- DL manuals

- Oki

- Printer

- Microline 4410

- Maintenance Manual

Oki Microline 4410 Maintenance Manual

Summary of Microline 4410

Page 1

40496501th rev.1 1 / 214 pacemark 4410/ microline 4410 printer maintenance manual oda/oel/int 1999. 3. 26 rev.1.

Page 2

40496501th rev.1 2 / rev.No. Date corrected items person in no. Page description of change change.

Page 3

40496501th rev.1 3 / preface this maintenance manual describes how to maintain the pacemark 4410/microline 4410 printer in the field. This manual is for customer engineers. For further information, refer to the users manual for handling or operating the equipment..

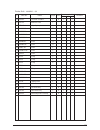

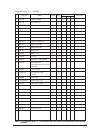

Page 4: Contents

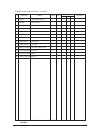

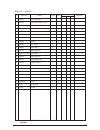

40496501th rev.1 4 / contents 1. Configuration ..................................................................................... 6 1.1 basic system configuration ............................................................... 6 1.2 printer specifications ............................................

Page 5

40496501th rev.1 5 / 3.3.16 operator board (poa printed board) ...................................................... 70 3.3.17 ribbon feed assy ................................................................................... 71 3.3.18 printing head ..................................................

Page 6

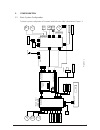

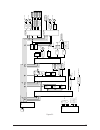

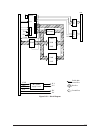

40496501th rev.1 6 ribbon feed motor ag motor power supply fan fuse holder head fan motor/sensor pcb power supply unit paper width sensor print head bail pe sensor head driver pcb main control/ motor driver pcb interface board (option) interface/motor /sensor pcb rs232c i/f ieee 1284 i/f bail motor ...

Page 7

40496501th rev.1 7 1.2 printer specifications this printer unit is composed with the following hardware. • printer mechanism • main control/motor driver board • head driver board • interface/motor/sensor board (including ieee 1284 bidirectional parallel interface and rs- 232c serial interface) • mot...

Page 8

40496501th rev.1 8 1.3 option specifications options available for pacemark 4410/ microline 4410 are as follows. (1) interface boards (a) oki-hsp (mupis) network card (b) 300/500 series serial/ hsp adapter • rs232c • rs422a • current loop.

Page 9

40496501th rev.1 9 1.4 basic specifications (1) dimensions width: 768mm(30.24inches) length: 385mm(15.16inches) height: 358mm(14.09inches) (2) weight approx. 42kg (92.6lbs) (3) form continous paper one-part paper ream weight: 45 to 90g/m 2 (12 to 24 lb) multiple-part paper max.0.79mm(0.031inches)tot...

Page 10

40496501th rev.1 10 (5) maximum number of dot columns per line a) graphics single density double density quadruple density 816 1,632 3,264 b) text print mode character pitch (cp) 10 cpi 12 cpi 15 cpi 17.1 cpi 20 cpi ml, epson, ibm utility 1,632 1,958 2,448 2,798 3,264 ml, epson, ibm nlq 3,264 3,917 ...

Page 11

40496501th rev.1 11 (11) ambient temperature and relative humidity operating non-operating storage transportation unit temperature 41 to 95 32 to 109.4 14 to 122 -40 to 158 ° f (5 to 35) (0 to 43) (-10 to 50) (-40 to 70) ( ° c) relative 20 to 80 10 to 90 5 to 95 5 to 95 %rh humidity avoid condensati...

Page 12

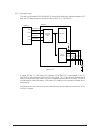

40496501th rev.1 12 2. Theory of operation 2.1 electrical operation the electrical operation of the printer circuit is described in this section. 2.1.1 summary fig. 2-1 shows the block diagram of the printer. The control board is made up of the microprocessors, peripheral circuits, drive circuits, s...

Page 13

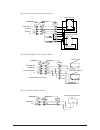

40496501th rev.1 13 figure 2.1 to alm circuit lf motor driver sub lsi #1 72v017 sub lsi #2 72v017 ag motor driver sensor, sw dip sw bail motor driver paper path switching motor driver to alm circuit to alm circuit to alm circuit to alm circuit alm circuit head/ motor driver poweroff-p sp motor sp mo...

Page 14

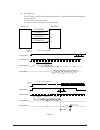

40496501th rev.1 14 (2) pg rom (ic46) this is a 256 x16 bits (4m bit) eprom with the control program for the printer stored. The mpu executes instructions under this program. The program rom is assigned to the program memory area of the mpu and is fetched by the rd signal of the mpu. The following s...

Page 15

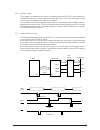

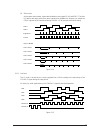

40496501th rev.1 15 figure 2.3 (3) dram(ic28) the ram is cmos dynamic ram with (256k x 16 bit) configuration, and used as buffers (such as receiving buffer, printing buffer, dll buffer and working buffer). The following shows the examples of the memory access operation. Mpu clock ale a16~bhe ad0~ad1...

Page 16

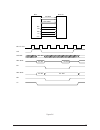

40496501th rev.1 16 figure 2.4 (4) cg rom (ic48) this is a 256k x 16 bits (4m bits) eprom with the font data for the characters stored. Cg rom is assigned to the program memory area of the mpu and is fetched by the rd signal of the mpu. The following shows the memory access operation. Mpu clock ale ...

Page 17

40496501th rev.1 17 (5) eeprom(ic40) the eeprom is a cmos serial i/o type memory which is capable of electrically erasing and writing 1,024 bits. The eeprom contains menu data. The following shows the memory access operation. Figure 2.5 nhdc lsi eeprom eepromwr-p eepromcs-p eepromrd-p eepromclk-p di...

Page 18

40496501th rev.1 18 (6) main lsi (ic38: msm91u036) msm91u036 is control lsi for head data, dc motor and modification of print data, which has the following functions. (a) head data control it distributes print data stored in the dram over wire arrangements of the print head and outputs it as dot dat...

Page 19

40496501th rev.1 19 figure 2.6 mpu clock ale a16~bhe ad0~ad15 rd ad0~ad15 wr cs ad0~ad15 a16~bhe mpu main lsi a16~bhe a0–a15 d0–d15 a0–a15 d0–d15 ale rd wr cs clk.

Page 20

40496501th rev.1 20 (7) nhdc lsi(ic27: tc190g08cf-7036) this lsi controls timer, interruption, memories, printing, external interface, motor drive interface. (a) timer control it controls the watchdog timer for detecting any out-of-control program, baud rate generator for setting the baud rate of th...

Page 21

40496501th rev.1 21 2.1.3 initialization this printer is initialized when the power is tumed on or when the i-prime-n signal is input from the host side via the parallel interface. For the initialize operation, the reset-n signal is first output from the reset circuit to reset the mpu and lsis. When...

Page 22

40496501th rev.1 22 2.1.4 interface control the pm4410 is provided with the centronics parallel interface and rs-232c serial interface as standard features.Also, it can be connected to option oki hsp or opt. Card. The interface cable can be connected simultaneously with these interfaces. These inter...

Page 23

40496501th rev.1 23 2.1.6 serial interface the mpu sets the baud rate which is selected with the menu switch for the nhdc lsi and have the serial i/f lsi to output the clock frequency of the baud rate. Input signals from the serial i/f (dsr, cts, cd and rd) are converted into ttl level ones by the l...

Page 24

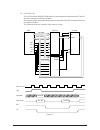

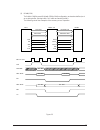

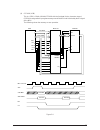

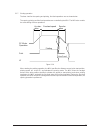

40496501th rev.1 24 2.1.7 printing operation the time chart for the spacing and printing, line feed operations are as shown below. The spacing, printing and line feed operations are controlled by the mpu. The mpu also controls the entire timing of these operations. When starting the printing operati...

Page 25

40496501th rev.1 25 2.1.8 printhead control the printhead is controlled by the main lsi and nhdc lsi. Printing is synchronized with the itout signal from the nhdc lsi. The nhdc lsi outputs the dot timing1 signals (dt1:1~18) and the dot timing2 signals (dt2:1~18), and the driver ic drives each dot ma...

Page 26

40496501th rev.1 26 figure 2.12 dot magnet drive coil current dt 1 signals (d1–d18) dt 2 signals (d1–d18) dt 2 basic drive time (1)+(2)+(3) dt 1 basic drive time (3).

