- DL manuals

- Oki

- Printer

- OKICOLOR 8

- Maintenance Manual

Oki OKICOLOR 8 Maintenance Manual

Summary of OKICOLOR 8

Page 1

41057601th rev.1 1 / 199 okipage 8c plus / okicolor 8 color led page printer maintenance manual oda/oel/int 1999.8.12 rev.1.

Page 2

41057601th rev.1 2 / rev.No. Date corrected items person in no. Page description of change change 1 1999.8.12 issue e4 yamazaki.

Page 3: Preface

41057601th rev.1 3 / preface this maintenance manual provides procedures and techniques for the troubleshooting, maintenance, and repair of okicolor 8 / okipage 8c plus. This manual is written for maintenance personnel, but it should always be accompanied with the okicolor 8 / okipage 8c plus user’s...

Page 4: Contents

41057601th rev.1 4 / contents 1. Specifications ............................................................................................ 7 1.1 basic system configuration ............................................................................................. 7 1.2 printer specifications ......

Page 5

41057601th rev.1 5 / 3.3.19 hopping motor .................................................................................................. 66 3.3.20 gear one-way .................................................................................................. 67 3.3.21 feeder unit front ............

Page 6

41057601th rev.1 6 / 7. Wiring diagram ...................................................................................... 146 7.1 resistance check ........................................................................................................ 146 7.2 program/font rom location .............

Page 7

41057601th rev.1 7/ m m m m m m m m led head discharging indicators centronics interf ace hsp controller j unction board pulse motors engine controller lo w-v oltage po w er unit fixing unit high-v oltage po w er unit second tr a y belt unit , s witches , and ther mistors> p aper width sensor f o rm...

Page 8

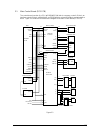

41057601th rev.1 8/ 1.2 printer specifications this printer unit is composed with the following hardware. • electro-photographric processor • paper feeder • controller (cu part / pu part) • operator panel • power board (high voltage part / pu part) figure 1-2 show the printer unit configuration. Fig...

Page 9

41057601th rev.1 9/ 1.3 option specifications options available for okicolor 8 / okipage 8c plus are as follows. (1) 2nd-feeder (2) ram simm module (72 pin simm, 4mb/8mb/16mb/32mb) * make sure to use a set of 2 of the same volume size modules..

Page 10

41057601th rev.1 10/ 1.4 basic specifications (1) dimensions width: 18.8" (478mm) length: 24.5" (622mm) height: 15.6" (396mm) (2) weight approx. 48kg (106lbs) (3) form type: ordinary paper (hammermill 24lbs) and ohp (only cg3710) recommended paper (for color printing) color laser paper (20lb to 24lb...

Page 11

41057601th rev.1 11/ (13) temperatures and relative humidities temperature temperature conditions temperature (in _f) temperature (in _c) remarks 50 to 89.6 32 to 109.4 14 to 109.4 -20 to 122 -20 to 122 10 to 32 0 to 43 -10 to 43 -29 to 50 -29 to 50 operating non-operating storage (1 year max.) deli...

Page 12

41057601th rev.1 12/ 2. Operation okicolor 8 / okipage 8c plus is a tandem color electrophotographic page printer, using 4992- led technologies , opc, dry single-component non-magnetic developing, roller transfer, heat- compression fixing and so on. The printing method used is a black writing method...

Page 13

41057601th rev.1 13/ 2.1 main control board (pce pcb) the control board consists of a cpu ( µ pd30500s2-200) block, a memory control lsi block, an interface control lsi block, a dram block, an eeprom block, a mask rom block, and an interface block. Figure 2.2 shows the functional block diagram of th...

Page 14

41057601th rev.1 14/ (1) cpu the cpu is a 64-bit risc architecture processor (provided by nec). It inputs a frequency of 50mhz and runs at 200mhz. It transfers data to and from memory at 50mhz. (2) otp rom the otp rom block consists of four 16mbit (1m x 16bits) chips and its total size is 8m bytes. ...

Page 15

41057601th rev.1 15/ • basic specificaton - type: 72 pins simm (32 bits buss width) - access time: 60ns, 70ns, 80ns - capacity: 4, 8, 16 or 32mb - parity: none (for the electrical/physical characteristics of the hsp interface, see the hsp interface technical manual.) (9) 2nd cache and 2nd cache cont...

Page 16

41057601th rev.1 16/ figure 2.4 the engine control block (pu) is controlled by the engine control board (px4 pcb) which consists of a cpu (msm65524), general purpose lsi chips, eprom, eeprom, pulse motor drivers, and video memory. (see figure 2.4.) (1) cpu this is an 8-bit cpu (oki msm65524) contain...

Page 17

41057601th rev.1 17/ output voltage use +3.3 v cu unit cpu, led head +5 v logic circuit supply voltage +32 v motor and fan drive voltage and source voltage for high-voltage supply, discharge lamp +12 v hsp, op amp, high voltage power supply –12 v hsp output voltage use remarks ch -1.35 kv ± 50v volt...

Page 18

41057601th rev.1 18/ 2.4 mechanical processes figure 2.5 shows the mechanical processes of okicolor 8/ okipage 8c plus. Figure 2.5 paper ejection roller paper ejection (face down) power supply charging roller cleaning blade paper path selection heat roller ejection roller fixing backup roller contro...

Page 19

41057601th rev.1 19/ 2.4.1 electrophotographic processing mechanism (1) electrophotographic processes each process of the electrophotographic processing mechanism is outlined below. 1 paper pickup this process causes the roller to give a dc voltage to the paper to have a negative charge. With this n...

Page 20

41057601th rev.1 20/ a dc voltage (0v to 2kv) is applied to the driven roller a to positive charge the lower surface of the paper. The negatively-charged paper is electrostatically attracted to the pickup roller. With this, the paper is in close-contact with the conveying belt and conveyed steadily....

Page 21

41057601th rev.1 21/ (4) exposure the light beams from the led head are applied to the surface of the opc drum which is charged negatively. The negative charge on the illuminated surface of the opc drum is reduced according to magnitudes of the light beams and a latent image is formed on the surface...

Page 22

41057601th rev.1 22/ 2 the toner blade scrapes away excessive toner on the developing roller to form a thin film of toner on the surface of the developing roller. 3 the toner is attracted to the latent image on the surface of the opc drum at which the opc drum is in contact with the developing rolle...

Page 23

41057601th rev.1 23/ (6) transferring the transfer roller made of conductive sponge presses the paper against the surface of the opc drum so that the paper may be close contact with the surface of the opc drum. This process fits the paper to the surface of the opc drum by the transfer roller and app...

Page 24

41057601th rev.1 24/ (8) cleaning the toner which remains on the opc drum without being fused is scraped by a cleaning blade and discarded in the waste toner tank. (7) fixing the toner image just transferred to the paper is fused and fixed to the paper while the paper is passing through the gap betw...

Page 25

41057601th rev.1 25/ 2.4.2 paper running process figure 2.6 shows how paper moves in the okicolor 8/ okipage 8c plus. Figure 2.6 paper route face down stacker oil roller fuser low-voltage power supply ac switch transfer roller x 4 light rejector x 4 transfer belt unit id unit up / down actuater belt...

Page 26

41057601th rev.1 26/ (1) paper hopping and transfer and up/down movement of pinch roller 2 paper is hopped and delivered by the mechanism shown below. This mechanism is driven by a single pulse motor. The pulse motor turns in the arrow direction (a) and drives the hopping roller in the direction of ...

