray module pwb pl20.6.1 p/j522 9 +24vdc 8 take away clutch on(l)+24vdc takeaway clutch pl20.6.2 p/j554 2 1 fs812 1 fs813 1 sg left cover open(h)+5vdc left cover interlock switch pl20.5.27 +24vdc fi72002aa p/j522 7 6 2 1 p822 1 2 5 4 3 2 1 p/j826 1 2 3 4 5 6 7 takeaway motor pl20.6.7 m +24vdc r...

Page 117: 2 Tray3

4-26 2 tray3 signal line name description takeaway clutch on(l)+24vdc takeaway clutch on/off control signal takeaway motor on(l)+5vdc takeaway motor on/off control signal takeaway motor clock clock signal to takeaway motor m/c clock clock signal from takeaway motor left cover open(h)+5vdc left cover...

Page 118

4-27 tray module pwb pl20.6.1 p/j549 b1 p661b 15 j661b 1 p/j220b 6 tray3 feed lift up motor pl20.4.2 fmot3 /b 5 4 3 2 1 b2 b3 b4 b5 b6 m 14 2 13 3 12 4 11 5 10 6 fmot3 /a +24vdc +24vdc fmot3 b fmot3 a +24vdc sensor (tray3 level sensor) pl20.4.14 p/j101b 3 2 1 p661b 9 j661b 7 8 8 7 9 p/j549 b7 b8 b9 ...

Page 119: 3 Tray4

4-28 paper size detection - the on/off pattern of each switch (s1-s5) of tray3 paper size switch and the relation of paper size and the output voltage of tray3 size switch signal are as fol- lows. 3 tray4 signal line name description fmot3 a, fmot3 b, fmot3 /a, fmot3 /b tray3 feed lift up motor exci...

Page 120

4-29 tray module pwb pl20.6.1 p/j549 p6614 15 j661a 1 p/j220a 6 tray4 feed lift up motor pl20.4.2 fmot4 /b 5 4 3 2 1 a2 a3 a4 a5 a6 m 14 2 13 3 12 4 11 5 10 6 fmot4 /a +24vdc +24vdc fmot4 b fmot4 a +24vdc sensor (tray4 level sensor) pl20.4.14 p/j101a 3 2 1 p661a 9 j661a 7 8 8 7 9 p/j549 a7 a8 a9 +5v...

Page 121: Duplex

4-30 ◆ paper size detection the on/off pattern of each switch (s1-s5) of tray4 paper size switch and the relation of paper size and the output voltage of tray4 size switch signal are as follows. Duplex general wiring diagram the following describes the legend of the general wiring diagram shown on t...

Page 122

4-31 a frame not having parts name inside denotes the connector (p/j). Numeric value inside implies the connector number. A frame of broken line denotes the connector (p/j) written in several places separately. Numeric value inside implies the connector number. A frame having parts name inside denot...

Page 123: Wiring Diagram Between Parts

4-32 wiring diagram between parts configuration the wiring diagram is separated into 1 sections to show detailed connection between parts. • 1 duplex - connection between pwba duplex and sensor-photo in (duplex sensor) - connection between pwba duplex and switch-i/l,cab (duplex open switch) - connec...

Page 124: 1 Duplex

4-33 1 duplex denotes functional parts attached with functional parts name. Denotes the control and its outline in pwb. Denotes a connection between parts with harnesses or wires, attached with signal name/contents. Denotes the function, and logic value of the signal to operate the function (low: l,...

Page 125

4-34 signal line name description duplex sensor paper sensed(l)+5vdc paper detection signal by sensor-photo in (duplex sensor) in duplex duplex open(h)+5vdc duplex cover open/close detection signal by switch-i/l,cab (duplex open switch) duplex motor a, duplex motor b, duplex motor /a, duplex motor /...

Page 126: Exit

4-35 exit general wiring diagram the following describes the legend of the general wiring diagram shown on the next page. Symbols description denotes a connection between parts with harnesses and wires. A frame not having parts name inside denotes the connector (p/j). Numeric value inside implies th...