Page 27

40496501th rev.1 27 2.1.9 print compensation control the print compensation can be made as shown below: (a) simultaneous compensation of the number of impact pins the nhdc lsi is provided with the compensation table for each pin to make necessary compensation. Number of impact pins few many drive ti...

Page 28

40496501th rev.1 28 (2) slit encoder as the space motor rotates, it generates feedback pulse signals spa-p and spb-p. The main lsi detects the edge pulses from these signals and multiplies the frequency to output the s720-p signals as the normalized timing to nhdc lsi to generate head drive timing. ...

Page 29

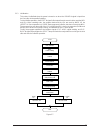

40496501th rev.1 29 2.1.12 bail, tractor switching, ag, ribbon motor control bail, tractor switching, ag and ribbon motor control is as shown below. The ag motor is locked with aghold-p. Mo ø1 mo ø2 mo ø3 mo ø4 mo ovdv aghold-p figure 2.16.

Page 30

40496501th rev.1 30 2.1.13 operation panel the clock synchronization opclk of nhdc lsi is used to input the switch data and output the led data and lcd data through the operation panel control lsi (ic1: bu6152s). A 2-byte (15 bits + 1 even parity bit) command (opdataout-p) is transmitted to the lsi ...

Page 31

40496501th rev.1 31 note: from the illustration above, you can see that the command and the command response are output at the same time. This is b ecause the bit 0 to bit 3 of opdatain-p are fixed so that the response can be returned before decoding the command. Opdataout-p opsclk-n opdatain-p opsq...

Page 32

40496501th rev.1 32 2.1.14 alarm circuits (1) driver circuit abnormality detection alarm. This protective circuite prevents secondary troubles by stopping the power supply upon detection of an abnormality in the print head, sp motor driver circuit or other motor driver circuits. This circuit monitor...

Page 33

40496501th rev.1 33 (6) head thermistor short/open alarm circuit the head thermistor voltage is monitored physically. When short or open circuit occurs, the hdthalm-n signal is input to the sub lsi (ic18) and read by the mpu. The mpu stops the printing operation, informs the host of the short/open a...

Page 34

40496501th rev.1 34 2.1.15 power supply circuit this switching type power supply circuit supplies the +5 vdc, ± 12 vdc and +44 vdc. Rectification and smoothing circuit +44 v primary switching circuit noise filter circuit alarm control circuit switching control circuit ac input monitoring circuit rec...

Page 35

40496501th rev.1 35 2.2 mechanical operation 2.2.1 printhead mechanism and operation (see figure 2-13) teh printhead is a spring charged 18-pin driving head using a permanent magnet. It is attached to the carriage, which moves in parallel with the platen. Electrically, this unit is connected to the ...

Page 36

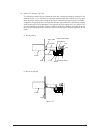

40496501th rev.1 36 (2) motion of printhead (fig.2-14) the armature usually looses the armature sprint with a permanent magnet, making it to be attracted by the core. In this time, the print wire integrated with the armature is also in reset state, when the magnet coil is energized by a print comman...

Page 37

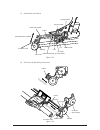

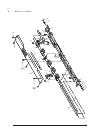

40496501th rev.1 37 2.2.2 spacing operation (see figure.2-15) spacing is effected by driving the carriage assembly installed to the main shaft and slide beam set in parallel with the platen by the dc servo motor. (a) dc motor with motor (b) carriage frame (c) carriage shaft (d) space belt (e) sensor...

Page 38

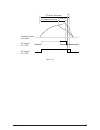

40496501th rev.1 38 2.2.3 head gap adjusting the auto gap adjusting mechanism automatically adjusts the space between the platen and print head according to the thickness of papers. This mechanism does this driving the platen back and forth with the ag motor (pulse motor), and effects the auto gap m...

Page 39

40496501th rev.1 39 (1) ag detection mechanism (2) ag sensor slit disk driving mechanism platen sheet guide eccentric collar moving direction of platen platen bearing cam roller core coil ei sensor sensor frame deflecting direction of sensor frame ag press plate carriage frame platen platen bearing ...

Page 40

40496501th rev.1 40 (3) ag detector detail drawing head ag plate paper ag sensor flame core gap ag plategap ferrite core figure 2.25.

Page 41

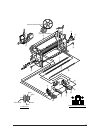

40496501th rev.1 41 2.2.4 ribbon drive (see figure) the ribbon feed mechanism feeds the ink ribbon and functions by driving the ribbon motor (pulse motor). (1) ribbon cartridge this has a mechanism of capable of printing clear characters at all times by using a one-way- feed endless ribbon. (2) feed...

Page 42

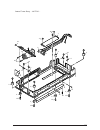

40496501th rev.1 42 2.2.5 paper feed mechanism the line feed on the print paper is driven by the lf motor (pulse motor) and done by rotating the sheet feeder and feed roller. (1) front tractor the rotation of the lf motor rotates the drive shaft through the lf gear, change gear and front tractor dri...

Page 43

40496501th rev.1 43 (2) rear tractor the rotation of the lf motor rotates 2 drive shafts through the lf gear, change gear and rear tractor drive gear a/b, driving the pin wheel and pin belt of the tractor assy. This feeds a continuous paper set on the pin belt. Simultaneously, this drives the feed r...

Page 44

40496501th rev.1 44 (3) tractor changing motion the front tractor and rear tractor are switched by exclusive tractor change motor (pulse motor). Operating keys on the operating panel and receiving a command rotates the tractor change motor, moving the tractor change lever back and forth through gear...

Page 45

40496501th rev.1 45 front drive shaft front tractor drive gear change gear lf gear rear tractor drive gear change motor change lever rear drive shaft • rear tractor drive • front tractor drive figure 2.30

Page 46

40496501th rev.1 46 2.2.6 bail feed mechanism (see figure ) this mechanism automatically opens the bail for pulling a paper into, and closes it after the paper passes through the bail. This function is operated by exclusive bail motor (pulse motor). The bail motor rotates depending on the position o...

Page 47

40496501th rev.1 47 (i) close position (ii) open position (iii) half open position half open open open close close close cam bail lift pin bail lift lever figure 2.32.

Page 48

40496501th rev.1 48 2.2.7 paper end detection mechanism (see figure ) (1) front/ rear form end detection mechanism (when the form with sprocket holes is used) the form prevents the paper end lever tip end from coming into the hole on the sheet feeder cover rib and the microswitch is set to the on st...

Page 49

40496501th rev.1 49 (3) rear tractor form sheet feed cover rib pin tractor l paper end lever micro switch figure 2.34 rear form end detection mechanism.

Page 50

40496501th rev.1 50 (2) do not try disassembly as long as the printer is operating normally. (3) do not remove unnecessary parts: try to keep disassembly to a minimum. (4) use specified service tools. (5) when disassembling, follow the determined sequence. Otherwise, parts may be damaged. (6) since ...

Page 51

40496501th rev.1 51 (10) disassembly prohibited parts the following units and parts should not be disassembled because they cannot reassembled if they are broken apart.) unit print head printer unit disassembly prohibited parts print head space motor ribbon pulse motor autogap motor tractor change m...

Page 52

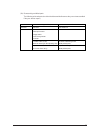

40496501th rev.1 52 [service tools] table 3-1 shows the tools required for field replacement of printed circuit boards and units. Table 3-1 service tools no. No. 1-100 philips screwdriver q' ty place of use remarks service tools 1 2 3 4 5 6 8 no. 2-250 philips screwdriver, magnetized no. 3-100 screw...

Page 53

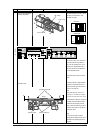

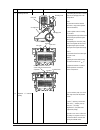

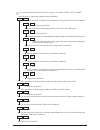

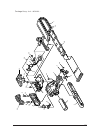

40496501th rev.1 53 figure 3-1 3.2 parts layout sheet guide cover assy rear cover assy access print head printer unit cover-assy-side(r) operation panel assy cover assy front door assy front cover assy lower cover assy side(l) control board cover rear b guide paper b driver board power supply assy p...

Page 54

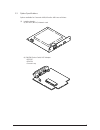

40496501th rev.1 54 3.3 how to change parts this section explains how to change parts and assemblies appearing in the disassembly diagram below..

Page 55

40496501th rev.1 55 3.3.1 cover-assy-access / cover-assy-side (r) / cover-assy-side (l) /cover-assy-front / frame- assy-rear / plate-front (stuck) (1) remove guide sheet 1 and cover assy access 2 . (2) unscrew 2 screws 3 and the screw 4 and the screw 5 , then remove cover assy side (r) 6 , sliding i...

