- DL manuals

- Oki

- All in One Printer

- ES9466 MFP

- Hardware Troubleshooting Manual

Oki ES9466 MFP Hardware Troubleshooting Manual

Summary of ES9466 MFP

Page 1

Multifunctional digital color systems hardware troubleshooting guide es9466 mfp/es9476 mfp.

Page 2

©2016 oki data corporation all rights reserved under the copyright laws, this manual cannot be reproduced in any form without prior written permission of oki data..

Page 3: Preface

Preface 3 preface thank you for purchasing oki multifunctional digital systems. This manual describes how to troubleshoot the problems that could occur while you are using the equipment. Keep this manual within easy reach, and use it to configure an environment that makes the best use of the oki mfp...

Page 4

4 preface.

Page 5: Contents

Contents 5 contents preface................................................................................................................................................. 3 how to read this manual ........................................................................................................

Page 6

6 contents.

Page 7

1. Troubleshooting for the hardware this chapter describes how to troubleshoot problems with paper, toner and other finishing processes. This chapter also describes how to supply the paper, toner and staples. When this screen is displayed ................................................................

Page 8

1.Troubleshooting for the hardware 8 inner finisher hole punch unit ...........................................................................................................................84 when printed sheets overflow from the stacker ...............................................................

Page 9

When this screen is displayed 9 troubleshooting for the ha rdwa re 0. When this screen is displayed various screens are displayed on the touch panel depending on the state of the equipment. This section describes how to solve problems with some of the screen examples. Screen description / remedy a m...

Page 10

1.Troubleshooting for the hardware 10 when this screen is displayed an incorrect paper size or “ ” indicates an unsuccessful paper size detection. In this case, check the following items. Check if the paper with an unacceptable size is placed in the tray. For details about the acceptable paper size,...

Page 11

1.Troubleshooting for the hardware when this screen is displayed 11 troubleshooting for the ha rdwa re the original or copy paper is jammed. Remove it following the guidance on the touch panel. P.18 “clearing a paper jam” a cover is open. Check which cover on the touch panel and then close it secure...

Page 12

1.Troubleshooting for the hardware 12 when this screen is displayed the waste toner box is full. Replace it following the guidance on the touch panel. P.72 “replacing the waste toner box” the equipment requires adjusting by a service technician. Contact your service representative with the error cod...

Page 13

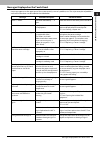

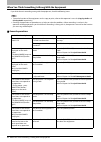

Messages displayed on the touch panel 13 troubleshooting for the ha rdwa re 0. Messages displayed on the touch panel a message appears on the upper part of the screen to notify users of a problem, etc. The major examples of problems and how to solve them are described in the table below. Message pro...

Page 14

1.Troubleshooting for the hardware 14 messages displayed on the touch panel cannot print this paper size select the other tray. Printing was attempted but failed. The paper could not be output on the stacker selected for the paper output because of a mismatch between the paper size and the stacker. ...

Page 15

1.Troubleshooting for the hardware messages displayed on the touch panel 15 troubleshooting for the ha rdwa re cannot copy check department counter the number of originals to be scanned has exceeded the limit specified with the department code during scanning. Ask your administrator for details of s...

Page 16

1.Troubleshooting for the hardware 16 messages displayed on the touch panel erasing data the data overwrite enabler is clearing the data. This message is displayed if the data overwrite enabler is installed. You can operate the equipment while the message is displayed. Check paper size setting on co...

Page 17

1.Troubleshooting for the hardware messages displayed on the touch panel 17 troubleshooting for the ha rdwa re error codes the error codes indicating the status of the equipment may appear on the touch panel. For details, please refer to the software troubleshooting guide . This original is copy pro...

Page 18: Clearing A Paper Jam

18 clearing a paper jam 0. Clearing a paper jam locating a paper jam the equipment stops copying when the original or copy paper is jammed. Paper jams are notified on the touch panel as follows: the paper jam symbol helps you locate the paper jam. 1. Radf or dsdf (lower) ( p.21) 2. Radf or dsdf (upp...

Page 19

1.Troubleshooting for the hardware clearing a paper jam 19 troubleshooting for the ha rdwa re clearing a paper jam 1 clear the paper jam. Clear the paper jam following the guidance shown on the touch panel. Press or to scroll the pages. 2 after clearing the jam, close all the opened covers. The equi...

