- DL manuals

- Oki

- Printer

- IP-7700-20

- Basic Operation Manual

Oki IP-7700-20 Basic Operation Manual

Summary of IP-7700-20

Page 1

Read this user’s guide carefully before use of this printer and handle it properly. After reading, keep it for later use. Basic operation guide 1 d o c u m e n t n u m b e r wide format solvent inkjet printer ip-7900-20/21 ip-7700-20/21 ip-7700-20/21 ip-7900-20/21 u00125348503 introduction for your ...

Page 2

Ip-7900-20/-21/ip-7700-20/-21 wide format solvent inkjet printer basic operation guide documents number u00125348503, fourth edition, december 2015 copyright© 2015 oki data infotech corporation. All rights reserved oki data infotech corporation. Reserves the right to make changes without notice to t...

Page 3: Introduction

3 introduction ip-7900-20/-21/ip-7700-20/-21 wide format solvent inkjet printer (hereafter simply called the printer.) is equipped with built-in usb interface that adopts solvent ink and supports media of up to 74-inch width. The ip-7900-20/-21/ip-7700-20/-21 wide format solvent inkjet printer basic...

Page 4: Basic Operation Guide

Ip-7900/ip-7700 basic operation guide 4 to perform your first printing basic operation guide read the basic operation guide before your first printer operation. This guide describes the basic handling and daily operation of media, printing, and maintenance. Advanced operation guide read the advanced...

Page 5: Basic Operation Guide

5 to perform your first printing basic operation guide read the basic operation guide before your first printer operation. This guide describes the basic handling and daily operation of media, printing, and maintenance. Advanced operation guide read the advanced operation guide so that you can opera...

Page 6: Table of Contents

Ip-7900/ip-7700 basic operation guide 6 table of contents introduction 3 safety precautions 7 general warning and cautions 7 handling precautions 9 manual legend (notational rules) 12 components delivered with this product 15 operating conditions 17 introduction 18 appearance / main components and t...

Page 7: Warning

7 the following symbols are used in the guides to ensure the printer’s proper operation and to prevent the printer from being damaged. Follow the instructions marked with these symbols: this symbol ( ) denotes items that require special care while executing a certain procedure or operation. This sym...

Page 8: Caution

Ip-7900/ip-7700 basic operation guide 8 do not disconnect or connect the power cord with wet hands. Doing so may lead to electric shock. Power off the printer, unplug the power cord from the power outlet, and contact your service representative in any of the following cases. Using the printer contin...

Page 9: Handling Precautions

9 handling precautions the precautions below are recommended to avoid damage to the printer and its components. Power supply 1. Install the printer near the socket. To pull out the power plug in an emergency, the power socket must be reached easily. 2. Do not share the power supply with the noise ge...

Page 10

Ip-7900/ip-7700 basic operation guide 10 media ¢ supported media the printer supports the solvent inkjet media of the types below. Note that the print condition may change depending on the environmental conditions and the media production batch. So you are recommended to test the print with the medi...

Page 11

11 ¢ other precautions ¯ media loses its color and quality with age. Check the media condition and select the media with better condition. ¯ cut the media carefully, as its paper dust may cause bubble surface at laminated. ¯ when adhesive-backed media is applied, some adhesive agent may be left on t...

Page 12: Warning

Ip-7900/ip-7700 basic operation guide 12 the notational rules such as marks, keys, lcd, and leds used for explanation in this guide are as follows: marks warning - boxes marked with a "warning" describe points of caution for avoiding serious personal injury. Caution - boxes marked with a "caution" d...

Page 13

13 this is the example page for the operation guidance. Ink media reg media m.Adv operation guide’s quick index the quick index on the right edge is a shortcut for users to access the target page. Shows the lcd on the operation panel. Shows that the lcd menu automatically changes in the arrow direct...

Page 14

Ip-7900/ip-7700 basic operation guide 14 the following components are delivered with the printer, and installed to the printer at the printer installation, check that all the components below are delivered. If any item is missing or damaged, contact your dealer from whom you purchased the printer or...

Page 15

15 components delivered with this product - with usb interface - with the feed unit and take-up reel unit printer scloller flange flange spacer tension bar (with flange: 1 piece) (with no flange 1 s: 2, ml: 1, l: 1) (with no flange 2 l (light): 1) tension bar flange fixing ring tension bar flange wi...

Page 16: Operating Conditions

Ip-7900/ip-7700 basic operation guide 16 installation and maintenance space adequate space is required around the printer for supplies replacement of consumables and parts, print processing, and ventilation during normal operation and maintenance. Keep the space shown in the figure below. 4183mm or ...