Page 56

40496501th rev.1 56 3.3.2 printer unit (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew 4 screws 2 which fix printer unit 1 . (3) unplug i/f connecting cable 4 and head cable 5 from control boa...

Page 57

40496501th rev.1 57 3.3.3 control block [control board (pma printed board), driver board (pda printed board)] (1) remove cover rear (b). (see 3.3.1) (2) unscrew 2 screws 1 and unplug all the connecting cords to control block 2 . (3) remove control block 2 , sliding it into the arrow direction. [cont...

Page 58

40496501th rev.1 58 3.3.4 power supply assy (1) remove guide paper (b), cover blank lower and rear cover (b). (see 3.3.1) (2) unplug connectors to power supply unit 1 . (3) unscrew the screw 2 and release earth wire 3 . (4) unscrew the screw 4 and remove bracket pg 5 . (5) unscrew 2 screws 6 . Pulli...

Page 59

40496501th rev.1 59 3.3.5 pg cooling fan (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear. (see 3.3.1) (2) unplug the connectors 2 to junction board (pra printed board)(cn13) 1 . (3) unscrew 2 screws 3 and remove pg cooling fan 4 . (4) for ...

Page 60

40496501th rev.1 60 3.3.6 i/f board (pha printed board) (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew the screw 1 and remove cable holder 2 . (3) unscrew 2 screws 3 and remove i/f board hold...

Page 61

40496501th rev.1 61 3.3.7 ag board (pga printed board) / connector cord (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug the connectors 0 to junction board (pra printed board)(cn3) 9 . (3) unscr...

Page 62

40496501th rev.1 62 3.3.8 ag motor assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew 2 screws 1 and remove bail gear assy 2 . (3) unscrew 2 screws 3 and remove ag motor assy 4 . (4) unscrew...

Page 63

40496501th rev.1 63 3.3.9 mini pitch belt (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew 2 screws 1 and remove shaft support plate (press fit) 2 . (3) screw down the screw 3 and turn idle pul...

Page 64

40496501th rev.1 64 3.3.10 tractor change motor assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printer unit. (see 3.3.2) (3) remove i/f board. (see 3.3.6) (4) release the cords from cord ...

Page 65

40496501th rev.1 65 3.3.11 bail motor assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug the connectors 1 from i/f board (pha printed board)(cn2) b . (3) unplug the connectors a from i/f boar...

Page 66

40496501th rev.1 66 3.3.12 lf motor assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove i/f board. (see 3.3.6) (3) remove printer unit. (see3.3.2) (4) remove tractor change motor assy. (see3.3...

Page 67

40496501th rev.1 67 3.3.13 head cooling fan 1 (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug the connector 1 from junction board (pra printed board)(cn6) 6 . (3) release the cords from the cor...

Page 68

40496501th rev.1 68 3.3.14 head cooling fan 2 (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew the screw 1 and remove cable holder cover 2 . (3) unplug the connector 3 from i/f board (pha print...

Page 69

40496501th rev.1 69 3.3.15 space motor (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printer unit. (see 3.3.2) (3) remove the stopper 1 . (4) screw down 2 fixing screws 2 on idle pulley brack...

Page 70

40496501th rev.1 70 3.3.16 operator board (poa printed board) (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug the connector 2 from operator board (poa printed board)(cn1) 1 . (3) unscrew 2 scre...

Page 71

40496501th rev.1 71 3.3.17 ribbon feed assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug the connector 1 from junction board (pra printed board)(cn9) 7 . (3) unscrew 2 screws 2 and remove ri...

Page 72

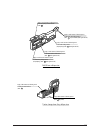

40496501th rev.1 72 3.3.18 printing head (1) lean frame assy rear backward and open access cover. (2) move the printing head to the recess on the right seen from the front. (3) pull out ribbon guide 1 upward. (4) unscrew 2 screws 2 and remove printing head 3 from the connector. (5) for installation,...

Page 73

40496501th rev.1 73 3.3.19 head cable (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printing head. (see 3.3.18) (3) remove printer unit. (see 3.3.2) (4) remove cable holder cover. (see 3.3.6)...

Page 74

40496501th rev.1 74 3.3.20 ribbon protector (1) remove printing head. (see 3.3.18) (2) open access cover 1 . (3) unscrew the screw 2 and remove the cord clamp 3 . (4) unscrew the screw 4 and remove paper width sensor 5 . (5) unplug the connector 6 . (6) remove 2 ribbon guide posts 7 and 2 washers 8 ...

Page 75

40496501th rev.1 75 3.3.21 space motor fan (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printer unit. (see 3.3.2) (3) unscrew 2 screws 1 and unplug the connector 2 from junction board (pra p...

Page 76

40496501th rev.1 76 3.3.22 junction board (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug all the connectors from the above. (3) unscrew 2 screws 1 and remove junction board (pra printed board)...

Page 77

40496501th rev.1 77 3.3.23 cover open switch assy / ribbon rotation sensor (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove head cooling fan 1. (see 3.3.13) (3) unscrew 2 screws 1 and 2 screws 2...

Page 78

40496501th rev.1 78 3.3.24 interlock switch / interlock switch cord assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unplug 4 cables 1 . (3) unscrew 2 screws 2 and remove interlock switch 3 . (4) ...

Page 79

40496501th rev.1 79 3.3.25 knob bracket assy (1) remove bail motor. (see 3.3.11) (2) unscrew the screw 1 and remove the gear 2 . (3) unscrew 2 screws 3 and remove knob bracket assy 4 . (4) unscrew 2 screws 5 and remove ag sensor cover 6 . (5) unscrew the screw 7 and remove knob cover 8 . (6) remove ...

Page 80

40496501th rev.1 80 3.3.26 space belt (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove space motor. (see 3.3.15) (3) remove printing head. (see 3.3.18) (4) remove idle pulley 1 from idle pulley ...

Page 81

40496501th rev.1 81 3.3.27 ag sensor frame / start searching sensor (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew 2 screws 1 and remove rear plate 2 . (3) unscrew 2 screws 3 and remove ag se...

Page 82

40496501th rev.1 82 3.3.28 paper jam sensor assy / bail pe sensor assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) unscrew the screw 1 and release the latch, then remove paper jam sensor assy 2 . ...

Page 83

40496501th rev.1 83 3.3.29 sprocket assy (l) (r) (front tractor) (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printer unit. (see 3.3.2) (3) remove space motor fans. (see 3.3.21) (4) remove 2...

Page 84

40496501th rev.1 84 3.3.30 sheet feeder assy (l) rear / sheet feeder assy (r) rear (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuck). (see 3.3.1) (2) remove printer unit. (see 3.3.2) (3) remove pg cooling fan. (see 3.3....

Page 85

40496501th rev.1 85 2 a 6 7 4 2 b 5 8 3 d 1 e e f 9 c b align the hole positions [when mounting] releasing the gear latches wave eling washer bush drive shaft r side view.

Page 86

40496501th rev.1 86 wheel wheel pin wheel match the position of marks rear tracor assy gears phase drawing 4 match the direction of projections 8 assembling friction piece open up the notch to 1mm and assemble it, positioning the notch as shown in figure. Notch is rotated by 45 ° rotated notch 45 ° ...

Page 87

40496501th rev.1 87 c e a a 2 3 8 4 7 0 9 6 5 4 b 1 6 9 d e d gear wave washer wave washer bush washer bush left side flame bush washer bail lift lever(l) 3.3.31 bail assy (1) remove cover assy access / cover assy side (r) / cover assy side (l) /cover assy front / frame assy rear / plate front (stuc...

Page 88

40496501th rev.1 88 4. Adjustments (1) be sure to carry out this adjustment with the printer mechanism mounted on the lower cover. (2) be sure to carry out this adjustment operation on a level and highly rigid work table (flatness: less than 0.039 inch or 1 mm) so as to minimize adjustment error. [s...

Page 89

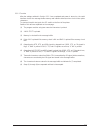

40496501th rev.1 89 item no. 1 items protector gap adjustment (1)range adjustment (2)protector gap standard value illustration adjustment method 1 remove the rear cover (b), and set dip switch 1 on the board to “on” (maintenance mode). 2 close the access cover, and turn on the printer while pressing...

Page 90

40496501th rev.1 90 item no. 2 3 items ag plate gap auto gap correction standard value c=0.14 ± 0.02mm illustration 3 turn on the printer while pressing switches b and c . 4 the auto gap correction has completed if “av” is printed. Adjustment method 1 insert the thickness gauge between the ag frame ...