Page 27

41057601th rev.1 27/ (a) hopping 1 the pulse motor turns in the arrow direction of “a” (counterclockwise) and drives the hopping roller to move the paper until the entrance sensor turns on. Although the one- way gears b and c are also driven, the resist roller 2 does not turn because the reverse rot...

Page 28

41057601th rev.1 28/ (2) the hopping operation of the front feeder and the up/down operation of the pinch roller 2 are performed by a single pulse motor, as shown below. Idle gear a hopping roller from front one-way clutch gear a idle gear b cam one-way clutch gear b sensor position up/down pinch ro...

Page 29

41057601th rev.1 29/ (a) first and second hopping rollers 1 when the front edge of the paper passes by the pickup roller, the pulse motor of the front feeder turns left (in the direction of “b” to drive the cam. The cam moves up the pinch roller 2. Although the one-way clutch gear a is also rotating...

Page 30

41057601th rev.1 30/ (c) conveying 1 after paper hopping is completed, the pulse motor turns right (in the direction of “b”) to drive the resist rollers 1 and 2. The resist rollers feed the paper until the form sensor turns on. 2 although the one-way gear a is also driven, the first hopping roller d...

Page 31

41057601th rev.1 31/ (2) up/down movement of the i/d unit and rotation of the ep drum the up/down movement of the i/d unit and the rotation of the ep drum are performed by a mechanism shown below. (see figure 2.6-a) this mechanism is driven by a single pulse motor. When the pulse motor turns left (c...

Page 32

41057601th rev.1 32/ figure 2.6-b i/d unit up/down actuator up/down lever i/d unit figure 2.6-c up/down lever i/d unit.

Page 33

41057601th rev.1 33/ (3) lubrication and cleaning of fixing, ejecting, and heat rollers heat motor fixer backup roller a a a a a a a hear roller oil roller oil cleaning roller ejection roller face-down stacker the fixing roller, the ejecting roller, and the heat roller are lu- bricated and cleaned b...

Page 34

41057601th rev.1 34/ 2.5 sensors 2.5.1 paper related sensors sensor status on: front edge detected off: front edge not detected on: a4 size or bigger off: smaller than a4 size on: form present off: form absent on: form present off: form ejected sensor ff sensor 1/2 (entrance sensor 1/2) form width s...

Page 35

41057601th rev.1 35/ 2.5.2 other sensors 1 form end sensor this sensor checks whether the paper cassette is empty. 2 ff form end sensor this sensor checks whether the front feeder has paper. 3 ff home switch this microswitch checks whether the front feeder stage is in the up or down position. 4 ep u...

Page 36

41057601th rev.1 36/ 2.6 correction of color deviation okipage 8c is equipped with an array of i/d units which cannot be from generation of color deviations. This mechanically caused color deviation is corrected electronically as shown below. (1) color deviations to be corrected 1 color deviation in...

Page 37

41057601th rev.1 37/ 2.9 cover opening when the upper, side, or front cover of okicolor 8/ okipage 8c plus is opened, the cover open microswitch turns off, a voltage of 32v to the high-voltage power supply is shut off, and all high-voltage outputs are shut off. At the same time, the cpu receives a s...

Page 38

41057601th rev.1 38/ 2.10 toner low detection • composition the device consists of the stirring gear which rotates at a constant rate, the stirring bar and the magnet on the stirring bar. The stirring bar rotates through the engagement of concave in the stirring gear. Magnet concave stirring bar sti...

Page 39

41057601th rev.1 39/ state of microswitches paper size sw1 sw2 sw3 sw4 0 1 1 1 letter 0 1 0 1 executive 0 0 1 1 a4 1 1 1 0 legal 14 1 0 1 1 legal 13 1 1 0 1 b5 1 1 0 0 a5 1 0 0 1 a6 • when the toner low state is detected for 2 times consecutively, toner low is established. • when the toner full stat...

Page 40

41057601th rev.1 40/ 2.12 power-on processing 2.12.1 self-diagnostic test (1) initial test the following checks are automatically performed when the okicolor 8 / okipage 8c plus page printer is powered on: (a) rom check (b) ram check (c) eeprom check (d) flash rom check (2) rom check (a) checks rom ...

Page 41

41057601th rev.1 41/ (2) do not try disassembly as long as the printer is operating normally. (3) do not remove unnecessary parts: try to keep disassembly to a minimum. (4) use specified service tools. (5) when disassembling, follow the determined sequence. Otherwise, parts may be damaged. (6) since...

Page 42

41057601th rev.1 42/ [service tools] table 3-1 shows the tools required for field replacement of printed circuit boards and units. Table 3-1 service tools no. No. 1-100 philips screwdriver q' ty place of use remarks service tools 1 2 3 4 5 6 8 no. 2-200 philips screwdriver, magnetized no. 3-100 scre...

Page 43

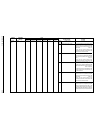

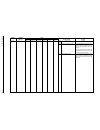

41057601th rev.1 43/ figure 3-1 3.2 parts layout.

Page 44

41057601th rev.1 44/ figure 3-2.

Page 45

41057601th rev.1 45/ figure 3-3.

Page 46

41057601th rev.1 46/ figure 3-4.

Page 47

41057601th rev.1 47/ 3.3 how to change parts this section explains how to change parts and assemblies appearing in the disassembly diagram below. Printer unit cover assy rear (3.3.1) cover (3.3.8) belt cassette assy (3.3.32) heat unit assy (3.3.40) oil roller assy (3.3.41) holder led assy (3.3.45) f...

Page 48

41057601th rev.1 48/ 3.3.1 cover assy rear 1. Unscrew 2 screws 1 then lift the cover assy rear 2 a little bit, then remove the cover assy rear by releasing the lock of two claws. 1 2 figure 3.3.1 cover assy rear.

Page 49

41057601th rev.1 49/ 3.3.2 motor-fan (80-25) 1. Remove the cover assy rear. (see 3.3.1) 2. Unscrew 2 screws 1 . 3. Detach the motor-fan 2 from the guide with its right side lifted then draw the motor-fan. 4. Unplug the cable 3 then remove the motor-fan 2 . 1 2 3 figure 3.3.2 motor-fan (80-25).

Page 50

41057601th rev.1 50/ 3.3.3 paper eject assy the paper eject assy comprises the frame eject assy and the guide paper eject assy. 1. Remove the cover assy rear. (see 3.3.1) 2. Open the top cover. 3. Unscrew 4 screws 1 then remove the frame eject assy 2 . 4. Remove the guide paper eject assy 3 by relea...

Page 51

41057601th rev.1 51/ 3.3.4 cover assy stacker, guide eject fd assy remove the belt cassette assy and the heat unit assy. 1. Remove the cover assy rear. (see 3.3.1) 2. Detach the cable from the cable clamp 1 by releasing its lock. 3. Unscrew 8 screws 2 then remove the cover assy stacker. 4. Unscrew 4...

Page 52

41057601th rev.1 52/ 3.3.5 frame assy upper 1. Remove the cover assy rear. (see 3.3.1.) 2. Remove the cover assy stacker. (see 3.3.4.) 3. Remove the holder led assy. (see 3.3.45.) 4. Detach the cable from the cable clamp 1 by releasing its lock. 5. Remove connections of 4 connector cables 2 and 4 ca...

Page 53

41057601th rev.1 53/ 3.3.6 plate support assy the plate support assemblies are provided right and left. The method of those replacements is the same. 1. Remove the heat unit assy. (see 3.3.40) 2. Remove the cover assy rear. (see 3.3.1) 3. Remove the cover assy stacker. (see 3.3.4) 4. Remove the fram...