Page 127: Wiring Diagram Between Parts

4-36 wiring diagram between parts configuration the wiring diagram is separated into 2 sections to show detailed connection between parts. • 1 motor / solenoid - connection between pwb a exit and motor assy-offset pwb a exit pl8.1.4 p/j433 motor assy-offset pl24.2.30 p/j606a p/j207 motor assy exit 2...

Page 128

4-37 - connection between pwb a exit and motor assy exit 2 - connection between pwb a exit and solenoid assy (exit gate solenoid) - connection between pwb a exit and solenoid assy fu (face up gate solenoid) • 2 sensor / fan - connection between pwb a exit and sensor-photo in (oct home2 sensor) - con...

Page 129: 1 Motor / Solenoid

4-38 1 motor / solenoid denotes the function, and logic value of the signal to operate the function (low: l, high: h). The given voltage is for signal in high status. The arrow indicates the direction of signal. Denotes the function, and logic value of the signal when the func- tion operated (low: l...

Page 130: 2 Sensor / Fan

4-39 2 sensor / fan signal line name description offset motor2 a, offset motor2 b, offset motor2 /a, offset motor2 /b motor assy-offset exciting signal exit motor a, exit motor b, exit motor /a, exit motor /b, motor assy exit 2 exciting signal exit gate solenoid on(l)+24vdc solenoid assy (exit gate ...

Page 131

4-40 pwb a exit pl8.1.4 p/j111 3 1 2 p/j434 1 2 +5vdc oct2 home sensed(l)+5vdc +5vdc sensor-photo in (oct2 home sensor) pl24.2.35 p606b 1 j606b 16 2 15 sj1 1 p/j112 3 1 2 p/j434 3 4 exit2 paper sensed(l)+5vdc +5vdc sensor-photo in (exit2 sensor) pl24.2.35 p606b 3 j606b 14 4 13 p/j113 3 1 2 p/j434 5 ...

Page 132: Finisher

4-41 finisher general wiring diagram the following describes the legend of the general wiring diagram shown on the next page. Signal line name description oct2 home sensed(l)+5vdc oct2 home position detection signal by sensor- photo in (oct2 home sensor) exit2 paper sensed(l)+5vdc paper detection si...

Page 133

4-42 configuration the wiring diagram is separated into 10 sections to show detailed connection between parts. Sensor (punch full sensor) pl25.7.26 h-transport motor pl25.3.7 pwb a mcu f pl8.1.5 p/j400 pwb main-c pl25.14.5 lvps-c pl25.14.9 p/j8300 pwb h-tra pl25.14.3 p/j502 p/j8315 p/j505 p/j8314 in...

Page 134

4-43 • 1 power supply - connection between pwb main-c and pwb a mcu f - connection between pwb main-c and lvps-c - connection between pwb main-c and pwb t-tra - connection between pwb main-c and interlock switch (front door switch) - connection between pwb main-c and sensor assy (eject switch) • 2 h...

Page 135

4-44 • 6 motor / clutch / solenoid - connection between pwb main-c and motor assy-dc (eject clamp motor) - connection between pwb main-c and clutch z34 (set clamp clutch) - connection between pwb main-c and solenoid assy (sub paddle solenoid) - connection between pwb main-c and bracket assy sol (tra...

Page 136

4-45 denotes pin yy and jack yy of the connector pxx and jxx. Denotes the parts. Pl x.Y.Z implies the item "z" of plate (pl) "x.Y" in chapter 5. Parts list. Denotes functional parts attached with functional parts name. Denotes the control and its outline in pwb. Denotes a connection between parts wi...

Page 137: 1 Power Supply

4-46 1 power supply rtn denotes the return. Symbols description +24vdc supply pwb main-c pl25.14.5 lvps-c pl25.14.9 j2 1 4 p/j502 1 2 5 6 p/j8315 1 4 2 5 +24vdc +24vdc rtn rtn p/j505 3 4 j8315 3 6 lvps sq lvps sq on/off pwb a mcu f pl8.1.5 interlock switch pl25.5.2 j8365 2a 2b j8314 3 2 sg j8365 1a ...

Page 138: 2 H-Transport

4-47 2 h-transport signal line name description lvps sq on/off control signal of lvps-c (finisher) from pwb a mcu f (engine) fuser exit (fuser exit paper sensed(h)+5vdc) paper detection signal in fuser by fuser exit sensor in fuser assy (engine->finisher) regi clutch on (regi clutch on(l)+5vdc) clut...

