- DL manuals

- Oki

- Printer

- OKIOFFICE 1200

- Field Engineering Manual

Oki OKIOFFICE 1200 Field Engineering Manual

Summary of OKIOFFICE 1200

Page 1

Okioffice 1200 1600 field engineering manual version 2.0 (11 june 2002).

Page 2: Safety Information

Safety information led safety label a led safety label is attached to the outside of the machine as shown below. Battery precautions caution danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Dispose of used batterie...

Page 3

Finland only varoltus paristo voi räjähtää, los se on virheellisesti asennettu. Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti. All areas caution “replace only with the same or equivalent type recommended by the manufacture...

Page 4: Table Of Contents

I table of contents safety information..........................................................................................................................................1 led safety label.............................................................................................................

Page 5

Ii 3.10.2 printer test ................................................................................................................................3-65 3.10.3 feeder test ................................................................................................................................

Page 6: Section 6 Options

Iii 4.12.9 toner smudges .........................................................................................................................4-12 4.13 lcd error messages ........................................................................................................................4-13 ...

Page 7

Iv packaging contents: .............................................................................................................................6-22 installation .........................................................................................................................................

Page 8: Section 1

1-1 section 1 general description 1.1 product description the okioffice 1200 and okioffice 1600 is multi-function product with flat bed scanner and group 3 and v.34 hdx modem facsimile machine. Documents are printed on plain paper using dry electrophotographic printing..

Page 9: 1.2 Specifications

1-2 1.2 specifications item 1200 1600 type desktop type telephone network pstn (public switched telephone network) or equivalent. Compatibility itu-t t.4 and t.30 coding method itu-t-standard mh, mr, mmr and murata-proprietary mse. Itu-t-standard mh, mr, mmr, jbig and murata-proprietary mse. Modem s...

Page 10

1-3 item 1200 1600 first copy time 12 seconds (using a4-sized paper in 1st paper cassette) 10 seconds (using a4-sized paper in 1st paper cassette) printing speed 12 ppm (when loading a4-sized paper from 1st paper cassette.) 16 ppm (when loading a4-sized paper from 1st paper cassette.) toner yield ap...

Page 11: Section2

2-1 section2 machine composition 2.1 okioffice 1200 interconnect block diagram (1/2) okioffice 1200 connection diagram (1/2).

Page 12

2-2 okioffice 1200 interconnect block diagram (2/2) okioffice 1200 connection diagram (2/2).

Page 13

2-3 okioffice 1600 interconnect block diagram (1/2) okioffice 1600 connection diagram (1/2).

Page 14

2-4 okioffice 1600 interconnect block diagram (2/2) okioffice 1600 connection diagram (2/2).

Page 15: 2.2 Main Control Pcb

2-5 2.2 main control pcb the main control pcb controls the operations of all machine functions. Jumper jp2 on the main control pcb is used for battery back-up of the sdram. Removing jp2 will initialize the sdram. If the power is turned off, the battery will provide up to 72 hours (8mb) of back- up w...

Page 16

2-6 ci oh cpu afg panel pcb speaker monitor control logic ic key rs232c sdram extension memory lcd ni-mh battery lithium battery +24v, +5v, gnd +24v, +12v, -12v, +5v, gnd ac 220v battery pcb connector (scanner) pcb sdram flash rom ccd led lamp sdram printer control 1 motor control system g/a1 system...

Page 17

2-7 2.3 network control unit (ncu) pcb the ncu pcb provides the connection to the telephone line. It consists of the interface circuit, dial pulse generator, ring signal detector and telephone control circuit. Txa tone oh ci rxa generator ncu pcb modular pcb +24v, +5v, gnd +12v, -12v s dp ncu pcb bl...

Page 18

2-8 2.4 power supply unit (psu) the power supply unit receives the input line voltage and currents it to output voltages of +5 vdc, +24 vdc, +12 vdc, and -12 vdc. The heater circuit controls output voltage to the fuser heater according to instructions received from the heater control circuit. If an ...

Page 19: 2.5 Sensors

2-9 2.5 sensors 2.5.1 sensor locations the following illustration shows the relative positions of the machine’s sensors. Txil home end aps ds1 ds2 pss tos pds pes hpes cover sw drum sw casop jcop.

Page 20

2-10 2.5.2 sensor descriptions the following table gives a brief description of each sensor and its function. Code name detects sensor type ds1 document sensor 1 presence of document in feeder photo interrupter ds2 document sensor 2 leading and trailing edge of document mechanical switch home mirror...