Page 20

1.Troubleshooting for the hardware 20 clearing a paper jam if paper jams occur frequently the following are the common causes of paper jams. If the problem persists, check for the following situations. An unsuitable original is placed on the adf. Unavailable paper with the equipment is used. Paper s...

Page 21

1.Troubleshooting for the hardware clearing a paper jam 21 troubleshooting for the ha rdwa re adf radf (lower) 1 open the radf. 2 lower the green lever, open the reverse cover and remove the original. 3 close the radf. Radf (upper) 1 raise the lever and open the upper cover..

Page 22

1.Troubleshooting for the hardware 22 clearing a paper jam 2 remove the original. 3 turn the inner green dial and remove the jammed original. 4 raise the green lever and open the transport guide. 5 raise the green lever under the transport guide, and remove the original under the guide plate. 6 clos...

Page 23

1.Troubleshooting for the hardware clearing a paper jam 23 troubleshooting for the ha rdwa re 7 raise the original feeder tray, and remove the original under the tray. 8 lower the original feeder tray. 9 close the upper cover. Dsdf (lower) 1 remove the originals on the dsdf and open it. 2 push the g...

Page 24

1.Troubleshooting for the hardware 24 clearing a paper jam 3 turn the inner green dial and remove the jammed original. 4 remove the jammed originals. 5 push the green part to close the lower cover. 6 close the dsdf..

Page 25

1.Troubleshooting for the hardware clearing a paper jam 25 troubleshooting for the ha rdwa re dsdf (upper) 1 raise the lever and open the upper cover. 2 remove the jammed originals. 3 if it is not easy to remove the jammed originals under the feed roller unit, take it off. 4 remove the jammed origin...

Page 26

1.Troubleshooting for the hardware 26 clearing a paper jam 5 attach the feed roller unit. 6 remove the originals under the original feeder tray. 7 close the upper cover. Confirm that the lever of the upper cover is closed firmly..

Page 27

1.Troubleshooting for the hardware clearing a paper jam 27 troubleshooting for the ha rdwa re tray feeding portion 1 open the feeder cover on the right side. 2 remove the jammed paper from the tray and close the feeder cover. If the paper is jammed on the cover side, remove it as shown in the figure...

Page 28

1.Troubleshooting for the hardware 28 clearing a paper jam large capacity feeder 1 open the feeder cover of the large capacity feeder on the right. 2 remove the jammed paper and close the feeder cover. Paper feed pedestal 1 open the feeder cover of the paper feed pedestal on the right. 2 remove the ...

Page 29

1.Troubleshooting for the hardware clearing a paper jam 29 troubleshooting for the ha rdwa re trays 1 open the paper source tray, and remove the jammed paper. 2 check that the guide width is correct, there is no folded/curled paper or overloading, and then close the tray. Be sure that the height of ...

Page 30

1.Troubleshooting for the hardware 30 clearing a paper jam envelope tray 1 open the paper source tray, and remove the jammed paper. 2 check that the guide width is correct, there is no folded/curled paper or overloading, and then close the tray. Be sure that the height of the stacked paper does not ...

Page 31

1.Troubleshooting for the hardware clearing a paper jam 31 troubleshooting for the ha rdwa re 3 check that there is no folded/curled paper or overloading, and then close the tray of the large capacity feeder. Be sure that the height of the stacked paper does not exceed the line indicated inside of t...

Page 32

1.Troubleshooting for the hardware 32 clearing a paper jam automatic duplexing unit be careful not to let your fingers be caught between the equipment and the duplexing unit cover or automatic duplexing unit cover. This could injure you. 1 open the automatic duplexing unit cover on the right. 2 remo...

Page 33

1.Troubleshooting for the hardware clearing a paper jam 33 troubleshooting for the ha rdwa re paper transport path be careful not to let your fingers be caught between the equipment and the duplexing unit cover or automatic duplexing unit cover. This could injure you. 1 open the automatic duplexing ...

Page 34

1.Troubleshooting for the hardware 34 clearing a paper jam fuser unit be careful not to let your fingers be caught between the equipment and the duplexing unit cover or automatic duplexing unit cover. This could injure you. Do not touch the fuser unit or the metal portion around it. Since they are v...