Page 91

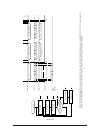

40496501th rev.1 91 item no. 4 5 6 items lf motor belt tension slice level setting-paper width sensor position correction - paper front edge sensor standard value 200 ~ 250gf illustration adjustment method 1 adjust the lf motor belt tension, with the idle pulley assy, to produce the standard value w...

Page 92

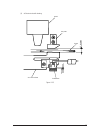

40496501th rev.1 92 item no. 7 8 items auto gap motor assy backlash bail gear assy backlash standard value j=0.1mm k=0.2mm illustration adjustment method 1 verify the backlash is 0.1 mm bet- ween the idle gear and the adjusting cam. 2 if adjustment is required, screw down the 2 screws fixing the aut...

Page 93

40496501th rev.1 93 item no. 9 10 items installing print head alignment of horizontal printing standard value illustration adjustment method 1 in installing the print head, accurately bump it to the inpinging plate on the carriage frame. Notes: the print head should be installed/ removed at 1-range ...

Page 94

40496501th rev.1 94 item no. Items standard value illustration adjustment method correct the printing alignment in each "registration1 ....7". (note2)(note3) note2)after printing, change items with 4 switch note3)the reverse printing position is shifted by 0.05mm to the reference position by pressin...

Page 95

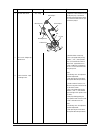

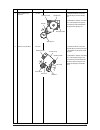

40496501th rev.1 95 5. Cleanig and lubrication 5.1 cleaning [caution] 1. Be sure to turn off the ac power switch before cleaning. Remove the ac power cord from the printer. 2. Avoid dust inside the printer mechanism when cleaning. 3. If a lubricated part has been cleaned, be sure to apply lubricatin...

Page 96

40496501th rev.1 96 5.2 lubrication this printer is designed to be maintenance free and requires no lubrication during normal operation. However it is necessary to apply lubricant in case the printer is disassembled, reassembled, cleaned or parts have been changed. (1) cleaning time remarks: 1) turn...

Page 97

40496501th rev.1 97 sliding surface between bail life lever and shaft(at left and right) gep- a (2 points at upper and lower) gear teeth surfasce gep- a gear teeth surfasce gep- a shaft pm- b (2 points at left and right) bail lift lever rack gep- a (at left and right) sliding surface between feed sh...

Page 98

40496501th rev.1 98 left side view sliding surface between bail life lever and stud(at left and right) gep- a (at left and right) sliding surface between bail life lever and bail motor bracket gep- a gear teeth surface gep- a adjusting cam surface gep- a (at left and right) idle pulley shaft pm- b s...

Page 99

40496501th rev.1 99 sliding surface between platen slide plate and platen tep- a (2 points at upper and lower) platen slide plate platen side frame.

Page 100

40496501th rev.1 100 sliding surface between pressure roller piece and feed roller shaft (3 points) gep- a feed roller shaft fu pressure roller piece front spring.

Page 101

40496501th rev.1 101 gear teeth surfasce gep- a gear teeth surfasce gep- a between bush and shaft pm- b between bush and shaft pm- b between gear and shaft pm- b between gear and shaft pm- b between gear and bracket gep- a between gear and bracket gep- a gear teeth surfasce gep- a gear teeth surfasc...

Page 102

40496501th rev.1 102 apply a small amount of albania grease on the bearing sliding surface. (all periphery) (gep- b )(both right and left) apply a little amount of albania grease on lack gear teeth surface. (gep- b ) apply a little amount of albania grease on the diagonally shaded section. (gep- b )...

Page 103

40496501th rev.1 103 apply a small amount of albania grease on the stud sliding surface. (gep- b )(both right and left).

Page 104

40496501th rev.1 104 6. Troubleshooting and repair 6.1 items to check before repair (1) check the inspection items specified in the instruction manual. (2) find out as many details of the trouble as possible from the customer. (3) inspect in the conditions as close as possible to those at the time t...

Page 105

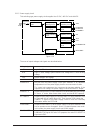

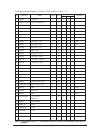

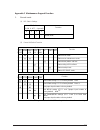

40496501th rev.1 105 6.3 lamp and lcd display (1) printer mode display table 6.2 pr inter mode led condition lcd alarm select oper ation mode oper ator alar m on line hex dump self test menu fr ont paper end rear p aper end eject j a m lo ad j a m park j a m feed j a m paper j a m rebbon j a m pa th...

Page 106

40496501th rev.1 106 pr inter mode led condition lcd alarm select oper ator alar m fault alar m ther mal alar m co ver open d at a remain head ther mal sp ther mal contents the access co ver is open. A status where the pr inter alar ms co ver open with data remained inside the pr inter (the space is...

Page 107

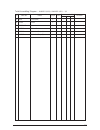

40496501th rev.1 107 table 6.3 fault alarm (1/3) error categor y lcd ram err or r om err or pr ogram err or engine err or d-ram err or s-ram err or pr ogram err or cg-r om err or eep-r om err or w atchdog timer err or inv alid interr upt err or sp a cing err or homing err or centering err or po wer ...

Page 108

40496501th rev.1 108 table 6.3 fault alarm (2/3) error categor y lcd engine err or opera tion panel err or flash memor y err or mupis err or fuse err or head thermister err or a u t o gap err or pa th change err or bail mo t or err or ribbon err or main lsi err or lcd timeout err or flash memor y ch...

Page 109

40496501th rev.1 109 table 6.3 fault alarm (3/3) error categor y lcd option err or option card r om err or option card ram err or option card connect err or contents a chec ksum error of the r om on the optional ser ial i/f card. A wr ite/read error of the ram on the optional ser ial i/f card. The c...

Page 110

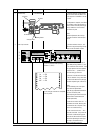

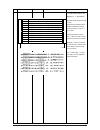

40496501th rev.1 110 6.4 part layout (1) board pra ac inlet pga power supply unit pma pda pha control block assy operation panel assy interface assy lcd unit option board mupis card or paa-pcb poa cn2 cn13 cn6 cn4 cn2 cn5 cn2 cn1 cn1 cn4 cn2 cn12 cn9 cn8 cn1 cn10 cn5 cn1 cn3 dcout2 dcout1 cn3 cn8 cn...

Page 111

40496501th rev.1 111 (2) other path-change motor bail motor lf motor front tractor paper end switch print head optical sensor platen ribbon motor ribbonjam sensor interlock switch sp motor space slit sensor pga-pcb auto-gap slit sensor auto-gap motor connector to auto cutter unit rear tractor sheet ...

Page 112

40496501th rev.1 112 (3) option serial i/f card serial cn1 cn2 cn1 paa option serial i/f card.

Page 113

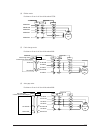

40496501th rev.1 113 6.5 connection (1) printhead resistance of each coil should be about 5.8 Ω cn5 cn1 cn1 pda pcb pma pcb head driver circuite diagram head connector head pin number #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14 #15 #16 #17 #18 fg nc 40, 38...4, 2 39, 37...3, 1 12 30 42 49 14 32 4...

Page 114

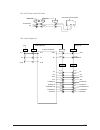

40496501th rev.1 114 (2) line feed motor resistance of each coil should be about 4.2 Ω (3) space motor resistance of motor should be about 1.08 Ω pma-pcb cn6 49 65 57 53 67 61 6 2 4 5 1 3 6 2 4 5 1 3 50 66 58 54 68 62 cn1 cn13 lf m0 pha-pcb lfdv1 lfcom lfdv3 lfdv2 lfdv4 pma-pcb 46 48 50 pra-pcb inte...

Page 115

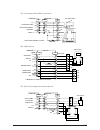

40496501th rev.1 115 (4) ribbon motor resistance of each coil should be about 155 Ω (5) path-change motor resistance of each coil should be about 90 Ω (6) auto-gap motor resistance of each coil should be about 90 Ω pma-pcb cn2 40 42 36 38 34 4 5 2 3 6 1 1 5 3 2 6 4 40 42 36 38 34 cn1 cn9 ribbon m0 p...

Page 116

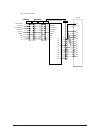

40496501th rev.1 116 (7) bail motor resistance of each coil should be about 90 Ω pma-pcb cn6 52 68 60 56 64 4 5 2 3 6 1 1 5 3 4 6 2 51 67 59 55 63 cn1 cn2 bail m0 pha-pcb beil-mdv1 bail-mcom beilmdv3 bailmdv2 beil-mdv4 (8) space fan1 pma-pcb cn2 2 1 3 2 1 3 7 5 1~4 7 5 1~4 cn1 cn12 pra-pcb spfandv-p...