Page 139

4-48 3 sensor (paper feed section) signal line name description h-transport motor a, h-transport motor b, h-transport motor /a, h-transport motor /b h-transport motor exciting signal entrance sensor paper sensed(l)+5vdc paper detection signal by h-transport entrance sensor in h-transport exit sensor...

Page 140

4-49 signal line name description buffer path paper sensed(l)+5vdc paper detection signal by sensor assy (buffer path sensor) in buffer path top tray full sensed(l)+5vdc top tray paper full detection signal by sensor (top tray full sensor) top tray exit paper sensed(l)+5vdc discharge paper detection...

Page 141: 4 Sensor (Exit Section)

4-50 4 sensor (exit section) pwb main-c pl25.14.5 sensor (eject clamp sensor) pl25.9.13 p/j8324 1 2 3 p/j8302b 8 7 6 +5vdc eject clamp up(l)+5vdc sg +5vdc sensor (stacker encode sensor) pl25.6.17 p/j8328 1 2 3 p/j8302b 14 13 12 +5vdc stacker encode sensor sensed(l)+5vdc sg +5vdc sensor (set clamp ho...

Page 142: 5 Motor

4-51 5 motor signal line name description upper limit sensed(l)+5vdc maximum detection signal at the time of stack tray rise by sensor (upper limit sensor) stacker paper sensed(l)+5vdc paper detection signal in stack tray by sen- sor (stacker no paper sensor) stacker encode sensor sensed(l)+5vdc enc...

Page 143: 6 Motor / Clutch / Solenoid

4-52 6 motor / clutch / solenoid signal line name description exit motor a, exit motor /a, exit motor b, exit motor /b motor assy (exit motor) exciting signal regi motor a, regi motor /a, regi motor b, regi motor/b motor assy (regi motor) exciting signal eject motor a, eject motor /a, eject motor b,...

Page 144

4-53 pwb main-c pl25.14.5 p/j8304 31 33 p/j8339 2 1 motor assy -dc (eject clamp motor) pl25.9.11 m eject clamp motor ccw on(h)+24vdc eject clamp motor cw on(h)+24vdc p/j8304 20 22 j8338b 1 2 2 1 clutch z34 (set clamp clutch) pl25.10.15 set clamp clutch on(l)+24vdc i/l +24vdc interlock +24vdc p/j8304...

Page 145: 7 Tamper

4-54 7 tamper signal line name description eject clamp motor ccw on(h)+24vdc ccw direction rotation on/off control signal of motor assy-dc (eject clamp motor) (eject clamp up/down) eject clamp motor cw on(h)+24vdc cw direction rotation on/off control signal of motor assy-dc (eject clamp motor) (reve...

Page 146: 8 Stapler

4-55 8 stapler signal line name description rear tamper motor a, rear tamper motor /a, rear tamper motor b, rear tamper motor /b motor assy (rear tamper motor) exciting signal front tamper motor a, front tamper motor /a, front tamper motor b, front tamper motor /b motor assy (front tamper motor) exc...

Page 147: 9 Puncher1

4-56 9 puncher1 signal line name description stapler home position sensed(l)+5vdc stapler home position detection signal by sensor (stapler move home position sensor) low staple sensed(l)+5vdc detection signal of the needle of stapler by low staple sensor in stapler assy. Staple ready sensed(l)+5vdc...

Page 148: 10 Puncher2

4-57 10 puncher2 signal line name description punch box set(l)+5vdc punch box wearing direction signal by sensor (punch box set sensor) puncher home sensed(l)+5vdc puncher home position detection signal by sen- sor (puncher move home sensor) side regi sensor2 sensed(l)+5vdc paper detection signal by...

Page 149

4-58 signal line name description punch move motor a, punch move motor /a, punch move motor b, punch move motor /b bracket assy-motor,punch exciting signal puncher motor ccw on(h)+24vdc ccw direction rotation on/off control signal of motor assy (puncher motor) (it moves to the puncher rear side) pun...