Page 35

1.Troubleshooting for the hardware clearing a paper jam 35 troubleshooting for the ha rdwa re 3 remove the paper from the exit section. 4 when the finisher is installed, open the bridge kit cover while holding the handle. 5 remove the jammed paper. 6 when the finisher is installed, close the bridge ...

Page 36

1.Troubleshooting for the hardware 36 clearing a paper jam bridge kit 1 open the cover holding the handle of the bridge kit. 2 remove the jammed paper inside the bridge unit. If the jammed paper cannot be removed because the right side is caught by the fuser unit, follow the steps on p.34 “fuser uni...

Page 37

1.Troubleshooting for the hardware clearing a paper jam 37 troubleshooting for the ha rdwa re 3 open the cover holding the handle of the bridge unit. When the hole punch unit is installed, proceed to step 5. 4 remove the jammed paper. Proceed to step 8. When the hole punch unit is installed 5 open t...

Page 38

1.Troubleshooting for the hardware 38 clearing a paper jam 7 close the hole punch unit cover. 8 close the bridge kit cover. 9 close the upper receiving stacker of the finisher. Place your hands on the near and far side of the lever and push to close the stacker until it clicks. Be careful not to let...

Page 39

1.Troubleshooting for the hardware clearing a paper jam 39 troubleshooting for the ha rdwa re paper jam in the lower receiving stacker 1 raise the lever and open the upper receiving stacker of the finisher. 2 remove the jammed paper. 3 remove the jammed paper. If the paper is caught by the roller in...

Page 40

1.Troubleshooting for the hardware 40 clearing a paper jam 4 open the cover holding the handle of the bridge unit. When the hole punch unit is installed, proceed to step 6. 5 remove the jammed paper. Proceed to step 9. When the hole punch unit is installed 6 open the hole punch unit cover. 7 turn th...

Page 41

1.Troubleshooting for the hardware clearing a paper jam 41 troubleshooting for the ha rdwa re 8 close the hole punch unit cover. 9 close the bridge kit cover. 10 close the upper receiving stacker of the finisher. Place your hands on the near and far side of the lever and push to close the stacker un...

Page 42

1.Troubleshooting for the hardware 42 clearing a paper jam saddle stitch finisher and hole punch unit 1 raise the lever and open the upper receiving stacker of the finisher. 2 open the cover of the hole punch unit when it is installed. 3 open the front cover of the finisher. 4 remove the jammed pape...

Page 43

1.Troubleshooting for the hardware clearing a paper jam 43 troubleshooting for the ha rdwa re 5 open the cover holding the handle of the bridge unit. 6 remove the jammed paper inside the bridge unit. 7 if the paper size is small, turn the knob shown in the following figures to send the paper, and th...

Page 44

1.Troubleshooting for the hardware 44 clearing a paper jam 8 remove the jammed paper. If the paper is caught by the roller in the exit section, remove it by lifting the roller up with your fingers. 9 close the cover of the bridge unit. 10 close the upper receiving stacker of the finisher. Place your...

Page 45

1.Troubleshooting for the hardware clearing a paper jam 45 troubleshooting for the ha rdwa re be careful not to let your fingers be caught between the finisher body and the stacker (upper) of the finisher. This could injure you. The upper receiving stacker of the finisher can also be closed by press...

Page 46

1.Troubleshooting for the hardware 46 clearing a paper jam saddle stitch unit of the saddle stitch finisher 1 remove the jammed paper from the exit side of the saddle stitch unit. 2 open the front cover of the finisher. 3 holding the green knob, move the guide to the right. 4 raise the lever and ope...

Page 47

1.Troubleshooting for the hardware clearing a paper jam 47 troubleshooting for the ha rdwa re 5 open the cover of the hole punch unit when it is installed. 6 turn the knob shown in the following figures to send the paper, and then remove the jammed paper. When the hole punch unit is installed, open ...

Page 48

1.Troubleshooting for the hardware 48 clearing a paper jam 7 close the upper receiving stacker of the finisher. Place your hands on the near and far side of the lever and push to close the stacker until it clicks. Be careful not to let your fingers be caught between the finisher body and the stacker...

Page 49

1.Troubleshooting for the hardware clearing a paper jam 49 troubleshooting for the ha rdwa re 10 pull out the saddle stitch unit until it stops. Do not put your hands in the opening section (a) which is located behind the saddle stitch unit. Your hands may be caught, resulting in injury. 11 open the...