Page 54

41057601th rev.1 54/ 3.3.7 limiter 2way (l), (r) / plate guide (l) , (r) 1. Remove the plate support assy (l) and (r). (see 3.3.6) 2. Unscrew 2 screws 1 then remove the limiter 2way (l) 2 and the plate guide (l) 3 . 3. Unscrew 2 screws 4 then remove limiter 2way (r) 5 and the plate guide (r) 6 . 5 6...

Page 55

41057601th rev.1 55/ 3.3.8 cover describes the method of removing the cover assy side (l)/(r), cover assy op panel, cover front (l)/(r) and the cover rear (l). Remove the belt cassette assy and the heat unit assy. 1. Remove the cover assy rear. (see 3.3.1) 2. Remove the cover assy stacker. (see 3.3....

Page 56

41057601th rev.1 56/ 3.3.9 pcb assy : pce remove the belt cassette assy and the heat unit assy. 1. Open the top cover. 2. Unscrew 2 screws 1 to release the lock of the claw by lifting the cover assy side (r) 2 a little bit, then remove the cover assy side (r). 3. Unscrew 2 screws 8 to remove the pla...

Page 57

41057601th rev.1 57/ 3.3.10 motor fan (cu) 1. Open the top cover. 2. Remove the cover assy side (r), frame side (l), cover assy op panel and the cover front (r). (see 3.3.8) 3. Unplug the cable 1 and unscrew 2 screws 2 , 2 collars 4 and then remove the motor fan (cu) 3 . 2 4 1 3 figure 3.3.10 motor ...

Page 58

41057601th rev.1 58/ 3.3.11 pxf pcb/px4 pcb since the pxf pcb and px4 pcb are connected with each other via the connector, remove them at the same time. 1. Remove the pcb assy : pce. (see 3.3.9) 2. Unscrew 5 screws 1 then remove the cover cu 2 . 3. Unplug all the cables 5 connected to the pxf pcb 3 ...

Page 59

41057601th rev.1 59/ 3.3.12 gear heat assy 1. Remove the cover assy side (r), cover assy op panel, cover front (r) and the cover rear (l). (see 3.3.8) 2. Remove the cover cu then unplug all the cables connected to the pxs pcb and unscrew 3 screws. (see 3.3.11) 3. Unplug all the cables connected to t...

Page 60

41057601th rev.1 60/ 3.3.13 main motor (a), (b) assy 1. Remove the pxf pcb and px4 pcb. (see 3.3.11) 2. Unscrew 4 screws 8 and remove 4 plate-earth 9 and 4 lever up/dn 2 1 . 3. Unplug all the cables 2 connected and unscrew 4 screws 3 , then remove the main motor (a) assy 4 . 4. Unplug all the cables...

Page 61

41057601th rev.1 61/ 3.3.14 gear one-way (z30) four gear one-ways (z30) are provided but the method of those replacements is the same. Do not disassemble the gear one-ways (z30) because they are assemblies requires adjustment. 1. Remove the pcb assy : pcm. (see 3.3.9) 2. Remove the cover cu. (see 3....

Page 62

41057601th rev.1 62/ 3.3.15 motor assy bt 1. Remove the main motor (b) assy. (see 3.3.13) 2. Unplug 2 cables 1 connected and unscrew 2 screws 2 , then remove the motor assy bt 3 . 3 1 2 figure 3.3.15 motor assy bt.

Page 63

41057601th rev.1 63/ 3.3.16 power supply unit, holder inlet, sheet insulation 1. Remove the motor-fan (80-25). (see 3.3.2) 2. Remove the frame side (l), the cover assy side (r) and the cover rear (l). (see 3.3.8) 3. Unplug the cable 1 . 4. Remove the holder inlet 3 by unscrewing 2 screws 2 , then re...

Page 64

41057601th rev.1 64/ 3.3.17 sensor assy box toner 1. Remove the power supply unit. (see 3.3.16) 2. Unscrew the screw 1 then remove the sensor assy box toner 2 together with the bracket 3 . 3. Unscrew the screw 4 then remove the sensor assy box toner 2 . 3 2 4 1 figure 3.3.17 sensor assy box toner.

Page 65

41057601th rev.1 65/ 3.3.18 square-shaped connector remove the heat unit assy. 1. Draw the power supply unit. (see 3.3.16) (do not remove the power switch and ac socket from the holder inlet.) 2. Unplug the cable 1 . 3. Remove cable 2 , screw 5 bracket 6 and cable 7 in order and then take off sw fro...

Page 66

41057601th rev.1 66/ 3.3.19 hopping motor 1. Remove the cover assy side (r), cover assy op panel and the cover front (r). (see 3.3.8) 2. Unscrew 2 screws 1 and unplug the cable 2 , then remove the bracket hopping motor 3 . (be careful not to lose the gears 5 , 6 and 7 which slip off at this time.) 3...

Page 67

41057601th rev.1 67/ 3.3.20 gear one-way 1. Remove the bracket hopping motor. (see 3.3.19) 2. Remove the spacer 4 first and release the locks with the shaft by spreading the claws of the gear one-way 1 , 2 and 3 , then remove the gear one-ways. 3 2 1 4 4 4 claw figure 3.3.20 gear one-way.

Page 68

41057601th rev.1 68/ 3.3.21 feeder unit front 1. Remove the cover assy side (r), cover assy op panel, cover front (r) and the cover front (l). (see 3.3.8.) 2. Remove the cover cu. (see 3.3.11) 3. Unscrew the screw 8 and remove the cable 9 . 4. Unplug the cable 1 and unscrew the screw 2 , then remove...

Page 69

41057601th rev.1 69/ 3.3.22 manual feed hopper assy 1. Open the manual feed hopper assy. 2. Release the engagement between the holder and the link then remove the manual feed hopper assy. (be careful not to damage the holder.) holder link 1 figure 3.3.22 manual feed hopper assy.

Page 70

41057601th rev.1 70/ 3.3.23 guide paper input assy 1. Remove the cover assy op panel, cover front (r) and the cover front (l). (see 3.3.8) 2. Remove the feeder unit front. (see 3.3.21) 3. Unscrew 4 screws 1 then draw out the guide paper input assy 2 from the left side by rotating its upper part . (b...

Page 71

41057601th rev.1 71/ 3.3.24 two lever input sensors, lever 2nd feed sensor 1. Remove the guide paper input assy. (see 3.3.23) 2. Release the engagement with the guide by pressing 2 lever input sensors 2 in the arrow direction, then remove them. 3. Release the engagement with the guide by pressing th...

Page 72

41057601th rev.1 72/ 3.3.25 roller registration, roller assy hopping 1. Remove the guide paper input assy. (see 3.3.23) 2. Remove the bracket hopping motor. (see 3.3.19) 3. Remove the gear one-way. (see 3.3.20) 4. Remove the holder gear toner assy. (see 3.3.30) [removal of the roller registration] 5...

Page 73

41057601th rev.1 73/ 3.3.26 roller hopping 1. Remove the roller assy hopping. (see 3.3.25) and remove the 2 sub-roller hopping guide 3 . (be careful not to lose the knock-pin which slips off together when removing the roller assy hopping.) 2. Detach the roller hopping 2 from the shaft 1 . 1 3 2 knoc...

Page 74

41057601th rev.1 74/ 3.3.27 pxu pcb/pxm pcb, lever resist sensor since the pxu pcb and pxm pcb are connected with each other via the cable, remove them at the same time. 1. Remove the guide paper input assy. (see 3.3.23) 2. Unscrew 4 screws 1 and unplug the cable 2 , then remove the pxu pcb 3 and px...