Page 150: Hcf

4-59 hcf general wiring diagram the following describes the legend of the general wiring diagram shown on the next page. Symbols description denotes a connection between parts with harnesses and wires. A frame not having parts name inside denotes the connector (p/j). Numeric value inside implies the...

Page 151: Wiring Diagram Between Parts

4-60 wiring diagram between parts configuration the wiring diagram is separated into 3 sections to show detailed connection between parts. • 1 switch - connection between pwb assy and pwb a mcu f - connection between pwb assy and sw il assy docking - connection between pwb assy and switch (top inter...

Page 152

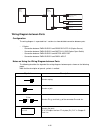

4-61 - connection between pwb assy and sensor assy (hcf pre feed sensor) - connection between pwb assy and sensor-photo in (hcf no paper sensor) notes on using the wiring diagram between parts the following describes the legend of the wiring diagrams between parts shown on the following pages. Note ...

Page 153: 1 Switch

4-62 1 switch denotes a connection between wires. I/l +24vdc denotes dc voltage when the interlock switch in hnb mcu with cpu turns on +5vdc +3.3vdc denotes dc voltage. Sg denotes signal ground. Ag denotes analog ground. Rtn denotes the return. Symbols description.

Page 154: 2 Sensor

4-63 2 sensor signal line name description docking switch close(l)+5vdc wearing detection signal of hcf and engine by sw il assy docking Åi low Åf wearing Åj engine to hcf communication signal of pwb assy(hcf) and pwb a mcu f (engine) (engine->hcf) hcf to engine communication signal of pwb assy(hcf)...

Page 155

4-64 pwb assy pl22.8.1 sensor (hcf size sensor l) pl22.1.4 pf51 1 jf51 3 2 2 3 1 p/jf01 12 11 10 +5vdc hcf size sensor l sensed(l)+5vdc sg +5vdc sensor (hcf size sensor r) pl22.1.4 pf52 1 jf52 3 2 2 3 1 p/jf01 9 8 7 +5vdc hcf size sensor r sensed(l)+5vdc sg +5vdc sensor (hcf tray set sensor) pl22.1....

Page 156: 3 Sensor/motor/solenoid

4-65 • paper size detection - the on/off pattern of hcf size sensor l and hcf size sensor r and the relation of paper size are as follows. 3 sensor/motor/solenoid signal line name description hcf size sensor l sensed(l)+5vdc hcf size sensor l on/off detection signal hcf size sensor r sensed(l)+5vdc ...

Page 157

4-66 pwb assy pl22.8.1 p/jf06 5 p/jf58 6 motor assy hcf (hcf feed motor) pl22.4.2 hcf feed motor nb 5 4 3 2 1 4 6 2 3 1 m hcf feed motor na +24vdc +24vdc hcf feed motor b hcf feed motor a +24vdc sensor-photo in (hcf level sensor) pl22.5.16 pf56b 1 jf56b 6 2 5 3 4 p/jf02 3 2 1 +5vdc hcf lift up(h)+5v...

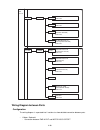

Page 158: Tandem Tray

4-67 tandem tray general wiring diagram the following describes the legend of the general wiring diagram shown on the next page. Signal line name description hcf feed motor a, hcf feed motor na, hcf feed motor b, hcf feed motor nb, hcf feed motor exciting signal hcf t/a motor a, hcf t/a motor na, hc...

Page 159: Wiring Diagram Between Parts

4-68 wiring diagram between parts configuration the wiring diagram is separated into 3 sections to show detailed connection between parts. • 1 drive - connection between tray module pwb and clutch (takeaway clutch) - connection between tray module pwb and main motor - connection between tray module ...

Page 160

4-69 - connection between tray module pwb and sensor (tray3 level sensor) - connection between tray module pwb and sensor (tray3 no paper sensor) - connection between tray module pwb and sensor (tray3 pre feed sensor) - connection between tray module pwb and tray3 paper size switch - connection betw...

Page 161: 1 Drive

4-70 1 drive denotes a connection between parts with harnesses or wires, attached with signal name/contents. Denotes the function, and logic value of the signal to operate the function (low: l, high: h). The given voltage is for signal in high status. The arrow indicates the direction of signal. Den...