Page 50

1.Troubleshooting for the hardware 50 clearing a paper jam 14 close the transport guide. 15 holding both green knobs with your fingers, open the transport guide on the left. 16 lower the two green levers. 17 remove the paper. 18 raise the two green levers..

Page 51

1.Troubleshooting for the hardware clearing a paper jam 51 troubleshooting for the ha rdwa re 19 holding both green knobs with your fingers, close the transport guide on the left. 20 return the saddle stitch unit to its original position. 21 close the cover of the hole punch unit when it is installe...

Page 52

1.Troubleshooting for the hardware 52 clearing a paper jam inner finisher and hole punch unit 1 lift up the control panel and then open the front cover of the finisher. 2 while holding the green lever, move the finisher to the left until it stops. 3 pull down the green lever on the right-hand unit o...

Page 53

1.Troubleshooting for the hardware clearing a paper jam 53 troubleshooting for the ha rdwa re 5 return the green lever to its original position. 6 when the hole punch unit is installed and used for punching holes, while pulling the green dial toward you, turn it to align the yellow marks on the part...

Page 54

1.Troubleshooting for the hardware 54 clearing a paper jam 9 holding the green knob, open the upper cover. 10 remove the jammed paper and then close the upper cover. 11 while holding the green lever, open the hole punch unit to remove the jammed paper. 12 return the hole punch unit to its original p...

Page 55

1.Troubleshooting for the hardware clearing a paper jam 55 troubleshooting for the ha rdwa re 13 carefully return the finisher to its original position. Do not put your hand or fingers on the top of the finisher when closing it. They could be caught and this could injure you. 14 close the front cove...

Page 56

1.Troubleshooting for the hardware 56 clearing a paper jam jam when making copies or prints (using a tray) 1 clear the paper jam following the guidance shown on the touch panel. 2 open the paper source tray, check that the guide width is correct and there is no folded/curled paper or overloading, an...

Page 57

1.Troubleshooting for the hardware clearing a paper jam 57 troubleshooting for the ha rdwa re 6 press the [user] tab to enter the user menu and press [tray]. 7 press the tray button indicated in the message. 8 set the paper size again and press [ok]. For details about how to set the paper size, refe...

Page 58

1.Troubleshooting for the hardware 58 clearing a paper jam 10 confirm that the paper size is correctly detected if you selected [auto (mm)] or [auto (inch)] in step 8. The detected paper size is indicated on the tray button in the equipment status indication area on the left. An incorrect paper size...

Page 59

1.Troubleshooting for the hardware clearing a paper jam 59 troubleshooting for the ha rdwa re jam when printing from the fax 1 pull out the tray in which paper jams occurred and remove all the paper from it. If such paper jams occur although [auto (mm)] or [auto (inch)] has been selected as the pape...

Page 60: Clearing A Staple Jam

60 clearing a staple jam 0. Clearing a staple jam when a staple jam has occurred in the stapler of the finisher or saddle stitch unit, clear the jam following the procedure below. P.60 “finisher” p.65 “saddle stitch unit” finisher finisher / saddle stitch finisher 1 open the front cover of the finis...

Page 61

1.Troubleshooting for the hardware clearing a staple jam 61 troubleshooting for the ha rdwa re 4 remove the top staple sheet. 5 holding the knob, raise the guide, and return it to its original position. 6 remove the staples if they have fallen between the staple cartridge and the staple case or in t...

Page 62

1.Troubleshooting for the hardware 62 clearing a staple jam inner finisher 1 lift up the control panel and then open the front cover of the finisher. 2 while holding the green lever, move the finisher to the left until it stops. 3 open the hole punch unit while pushing the green lever. 4 remove the ...

Page 63

1.Troubleshooting for the hardware clearing a staple jam 63 troubleshooting for the ha rdwa re 5 lower the guide while holding the knob. Do not touch the stapling area. The actual needle point could cause you personal injury. 6 remove the top staple sheet. 7 holding the knob, raise the guide, and re...

Page 64

1.Troubleshooting for the hardware 64 clearing a staple jam 9 fit the staple cartridge into the stapler. Insert the cartridge until it is caught by the latch and fixed with a click. 10 return the hole punch unit to its original position. 11 carefully return the finisher to its original position. Do ...