Page 75

41057601th rev.1 75/ 3.3.28 paper end lever 1. Remove the guide paper input assy. (see 3.3.23) 2. Remove the paper end lever 1 by releasing the engagement with the guide. 1 figure 3.3.28 paper end lever.

Page 76

41057601th rev.1 76/ 3.3.29 pco pcb (operator panel) 1. Remove the cover assy side (r) and the cover assy op panel. (see 3.3.8) 2. Unscrew 4 screws 1 and unplug the operator panel cable 2 . 6. Remove the pco pcb 3 by releasing 6 claws. (be careful not to drop the lcd (liquid crystal display) 4 and 5...

Page 77

41057601th rev.1 77/ 3.3.30 holder gear toner assy 1. Remove the cover assy side (r), cover assy op panel, cover front (r) and the cover rear (l). (see 3.3.8) 2. Unplug the cable 1 and unscrew the screw 2 , then remove the holder gear toner assy 3 . 2 3 1 figure 3.3.30 holder gear toner assy.

Page 78

41057601th rev.1 78/ 3.3.31 plate latch lever (fd), spring latch lever (fd) remove the belt cassette assy. 1. Remove the cover assy side (r), cover assy op panel, cover front (r) and the cover front (l). (see 3.3.8) 2. Open the cover cu. (see 3.3.11) 3. Unplug the cable 1 . 4. Unscrew 4 screws 4 the...

Page 79

41057601th rev.1 79/ 3.3.32 belt cassette assy 1. Open the top cover. 2. Release the lock by drawing the cover knob then open the cover assy side (l). 3. Turn the waste toner box (box toner assy) 1 to the left by pressing it down, then remove it. 4. Draw out the belt cassette assy 2 by lifting it a ...

Page 80

41057601th rev.1 80/ 3.3.33 high voltage power supply unit, bracket hv (bt) assy 1. Remove the belt cassette assy. (see 3.3.32) 2. Unscrew 2 screws 1 with the stacker cover opened, then remove the plate hv 2 . 3. Unplug the cable 3 and 7 codes 4 . 4. Unscrew 2 screws 5 then remove the high voltage p...

Page 81

41057601th rev.1 81/ 3.3.34 eraser bracket assy, eraser bracket (kcm) assy 1. Remove the belt cassette assy. (see 3.3.32.) 2. Open the stacker cover. 3. Remove four screws 5 and then remove the plate blind 6 . [removing the eraser bracket assy] 4. Remove the screw 1 and the connector 2 . 5. Release ...

Page 82

41057601th rev.1 82/ 3.3.35 shaft link 1. Remove the eraser bracket assy. (see 3.3.34.) 2. Remove the gear one-way (z30). (see 3.3.14.) 3. Remove the e-ring 3 by sliding the sensor assy t (kcm) 1 and bracket sensor t (kcm) 2 together in the arrow (a) direction. When removing shaft (k) assy, remove 3...

Page 83

41057601th rev.1 83/ 3.3.36 contact (bl-r) assy, contact (cl-r) assy 1. Remove the gear one-way (z30). (see 3.3.14) 2. Remove the motor assy bt. (see 3.3.15) 3. Remove the high voltage power supply unit. (see 3.3.33) 4. Remove the shaft link. (see 3.3.35) [removal of the contact (bl-r) assy] 5. Unsc...

Page 84

41057601th rev.1 84/ 3.3.37 contact (bl-l) assy, contact (cl-l) assy 1. Remove the shaft link. (see 3.3.35) [removal of the contact (bl-l) assy] 2. Unscrew 2 screws 1 then remove the contact (bl-l) assy 2 . [removal of the contact (cl-l) assy] 3. Unscrew 2 screws 3 then remove the contact (cl-l) ass...

Page 85

41057601th rev.1 85/ 3.3.38 contact sb assy 1. Remove the contact (bl-l) assy and contact (cl-l) assy. (see 3.3.37) 2. Unscrew 3 screws 1 then remove the plate blink 2 . 3. Unplug 7 codes 3 . 4. Unscrew 3 screws 4 then remove the contact sb assy 5 . 3 1 3 2 5 4 3 figure 3.3.38 contact sb assy.

Page 86

41057601th rev.1 86/ 3.3.39 pxc pcb 1. Remove the contact (bl-r) assy and contact (cl-r) assy. (see 3.3.36) 2. Remove the contact (bl-l) assy and contact (cl-l) assy. (see 3.3.37) 3. Remove the hopping motor. (see 3.3.19) 4. Remove the motor assy bt. (see 3.3.15) 5. Remove the gear heat assy. (see 3...

Page 87

41057601th rev.1 87/ 3.3.40 heat unit assy 1. Open the stacker cover. 2. Release the lock by turning down the lever lock heat guides (blue) on both sides, then lift the heat unit assy 1 and remove it. 1 lever lock heat guide figure 3.3.40 heat unit assy.

Page 88

41057601th rev.1 88/ 3.3.41 oil roller assy 1. Remove the heat unit assy. (see 3.3.40) 2. Release the lock by turning down the lever in the arrow (a) direction, then slide the oil roller assy 1 with its right side lifted and remove it. 1 lever (a) figure 3.3.41 oil roller assy.

Page 89

41057601th rev.1 89/ 3.3.42 lever lock heat (l)/(r), guide side heat, spring lock removing methods for right side and left side of each part are the same. Here describes the method for right side. 1. Remove the heat unit assy. (see 3.3.40) 2. Unscrew 2 screws 1 then remove the guide side heat 2 . 3....

Page 90

41057601th rev.1 90/ 3.3.43 pxl pcb 1. Remove the paper eject assy. (see 3.3.3) 2. Remove the belt cassette assy. (see 3.3.32) 3. Remove the heat unit assy. (see 3.3.40) 4. Unplug the cable 1 and the screw 2 , then remove pxl pcb 3 . 5. Release the lock of the claw then remove the sensor cover 4 . 1...

Page 91

41057601th rev.1 91/ 3.3.44 heat unit guide assy 1. Remove the cover assy rear. (see 3.3.1) 2. Remove the paper eject assy. (see 3.3.3) 3. Remove the gear heat assy. (see 3.3.12) 4. Remove the belt cassette assy. (see 3.3.32) 5. Open the stacker cover and remove the heat unit assy. (see 3.3.40) 6. U...

Page 92

41057601th rev.1 92/ 3.3.45 holder led assy, led head remove the belt cassette assy and the heat unit assy. 1. Unplug the cable 1 . 2. Remove the led head 3 by spreading the holder led assy 2 a little bit. (be careful not to lose the spring 4 which slips off together.) 3. Remove the holder led assy ...

Page 93

41057601th rev.1 93/ 4. Adjustments adjustments are carried out by key operations on the operator panel, by software operation panel, and by eeprom of pu (px4-pcb) setting. This page printer supports three maintenance modes. Select and set a maintenance mode fit for the adjustment. 4.1 maintenance m...

Page 94

41057601th rev.1 94/ user maintenance mode memu system category selection df after pressing enter key after completing the process menu menu menu reset resetting reset hex dump on-line hex dump resource save auto * off 400kb 900kb 1.6mb 2.5mb • • • 19.6mb 22.5mb receive buffer auto * off 100kb 512kb...

Page 95

41057601th rev.1 95/ 4.1.2 system maintenance mode to set the system maintenance mode, turn on the power switch of the page printer while pressing on the recover key. Note: the system maintenance mode is hidden and not available to the user. To exit this mode, press the online switch except during r...