Page 117

40496501th rev.1 117 (11) head fan2 (12) power fan pma-pcb cn6 2 1 3 2 1 3 56 52 2, 4, 6 55 51 1, 3, 5 cn1 cn6 pha-pcb hdfan2dv-p hdfan2alm-p sg head fan2 pma-pcb cn2 2 1 3 2 1 3 11 9 1~4 11 9 1~4 cn1 cn13 pha-pcb powfandv-p powfanalm-p sg power fan (13) space slit sensor pma-pcb cn8 4 2 1 5 3 4 2 1...

Page 118

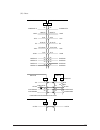

40496501th rev.1 118 (15) cover open switch/ ribbon jam sensor pma-pcb cn2 1~4 14 12 10 17 1~4 14 12 10 17 2 1 3 4 5 6 8 7 cn1 cn4 nc nc c a k e c no nc pra-pcb sg coveropn 1sw-p *rtrcoveropnsw-p rbnsen-p sns5v-1 180 Ω 1/4w * rtrcoveropnsw-p is unused. Cover open switch ribon jam sensor (16) optical...

Page 119

40496501th rev.1 119 (18) paper jam sensor/ bail paper end sensor pma-pcb cn6 46 42 47 1,3,5 45 41 48 2,4,6 3 4 7 1 2 5 6 cn1 cn3 a k e c pha-pcb sheetjam-p sns5v-0 beilpe-p sg a k e c 150 Ω 1/4w 180 Ω 1/4w bail paper end sensor paper jam sensor (19) bail open switch/ front tractor on switch pma-pcb...

Page 120

40496501th rev.1 120 (21) rear tractor paper end switch pma-pcb cn6 41 1,3,5 42 2,4,6 2 1 cn1 cn4 nc c no pha-pcb rtrpesw-p sg rear tractor paper end switch (22) power supply unit 1~3 4~6 7 8 9 10 11 12 13 1~6 7~12 1~6 7~12 +44v ep +44v ep ac-l fg ac-n ac-l fg ac-n 1~3 4~6 7 8 9 10 11 12 13 sg +5v +...

Page 121

40496501th rev.1 121 (23) operation panel 1,12 2 3 4 5 6 7 8 9 10 11 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 15 sg +5v +4v rs r/w e nc nc nc nc db4 db5 db6 db7 sg bl5v sg +5v +4v rs r/w e db4 db5 db6 db7 bl5v cn2 38 26 28 30 32 36 34 4 1,3,5 37 25 27 29 31 35 33 3 2,4,6 1 2 3 4 5 6 7 8 9,10 shiftswon-n ...

Page 122

40496501th rev.1 122 (24) standard interface 16 23 25 27 29 31 33 35 37 8 6 10 12 18 1,3,5 24 20 14 39 22 15 19 17 21 7 13 9 11 strob-n data1-p data2-p data3-p data4-p data5-p data6-p data7-p data8-p ack-n busy-n perror-p select-p autofd-n sg plogic-h init-n fault-n nc/if-h selectin-n txd ssd rts dt...

Page 123

40496501th rev.1 123 (25) short plug * for setting details see the maintenance manual 1 2 3 t1 +5v ic45-byte ic47-byte pgromcs-n 1 2 3 t2 nc cnif-h +5v 10k Ω 1/10w 3.3k Ω 1/10w 1 2 3 t3 +5v pgromsel-n sg 10k Ω 1/10w 1 2 3 t4 +5v cnplogic-h +5v 3.9k Ω 1/10w.

Page 124

40496501th rev.1 124 (26) others 62 68,69,70 20,21 35~40,75 73,74,76~80 71,72 25 24 23 22 poweroff-p +44vf +12v ep +44v +12vr dvrev3-p dvrev2-p dvrev1-p dvrev0-p poweroff-p +44vf +12v ep +44v +12vr dvrev3-p dvrev2-p dvrev1-p dvrev0-p 62 68,69,70 20,21 35~40,75 73,74,76~80 71,72 25 24 23 22 pma-pcb p...

Page 125

40496501th rev.1 125 (27) mupis interface (option) a1 a2 a3 a4 a5 a6 a7 a8 a9 a10 a11 a12 a13 a14 a15 a16 a17 a18 a19 a20 a21 a22 a23 a24 a25 a26 a27 a28 a29 a30 a31 a32 mpsd03-p mpsd10-p mpsd02-p mpsd09-p mpsd01-p mpsd08-p mpsd07-p mpsrd-n mpsa08-p mpsa01-p mpsa02-p mpsa03-p mpsa04-p mpsa05-p mpsa0...

Page 126

40496501th rev.1 126 b1 b2 b3 b4 b5 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15 b16 b17 b18 b19 b20 b21 b22 b23 b24 b25 b26 b27 b28 b29 b30 b31 b32 nc nc nc nc nc pe-n ack-n sifsel-n nc busy-p ifdata4-p ifdata3-p nc ifdata5-p ifdata2-p ifdata6-p nc ifdata1-p ifdata7-p ifdata8-p nc sifrst-p rstin-n sifstb-n ...

Page 127

40496501th rev.1 127 (28) option interface b6 b7 b8 b9 b10 b11 b12 b13 b14 b15 b16 b17 b18 b19 b20 b21 b22 b23 b1~b5,b9,b28~b32, b13,b17,b21,b25 b28 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15 b16 b17 b18 b19 b20 b21 b22 b23 b1~b5,b9,b28~b32, b13,b17,b21,b25 b28 26 25 24 23 22 8 9 10 5 3 4 7 20 6,13,14,17 2...

Page 128

40496501th rev.1 128 a1 a2 a3 a4 a6 a7 a8 a10 a11 a12 a14 a15 a16 a18 a19 a20 a22 a23 a24 a26 a27 a28 a29 a5,a9,a13 a21,a25 a2~a4,a5~a8, a10~a12,a14~a20, a22~a24,a26~a32 a1 a2 a3 a4 a6 a7 a8 a10 a11 a12 a14 a15 a16 a18 a19 a20 a22 a23 a24 a26 a27 a28 a29 a5,a9,a13 a21,a25 a2~a4,a5~a8, a10~a12,a14~a2...

Page 129

40496501th rev.1 129 (29) continuous-form paper cutter (option) 39,41,43,44 31 29 27 25 23 21 19 1~4 39,41,43,44 31 29 27 25 23 21 19 1~4 9 8 7 6 5 4 3 2 1 ep 44vf cutmovdv-p cutm1-p cutm2-p cutm3-p cutm4-p rencut-n sg pma-pcb pra-pcb cn2 cn1 cn8 continuous-form paper cutter.

Page 130

40496501th rev.1 130 1 power is not supplied. • the printer cannot be powered at all. : to a the printer changes off during initialization. : to b a is the connection of ac cable properly made? Yes no • properly reconnect the ac cable. ▼ • is the ac input fuse burnt? No yes • replace the ac input fu...

Page 131

40496501th rev.1 131 b can the printer be powered on and off when the cn3 cable of the pma board is disconnected? No yes • replace the power supply unit. ▼ • can the printer be powered on and off when the cn2 and the cn6 of the pma board, and the cn5 of the pda board is disconnected? No yes • is the...

Page 132

40496501th rev.1 132 2 the printer can be powered on, but stays still without displaying anything on the lcd. Can the printer recover after the program rom is replaced? No yes • end ▼ • can the printer recover after the poa board is replaced? No yes • end ▼ • replace the pma..

Page 133

40496501th rev.1 133 3 the printer cannot normally complete the initialization. Printer status and message on the lcd: although the access cover is close, the printer is in cover open state. : to c alarm lamp flashes message on the lcd “error, fuse” : to d alarm lamp flashes message on the lcd “erro...

Page 134

40496501th rev.1 134 c although the access cover is close, the printer is in cover open state. • check that the cover open switch can normally switch on and off with manufacturing aid function. • can it switch on and off normally? Yes no • is the connection of cables to the cn1 and the cn4 on the pr...

Page 135

40496501th rev.1 135 d the printer does not operate. The alarm lamp flashes. The lcd reads “error fuse”. Is the connection of cable properly made to the cn3 on the pma board? Yes no • properly reconnect the cable. ▼ • is the connection of cable properly made to the printer unit connector dcout2? Yes...

Page 136

40496501th rev.1 136 e alarm lamp flashes. Message on the lcd “error, flash unload” is a flash memory used? Yes no • confirm the settings of the short plug t3 on the pma board. 1-2 setting: flash rom selected 2-3 setting: ep rom selected • has the eprom been selected? Yes no • make a proper selectio...