Page 162

4-71 tray module pwb pl21.8.5 p/j522 9 +24vdc 8 take away clutch on(l)+24vdc takeaway clutch pl21.8.7 p/j554 2 1 fs812 1 fs813 1 sg left cover open(h)+5vdc left cover interlock switch pl21.7.15 +24vdc fi72102aa p/j522 7 6 2 1 p822 1 2 5 4 3 2 1 p/j826 1 2 3 4 5 6 7 takeaway motor pl21.8.3 m +24vdc r...

Page 163: 2 Tray3

4-72 2 tray3 signal line name description takeaway clutch on(l)+24vdc takeaway clutch on/off control signal takeaway motor on(l)+5vdc takeaway motor on/off control signal takeaway motor clock clock signal to takeaway motor m/c clock clock signal from takeaway motor left cover open(h)+5vdc left cover...

Page 164

4-73 tray module pwb pl21.8.5 p/j549 b1 p661b 15 j661b 1 p/j220b 6 tray3 feed lift up motor pl21.6.2 fmot3 /b 5 4 3 2 1 b2 b3 b4 b5 b6 m 14 2 13 3 12 4 11 5 10 6 fmot3 /a +24vdc +24vdc fmot3 b fmot3 a +24vdc sensor (tray3 level sensor) pl21.6.14 p/j101b 3 2 1 p661b 9 j661b 7 8 8 7 9 p/j549 b7 b8 b9 ...

Page 165: 3 Tray4

4-74 paper size detection - the on/off pattern of each switch (s1, s2) of tray3 paper size switch and the relation of paper size and the output voltage of tray3 size switch signal are as fol- lows. 3 tray4 signal line name description fmot3 a, fmot3 b, fmot3 /a, fmot3 /b tray3 feed lift up motor exc...

Page 166

4-75 tray module pwb pl21.8.5 p/j549 p6614 15 j661a 1 p/j220a 6 tray4 feed lift up motor pl21.6.2 fmot4 /b 5 4 3 2 1 a2 a3 a4 a5 a6 m 14 2 13 3 12 4 11 5 10 6 fmot4 /a +24vdc +24vdc fmot4 b fmot4 a +24vdc sensor (tray4 level sensor) pl21.6.14 p/j101a 3 2 1 p661a 9 j661a 7 8 8 7 9 p/j549 a7 a8 a9 +5v...

Page 167

4-76 paper size detection - the on/off pattern of each switch (s1, s2) of tray4 paper size switch and the relation of paper size and the output voltage of tray4 size switch signal are as fol- lows. Signal line name description fmot4 a, fmot4 b, fmot4 /a, fmot4 /b tray4 feed lift up motor exciting si...

Page 168: Chapter 4

Chapter 4 plug/jack engine connector [p (plug) / j (jack)] list of p/j p/j coordinat es remarks 1 d-204 connects power unit and main switch harness assembly 2 d-243 connects power unit and finisher outlet 3 d-245 connects power unit and heater harness assembly 6 e-245 connects power unit and fuser a...

Page 169

5-2 133 h-181 connects tray 1 pre feed sensor and tray 1 feeder harness assembly 134 h-181 connects tray 2 pre feed sensor and tray 2 feeder harness assembly 140 f-123 connects ros and ros harness assembly 150 g-166 connects hum & temp sensor and regi harness assembly 160 f-123 connects ros and ros ...

Page 170

5-3 p/j layout diagram 601 c-183 connects tray 1 feeder harness assembly and feeder harness assembly 602 c-184 connects tray 2 feeder harness assembly and feeder harness assembly 605 i-199 connects mpf assembly and mpf harness assembly 606 g-195 connects exit 2 harness assembly and exit harness asse...

Page 171

5-4 a 102 103 104 105 106 107 108 109 110 111 112 113 114 115 101 b c d e f g h i j k l fi40001ac 127 221 125 500 610 216.

Page 172

5-5 a 117 118 119 120 121 122 123 124 125 126 127 128 129 130 116 b c d e f g h i j k l fi40002ab 170 140 160 620 126 430 432 434 433 431 130 exit pwb.

Page 173

5-6 a 132 133 134 135 136 137 138 139 140 141 142 143 144 145 131 b c d e f g h i j k l fi40003aa 600 131 132 133 117 118 20 21 22 no.1 oct unit fuser assembly.