Page 96

41057601th rev.1 96/ system maintenance mode menu system category selection df after pressing enter key after completing the process page cnt nnnnnn page prt disable * enable cont prt cont prt cont prt printing cancelled (on line sw press) eeprom eeprom eeprom reset resetting reset hsperr recover * ...

Page 97

41057601th rev.1 97/ 4.1.3 engine maintenance mode to set the engine maintenance mode, turn on the power switch of the page printer while pressing on the enter and form feed keys. The engine maintenance mode is set and “eng mnt” is displayed on-screen. Note: the engine maintenance mode is hidden and...

Page 98

41057601th rev.1 98/ engine maintenance mode memu system (1/2) category selection df after pressing enter key after completing the process yellow led head no.1 setting eeprom no.2 - no.16 no.17 - no.32 magenta led head no.1 setting eeprom no.2 - no.16 no.17 - no.32 cyan led head no.1 setting eeprom ...

Page 99

41057601th rev.1 99/ engine maintenance mode menu system (2/2) category selection df after pressing enter key after completing the process yellow drmcnt nnnn yellow drmcnt t nnnnnnn magenta drmcnt nnnn magenta drmcnt t nnnnnnn cyan drmcnt nnnn cyan drmcnt t nnnnnnn black drmcnt nnnn black drmcnt t n...

Page 100

41057601th rev.1 100/ 4.2 adjustments after parts replacement adjustments required after parts replacement are listed below. Adjustment and correction of color deviations are always required after parts are replaced. Part replaced adjustment required led head correct color deviations. Drum cartridge...

Page 101

41057601th rev.1 101/ find a parameter value corresponding to the illumination level of the led head in the table below. A. Illumination level - led driving time table parameter value illumination level parameter value illumination level (displayed on lcd) of led head (displayed on lcd) of led head ...

Page 102

41057601th rev.1 102/ 4.2.2 color deviation correction after replacing a part of the page printer, be sure to check whether colors are matched. If not, correct the deviations. - method of correcting color deviations (a) enter menu 2 mode, select the color deviation correction mode (color reg adjust ...

Page 103

41057601th rev.1 103/ menu menu enter menu – + menu menu print pattern color reg adjust color balance adjust 0 #1 adjust +7 #1 adjust -7 #1 adjust -1 #1 language print pattern exit enter adjust 0 #1 adjust 0 #2 adjust 0 #9 print excute print pattern color reg adjust print pattern color reg adjust pr...

Page 104

41057601th rev.1 104/ olor check pattern.

Page 105

41057601th rev.1 105/ 5.2 cleaning periodically clean the inside and outside the page printer with soft cloth and small vacuum cleaner (handy cleaner) when necessary. Caution: do not touch the terminals of the image drums, the led lens array, and the led head connector block. 5.3 cleaning the led le...

Page 106

41057601th rev.1 106/ 6. Troubleshooting procedures 6.1 troubleshooting tips (1) check the basic check points covered in the user’s manual. (2) gather as much information on the problem from the customer as possible. (3) perform inspections in conditions close to those in which the problem had occur...

Page 107

41057601th rev.1 107/ 6.5.1 lcd status message/trouble list table 6-1 lists the status and troubles that may be indicated by messages on the lcd. Xxx: emulation in operation (aut, pcl, ps) ffff: trays (tray1, tray2, front) mmmmmm: paper size (letter, a4, etc...) 6.4 preparation for troubleshooting (...

Page 108

Category lcd status led message k c m y ready attention trouble or status remedy 41057601th rev.1 108/ daily status buffer overflow paper size error paper jam error on on on on undefined on undefined undefined undefined undefined off blink undefined undefined undefined undefined off blink undefined ...

Page 109

Category lcd status led message k c m y ready attention trouble or status remedy 41057601th rev.1 109/ check the size of paper in the tray or whether two or more paper sheets were fed at a time. When the cover is opened and closed, this error is reset and printing resumes. If this error occurs frequ...

Page 110

Category lcd status led message k c m y ready attention trouble or status remedy error nn controller error undefined undefined undefined undefined off blink details of error code (nn) remedy 41057601th rev.1 110/ indicates that an error was found in the program rom by the pro- gram rom check. Indica...

Page 111

Category lcd status led message k c m y ready attention trouble or status remedy error nn controller error details of error code (nn) remedy 41057601th rev.1 111/ indicates that toner sensor is abnormal when page counter is below thirty.(alarm) indicates that a timeout occurred on interface between ...

Page 112

Category lcd status led message k c m y ready attention trouble or status remedy error nn controller error undefined undefined undefined undefined off blink details of error code (nn) remedy 41057601th rev.1 112/ humidity sensor error waste-toner sensor error pinch roller up/down error fusing unit e...

Page 113

Category lcd status led message k c m y ready attention trouble or status remedy error nn controller error undefined undefined undefined undefined off blink details of error code (nn) remedy 41057601th rev.1 113/ engine firmware lost control eeprom error (timeout) eeprom error (not exist) engine rom...

Page 114

Category lcd status led message k c m y ready attention trouble or status remedy error nn controller error undefined undefined undefined undefined off blink details of error code (nn) remedy 41057601th rev.1 114/ f1 f4 monitor error (argument error) engine background error turn on the power of the p...

Page 115

Category lcd status led message k c m y ready attention trouble or status remedy error controller nn-aaaaaaaa controller error undefined undefined undefined undefined off blink details of error code (nn) remedy indicates that the controller error has occurred. Turn on the power of the page printer a...

Page 116

41057601th rev.1 116/ no. Trouble flowchart number 1 the printer does not work normally after being turned on. 1 2 jam error paper input jam (1st tray) 2 -1 paper input jam (front feeder) 2 -2 paper feed jam 2 -3 paper exit jam2-4 2 -4 3 paper size error 3 4 i/d unit up/down error 4 5 fusing unit er...

Page 117

41057601th rev.1 117/ 1 the printer does not work normally after turned on the power of rhe printer. • turn off the power of the printer, wait a few seconds, then turn on power again. • is displayed on the lcd (for about 1 second)? • no is the ac cable connected correctly? No connect the ac cable co...

Page 118

41057601th rev.1 118/ 2 -1 paper input jam (1st tray) • does the paper reach the ff sensor 1 or 2? • yes remove the paper jam. Do the sensor levers (ff sensor 1, ff sensor 2) work right? • no replace the defective sensor lever (ff sensor 1, ff sensor 2). ▼ • yes do the sensors (ff sensor 1, ff senso...

Page 119

41057601th rev.1 119/ 2 -2 paper input jam (front feeder) • is the paper jam immediately occur after the page printer is powered on? • yes is the paper jam occur ff sensor 2? Yes remove the paper jam. ▼ • no do the sensor levers (ff sensor 2) work right? No replace the defective sensor lever (ff sen...

Page 120

41057601th rev.1 120/ a 2 -3 paper feed jam • is the paper jam immediately occur after the page printer is powered on? • yes is there jam med paper at the write sensor? Yes remove the paper jam. ▼ • no does the lever of the write sensor work right? No replace the lever of write sensor. ▼ • yes does ...

Page 121

41057601th rev.1 121/ b c • no is the resistance of belt motor about 7.1 ohms? No replace the belt motor. ▼ • yes check the gear engagement or replace the engine board. ▼ • yes check the gear engagement or replace the belt cassette assy. ▼ • no does the leading edge of a paper pass by the exit senso...