Page 21

2-11 2.6 document scanning sequence 2.6.1 document detection when a document is placed into the document feeder, document sensor 1 (ds1) is activated and you will hear the short beep. 2.6.2 document separation document separation is the process that allows a multi-page document to go through the sca...

Page 22

2-12 when ds2 detects the trailing edge of the document, the image signal output is turned off. The scanner continues to remain active for a few more seconds in case there is another document to follow. Ds1 ds2 mirror a mirror b mirror c ccd lens press roller a feed roller a feed roller b separator ...

Page 23: 2.7 Recording Section

2-13 2.7 recording section 2.7.1 recording paper feed path a sheet of the recording paper is separated from the remaining paper by the friction of the pickup roller. The paper is moved along the paper guide until it reaches the platen roller. Is then fed by the rotation of the platen roller. 2.8 ima...

Page 24

2-14 2.8.1 drum charge • the drum is charged with static electricity before led exposure. The rotating charge brush is used for the charging method. • the rotating brush charging generate little ozone in the printer. Because the charge is directly given to the drum, the drum can be charged by low vo...

Page 25

2-15 2.8.4 image transfer image transfer is the process of transferring the toner image created on the drum in the developing process to paper. We use the roller image transfer instead of the corona image transfer, as the image transfer method. In the roller image transfer, there is little generatio...

Page 26

2-16 2.8.6 fusing an overview the toner image transferred on to the paper is securely fixed. A heat roller system is used as the fusing system. The toner image is fused by heater roller heated by the heater lamp, and securely fixed by the pressure between the heater roller and press rollers. A therm...

Page 27

2-17 fusing temperature 1) warming up after the initialization of the printer, warming up of the printer starts and the heater lamp turns on until the temperature of the heater roller reaches approx. 185 °c. 2) printing when the printer obtains the printing command from its controller, the heater ro...

Page 28: Section3

3-1 section3 adjustment procedures 3.1 field service program modes the fax machine feature maintenance modes for machine adjustment. Each mode is listed below along with the command used to activate the mode and a brief functional description. Note: when you press “ * ”, you will hear short beeps. H...

Page 29

3-2 3.2 machine parameter adjustment 3.2.1 setting the machine parameters these switches are used to program internal machine parameters. The primary back up battery maintains these settings if power is lost. 1. From standby, press program key, *, 0. Set parameters / /enter 2. Press enter. A0: 00000...

Page 30

3-3 machine parameter a:0 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 0 0 0 country code the country code enables the rom to output the correct programming information for the respective country. Machine parameter a:1 switch initial setting adjust usage/comments 7 0 non-lo...

Page 31

3-4 machine parameter a:2 switch initial setting adjust usage/comments 7 1 factory use only 6 0 factory use only 5 1 factory use only 4 0 factory use only 3 * 2 * 1 * 0 * dtmf output level attenuation see table below. Machine parameter a:2 … dtmf output level attenuation switch 3 switch 2 switch 1 s...

Page 32

3-5 machine parameter a:3 switch initial setting adjust usage/comments 7 * 6 * 5 * 4 * 3 * 2 * 1 * 0 * leading edge document margin adjustment (adf) adjusts the leading edge margin from document sensor 2 (ds2) to the start of the scanning position. Each setting changes by 0.847mm. Note: these values...

Page 33

3-6 machine parameter a:7 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 0 0 1 dram capacity indication (this switch can indicate 8 to 64 mb memory capacity) this switch indicates the dram capacity. This switch is read only, do not set any character. You can see the memory ca...

Page 34

3-7 machine parameter b:1 switch initial setting adjust usage/comments 7 * 6 * 5 * 4 * 3 * 2 * 1 * 0 * leading edge document margin adjustment (adf) adjusts the leading edge margin from the mirror carriage passes end sensor to the start of the scanning position. Each setting changes by 0.847mm. Note...

Page 35

3-8 machine parameter b:3 switch initial setting adjust usage/comments 7 * 6 * 5 * 4 * 3 * 2 * 1 * 0 * fbs scanner registration adjustment (horizontal) adjusts the start point to scan the document. The plus setting increase the left margin and the minus setting decrease it. Each setting changes by 0...

Page 36

3-9 machine parameter b:7 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 0 0 0 leading edge document margin adjustment (adf) adjusts the leading edge margin from document sensor 2 (ds2) to the start of the scanning position. Each setting changes by 0.0847mm. Note: these value...