Page 17: Note

17 environmental conditions ¢ operating temperature and humidity levels use the printer within the temperature and humidity levels shown below. Temperature: 15°c to 30°c (60°f to 80°f) humidity: 30% to 70% ¯ to obtain better print quality, use the printer within a temperature range of 20 to 25°c (68...

Page 18: Introduction

Ip-7900/ip-7700 basic operation guide 18 appearance / main components and their functions printer front (take-up side) operation panel provided with leds and lcd to display printer status and keys to set functions. Media drying fan equipped to dry ink after printing. Pressure control knob switches t...

Page 19

19 introduction for your basic operation maintenance when encountering a problem appendix appearance / main components and their functions / online and offline / supported media media advance/rewind switch advances or rewinds media. Media advance/rewind switch advances or rewinds media. Flange holde...

Page 20

Ip-7900/ip-7700 basic operation guide 20 printer front (take-up side) printer rear (supply side) stopper caution be sure to unlock the stopper before closing the wiping cover and capping cover. Wiping unit removes foreign substances on the print head’s nozzle surface. Capping unit prevents the print...

Page 21: Warning

21 introduction for your basic operation maintenance when encountering a problem appendix operation panel the keys, leds and lcd are laid on the printer's operation panel of the printer as shown below. In addition, the operation panel is also equipped with a buzzer function for attention in case an ...

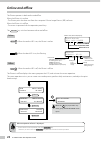

Page 22: Online and Offline

Ip-7900/ip-7700 basic operation guide 22 online and offline the printer operates in both online and offline. When the printer is in online: - the printer prints the data sent from the computer’s raster image process (rip) software. When the printer is in offline: - the menu is operated with the oper...

Page 23: Cp_Manager

The printer supports the cp_manager software that provides a general view of the printer status. The following operations can be performed with cp_manager™. Panel operations - display printer status - create media preset, input adjustment values - execute nozzle printing, adjustment patterns printin...

Page 24: Supported Media

Ip-7900/ip-7700 basic operation guide 24 vinyl vinyl is media with pvc-material surface. As a general vinyl is adhesive-backed, by peeling the release paper on the back you can stick the media easily. Depending on its gloss grade, the vinyl is classified into three: glossy vinyl (with high gloss), m...

Page 25

25 introduction for your basic operation maintenance when encountering a problem appendix.

Page 26: For Your Basic Operation

Ip-7900/ip-7700 basic operation guide 26 for your basic operation note that the media on the platen may bunch up when the front media edge reaches the floor. To avoid media wrinkle, turn off the preheater and printheater. At printing on paper-based media at setting media at taking up media in loose ...

Page 27

27 introduction for your basic operation maintenance when encountering a problem appendix note that the media on the platen may bunch up when the front media edge reaches the floor. To avoid media wrinkle, turn off the preheater and printheater. At printing on paper-based media at setting media at t...

Page 28: Front

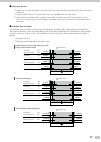

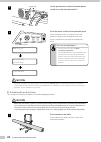

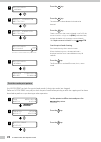

2 1 9 10 8 7 3 2 4 5 6 3 6 10 11 5 7 8 9 4 1 3 3 1 2 2 front front rear rear 1 f e e d i n g m e d i a f e e d i n g m e d i a 1m blip c h e c k e d g e g u a r d * o k ? S e l e c t m e d i a r o l l / s h e e t : r o l l … s e l e c t m e d i a m e d i a : Banner s e l e c t m e d i a m e d i a : ...

Page 29: Front

2 1 9 10 8 7 3 2 4 5 6 3 6 10 11 5 7 8 9 4 1 3 3 1 2 2 front front rear rear 1 f e e d i n g m e d i a f e e d i n g m e d i a 1m blip c h e c k e d g e g u a r d * o k ? S e l e c t m e d i a r o l l / s h e e t : r o l l … s e l e c t m e d i a m e d i a : Banner s e l e c t m e d i a m e d i a : ...

Page 30

Ip-7900/ip-7700 basic operation guide 30 to connect usb cable 1 usb connector usb 2.0 cable (b-type connector) connect the printer’s usb 2.0 cable to the usb connector at the rear center of the printer. Important! - use the supplied usb 2.0 cable. - for the usb connection and the related system, use...

Page 31: Caution

31 introduction for your basic operation maintenance when encountering a problem appendix turn the printer on with the procedure below, supply the power to the printer’s two 200v power system. Caution - do not use any power cable other than those supplied with the printer. - the supplied power cable...

Page 32: Caution

Ip-7900/ip-7700 basic operation guide 32 3 switch on (i) set the printer power switch and heater power switch to on, the side marked with i. 4 menu online heater cancel power on/off switch b o o t i n g u p . . . I n i t i a l i z i n g . . . P l e a s e w a i t l o a d m e d i a press the power swi...