Page 122

41057601th rev.1 122/ 2 -4 paper exit jam • is the paper jam immediately occur after the page printer is powered on? • yes is the jammed paper at the exit sensor? Yes remove the paper . ▼ • no does the sensor lever work correctly? No replace the defective sensor lever. ▼ • yes does the exit sensor w...

Page 123

41057601th rev.1 123/ 3 paper size error • is the paper which being used under the specification? No use paper which is under the specification. Yes is the paper jam med at the lever regist sensor or the write sensor? Yes remove the paper. ▼ • yes does the sensor levers (lever regist sensor ) work c...

Page 124

41057601th rev.1 124/ 4 image drum unit (idu) up/down error • turn off power to the page printer, wait a few seconds, then turn on power again. • each image drum unit (idu) motor rotating for printout? • no is the value of idu motor resistance about 7.1 ohms? No replace the defective idu motor. ▼ • ...

Page 125

41057601th rev.1 125/ 5 fusing unit error • is the fusing unit trouble occur immediately after the page printer is powered on? • yes is heat roller thermistor open or shorted? (see figure 6.1.) (normal registance and temperature are about between 90 ohms the 700 ohms at room temperature between 0 ° ...

Page 126

41057601th rev.1 126/ 6 fan motor error • is the low-voltage power supply fan rotating after the page printer is powered on? • no is +32v being supplied on the fu2 of the engine board (px4 pcb)? • no is +32v being supplied on the power connector of the engine board (px4 pcb)? 32v: pin 7, 8, 9, 10 no...

Page 127

41057601th rev.1 127/ 7 cannot receive data from parallel interface. • is “parallel i/f” (in menu 1) set to “enable”? No set the “parallel i/f” (in menu 1) to “enable.” ▼ • yes is parallel interface of the host computer set to “bidirectional communication”? Yes set the “bidirectional communication” ...

Page 128

41057601th rev.1 128/ 8 cannot receive data from hsp interface. • is hsp i/f board connected correctly to the main board (pce pcb)? No connect the hsp i/f board correctly to the main board (pce pcb). ▼ • yes is there any bent or broken pin on the hsp i/f board? Yes replace the hsp i/f board. ▼ • no ...

Page 129

41057601th rev.1 129/ printout problem reference flowchart no. Light or blurred images on the whole printout area (figure 6.2-a) 1 dirty stained ground (figure 6.2-b) 2 no printout data on blank paper (figure 6.2-c) 3 black stripe or lines in the vertical direction (figure 6.2-d) 4 white stripe or l...

Page 130

41057601th rev.1 130/ 1 light or blurred images on the whole printout area • is toner low? (“toner low” indicator on?) yes supply toner. ▼ • no specified paper? No use the specified paper. ▼ • yes is the lens of the led head dirty? Yes clean the led head lens. ▼ • no is each led head assembly connec...

Page 131

41057601th rev.1 131/ a ▼ • yes check the connection of the cables, replace the high-voltage power supply, or belt cassette assembly. Recovered? Yes end ▼ • no is each terminal of each image drum unit connected correctly to the contact assembly? (see figure 6.2.) no make the terminals be in contact ...

Page 132

41057601th rev.1 132/ 2 dirty stained ground (figure 6.2-b) • each image drum exposed to external lights for a long time? Yes replace the image drum unit or put the image drum unit in the printer and close the upper cover and wait for 15min. Note: after replacing the image drum unit, be sure to rese...

Page 133

41057601th rev.1 133/ a no check the connection of the cables or replace the low-voltage power supply. ▼ • yes is +32v on pin 2 of the hvolt connector of the engine board (px4 pcb) being supplied? No replace the engine board. ▼ • yes check the connection of the cables or replace the high-voltage pow...

Page 134

41057601th rev.1 134/ 3 void print out • is each led head assembly connected to the junction board (pd6 pcb) correctly? No check whether or not the connection of the cables or connect the led assembly to the junction board (pd6 pcb) correctly. ▼ • yes is +3.3v on the following pins of the headpow co...

Page 135

41057601th rev.1 135/ notes: 1. When replacing the engine board (px4 pcb), demount the eeprom chip from the old engine board and remount it on the new one. 2. After replacing the image drum unit and the belt cassette assembly, be sure to reset their counters in the user maintenance mode. 3. After re...

Page 136

41057601th rev.1 136/ 4 black stripe or lines in the vertical direction • is each led head assembly connected to the junction board (pd6 pcb) correctly? No connect the led head assembly to the junction board correctly. ▼ • yes check the connection of the cables or replace the led head assembly. Is t...

Page 137

41057601th rev.1 137/ 5 white stripe or lines in the vertical direction • is each led head lens contaminated? Yes clean the led head lens. ▼ • no is each led head assembly connected to the junction board (pd6 pcb) correctly? No connect the led head assembly to the junction board (pd6 pcb) correctly....

Page 138

41057601th rev.1 138/ 6 poor fusing (image are blurred or peeled off when touched with finger.) • is the paper under specification being used? No use the paper under the specification. ▼ • yes is contacts of the fusing unit assembly connected correctly? No connect the contacts correctly. ▼ • yes are...

Page 139

41057601th rev.1 139/ note: after replacing the image drum unit the fusing unit and the belt cassette assembly, be sure to reset their counters in the user maintenance mode. Possibly defective part repairing 94.2 mm image drum replace the image drum unit. 44.0 mm developing rooler replace the image ...

Page 140

41057601th rev.1 140/ 8 missing characters or synthesization colors • is each led head lens contaminated? Yes clean the lens of led head. ▼ • no is each led head assembly connected to the junction board (pd6 pcb) correctly? No check the connection of the cables (between each led head and the junctio...

Page 141

41057601th rev.1 141/ no make the terminals be in contact with the contact assembly correctly. ▼ • yes replace the the image drum unit. Notes: 1. When replacing the engine board (px4 pcb), demount the eeprom chip from the old engine board and remount it on the new one. 2. After replacing the image d...

Page 142

41057601th rev.1 142/ 9 poor synthesization colors • correct color deviations of each led head by “color reg adjust execute.” is the problem recoverd? Yes end ▼ • no are there any gear broken of the unit (image drum unit gear assembly, front feeder assembly, belt unit assembly or belt motor assembly...

Page 143

41057601th rev.1 143/ 0 printout colors different from original colors • is each led head lens contaminated? Yes clean the led head lens. ▼ • no is each led head assembly connected to the junction board (pd6 pcb) correctly? No check the connection of the cables (between each led head and the junctio...

Page 144

41057601th rev.1 144/ no make the terminals be in contact with the contact assembly correctly. ▼ • yes replace the the image drum unit. Notes: 1. When replacing the engine board (px4 pcb), demount the eeprom chip from the old engine board and remount it on the new one. 2. After replacing the image d...

Page 145

41057601th rev.1 145/ charge roller ground developing roller toner supply roller figure 6.3.

Page 146

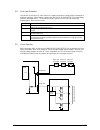

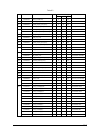

41057601th rev.1 146/ 7. Wiring diagram 7.1 resistance check unit circuit diagram illustration resistance between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω belt motor yidu motor midu...

Page 147

41057601th rev.1 147/ unit circuit diagram illustration resistance between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω cidu motor bidu motor resist motor blue blue blue blue m 1 2 3 4 ...

Page 148

41057601th rev.1 148/ brown brown brown brown m 1 2 3 4 unit circuit diagram illustration resistance between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω between pins 1 and 2: 7.1 Ω between pins 3 and 4: 7.1 Ω heater motor ff motor white white white white m 1 2 3 4.