Page 137

40496501th rev.1 137 f spacing error, alarm lamp flashes. Message on the lcd “error, homing”, “error, center- ing” or “error, spacing”. Does the carriage catch a paper? No yes • remove the print paper. ▼ • can the carriage run when the printer is powered on? No yes • to f-1 ▼ • is the connection of ...

Page 138

40496501th rev.1 138 f-1 is the carriage belt loose? No yes • properly adjust the tension of the belt. ▼ • is the connection of cable properly made to the cn8 on the pma board? Yes no • properly reconnect it. ▼ • is the slit sensor cable at the lower part of space motor properly connected to the cab...

Page 139

40496501th rev.1 139 g alarm lamp flashes. Message on the lcd “error autogap” does the carriage run during initialization? No yes • to g-1 ▼ • does the platen normally move during initialization? Yes no • g-4 is the connection properly made to the cn1 and the cn2 on the pra board? Yes no • make a pr...

Page 140

40496501th rev.1 140 g-2 has the autogap slit sensor and autogap slit disk been installed in a proper position? Yes no • reinstall them. ▼ • is the gear between the autogap motor and platen in a normal state? Does it lose a tooth (teeth)? Is the load too heavy? Yes no • reinstall the gear in place. ...

Page 141

40496501th rev.1 141 g-1 does the platen normally operate during initialization? Yes no • to g-4 ▼ • can the printer recover after the head gap is readjusted? No yes • end ▼ • can the printer recover after the core gap is readjusted? No yes • end ▼ • is the connection of cables properly made to the ...

Page 142

40496501th rev.1 142 g-5 can the printer recover after the print start sensor and/or coregap cable is replaced? No yes • end ▼ • can the printer recover after the pma board is replaced? No yes • end ▼ • can the printer recover after the connection cable between the cn2 on the pma board and the cn1 o...

Page 143

40496501th rev.1 143 h the alarm lamp flashes after the motion of carriage. Lcd reads “error, bail”. Does the bail operate during initialization? Yes no • is the connection of cables properly made to the cn2 and the cn1 on the pha board? Yes no • reconnect them properly. ▼ • is the connection of cab...

Page 144

40496501th rev.1 144 i the alarm lamp flashes after the motion of carriage. Lcd reads “error, path change” does the tractor change lever operate during initialization? Yes no • is the connection of cables properly made to the cn1 and the cn7 on the pha board? Yes no • properly reconnect them. ▼ • is...

Page 145

40496501th rev.1 145 j alarm lamp flashes. Lcd reads “error, opt card connect” has the optional i/f card properly mounted to the paa board? Yes no • properly remount the card. ▼ • can the printer recover after the optional serial i/f card is replaced? No yes • end ▼ • can the printer recover after t...

Page 146

40496501th rev.1 146 m alarm lamp flashes, message on the lcd “error, head 1 fan”, “error, head 2 fan” and “error, space fan” can the printer recover after the fan shown in the error message is replaced? No yes • end ▼ • can the printer recover after the pma board is replaced? No yes • end ▼ • can t...

Page 147

40496501th rev.1 147 4 function is not started when the switch is pressed on the operator panel. Is the connection of cable between the cn1 on the poa board and the cn12 on the pha board normal? Yes no • properly reconnect the cable. ▼ • check the electrical conductivity between the cn1 on the poa b...

Page 148

40496501th rev.1 148 5 alarm lamp flashes, lcd reads “error, ribon jam” is the ribbon feed during initialization? Yes no • is the connection of cable properly made to the cn1 and the cn9 on the pra board? Yes no • properly reconnect it. ▼ • is the connection of cable properly made to the cn2 on the ...

Page 149

40496501th rev.1 149 5-1 • can the printer recover after the pra board is replaced? No yes • end ▼ • replace the connection cable between the cn2 on the pma board and the cn1 on the pra board..

Page 150

40496501th rev.1 150 6 line feed trouble printer status and message on the lcd alarm lamp flashes, message on the lcd “error, feed jam” : to p paper has set on the tractor, but is not feed in. The lcd reads “off-line, paper end” : to q alarm lamp flashes, message on the lcd “error, paper jam” : to r.

Page 151

40496501th rev.1 151 p alarm lamp flashes. Lcd reads “error, feed jam” is any paper jammed in the paper feeding route? No yes • remove the print paper. ▼ • is the lf motor (tractor unit) running? No yes • to p-1 ▼ • is the connection of cables properly made to the cn1 and the cn13 on the pha board? ...

Page 152

40496501th rev.1 152 p-1 • is the connection of cables properly made to the cn1 and the cn3 on the pha board? Yes no • properly reconnect it. ▼ • is the connection of cable properly made to the cn6 connector on the pma board? Yes no • properly reconnect it. ▼ • is there any problem on the installati...

Page 153

40496501th rev.1 153 q paper has been set on the tractor, but is not feed in. Message on the lcd “off-line, paper end” • confirm that the tractor being used (front or rear) is normally switched on/off according to the maintenance manual. • is the tractor normally switched on/off? Yes no • is the con...

Page 154

40496501th rev.1 154 r alarm lamp flashes, message on the lcd “error, paper jam” is the paper on the feeding route torn? No yes • remove any torn paper and load a new paper. ▼ • is the connection of cables properly made to the cn1 and the cn9 on the pha board? Yes no • properly reconnect them. ▼ • i...

Page 155

40496501th rev.1 155 7 character and dot lack is the trouble identified as character lack? Yes no • in the event of dot lack, go to s . ▼ • can the self-test printing be normally performed? Yes no • replace the pma board. ▼ • is the interface cable and/or network cable properly connected? Yes no • p...

Page 156

40496501th rev.1 156 s has the headgap been accurately adjusted? Yes no • readjust the headgap as stated in the maintenance manual. ▼ • perform the head pin test as stated in the maintenance manual. • is a particular pin lacked? Yes no • go to d . ▼ • can the printer recover after the print head is ...

Page 157

40496501th rev.1 157 8 thin printing has the ink ribbon reached its life end? No yes • replace the ink ribbon. ▼ • has the headgap been accurately adjusted? Yes no • accurately readjust it. ▼ • can the printer recover after the print head is replaced? No yes • end ▼ • replace the pda board..

Page 158

40496501th rev.1 158 9 the printer can normally operate, but not start printing. • in the event of the use of optional serial board, go to 9-1 . • in the event of the use of mupis card, go to 9-2 . • can the printer perform the self-test. Yes no • replace the pma board. ▼ • is the interface cable pr...

Page 159

40496501th rev.1 159 9-1 can the printer perform the self-test? Yes no • replace the pma board. ▼ • is the interface cable properly connected? Yes no • properly reconnect it. ▼ • do the settings of serial interface meet the system? Yes no • accurately redo the settings. ▼ • can the printer recover a...

Page 160

40496501th rev.1 160 9-2 can the printer perform the self-test printing. Yes no • replace the pma board. ▼ • is the network cable (lan cable) properly connected to the mupis card? Yes no • properly reconnect it. ▼ • can the printer recover after the network cable (lan cable) to the mupis card is rep...

Page 161

40496501th rev.1 161 7. Parts list the main component parts of this printer are described as follows. Total assembling diagram 40496501 (oda) 40496502 (oel) printer unit 40496601 carriage unit 40501901 knob assy 40782001 ribbon feed assy 40506101 sprocket assy (l) 40507601 sprocket assy (r) 40508101...

Page 162

40496501th rev.1 162 total assembling diagram – 40496501 (oda) / 40496502 (oel) – 36 29 12 3 34 14 33 29 30 16 30 1 2 28 29 29 2 2 37 32 32 19 32 31 17 20 4 or 5 21 35 35 18 15 2 38 11 32 32 8 or 9 29 10 29 29 29 29 13 29 23 32 24 or 25 32 26 22 6 30 27 29 33 33 7 32 30 31 34 33 33.

Page 163

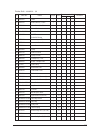

40496501th rev.1 163 1 40496601 printer unit 1 – – – – 2 4pb4053-1883p002 cup screw with washer 4 o 1 1 1 3 40538101 serial dot head-4410 1 o 20 40 80 4 40752201 pma/pda pcb 1 – – – – (oda) 5 40752202 pma/pda pcb 1 – – – – (oel) 6 40414001 power unit 1 o 6 11 21 7 40677101 cover assy. - lower 1 o 1 ...