Page 33: Caution

33 introduction for your basic operation maintenance when encountering a problem appendix 2 load a roll media onto the scroller flange and scroller shaft. (1) (3) (2) caution - hold the knob to move the flange stopper. Holding another part to move the flange stopper may lead to injuries. Caution - d...

Page 34

Ip-7900/ip-7700 basic operation guide 34 note: - if you keep loosening the scroller flange handle, it will block at a certain level. Unscrewing the handle beyond that limit may damage the scroller flange. Pay attention when loosening the handle. Check the flange spacer’s correct position. (3) remove...

Page 35: Caution

35 introduction for your basic operation maintenance when encountering a problem appendix ip-7700 only 3 capping unit side wiping unit side knob screw flange holder shaft holder remove the flange holder, and open the shaft holder. To open the shaft holder, loosen the knob screw. 4 ip-7700 ip-7900 pr...

Page 36: Caution

Ip-7900/ip-7700 basic operation guide 36 ip-7700 only 5 capping unit side wiping unit side knob screw flange holder shaft holder set the flange holder, and close the shaft holder. After closing the shaft holder, fasten the knob screw. 6 front cover protection bar remove the protection bar and open t...

Page 37: Blip

37 introduction for your basic operation maintenance when encountering a problem appendix 9 paper feeder printer rear insert the media end into the paper feeder, while smoothing out the media by hand to prevent wrinkles. If the media is curled - if it is hard to insert the media end into the paper f...

Page 38: Caution

Ip-7900/ip-7700 basic operation guide 38 12 supply side set the pressure to “normal” by rotating the pressure control knob counterclockwise. Point to be checked again - check that the media on the platen has no wave or wrinkle. 13 with pressing the media edge guard’s your side part, move each media ...

Page 39: • • •

39 introduction for your basic operation maintenance when encountering a problem appendix 17 s e l e c t m e d i a m e d i a : p a p e r • • • s e l e c t m e d i a m e d i a : b a n n e r select [banner] and press the key. With the or keys, select a media preset for the current media type. 18 s e t...

Page 40: L(Light)

Ip-7900/ip-7700 basic operation guide 40 to print without winding: use the l (light) tension bar use this tension bar when printing without winding, and with vinyl and solvent printing coated media. Use the tension bar with no flange 2 indicated on page 15 . 48 inches (123 cm) l(light) to print in l...

Page 41: Caution

41 introduction for your basic operation maintenance when encountering a problem appendix 20 create a slack area in the media. ♪ blip media advance/rewind switch tension bar peel roller (1) press the tension bar to the peel roller’s upper part. (2) by pressing the media advance/rewind switch, create...

Page 42: Caution

Ip-7900/ip-7700 basic operation guide 42 to load media on the take-up reel unit this section explains the procedure, taking in tension winding mode for instance. 1 load a paper tube onto the scroller flange and scroller shaft. 1 2 3 caution - hold the knob to move the flange stopper. Holding another...

Page 43

43 introduction for your basic operation maintenance when encountering a problem appendix note: - if you keep loosening the scroller flange handle, it will block at a certain level. Unscrewing the handle beyond that limit may damage the scroller flange. Pay attention when loosening the handle. (4) c...

Page 44: Caution

Ip-7900/ip-7700 basic operation guide 44 2 take-up direction switch off off set the take-up direction switch to off. Caution - if the printer processing proceeds to the next step with the take-up direction switch set to on, your hand may be caught as the scroller is not secured. 3 tension bar hook t...

Page 45: Caution

45 introduction for your basic operation maintenance when encountering a problem appendix 6 tape paper tube attach the media passed through the printer to the paper tube. (1) check the take-up direction, remove the slack of the media, and then make sure that the media position is not deviated on the...

Page 46

Ip-7900/ip-7700 basic operation guide 46 10 press the key to feed enough media to create a slack. F e e d i n g m e d i a be sure to create a sufficient slack so that you can install the tension bar at the bottom of the tension bar guide. 11 open the tension bar guide’s cover. 12 place the tension b...

Page 47: Caution

47 introduction for your basic operation maintenance when encountering a problem appendix procedure to remove media roll from the printer media at take-up side 1 take-up direction switch off off turn off the take-up direction switch. 2 open the tension bar guide’s cover. 3 place the take-up side ten...

Page 48

Ip-7900/ip-7700 basic operation guide 48 5 c l o s e c o v e r o n l i n e set the printer to offline state by pressing the o n l i n e key. 6 á i n k m e d i a r e g â ß m e d i a m . A d v à r o l l ( b a n n e r ) 1 6 2 5 m m press the key. The media advance/rewind switch is activated by selectin...