Page 149

41057601th rev.1 149/ unit circuit diagram illustration resistance fan 1 (to: low power supply) fan 2 (to: px4-pcb) red black +38 v 1 fanalm-n 3 0 v 2 m white red black +38 v 1 fanalm-n 3 0 v 2 m white a b c d thermostat heater backup roller thermistor between pins c and d: 205k Ω (at 25 ° c) betwee...

Page 150

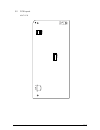

41057601th rev.1 150/ 7.2 program/font rom location (1) pce-pcb psimmh psimml cs02 cs04 cs01 cs03 panel mupis cent simm0_l simm1_l simm0_h simm1_h pu e2rom.

Page 151

41057601th rev.1 151/ (2) px4-pcb pxfif fan1 ff yidreg mckid hetbelt hvolt psize covopn head3 head2 head1 headpow sw1 cuif fan2 rsens therm power 1 2 29 30 a1 b1 a15 b15 ic4.

Page 152

41057601th rev.1 152/ (3) power-supply pcb tr-y tr-m tr-c tr-b cn1 db-b db-c gnd ch sb db-m db-y (4) pco pcb d4 d3 d2 d1 d5 d6 sw1 sw5 sw2 sw6 sw3 sw7 sw4 sw8.

Page 153

41057601th rev.1 153/ (5) pxf pcb option pendtnr toner updown b1 a1 b15 a15 8 1 8 1 fsens joden 14 1 1 12 pxfif.

Page 154

41057601th rev.1 154/ 8. Parts list fig.8-1 4 1 5 l j 8 9 0 a h b n n m d e c g f i 7 k 3 2 6 o.

Page 155

41057601th rev.1 155/ table.8-1 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 q'ty/u 1 1 1 1 1 1 - - 1 1 1 1 1 1 1 - - 1 1 1 1 4 1 1 1 2 1 parts no. 40315201 40098401 40187501 40187601 40314801 40315001 - - 40098301 40314905 40314906 40492603 40492604 40098201 40315101 - - 40...

Page 156

41057601th rev.1 156/ fig.8-2 2 1 o 3 n c 0 9 q 6 m j 8 7 8 s h e 7 k g 4 p d r l b a f t 5.

Page 157

41057601th rev.1 157/ table.8-2 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 q'ty/u 1 1 1 1 1 1 1 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 parts no. 40255201 40303501 40303401 40410701 40018901 40019001 40311201 40193501 40193601 40303301 40309801 40490801 40490802...

Page 158

41057601th rev.1 158/ no. 23 24 25 26 27 28 29 30 q'ty/u 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 parts no. 41070201 41070202 41070203 41070204 41070205 41070206 41070207 41070208 40191201 psw2w3-30c 40838801 40449001 40294201 40641801 40645401 40645402 remarks consumable: oda(120v) consumable: oda(120v) con...

Page 160

41057601th rev.1 160/ table.8-3 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 q'ty/u 1 2 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 2 1 1 3 1 1 2 1 2 1 1 1 1 1 1 parts no. 40175701 40096401 40135301 4pp4076-5154p001 40450401 40171401 40171301 40...

Page 161

41057601th rev.1 161/ no. 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 q'ty/u 2 1 1 1 1 1 2 1 1 1 4 1 1 1 1 1 1 (1) 1 1 1 1 1 1 1 1 1 1 2 3 1 1 4 1 1 parts no. 4pb4043-4718p001 40162101 40175101 40449401 40449701 40097301 40144301 40144401 ...

Page 162

41057601th rev.1 162/ fig.8-4 1 6 6 6 6 5 7 4 2 2 k 2 2 3 c e 0 i c a h h h h b c f j j j j d g 3 3 3 8 9 9 9.

Page 163

41057601th rev.1 163/ table.8-4 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 q'ty/u 3 1 1 1 3 1 1 1 3 3 4 4 16 4 4 3 4 1 3 1 1 parts no. 40324501 40278101 4pp4076-5308p001 40324401 40324601 40135301 40309001 40308501 40324301 40167901 40132301 40132401 re6-sus 40168401 40188501 40136201...

Page 164

41057601th rev.1 164/ fig.8-5 1 ` 2 [ ] x z e e k j h i y a l m l b b k n o b b 6 6 3 4 c d t v u c g r h h g s p q d e f i 5 j a a 5 5 7 a w 0 9 8 a a c b c d b d.

Page 165

41057601th rev.1 165/ table.8-5 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 1 1 1 1 4 3 1 1 1 1 3 1 1 1 1 1 1 2 1 1 1 1 1 1 (1) (1) 1 1 1 (1) (1) 1 (1) 1 2 (1) (1) 40310001 40392301 40309101 40309201 40208101 40664401 40175001 40143401 40143...

Page 166

41057601th rev.1 166/ no. 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 q'ty/u 1 - 1 1 1 4 1 (1) 1 1 1 1 1 1 parts no. 40450001 - 40135301 40448901 40664501 40583901 40704901 (40447201) 8164303m0000 816a2323m0000 41088101 41088201 41088301 41088401 remarks designated in fig.8-3 name belt_motor_mech_a...

Page 167

41057601th rev.1 167/ fig.8-6 h b e f 2 j 4 4 i 3 3 6 9 8 7 g c d a 0 5 1 5.

Page 168

41057601th rev.1 168/ table.8-6 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 q'ty/u 1 4 8 8 8 1 1 1 1 1 1 1 1 1 4 4 (1) 1 4 4 parts no. 40187901 40449101 40187801 40829701 40197705 40536001 40394201 40171702 40408601 40449301 40197401 40449201 40218301 lp-6665-1 2381005p0001 40547301 (4045...

Page 169

41057601th rev.1 169/ fig.8-7 1 2 5 6 3 4.

Page 170

41057601th rev.1 170/ table.8-7 no. 1 2 3 4 5 6 q'ty/u 1 1 1 1 1 1 parts no. 40449801 4pp4076-5360p001 220a1866p0140 40177701 40368301 4pp4076-5742p001 remarks name guide_cassette(r)sub_assy spring_detector square_shaped_connector connector_cord board-pxc plate_earth (link) 500 3 3 3 3 3 3 1000 6 6 ...

Page 171

41057601th rev.1 171/ fig.8-8 7 7 5 a 5 6 6 3 3 4 4 0 9 1 8 2.

Page 172

41057601th rev.1 172/ table.8-8 no. 1 2 3 4 5 6 7 8 9 10 11 q'ty/u 1 2 2 2 2 2 2 1 1 1 1 parts no. 40165301 40124101 40129901 40130701 40130601 40130201 40129501 40135301 40308601 40135301 40449601 remarks name frame_motor(id1) motor_pulse(id) gear_(25/75) gear_helical(67/43/24) gear_helical(67/18) ...

Page 173

41057601th rev.1 173/ fig.8-9 7 6 6 5 5 4 1 8 8 2 3 4 3 7.

Page 174

41057601th rev.1 174/ table.8-9 no. 1 2 3 4 5 6 7 8 q'ty/u 1 2 2 2 2 2 2 2 parts no. 40129401 40124101 40129901 40130701 40130601 40130201 40129501 40135301 remarks name frame_motor(id) motor_pulse(id) gear_(25/75) gear_helical(67/43/24) gear_helical(67/18) gear_z53/44 bracket_support(id) photo_inte...

Page 175

41057601th rev.1 175/ appendix a centronics parallel interface 1) connector • printer side : 36-pin receptacle (female) type 57re-40360-830b-d29 (made by daiichi denshi) or equivalent • cable side : 36-pin plug (male) type 57-30360 (made by daiichi denshi) or equivalent plug-552274-1 (amp), 552073-1...