Page 164

40496501th rev.1 164 33 d4-8g screw (bind) 6 – – – – 34 s3-6hh screw 2 – – – – 35 psw2w4-6c screw 2 36 40658201 guide - sheet 1 o 1 1 1 37 40936201 mechanical clamp (l) 1 – – – – 38 40936301 mechanical clamp (r) 1 – – – – total assembling diagram – 40496501 (oda) / 40496502 (oel) – 2/2 no. Parts no....

Page 165

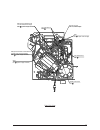

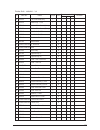

40496501th rev.1 165 printer unit – 40496601 –(1/3) 13 163 163 2 159 118 118 43 183 41 42 163 180 180 120 159 119 163 182 163 165 45 44 42 163 184 43 71 159 118 17 174 163 163 163 13 8 8 8 7 7 163 163 174 72 17 6 163 7 9 68 9 69 70 122 108 86 90 93 87 39 152 170 18 174 174 163 62 59 1 5 3 77 78 80 7...

Page 166

40496501th rev.1 166 printer unit – 40496601 –(2/3) 136 134 147 30 38 121 107 131 39 31 30 159 25 171 172 28 76 27 135 171 138 25 28 95 163 163 163 163 163 163 163 163 96 96 101 105 162 76 147 157 106 167 94 63 166 164 144 150 64 146 172 173 173 74 102 168 99 82 163 83 151 48 151 151 151 55 54 45 52...

Page 167

40496501th rev.1 167 printer unit – 40496601 –(3/3) 113 112 30 30 29 140 148 163 163 163 163 148 139 163 114 21 173 163 149 33 20 173 19 111 169 163 163 163 53 163 165 21 110 83 151 132 38 115 117 160 147 148 161 56 57 154 116 45 55 168 143 143 144 145 181 145 56 178 127 124 129 163 163 128 167 126 ...

Page 168

40496501th rev.1 168 1 40799801 flame - main 1 – – – – 2 40498401 plate - rear 1 – – – – 3 40537701 guide - paper 3 – – – – 4 40498501 beam - slide 1 – – – – 5 40498601 front guide - sheet (u) a 1 – – – – 6 40498701 front guide - paper (u) b 1 – – – – 7 40498801 spring - pressure 3 o 1 1 1 8 3pp4053...

Page 169

40496501th rev.1 169 printer unit – 40496601 – 2/6 no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 34 40500401 platen 1 – – – – 35 40500501 guide sheet (u) - platen 1 – – – – 36 40500601 sheet guide (l) a - platen 1 – – – – 37 40564001 cover - blank 2 – – – – 38 4pp4053-3712p00...

Page 170

40496501th rev.1 170 printer unit – 40496601 – 3/6 no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 66 40794301 fan cover bracket assy 1 – – – – 67 40506101 ribbon assy. - feed 1 – – – – 68 40558601 bracket - ribbon cassette (l) assy 1 – – – – 69 40558701 bracket - ribbon casset...

Page 171

40496501th rev.1 171 99 40906101 tractor change lever assy 1 o 1 1 1 100 40829301 lf motor assy 1 o 1 2 2 101 4lp-1313-33 mini pitch belt 1 o 1 1 1 102 40511201 gear - lf 1 o 1 1 1 103 40511301 change gear - tractor 1 o 1 1 1 104 4lb-190700-4 spring 1 o 1 1 1 (psp4.7/0.4-16*6.1/277g) 105 4pp4044-270...

Page 172

40496501th rev.1 172 130 40917301 open lever plate 1 – – – – 131 40644601 platen slide plate 1 – – – – 132 40788101 plate - guide platen r 1 – – – – 133 40794801 harness cover 1 – – – – 134 40750801 pha-pcb 1 o 1 1 1 135 40514701 holder i/f 1 – – – – 136 40744301 if-kiban-cover 1 – – – – 137 4lp-669...

Page 173

40496501th rev.1 173 printer unit – 40496601 – 6/6 no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 160 40534601 connection cord wire 1 o 1 1 1 161 40513201 holder ag pcb a 1 – – – – 162 40511401 idle pulley assy 1 o 1 1 1 163 psw2w3-6c screw 75 – – – – 164 psw2w3-8c screw 1 – –...

Page 174

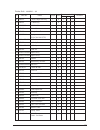

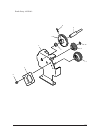

40496501th rev.1 174 carriage assy. -unit – 40501901 – 20 9 19 19 24 24 11 9 8 24 14 13 5 4 3 26 2 1 22 7 10 18 17 16 25 23 28 12 15 6.

Page 175

40496501th rev.1 175 carriage assy. -unit – 40501901 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 40502001 frame - carriage 1 – – – – 2 40547701 bias roller assy 1 – – – – 3 40502601 spring 1 – – – – 4 4pp4044-1473p001 felt 1 – – – – 5 40474701 space belt 1 o 1 1 1 6 405...

Page 176

40496501th rev.1 176 knob assy –40782001– 8 4 6 3 5 10 7 1 2 9.

Page 177

40496501th rev.1 177 knob assy – 40782001 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 40646401 bracket assy - knob 1 o 1 1 1 2 40794501 knob cover 1 o 1 1 1 3 4pp4043-2590p001 bush 1 o 1 1 1 4 40646101 idle gear shaft 1 o 1 1 1 5 4pp4122-1285p001 gear (z19-52) 1 o 1 1 1...

Page 178

40496501th rev.1 178 ribbon assy. - feed –40506101– 1 15 8 7 8 14 6 5 10 13 3 4 13 2 6 7 14 9 11 11 1.

Page 179

40496501th rev.1 179 ribbon assy. - feed – 40506101 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 40458201 motor - ribbon 1 o 2 3 5 2 40506201 frame assy. - ribbon feed 1 – – – – 3 4pp4044-4161g001 ribbon drive gear assy 1 – – – – 4 4pp4044-4347p001 drive gear bracket 1 –...

Page 180

40496501th rev.1 180 sprocket assy (l) – 40507601 – 3 2 5 6 1 19 19 7 4 21 10 8 9 20 18.

Page 181

40496501th rev.1 181 sprocket assy (l) – 40507601 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 3pp4053-3747p001 tractor frame a 1 – – – – 2 4pk4044-1936g001 sheet feeder frame b (l) 1 – – – – 3 40625201 cover - sheet feeder (l) 1 – – – – 4 40722601 lever lock 1 – – – – 5...

Page 182

40496501th rev.1 182 sprocket assy (r) – 40508101 – 3 7 11 11 1 6 5 2 13 4.

Page 183

40496501th rev.1 183 sprocket assy (r) – 40508101 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 3pp4053-3747p001 tractor frame 1 – – – – 2 4lr-194630 sprocket frame b (r) 1 – – – – 3 40625101 cover - sheet feeder (r) 1 – – – – 4 40722601 lever lock 1 – – – – 5 5lr-123486 ...

Page 184

40496501th rev.1 184 sheet feeder assy (l) rear – 40508701 – 9 10 4 16 2 12 5 6 7 13 11 3 8 1 14 10 15 16 pin protrucsion note : assembly should be done, meeting the protrusion 10 to the pin 4..

Page 185

40496501th rev.1 185 sheet feeder assy (l) rear – 40508701 – no. Parts no. Name q’ty/u rspl recommended q’ty remarks 500 1000 2000 1 40508801 frame sheet feeder (l) 1 – – – – 2 40508901 guide sheet (l) 1 – – – – 3 3pp4043-2443p001 sheet feeder cover (l) 1 – – – – 4 4pp4043-2445p001 pin tractor belt ...

Page 186

40496501th rev.1 186 sheet feeder assy (r) rear – 40509101 – 8 11 1 9 4 13 13 10 6 5 2 9 12 7 3 pin protrusion note : assembly should be done, meeting the protrusion 9 to the pin 4..

Page 187

40496501th rev.1 187 1 40509201 frame sheet feeder (r) 1 – – – – 2 40509301 guide sheet (l) 1 – – – – 3 3pp4043-2450p001 sheet feeder cover (r) 1 – – – – 4 4pp4043-2445p001 pin tractor belt 1 – – – – 5 3pp4043-2446p001 sprocket wheel 1 – – – – 6 5lr-39392-9 o ring 1 – – – – 7 4pp4043-2563p001 washer...

Page 188

40496501th rev.1 188 bail assy – 40499601 – 22 22 22 22 8 11 21 23 16 2 1 21 3 16 17 18 13 14 23 7 10 19 5 21 12 9 15 6.