Page 49: Caution

49 introduction for your basic operation maintenance when encountering a problem appendix 8 remove the tension bar from the tension bar hook. 9 knob screw tension bar hook loosen the knob screw of each tension bar hook and extend it laterally. 10 remove the media from the printer. Caution - media ro...

Page 50: Caution

Ip-7900/ip-7700 basic operation guide 50 media at supply side 1 c l o s e c o v e r o n l i n e set the printer to offline state by pressing the o n l i n e key. 2 á i n k m e d i a r e g â ß m e d i a m . A d v à r o l l ( b a n n e r ) 1 6 2 5 m m press the key. The advance/rewind switch switch is...

Page 51: Caution

51 introduction for your basic operation maintenance when encountering a problem appendix 5 rotate the scroller flange manually to take up the media. Ip-7700 only 6 capping unit side wiping unit side knob screw flange holder shaft holder remove the flange holder, and open the shaft holder. To open t...

Page 52: Caution

Ip-7900/ip-7700 basic operation guide 52 procedure to remove scroller flange from media roll 1 scroller recommended dolly put the media roll on the table. 2 flange stopper knob remove the flange stopper. Caution - hold the knob to move the flange stopper. Holding another part to move the flange stop...

Page 53: Caution

53 introduction for your basic operation maintenance when encountering a problem appendix 1 recommended dolly scroller shaft on carrying the media alone: when carried by two or more persons rest a media roll on the table or on the recommended dolly. 2 (1) (2) knob screw remove the scroller shaft fix...

Page 54: To Print On Other Media

Ip-7900/ip-7700 basic operation guide 54 use the l (light) tension bar regardless of the media width. - the l (light) tension bar is not equipped with joints and cannot be combined with other tension bars. This bar is to be used with vinyl and solvent printing coated media only. With vinyl and solve...

Page 55: To Print On Other Media

55 introduction for your basic operation maintenance when encountering a problem appendix use the l (light) tension bar regardless of the media width. - the l (light) tension bar is not equipped with joints and cannot be combined with other tension bars. This bar is to be used with vinyl and solvent...

Page 56

Ip-7900/ip-7700 basic operation guide 56 to take up media in loose winding mode to prevent media winding deviation, set the paper tube flange to the scroller. Note that the rubber spacers are required depending on the paper tube length as explained below. Rubber spacer c (1 pc) rubber spacer a (1 pc...

Page 57

57 introduction for your basic operation maintenance when encountering a problem appendix 1 install a paper tube to the scroller. (1) (2) (3) caution - hold the knob to move the flange stopper. Holding another part to move the flange stopper may lead to injuries. Run the paper tube through the two p...

Page 58

Ip-7900/ip-7700 basic operation guide 58 2 mount the scroller to the take-up roll. Which will make the operation easier from this step. 3 by pressing the key, feed the media until the front media edge is wound on the paper tube. F e e d i n g m e d i a 4 adjust the paper tube flange position. By loo...

Page 59: Caution

59 introduction for your basic operation maintenance when encountering a problem appendix 5 paper tube flange fixing screw (at three positions) paper tube flange media fix the paper tube flange. Evenly tighten the three screws on the paper tube flange’s external side. 6 sensor window no by rotating the...

Page 60: Caution

Ip-7900/ip-7700 basic operation guide 60 caution - apply the paper tube with the same length as the media width. 1 paper tube scroller flange scroller shaft install the scroller shaft and scroller flange onto the paper tube. (1) pass the scroller shaft through the roll spacer with fixtures at its bo...

Page 61

61 introduction for your basic operation maintenance when encountering a problem appendix 4 by pressing the key, feed the media until the front media edge is wound on the paper tube. F e e d i n g m e d i a 5 tape paper tube install the printed media to the paper tube. (1) check the take-up directio...

Page 62

Ip-7900/ip-7700 basic operation guide 62 to perform double-sided printing at double-sided printing - the printer does not contain the structure to feed media with correctly applying the media advance adjustment value. So the printer cannot correctly align the first side image with the second side im...

Page 63: Caution

63 introduction for your basic operation maintenance when encountering a problem appendix 3 start printing on the first side of the media. 4 reference dashed line for cutting reference solid line to align print position on first and second sides when printing is completed, open the front cover and c...

Page 64: Caution

Ip-7900/ip-7700 basic operation guide 64 before starting the second-side printing... - go to the operation panel and change the settings of [#suction fan level] in accordance with the used media. If the media tends to stick easily, set [#suction fan level] to [low] . During second-side printing, the...