Page 65

1.Troubleshooting for the hardware clearing a staple jam 65 troubleshooting for the ha rdwa re saddle stitch unit 1 open the front cover of the finisher, and pull out the saddle stitch unit until it stops. 2 remove the staple cartridge. 3 raise the guide while holding the knob. Do not touch the stap...

Page 66

1.Troubleshooting for the hardware 66 clearing a staple jam 5 holding the knob, lower the guide, and return it to its original position. 6 fit the staple cartridge. Insert the cartridge until it is caught by the latch and secured with a click. 7 return the saddle stitch unit to its original position...

Page 67: Replacing A Toner Cartridge

Replacing a toner cartridge 67 troubleshooting for the ha rdwa re 0. Replacing a toner cartridge when the toner cartridge runs out, the message “install new *** (color name) toner cartridge” appears. Replace the toner cartridge following the procedure below when you see this message. Never attempt t...

Page 68

1.Troubleshooting for the hardware 68 replacing a toner cartridge 3 shake the new toner cartridge strongly with its label side down to loosen the toner inside. 4 pull the seal straight out in the direction of the arrow. 5 align the new toner cartridge to the guide. Insert it up to the black line. 6 ...

Page 69

1.Troubleshooting for the hardware replacing a toner cartridge 69 troubleshooting for the ha rdwa re 7 close the front cover pressing both edges. Replacing a “near empty” toner cartridge the message “toner near empty” appears on the touch panel when there is not much toner left in a toner cartridge....

Page 70

1.Troubleshooting for the hardware 70 replacing a toner cartridge 2 press the [toner] tab. 3 press [replace toner cartridge]. 4 to replace a toner cartridge, press [yes]. To cancel, press [no]. If you press [yes], go to the next step. If you press [no], the previous screen appears..

Page 71

1.Troubleshooting for the hardware replacing a toner cartridge 71 troubleshooting for the ha rdwa re 5 press the button for the color you intend to replace. 6 to replace the toner cartridge, press [yes]. To cancel, press [no]. If you press [yes], go to the next step. If you press [no], the previous ...

Page 72

72 replacing the waste toner box 0. Replacing the waste toner box when the waste toner box becomes full, the symbol for replacement of the waste toner box blinks and the message “dispose of used toner” appears. Replace the waste toner box following the procedure below. Never attempt to incinerate wa...

Page 73

1.Troubleshooting for the hardware replacing the waste toner box 73 troubleshooting for the ha rdwa re 4 take the new waste toner box out of the carton. 5 put the used waste toner box in the plastic bag and seal it with adhesive tape. 6 clean the slit glass. Perform steps 5 to 9 on p.80 “the main ch...

Page 74: Refilling With Staples

74 refilling with staples 0. Refilling with staples refill with staples according to the following procedures when the staples in the stapler of the finisher and saddle stitch unit run out. P.74 “finisher” p.77 “saddle stitch unit” finisher finisher / saddle stitch finisher 1 open the front cover of...

Page 75

1.Troubleshooting for the hardware refilling with staples 75 troubleshooting for the ha rdwa re 5 fit the staple cartridge into the stapler. When fitting the staple cartridge, hold the green-labeled portion of the bracket securely so that the bracket will not move. Insert the cartridge until it is c...

Page 76

1.Troubleshooting for the hardware 76 refilling with staples 4 remove the staple cartridge. 5 take the empty staple case out of the staple cartridge. Pull up the empty staple case while pushing both sides as shown in the figure. 6 fit a new staple case on the staple cartridge. Push the staple case h...

Page 77

1.Troubleshooting for the hardware refilling with staples 77 troubleshooting for the ha rdwa re 8 return the hole punch unit to its original position. 9 carefully return the finisher to its original position. Do not put your hand or fingers on the top of the finisher when closing it. They could be c...

Page 78

1.Troubleshooting for the hardware 78 refilling with staples 2 remove the staple cartridges. Replace both cartridges at a time. 3 press the buttons on both sides of the cartridge. The transparent cover of the cartridge is lifted. 4 after the transparent cover is lifted, take the empty staple case ou...