Page 174

5-7 a 147 148 149 150 151 152 153 154 155 156 157 158 159 160 146 b c d e f g h i j k l fi40004aa 108 609 107 msi unit 205.

Page 175

5-8 a 162 163 164 165 166 167 168 169 170 171 172 173 174 175 161 b c d e f g h i j k l fi40005aa 150 215 104.

Page 176

5-9 a 177 178 179 180 181 182 183 184 185 186 187 188 189 190 176 b c d e f g h i j k l fi40006aa tray1 : 100 tray2 : 102 tray1 : 101 tray2 : 103 tray1 : 133 tray2 : 134 tray1 : 201 tray2 feeder assembly tray1 feeder assembly 601 106 602 608 105 tray2 : 202.

Page 177

5-10 a 192 193 194 195 196 197 198 199 200 201 202 203 204 205 191 b c d e f g h i j k l fi40007ab 206 613 120 600 204 800 605 110 109 606 214 607.

Page 178

5-11 a 207 208 209 210 211 212 213 214 215 216 217 218 219 220 206 b c d e f g h i j k l fi40008ab 407 420 421 412 401 400 416 413 417 414 415 411 409 410 405 406 402 404 403 408 419.

Page 179

5-12 a 222 223 224 225 226 227 228 229 230 231 232 233 234 235 221 b c d e f g h i j k l fi40009aa 50 72 75 74 73.

Page 180: 1000 Sheet Feeder

5-13 1000 sheet feeder connector [p (plug) / j (jack)] a 237 238 239 240 241 242 243 244 245 246 247 248 249 250 236 b c d e f g h i j k l fi40010ab 69 311 525 68 12 11 1 121 2 56 7 3 521 57 526 main switch 6.

Page 181

5-14 list of p/j p/j layout diagram p/j coordinat es remarks 101a c-304 connects level sensor 4 and tray 4 harness assembly 101b c-304 connects level sensor 3 and tray 3 harness assembly 102a d-305 connects no paper sensor 4 and tray 4 harness assembly 102b d-305 connects no paper sensor 3 and tray ...

Page 182

5-15 a 302 303 304 305 306 307 308 309 310 311 312 313 314 315 301 b c d e f g h i j k l fi40101aa tray3 : 101b tray4 : 101a tray3 : 102b tray4 : 102a tray3 : 202b tray4 feeder assembly tray3 feeder assembly tray4 : 202a 812 661b 842 661a 821 825 820 824 tray3 : 103b tray4 : 103a.

Page 183: Duplex

5-16 duplex connector [p (plug) / j (jack)] a 317 318 319 320 321 322 323 324 325 326 327 328 329 330 316 b c d e f g h i j k l fi40102aa 548 552 541 554 841 822 549a 549b 826.

Page 184

5-17 list of p/j p/j coordinat es remarks 123 d-606 connects dup sensor and dup sensor harness assembly 124 b-606 connects dup open switch and sensor harness assembly 212 c-608 connects dup motor and dup motor harness assembly 540 h-608 connects pwba dup and dup harness assembly 541 h-609 connects p...

Page 185: Exit 2

5-18 exit 2 connector [p (plug) / j (jack)] list of p/j a 602 603 604 605 606 607 608 609 610 611 612 613 614 615 601 b c d e f g h i j k l fi40501aa 542 541 124 123 540 212.

Page 186

5-19 p/j coordinat es remarks 111 d-707 connects oct home 2 sensor and exit 2 harness assembly 112 f-708 connects exit 2 sensor and exit 2 harness assembly 113 f-707 connects full stack sensor and exit 2 harness assembly 115 b-706 not used 116 c-706 connects interlock switch and exit 2 harness assem...

Page 187: Finisher

5-20 finisher connector [p (plug) / j (jack)] list of p/j a 702 703 704 705 706 707 708 709 710 711 712 713 714 715 701 b c d e f g h i j k l fi40601ab 112 111 116 115 207 210 209 208 113.

Page 188

5-21 p/j coordinat es remarks 2 e-903 connects lvps and ac inlet harness assembly 502 b-902 connects lvps and lvps harness assembly 505 b-902 connects lvps and lvps harness assembly 8300 g-894 connects pwba main-c and i/f harness assembly 8301 g-894 not connects 8302 e-895 connects pwba main-c and m...