Page 65

65 introduction for your basic operation maintenance when encountering a problem appendix 10 use the advance/rewind switch to create a slack inside the peel roller. Put the supply-side tension bar on the slack of the media at the supply side. See page 41 . Printer rear (supply side) peel roller peel...

Page 66: Daily Maintenance

Ip-7900/ip-7700 basic operation guide 66 daily maintenance maintenance it must be performed every day to ensure the printer operates without trouble. Pay particularly attention to the following three items. - regularly replenish the wiper cleaning liquid and spittoon absorber liquid. - regularly cle...

Page 67

67 introduction for your basic operation maintenance when encountering a problem appendix daily maintenance / cleaning / after today’s operation no. Item daily weekly monthly quarterly a media set b capping unit c waste ink bottle d cleaning e nozzle print f wiper blade g wiper cleaning liquid h spi...

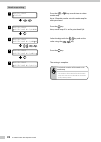

Page 68: Every Day

Every day start maintenance every week start maintenance after today’s operation protrusion appearing on the spittoon case prompts you to replenish spittoon absorber liquid. No no “x” appearing on the tray prompts you to replenish the liquid . F is the wiper blade dirty? H check the spittoon absorbe...

Page 69: Every Day

Every day start maintenance every week start maintenance after today’s operation protrusion appearing on the spittoon case prompts you to replenish spittoon absorber liquid. No no “x” appearing on the tray prompts you to replenish the liquid . F is the wiper blade dirty? H check the spittoon absorbe...

Page 70: Quarterly

Quarterly each month n is the spittoon unit dirty? Replace the spittoon unit o are the dust filters dirty? Replace the dust filters sheet mount cleaning start maintenance k are the exhaust fan filters dirty? N remove the head cleaning sheet. Exhaust fan filters m are the front cover and other extern...

Page 71: Quarterly

Quarterly each month n is the spittoon unit dirty? Replace the spittoon unit o are the dust filters dirty? Replace the dust filters sheet mount cleaning start maintenance k are the exhaust fan filters dirty? N remove the head cleaning sheet. Exhaust fan filters m are the front cover and other extern...

Page 72: Start Maintenance

Ip-7900/ip-7700 basic operation guide 72 check media wrinkles 1 c h e c k f o r m e d i a w r i n k l e check that the media is not wrinkled. If it is wrinkled, either set the media again or feed it up to an area without wrinkles. * printing on wrinkled media may damage the nozzle surfaces. Perform ...

Page 73: Caution

73 introduction for your basic operation maintenance when encountering a problem appendix 2 # s t a r t m a i n t e n a n c e > with the key select [#maintenance]. 3 # m a i n t e n a n c e > s p i t t o o n c a s e / u n i t ? Select [spittoon case/unit] and press the key. 4 o p e n c o v e r open ...

Page 74: Caution

Ip-7900/ip-7700 basic operation guide 74 9 knob discharge press the knob at the near side of the case containing the spittoon absorber liquid to open the lid, raise the front side of the spittoon absorber liquid case to discharge the spittoon absorber liquid to the backside. The discharged spittoon ...

Page 75

75 introduction for your basic operation maintenance when encountering a problem appendix replace the dust filters check that the suction fan filters are not encrusted with dust. Inside the printer, exhaust fan filters also called dust filters are attached to: - the four air exhaust outlets of the s...

Page 76

Ip-7900/ip-7700 basic operation guide 76 6 d u s t f i l t e r c h e c k e d ? Y e s : o k / n o : c a n c e l press the key. 7 when the media is installed on the take-up reel unit, remove the media. 8 by spreading an unnecessary media or cloth on the floor, prevent the floor from being smeared with...

Page 77

77 introduction for your basic operation maintenance when encountering a problem appendix 11 ② ② ② ② a ② the longer side of the dust filter is slightly longer than the sheet metal. B a b c install the new dust filters. (1) align the center of the dust filter’s longer side with the center of the shee...

Page 78

Ip-7900/ip-7700 basic operation guide 78 when replacing the exhaust fan filters from the operation panel menu, start the procedure from step 1. When replacing while executing [#start maintenance] , start the procedure in step 6. You will be prompted to replace the exhaust fan filters during the star...

Page 79: Caution

79 introduction for your basic operation maintenance when encountering a problem appendix 10 remove the old exhaust fan filters. 11 ① (1) ① (1) ② (2) longer filter guide shorter filter guide install the new exhaust fan filters. (1) with the brown magnetic side facing upward, set the filter’s one sid...

Page 80

Ip-7900/ip-7700 basic operation guide 80 carriage cleaning when executing the carriage cleaning from the operation panel menu, start the procedure from step 1. When cleaning the carriage while executing [#start maintenance] , start the procedure in step 6. You will be prompted to clean the carriage ...