Page 176

41057601th rev.1 176/ • connector pin arrangement 3) table of parallel i/f signals data strobe data bit - 1 data bit - 2 data bit - 3 data bit - 4 data bit - 5 data bit - 6 data bit - 7 data bit - 8 acknowledge busy paper end select auto feed - 0v +5v 0v signal ground input prime fault 0v - - select...

Page 177

41057601th rev.1 177/ 6) timing charts • compatible mode a) data receiving timing 4) signal level • low : 0 v to +0.8 v • high : +2.4 v to +5.0 v 5) specifications item description mode compatibility mode, nibble mode, ecp mode data bit length 8 bits: compatibility mode, 4 bits: nibble mode, 9 bits:...

Page 178

41057601th rev.1 178/ b) on-line off-line switching timing by on-line sw on-line sw busy 100 ms max. Select c) off-line on-line switching by on-line sw select acknowledge on-line sw busy 0 min. 100 ms max. 0.5 µ s to 10 µ s d) nlnit timing (when set to the effective input prime signal) input prime s...

Page 179

41057601th draft version 179/ appendix b high capacity second paper feeder 1. Outline 1.1 functions the printer is mounted on top of this high capacity second paper feeder, and it supplies paper automatically through the operation of hopping motor, which is driven by signals sent from the printer. T...

Page 180

41057601th draft version 180/ 2. Mechanism description 2.1 general mechanicsm the sheet at the very top of the stack in the paper cassette is fed into the printer, one sheet at a time, when the high capacity second paper feeder receives the signal from the printer. (1) first, the hopping motor rotat...

Page 181

41057601th draft version 181/ 2.2 hopper mechanism the hopper automatically feeds the printer with the paper being set, single sheet at a time. When the paper is loaded in the paper cassette, it is then transported by the hopping motor, carrying forward only a single sheet caught by hopping roller a...

Page 182

41057601th draft version 182/ 3. Parts replacement this section covers the procedures for the disassembly, reassembly and installations in the field. This section describes the disassembly procedures, and for reassembly procedures, basically proceed with the disassembly procedures in the reverse ord...

Page 183

41057601th draft version 183/ no. 1-100 philips screwdriver no. 2-100 philips screwdriver no. 3-100 screwdriver no. 5-200 screwdriver digital multimeter pliers handy cleaner 2~2.5 mm screws 3~5 mm screws 1 1 1 1 1 1 1 1 tweezers 1 no. Service tools q'ty place of use remarks 1 2 3 4 5 6 7 8 9 led hea...

Page 184

41057601th draft version 184/ 3.2 parts layout this section describes the layout of the main components. Cover upper upper plate second side frame (l) feed roller roller holder second side frame (r) feed gear (one-way) hopping gear (one-way) hopping motor idle roller idle roller hopping roller contr...

Page 185

41057601th draft version 185/ 3.3 parts replacement methods this section describes the parts replacement methods for the components listed in the disassem- bly order diagram below. High capacity second paper feeder idle rollers (3.3.1) aolt-pcb (3.3.2) hopping motor (3.3.3) feed roller (3.3.4) hoppi...

Page 186

41057601th draft version 186/ 3.3.1 idle rollers (1) remove 13 screws 1 and remove the cover upper 2 ,sliding it. (2) remove two screws 3 and remove the front panel assy 4 . (the earth plate 5 come off at the same time, so be careful not to lose them.) (3) remove two idle rollers 6 . 3 5 4 2 6 1 1 1...

Page 187

41057601th draft version 187/ 3.3.2 aolt-pcb (1) remove 13 screw 1 and remove the cover upper 2 , sliding it (see 3.3.1 step1.). (2) remove three connectors 3 and three screws 4 . (3) remove the aolt-pcb 5 . 2 4 4 3 3 3 5 1 1 1 1.

Page 188

41057601th draft version 188/ 3.3.3 hopping motor (1) remove the cover upper (see 3.3.1 step1). (2) remove the roller holder assy (see 3.3.1 step2). (3) remove two connectors 1 and two screws 2 , then remove the hopping motor assy 3 . Three gears 4 and the connecting lever 5 , as well as the wave wa...

Page 189

41057601th draft version 189/ 3.3.4 feed roller (1) remove the cover upper (see 3.3.1 step1). (2) remove the roller holder assy (see 3.3.1 step2). (3) remove the aolt-pcb (see 3.3.2). (4) remove the hopping motor assy (see 3.3.3). (5) remove the latch on the feed roller gear 1 and remove the feed ro...

Page 190

41057601th draft version 190/ 3.3.5 hopping roller (1) remove the feed roller (see 3.3.4). (2) remove two-e rings 1 and three knock pins 2 . (be careful no to lose knock pins 2 .) (3) remove the latch on the hopping roller gear 3 and remove the hopping roller gear 3 . The bearing f 4 comes off at th...

Page 191

41057601th draft version 191/ 3.3.6 side frame (l) assy (1) remove the hopping roller (see 3.3.5). (2) remove the four screws 1 and remove the cover lower. (3) remove three screws 2 and remove the upper plate 3 . (4) remove the cassette lock spring 4 , link 5 , pull block 6 (note the directions of t...

Page 192

41057601th draft version 192/ 3.3.7 side frame (r) assy (1) remove the hopping roller (see 3.3.5). (2) remove four screws 1 and remove the cover lower. (3) remove three screws 2 and remove the upper plate 3 . (4) remove the cassette lock spring 4 , link 5 , pull block 6 and earth plate 7 (note the d...

Page 193

41057601th draft version 193/ 4. Troubleshooting 4.1 precautions prior to the troubleshooting (1) go through the basic checking items provided in the operator guide. (2) obtain detailed information concerning the problem from the user. (3) go through the checking in the conditions similar to that in...

Page 194

41057601th draft version 194/ carry out detailed troubleshooting according to the troubleshooting flow (see 4.3.2) troubleshooting according to the lcd status message list (see 4.3.1) problem displayed by the lcd message paper input jam check tray 2 paper feed jam check tray 2 error paper size check...

Page 195

41057601th draft version 195/ 4.3.2 troubleshooting flow • ( jam error ) paper input jam • does paper jam occur at the inlet when the power is turned on? • yes is the paper located above the sensor plate (inlet)? • yes remove the paper. ▼ • no is the sensor plate (inlet) operating normally? • no rep...

Page 196

41057601th draft version 196/ 5. Connection diagram 5.1 interconnection diagram aolt - pcb cn24 1 op-m1a 2 op-m1b 3 op-m2a 4 op-m2b m cn23 op-psz1-n op-psz2-n op-psz3-n op-psz4-n ov + 5v 1 2 3 4 5 6 hopping motor to cassette switch board (aold-pcb) cn22 paperin-n sclk-n data-n optsdp-n ovd + 30v 1 2...

Page 197

41057601th draft version 197/ sen1 cn22 cn23 cn24 5.2 pcb layout aolt-pcb.

Page 198

41057601th draft version 198/ 6. Parts list 4 d 9 3 b 6 c a e f 2 j i l 0 1 k g g g 5 7 h 9 8.

Page 199

41057601th rev.1 199/199 table 6-1 high capacity second paper feeder no. Description part no. Q’ty 500 1000 2000 remarks 1 aold-pcb 4ya4046-1646g011 1 3 6 12 2 feed roller 41174001 1 3 6 12 3 hopping motor 4pb4076-5718p001 1 3 6 12 4 hopping gear 4pb4043-4486p001 1 3 6 12 5 hopping roller assy 4pa40...