Page 37

3-10 machine parameter d:0 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 1 0 0 slice level adjustment of “light” in the mode without grayscale. (only for okioffice 1200) switch 76543210 00000000 darkest setting 00000001 00000010 initial setting 00000011 00000100 lightest set...

Page 38

3-11 machine parameter d:4 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 1 0 0 slice level adjustment of “dark” in the mode without grayscale. (only for okioffice 1200) switch 76543210 00000000 darkest setting 00000001 00000010 initial setting 00000011 00000100 lightest sett...

Page 39

3-12 machine parameter d:8 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 1 0 0 slice level adjustment of “darker” in grayscale. (only for okioffice 1200) switch 76543210 00000000 darkest setting 00000001 00000010 initial setting 00000011 00000100 lightest setting machine par...

Page 40

3-13 machine parameter f:1 switch initial setting adjust usage/comments 7 * 6 * 5 * 4 * 3 * 2 * 1 * 0 * adjustment of the scanning stretching and squeezing for adf. (vertical) the plus setting stretch the image data and the minus setting squeeze it. Each setting changes by 0.1% switch 76543210 setti...

Page 43

3-16 machine parameter j:0 switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 3 0 2 0 1 0 0 0 printer registration adjustment (vertical) at the cassette. Adjusts the start point to print. The plus setting increase the top margin and the minus setting decrease it. Each setting changes by 0....

Page 44

3-17 machine parameter j:3 switch initial setting adjust usage/comments 7 1 6 0 5 0 4 0 3 0 2 1 1 0 0 0 printer registration adjustment (horizontal) at the optional second cassette. Adjusts the start point to print. The plus setting increase the left margin and the minus setting decrease it. Each se...

Page 45

3-18 3.3 memory switch adjustment 3.3.1 setting the memory switches these switches are used to program internal machine parameters. The primary back up battery maintains these settings if power is lost. 1. From standby, press program key, *, 1. Set memory switch / /enter 2. Press enter. A0: 00000110...

Page 46

3-19 memory switch a:0 - dialer switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 dis detect time after dialing 0: 80 sec 1: 70 sec sets the time dis signal is detected after dialing a number. 2 1 factory use only 1 1...

Page 47

3-20 memory switch a:5 - dialer switch initial setting adjust usage/comments 7 0 factory use only 6 1 5 1 4 0 ring signal detect time set the time that an incoming ring will not be detected after hanging up. (fax/tel ready mode only.) switch 6 5 4 0 0 0 100 ms 0 0 1 200 ms 0 1 0 300 ms 0 1 1 400 ms ...

Page 48

3-21 memory switch b:0 - transmission switch initial setting adjust usage/comments 7 1 busy tone detection 0: no 1: yes sets this switch to “0” if the ring tone of remote unit is mistaken for a busy signal. 6 0 fallback pattern (bps) 2400 4800 7200 9600 14400 set at 0: 2 times 2 times 2 times 2 time...

Page 49

3-22 memory switch b:1 - transmission switch initial setting adjust usage/comments 7 0 the time between reception of cfr and transmission of data when cfr and data overlap due to line echo, increase the interval between cfr and data transmission using this switch. 6 1 250 ms 500 ms 750 ms 1000 ms sw...

Page 50

3-23 memory switch b:2 - transmission switch initial setting adjust usage/comments 7 0 data signaling rate (dcs) 0: v.17 1: v.33 determines communication protocol. 6 0 forced received print when transmitting from memory 0: no 1: yes will force a remote okioffice machine with memory receive capabilit...

Page 51

3-24 memory switch b:5 - transmission switch initial setting adjust usage/comments 7 0 program individual autodialer attributes 0: no 1: yes allows individual setting of memory switches b:0 as attribute 1, b:1 as attribute 2, b:2 as attribute 3 and b:3 as attribute 4 when one-touch and speed dial lo...

Page 52

3-25 memory switch c:0 - reception switch initial setting adjust usage/comments 7 0 data error rate 0: 10% 1: 20% determines the allowable number of erred lines out of total lines received in a document. 6 0 pause one second after sending ced 0: no (75 ms) 1: yes (1 sec) a 2100 hz ced signal disable...

Page 53

3-26 memory switch d:0 - reception switch initial setting adjust usage/comments 7 0 number of hdlc end flags defines the number of hdlc end flags. Switch 7 6 5 4 0 0 0 0 1 6 0 0 0 0 1 2 0 0 1 0 3 initial setting 0 0 1 1 4 0 1 0 0 5 0 1 0 1 6 5 1 0 1 1 0 7 0 1 1 1 8 1 0 0 0 9 1 0 0 1 10 1 0 1 0 11 4 ...