Page 81: Caution

81 introduction for your basic operation maintenance when encountering a problem appendix clean the exterior (front cover) if the printer exterior is smeared, moisten a soft cloth with water or water-diluted neutral detergent, wring it, and clean the exterior with the wrung cloth. Caution - do not b...

Page 82

Ip-7900/ip-7700 basic operation guide 82 check for dirt or damage on the wiper blade when checking the wiper blade from the operation panel menu, start the procedure from step 1. When checking the wiper blade while executing [#start maintenance] , start the procedure in step 6. 1 á r e w i n d f o r...

Page 83

83 introduction for your basic operation maintenance when encountering a problem appendix 9 wiper blade wiper blade visually check the wiper blade for contamination and scratches. Ng no ng no if the wiper blade is stained or scratched, replace it. See " replace a wiper blade " on the page 118 . Repl...

Page 84: Caution

Ip-7900/ip-7700 basic operation guide 84 8 cleaning liquid port liquid level check the wiper cleaning liquid level. Check that the cleaning liquid supply hole is at the top face’s lower right of the wiping unit. Two types of bottle - wiper cleaning liquid is supplied in two different types of bottle...

Page 85: Note

85 introduction for your basic operation maintenance when encountering a problem appendix 4 # m a i n t e n a n c e > s p i t t o o n c a s e / u n i t ? Press the key. 5 # m a i n t e n a n c e > s p i t t o o n l i q u i d ? Select [spittoon liquid], and press the key. 6 o p e n c o v e r 7 s p i ...

Page 86

Ip-7900/ip-7700 basic operation guide 86 cleaning the media edge guard when executing cleaning of the media edge guards from the operation panel menu, start the procedure from step 1. When cleaning the media edge guards while executing [#start maintenance] , start the procedure in step 6. 1 á r e w ...

Page 87

87 introduction for your basic operation maintenance when encountering a problem appendix 9 dip a cleaning swab in the cap cleaning liquid. Tip - to prevent the cap cleaning liquid from being contaminated, do not soak the cleaning swab after you clean with it in the cap cleaning liquid bottle. - the...

Page 88

Ip-7900/ip-7700 basic operation guide 88.

Page 89: Caution

89 introduction for your basic operation maintenance when encountering a problem appendix 10 c a r r i a g e m o v i n g p l e a s e w a i t 11 c l e a n h e a d g u a r d ? Y e s : o k / n o : c a n c e l press the key. 12 carriage nozzle surface do not clean directly the nozzle surfaces. (execute ...

Page 90: Caution

Ip-7900/ip-7700 basic operation guide 90 4 open the front cover and then open the capping cover. 5 soak the cleaning roller in the cap cleaning liquid. Tip - to prevent the cap cleaning liquid contaminated, in the cap cleaning liquid bottle do not soak the cleaning roller after you clean the cap wit...

Page 91

91 introduction for your basic operation maintenance when encountering a problem appendix 8 c a r r i a g e m o v i n g p l e a s e w a i t 9 c a p c l e a n e d ? Y e s : o k / n o : c a n c e l press the key. A message prompting you to check the waste ink bottle is displayed. Check the waste ink b...

Page 92

Ip-7900/ip-7700 basic operation guide 92 4 # p h r e c o v e r y [ n o r m a l press the key. 5 # s e l e c t : 8 7 6 5 4 3 2 1 f b [ b o t t l e o k ? Press the key. The indicated number denotes the head to be cleaned. 6 # p h r e c 8 7 6 5 4 3 2 1 f b [ b o t t l e o k ? Press the key. Check visua...

Page 93

93 introduction for your basic operation maintenance when encountering a problem appendix 4 # n o z z l e p r i n t # e x e c u t e press the key. 5 # n o z z l e p r i n t # e x e c u t e > o k ? Press the key. 6 # n o z z l e p r i n t [ e x e c u t i n g 7 check for missing dots and incorrect pri...

Page 94

Ip-7900/ip-7700 basic operation guide 94 nozzle map setting 1 # n o z z l e p r i n t # e x e c u t e , press the , key several times to select nozzle map. Up to 10 nozzles can be set with nozzle map for each print head. 2 # n o z z l e p r i n t # n o z z l e m a p 0 1 g y 4 > 0 0 0 press the key. ...

Page 95: After Today’S Operation

95 introduction for your basic operation maintenance when encountering a problem appendix after today’s operation the printer has an internal clock which allows it to wash the print heads automatically, flushing some ink through the print heads, which keeps the print heads in good condition. To ensu...