Page 189

5-22 p/j layout diagram 8353 c-838 connects punch box set sensor and punch box set sensor harness assembly 8354 e-826 connects stapler move position sensor and staple harness assembly 8356 f-826 connects stapler unit and staple harness assembly 8357 f-826 connects stapler unit and staple harness ass...

Page 190

5-23 a 802 803 804 805 806 807 808 809 810 811 812 813 814 815 801 b c d e f g h i j k l fi40701aa 8379 8382 8381 8380

Page 191

5-24 a 817 818 819 820 821 822 823 824 825 826 827 828 829 830 816 b c d e f g h i j k l fi40702aa 8330 8331 8328 8327 8326 8365 8356 8357 8358 8354.

Page 192

5-25 a 832 833 834 835 836 837 838 839 840 841 842 843 844 845 831 b c d e f g h i j k l fi40703aa 8352 8348 8346 8347 8349 8353 8452 8345 8344 8350 8351.

Page 193

5-26 a 847 848 849 850 851 852 853 854 855 856 857 858 859 860 846 b c d e f g h i j k l fi40704aa 8339 8324 8340 8364 8320 8341 8394.

Page 194

5-27 a 862 863 864 865 866 867 868 869 870 871 872 873 874 875 861 b c d e f g h i j k l fi40705aa 8336 8361 8360 8359 8363 8362 8338 8325.

Page 195

5-28 a 877 878 879 880 881 882 883 884 885 886 887 888 889 890 876 b c d e f g h i j k l fi40706aa 8334 8335 8342 8319 8392 8432 8322 8321.

Page 196: Hcf

5-29 hcf connector [p (plug) / j (jack)] list of p/j a 892 893 894 895 896 897 898 899 900 901 902 903 904 905 891 b c d e f g h i j k l fi40707aa 8304 8308 8389 8306 8307 8300 8301 8310 8316 8314 8313 8315 8317 8311 8302 8376 8305 8309 8500 8372 8394 8373 8371 2 505 502.

Page 197: Pl 0.5 P/j Layout Diagram

5-30 pl 0.5 p/j layout diagram p/j coordinat es remarks 1 g-523 connects pwba hcf and sensor harness assembly 2 g-523 connects pwba hcf and hcf feeder 1 harness assembly 3 g-524 connects pwba hcf and hcf harness assembly 4 g-524 connects pwba hcf and hcf harness assembly 5 f-524 connects pwba hcf an...

Page 198

5-31 a 502 503 504 505 506 507 508 509 510 511 512 513 514 515 501 b c d e f g h i j k l fi40401aa 58 59 54 fs001 fs002 fs003 fs004 67 61 62 60 56.

Page 199: Tandem Tray

5-32 tandem tray connector [p (plug) / j (jack)] list of p/j p/j coordinat es remarks 101a c-404 connects level sensor 4 and tray 4 harness assembly 101b c-404 connects level sensor 3 and tray 3 harness assembly 102a d-405 connects no paper sensor 4 and tray 4 harness assembly a 517 518 519 520 521 ...

Page 200

5-33 102b d-405 connects no paper sensor 3 and tray 3 harness assembly 103a d-406 connects pre feed sensor 4 and tray 4 harness assembly 103b d-406 connects pre feed sensor 3 and tray 3 harness assembly 202a a-404 connects fmot 4 and tray 4 harness assembly 202b a-404 connects fmot 3 and tray 3 harn...

Page 201

5-34 p/j layout diagram a 402 403 404 405 406 407 408 409 410 411 412 413 414 415 401 b c d e f g h i j k l fi40301aa tray3 : 101b tray4 : 101a tray3 : 102b tray4 : 102a 812 661b 821 820 824 tray3 : 202b tray4 feeder assembly tray3 feeder assembly tray4 : 202a tray3 : 103b tray4 : 103a.

Page 202

5-35 a 417 418 419 420 421 422 423 424 425 426 427 428 429 430 416 b c d e f g h i j k l fi40302aa 554 541 822 826 549a 549b 552 548 825 661a 841 842.

Page 203

5-36.