Page 79

1.Troubleshooting for the hardware refilling with staples 79 troubleshooting for the ha rdwa re 6 press down the transparent cover of the cartridge. Press it down until it clicks. 7 pull out straight the seal bundling the staples. 8 fit the staple cartridge. Insert the cartridge until it is caught b...

Page 80

80 cleaning the inside of the equipment 0. Cleaning the inside of the equipment when the inside of the equipment needs to clean, the message “time for cleaning. Open the front cover and follow the guidance.” is displayed. In this case, clean the inside of the equipment following the guidance display...

Page 81

1.Troubleshooting for the hardware cleaning the inside of the equipment 81 troubleshooting for the ha rdwa re 4 place the waste toner box on a large sheet so as not to dirty the floor. Do not place the waste toner box with its collecting port face down. The waste toner may spill out from the box's c...

Page 82

1.Troubleshooting for the hardware 82 cleaning the inside of the equipment 8 insert the cleaner all the way in, and then pull it back out. Repeat this 3 times for each color. 9 attach the cleaner with its top on the right and its holding side on the left. Check that the cleaner is fixed to the cover...

Page 83

1.Troubleshooting for the hardware cleaning the inside of the equipment 83 troubleshooting for the ha rdwa re 12 press [finish]..

Page 84

84 cleaning the hole punch dust bin 0. Cleaning the hole punch dust bin when the hole punch dust bin becomes full, dispose of the paper punchings following the procedure below. Finisher / saddle stitch finisher hole punch unit 1 open the hole punch unit cover. 2 pull out the hole punch dust bin. 3 d...

Page 85

1.Troubleshooting for the hardware cleaning the hole punch dust bin 85 troubleshooting for the ha rdwa re 2 while holding the green lever, move the finisher to the left until it stops. 3 open the hole punch unit while pushing the green lever. 4 after moving the hole punch dust bin to the left, pull ...

Page 86

1.Troubleshooting for the hardware 86 cleaning the hole punch dust bin 7 return the hole punch unit to its original position. 8 carefully return the finisher to its original position. Do not put your hand or fingers on the top of the finisher when closing it. They could be caught and this could inju...

Page 87

When printed sheets overflow from the stacker 87 troubleshooting for the ha rdwa re 0. When printed sheets overflow from the stacker when thin, small size paper (a4-r/lt-r or smaller) is used, the end of the sheets may get stuck in the stacker walls. If 300 or more sheets are printed under such cond...

Page 88

1.Troubleshooting for the hardware 88 when printed sheets overflow from the stacker.

Page 89: Equipment

2. When something is wrong with the equipment try the troubleshooting tips in this chapter when you think there is something wrong with the equipment. This chapter also describes the daily care for the equipment. When you think something is wrong with the equipment .....................................

Page 90

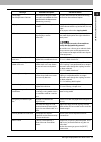

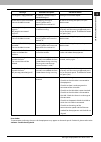

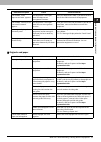

90 when you think something is wrong with the equipment 0. When you think something is wrong with the equipment if you think there is something wrong with the equipment, check the following items. To see the functions of the equipment such as copy or print, refer to their operator’s manuals ( copyin...

Page 91

2.When something is wrong with the equipment when you think something is wrong with the equipment 91 when something is wrong with th e equip m ent originals and paper the window “enter department code” appears. The equipment is managed under the department management function. Enter your department ...

Page 92

2.When something is wrong with the equipment 92 when you think something is wrong with the equipment sheets are not aligned when exiting. Sheets are not placed in the tray with correct side up for this equipment. Check the printing side of the sheets and place them correctly. Information about the p...

Page 93: Regular Maintenance

When something is wrong with th e equip m ent regular maintenance 93 0. Regular maintenance we recommend that you clean the following portions weekly so that the originals can always be scanned in unsoiled conditions. Be careful not to scratch the portions when cleaning them. When cleaning the surfa...

Page 94

2.When something is wrong with the equipment 94 regular maintenance.

Page 95: Index

Index 95 index c cleaning hole punch dust bin..................................................... 84 the main chargers and slit glass................................ 80 d deep sleep mode ............................................................ 90 department code ...................................

Page 96

96 index.

Page 97

Es9466 mfp/es9476 mfp.

Page 98

Www.Oki.Com/printing/ oki data corporation 4-11-22 shibaura, minato-ku,tokyo 108-8551, japan 46568616ee.