Page 96: Caution

Ip-7900/ip-7700 basic operation guide 96 sheet mount cleaning check the cleanliness of the print heads nozzle surfaces. If dirty, clean them using sheet mount cleaning. You will be prompted to perform cleaning after one month or 0.6 km of print length. Caution - do not wipe the print heads nozzle su...

Page 97

97 introduction for your basic operation maintenance when encountering a problem appendix 1 attach the support sheet ⓒ ⓓ ⓑ ⓐ hook two holes of the support sheet to the cleaning sheet mount attachment locations (a) and (b). Keep the sheet stretched and hook the two remaining holes to the attachment l...

Page 98

Ip-7900/ip-7700 basic operation guide 98 4 apply wiper cleaning liquid area (1) area (2) area (3) apply 4 cc of wiper cleaning liquid on the head cleaning sheet surface using a dropper. Apply 1 cc four times as follows. Apply 1 cc of liquid to each of the (1), (2) and (3) areas shown in the figure t...

Page 99

99 introduction for your basic operation maintenance when encountering a problem appendix head cleaning sheet usage procedure 1 s t a r t s h e e t m o u n t c l e a n i n g ? O k / c a n c e l press the key. 2 o p e n c o v e r , i n s t a l l s h e e t c l e a n i n g p a r t open the front cover ...

Page 100: 100

Ip-7900/ip-7700 basic operation guide 100 5 s h e e t m o u n t c l e a n i n g x x : x x h a s e l a p s e d to cancel the cleaning press the cancel key. C a n c e l s h e e t m o u n t c l e a n i n g ? Press the key to confirm cancellation. Cleaning ends automatically after 8 hours. Depending on ...

Page 101: 101

101 introduction for your basic operation maintenance when encountering a problem appendix remove the head cleaning sheet 1 o p e n c o v e r , r e m o v e s h e e t c l e a n i n g p a r t open the front cover and then the wiping cover. 2 r e m o v e s h e e t c l e a n i n g p a r t , c l o s e c ...

Page 102: 102

Ip-7900/ip-7700 basic operation guide 102 before deciding that there is a serious problem with the printer, check the following items. Power is not turned on. Items to be checked corrective measures power cable connection check that the power cable is correctly plugged into the power outlet. Power s...

Page 103: 103

103 introduction for your basic operation maintenance when encountering a problem appendix although the printer is in the print mode, printing does not start with "preheating" displayed on the operation panel. Items to be checked corrective measures room temperature raise the room temperature. (reco...

Page 104: 104

Ip-7900/ip-7700 basic operation guide 104 printing is slow. The carriage sometimes moves. Items to be checked corrective measures usb connection speed when the data transmission speed is slow, the printer waits for the data with the print heads capped. Check the usb’s transmission speed. If the usb ...

Page 105: 105

105 introduction for your basic operation maintenance when encountering a problem appendix if the printer reports a media jam, follow these steps. 1 w a r n i n g ! X c l e a r m e d i a j a m x: media jam type meaning 0: media jam 0 a jam on the media feed path is invalidating the printer's normal ...

Page 106: 106

Ip-7900/ip-7700 basic operation guide 106 when the error led lights up, check the message displayed on the operation panel display. Error messages shown below are classified into two groups. Service call errors: errors that the operator (customer) cannot recover, such as hardware/software failures. ...

Page 107: 107

107 introduction for your basic operation maintenance when encountering a problem appendix c h e c k n n x x x i n k p a c k nn: ink error code xxx: ink color/location meaning a problem occurred with an ink tray, or a genuine ink pack was not identified. Action you are advised to follow the message....

Page 108: 108

Ip-7900/ip-7700 basic operation guide 108 (media jam errors) w a r n i n g ! ( 0 ) c l e a r m e d i a j a m meaning an obstruction is left in the media feed path and the printer cannot feed the media normally. Action set the pressure control knob to “open”, and open the front cover. If the media ja...

Page 109: 109

109 introduction for your basic operation maintenance when encountering a problem appendix m e d i a m i s a l i g n e d o k / c a n c e l meaning media skew was detected during printing. Action continue to print or stop printing. R o l l e n d d e t e c t e d p r i n t / c a n c e l meaning media e...

Page 110: 110

Ip-7900/ip-7700 basic operation guide 110 out of ink while printing while printing in online, the printer allows the ink pack to be replaced without suspending the print operation. When an ink pack is out of ink, the ink led goes off. You are advised to follow the message. 1 m e n u o n l i n e h e ...

Page 111: 111

111 introduction for your basic operation maintenance when encountering a problem appendix the media was skewed. The printer checks for media skew at every 3m print. If the printer detects the skew level more than specified, the print operation is suspended and the operation panel message appears so...