Page 189

40496501th rev.1 189 1 40648701 bail sheet guide 1 – – – – 2 40613801 sheet guide holder (r) assy 1 – – – – 3 40613601 sheet guide holder (l) 1 – – – – 4 5 40500201 roller spring 1 – – – – 6 40887601 bail cover 1 – – – – 7 40607701 bail roller 5 – – – – 8 40500001 spring 5 – – – – 9 40634501 arm - r...

Page 190

40496501th rev.1 190 lower cover assy – 40677101 – 14 12 9 6 18 17 16 11 3 3 4 15 4 15 4 10 10 1 3 3 7 5 5 16 8 16 15 4 15 5 5 14 14.

Page 191

40496501th rev.1 191 1 40518901 cover - lower 1 – – – – 2 40898401 bracket - pg 1 – – – – 3 40557201 rubber dumper 4 – – – – 4 40890601 rubber - foot 4 – – – – 5 40650701 plate - earth 4 – – – – 6 40534401 connection cord - flat 1 o 1 1 1 7 40648601 plate - cable 1 – – – – 8 40742101 plate - cover (...

Page 192

40496501th rev.1 192 front cover assy – 40677201(oda) / 40677202 (oel) – 10 6 2 4 4 1 3 7 7 5 10 10 6 6.

Page 193

40496501th rev.1 193 1 40677301 cover assy. - front 1 – – – – 2 40643601 beam - cover 1 – – – – 3 40656101 latch (a) 1 – – – – 4 40655901 catch - ball 2 – – – – 5 40990101 diselectrification bar 1 – – – – 6 40652701 spring - earth (b) 3 – – – – 7 40668701 screw - tapping 4 – – – – 8 9 10 t2p3-6c tap...

Page 194

40496501th rev.1 194 rear cover assy – 40678301 – 11 6 5 9 10 10 8 10 10 10 9 4 1 10 3 2 7 13.

Page 195

40496501th rev.1 195 1 40519701 frame - rear 1 – – – – 2 40814501 frame bracket assy. - rear (l) 1 – – – – 3 40814601 frame bracket assy. - rear (r) 1 – – – – 4 40637601 bracket - rear (m) 1 – – – – 5 40678601 cover assy. - rear (a) 1 – – – – 6 40519801 cover access (rear) 1 – – – – 7 40678701 guide...

Page 196

40496501th rev.1 196 access cover – 40520201 – 1 6 4 3 8 10 10 10 9 7 8 3 4 6 5 2 8 13 13 13 11 12.

Page 197

40496501th rev.1 197 1 40795901 cover - access (a) 1 – – – – 2 40520401 cover - access (b) 1 – – – – 3 40739501 plate - guide 2 – – – – 4 40793801 ep clamp 2 – – – – 5 40656201 keeper 1 – – – – 6 40963601 spring (b) - access 2 – – – – 7 40668701 screw - tapping 2 – – – – 8 4pb4050-2914p001 tapping s...

Page 198

40496501th rev.1 198 frame assy. - opepane – 40755801 – 3 2 4 6 8 9 9 1 5.

Page 199

40496501th rev.1 199 1 40678901 frame - opepane (sticking) 1 – – – – 2 40751001 poa-pcb 1 o 1 2 3 3 40742901 lcd assy. 1 o 1 2 3 4 40666701 sheet - opepane 1 o 1 1 1 5 40519501 frame - opepane 1 – – – – 6 40658101 plate - acryl 1 – – – – 7 8 t2p2-6c tapping screw 4 – – – – 9 t2p3-6c tapping screw 3 ...

Page 200

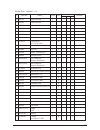

40496501th rev.1 200 pma/pda pcb assy – 40752201/4075202 – 4 or 6 5 or 7 1 or 2 12 or 13 3 8 9 11.

Page 201

40496501th rev.1 201 1 40750401 pma-pcb 1 – – – – (oda) 2 40750402 pma-pcb 1 – – – – (oel) 3 40750701 pda-pcb 1 o 1 1 2 4 40751201 control rom writing specifications 1 o 1 1 1 (oda) 5 40751301 font rom writing specifications 1 o 1 1 1 (oda) 6 40756201 control rom writing specification 1 o 1 1 1 (oel...

Page 202

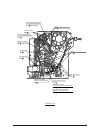

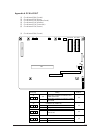

404965601th rev.1 202 appendix a pcb layout (1) circuit board pma (control) (2) circuit board pda (driver) (3) circuit board poa (operation panel) (4) circuit board pha (interface) (5) circuit board pra (connection) (6) circuit board pga (sensor) (1) circuit board pma (control) fg3 fg4 fg1 fg2 fg5 t...

Page 203

40496501th rev.1 203 (3) circuit board poa (operation panel) cn1 on-line power alarm on-line led1 led2 led3 group sw1 sw2 item sw3 option sw4 menu sw8 config sw7 shift sw13 path sw6 ff/load sw10 lf sw11 tear sw12 park sw9 store sw5 cn2 ic1 (4) circuit board pha (interface) cn2 cn15 fg4 fg3 fg2 fg6 f...

Page 204

404965601th rev.1 204 (5) circuit board pra (connection) cn1 cn2 cn9 cn6 cn4 cn2 cn13 cn8 cn10 cn3 f1 (6) circuit board pga (sensor) sn1 cn1.

Page 205

40496501th rev.1 205 appendix b rs-232c serial interface board (option) 1. General this section describes the operation of the rs-232c serial interface board installed in the printer as an option using a start-stop synchronization and serial communications circuit. This serial interface board is cap...

Page 206

40496501th rev.1 206 2. Operation description 2.1 element description (1) 80c51 with mask rom an eight-bit microprocessor controller that controls the following: (a.)serial interface protocol and data transfer through a serial port. (b.)message buffer. (c.) transmission of parallel data to the print...

Page 207

40496501th rev.1 207 figure b-2-1 block diagram " # * * + + 2 3 : ; ocs p1 p2 p0 p3 td rd if wr ls245 2764 rom 8 kb rd td ram 8 kb driver +5 vd +12v -12v +5 v +9 v –9 v +5v 0v ± 9 v power supply circuit serial data control line bus line control line " # $ * * + + , , 2 2 3 3 4 4 : ; adr latch receiv...

Page 208

40496501th rev.1 208 2.2.1 operation at power on after power is turned on, an rst out signal is sent from the printer control board to reset the printer. When the reset is canceled, the 80c51 cpu performs initialization. Initialization consists of setting the 80c51 timer, and setting the serial mode...

Page 209

40496501th rev.1 209 2.3 local test 2.3.1 circuit test mode 2.3.1.1 setting (1) diagnostic test (set by menu) (2) test connector connect the test connector shown in figure b-3-6 to the interface connector figure b-3-6 test connector connection diagram equivalent to cannon db-25p td rd rts cts cd ssd...

Page 210

40496501th rev.1 210 2.3.1.2 function after the settings outlined in section 3.3.1.1 are completed and power is turned on, the serial interface checks the message buffer memory and interface driver/receiver circuit. It then prints characters. To start and stop this test, push the sel switch on the f...

Page 211

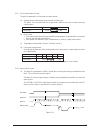

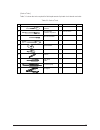

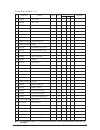

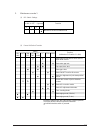

40496501th rev.1 211 appendix c maintenance-support function 1. Normal mode (1) dip switch settings (2) power on switch function function switch function menu sel/ reset path/ tof con- fig lf ff/ load park tear starts menu mode starts menu maintenance mode starts demo-pattern self test starts rollin...

Page 212

40496501th rev.1 212 2. Maintenance mode 1 (1) dip switch settings (2) power on switch function dip switch (o: on, x: off, –: ignored) function 3 4 1 2 maintence function enabled mode – – – switch function (valid when dip switch-1 is on) shift on- line path/ tof con- fig lf ff/ load park tear starts...

Page 213

40496501th rev.1 213 3. Maintenance mode 2 (1) dip switch settings (2) operator panel switch function dip switch (o: on, x: off, –: ignored) function 3 4 1 2 maintence information indication enabled mode – – – switch function (valid when dip switch-2 is on) shift store path/ tof con- fig lf ff/ load...

Page 214

40496501th rev.1 pb / pb (4) stored historical page number data this function counts a page each 11inch and stores it to eeprom. The storage capacity for the counter is 3byte, which equals to pages for 70 years at 20000 pages/ month. As the printer has no function which is capable of resetting this ...