Page 112: 112

Ip-7900/ip-7700 basic operation guide 112 warning messages after the online printing, occasionally you may see one of the following messages appear on the operation panel display with the error led flashing , which are warning messages. If so, follow the advice in the recommendation column. P e r f ...

Page 113: 113

113 introduction for your basic operation maintenance when encountering a problem appendix move the printer if you wish to move the printer several meters on the same site, across a horizontal floor with no steps and no slopes, see the following instructions. For more difficult movement, contact you...

Page 114: 114

Ip-7900/ip-7700 basic operation guide 114 caution - do not replace the waste ink bottle during printing. - replace the waste ink bottle carefully not to bump your head on the printer upper part. - always use both hands to carefully remove and carry an oki data infotech waste ink bottle to prevent th...

Page 115: 115

115 introduction for your basic operation maintenance when encountering a problem appendix 4 slide the lever up and install a empty waste ink bottle. 5 lever waste ink bottle lower the lever, and make sure that the splash guard was lowered. Then the operation panel will request you to reset the wast...

Page 116: 116

Ip-7900/ip-7700 basic operation guide 116 at installing ink trays, be sure to insert each tray into its correct slot position of the ink box. Note that ink tray position is decided depending on its ink color. R e m o v e l g 8 i n k p a c k ink color ink color at 8-color assignment lcd indication in...

Page 117: 117

117 introduction for your basic operation maintenance when encountering a problem appendix 2 hook ink pack ink tray (2) remove the ink pack from the hook of the ink tray. 4 take a new ink pack out of the box and set it on the ink tray. Hook the two holes 1 at the ink pack’s end on the ink tray’s two...

Page 118: 118

Ip-7900/ip-7700 basic operation guide 118 caution - when the printer firmware version is 4.20 or later, use an ip7-180 wiper blade (type s). The following describes the wiper blade replacement procedure. Replace the wiper blade when the replacement message appears or scratches are found at a daily i...

Page 119: 119

119 introduction for your basic operation maintenance when encountering a problem appendix 4 install a new wiper blade. Nip the rubber of the new wiper blade with the tweezers and insert it straight downward, and install it by hooking the hole in the rubber to the plastic projection. Rubber part che...

Page 120: 120

Ip-7900/ip-7700 basic operation guide 120 item specification / function ip-7900-20/21 ip-7700-20/21 print method piezo-type color inkjet printing resolution (main scanning direction) x (subscanning direction) 360dpi × 360dpi × ddp, 360dpi × 540dpi × ddp, 540dpi × 540dpi × ddp, 720dpi × 720 dpi, 900d...

Page 121: 121

121 introduction for your basic operation maintenance when encountering a problem appendix ink pack [8-color ink] one box contains one ink pack. Type ink color quantity ip7-101 y (yellow) 1500 ml ip7-102 m (magenta) 1500 ml ip7-103 c (cyan) 1500 ml ip7-104 k (black) 1500 ml ip7-105 lc (light cyan) 1...

Page 122: 122

Ip-7900/ip-7700 basic operation guide 122 cleaning swab type content quantity ip6-147 cleaning swab 300 pieces bag 6 pieces storage liquid kit type content quantity ip7-137 storage liquid pack 8 pieces dummy subcartridge 8 pieces cleaning liquid kit type content quantity ip7-136 cleaning liquid pack...

Page 123: 123

123 introduction for your basic operation maintenance when encountering a problem appendix options exhaust attachment (ip7-013) an optional unit to attach an exhaust duct to the printer the recommended flow of air is as follows. H-104s: 1.2 to 1.8 cmm (air velocity 3.0 to 4.5 m/s) h-74s: 1.2 to 1.3 ...

Page 124: 124

Ip-7900/ip-7700 basic operation guide 124 installation caution − turn off the power switch of the printer before installing the footswitch. Plug the other connector of the footswitch in the connector of the take-up reel unit, and then screw the ground line. Loosen the screw fixing the cable clamp to...

Page 125: 125

125 introduction for your basic operation maintenance when encountering a problem appendix index a absorbent sheet …………………………… 108 absorbent sponge ………………………… 108 afterheater …………………………………… 21 b backlit banner (ff) ……………………… 24 , 55 banner ………………………………………… 24 buzzer ………………………………………… 21 c cap cleanin...

Page 126: 126

Ip-7900/ip-7700 basic operation guide 126 media drying fan ………………………… 18 , 48 media edge guard ……………………… 20 , 36 mesh banner …………………………………… 24 mesh printing kit 74 ………………………… 109 move the printer ……………………………… 97 n nozzle print …………………………………… 77 o online ………………………………………… 22 offline ………………………………………… 2...