Page 54

3-27 memory switch d:2 - reception switch initial setting adjust usage/comments 7 0 eye-q slice level 0: disable 1: enable setting this bit to “1” enables memory switch d:2, bits 0-3 and memory switch d:1, bits 0-7 and enables eye-q check adjustment. 6 1 check eye-q 0: no 1: yes set at 0: line condi...

Page 55

3-28 memory switch e:0 - scanner switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 factory use only 2 0 factory use only 1 0 factory use only 0 1 document tx length limit 0: 3.6 meters 1: 1 meter setting to unlimited ...

Page 56

3-29 memory switch g:1 - remote reception switch initial setting adjust usage/comments 7 0 off-hook / on-hook detect time (remote reception) sets the time interval between the off-hook/on-hook condition for remote reception. The total time of this time and the time specified in g:6 will be the actua...

Page 57

3-30 memory switch g:2 - remote reception switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 1 cng detect in ans/fax ready 0: no 1: yes when set to “1”, the machine detects the cng signal in ans/fax ready. 3 0 switch-hook time if the switch ...

Page 58

3-31 memory switch g:3 - remote reception and tad interface switch initial setting adjust usage/comments 7 0 adjust silent detection time this switch adjusts the length of silence required for silent detection activation. Switch 7 6 5 4 time 0 0 0 0 0 sec 0 0 0 1 1 sec 6 1 0 0 1 0 2 sec 0 0 1 1 3 se...

Page 59

3-32 memory switch g:4 - remote reception and tad interface switch initial setting adjust usage/comments 7 0 cng detect period after tad begins recording icm sets the period during which cng is detected after the tad begins recording incoming message. Switch 7 6 5 4 time 0 0 0 0 0 sec 0 0 0 1 10 sec...

Page 60

3-33 memory switch g:5 - remote reception switch initial setting adjust usage/comments 7 0 6 0 5 0 4 0 adjust the detect time for regarding as the ci signal. Increase/decrease the time specified in this switch from the standard detect time. Determine it in g:5 bit 3 whether increase or decrease. Swi...

Page 61

3-34 memory switch h:0 - operation switch initial setting adjust usage/comments 7 0 display error line 0: no 1: yes the number of error lines contained in the received data will be shown in the lcd. 6 0 total line monitor 0: no 1: yes allows fax communication to be heard through the monitor speaker....

Page 62

3-35 memory switch h:2 - operation switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 factory use only 2 0 print the transmission time on rcr 0: no 1: yes determines if printing the communicating duration (in minutes a...

Page 63: 3.5 All Ram Clear

3-36 3.5 all ram clear the all ram clear setting will erase all user programmed information, all documents in memory, and reset the memory switches and machine parameters to factory defaults. This feature may also be used to try and clear a machine malfunction or lock up. If possible, when the all r...

Page 64

3-37 attribute 1 - individual autodialer setting (equivalent to memory switch b:0) switch initial setting adjust usage/comments 7 1 busy tone detection 0: no 1: yes sets this switch to “0” if the ring tone of remote unit is mistaken for a busy signal. 6 0 fallback pattern (bps) 2400 4800 7200 9600 1...

Page 65

3-38 output attenuation when individual autodialer attributes are set. Switch -15 db -14 db -13 db -12 db -11 db -10 db -9 db -8 db -7 db -6 db -5 db -4 db -3 db -2 db -1 db -0 db 3 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 2 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0 0 1 0 1 0 1 0 1 0 ...

Page 66

3-39 attribute 4 - individual autodialer setting (equivalent to memory switch b:3) switch initial setting adjust usage/comments 7 0 ansam detection (only for okioffice 1600) 0: yes 1: no during the v8 handshake, if some noise disturbs the handshake and an error occurs, set to “1”. 6 0 v.34 transmiss...

Page 67

3-40 3.7 unique switch adjustment 3.7.1 setting the unique switches these switches are used to program internal machine parameters. The primary back up battery maintains these settings if power is lost. 1. From standby, press program key, *, 4. Set uniq switch / /enter 2. Press enter. A0: 01100001 /...

Page 68

3-41 unique switch a:0 — dialer switch initial setting adjust usage/comments 7 0 factory use only 6 0 congestion tone detection 0: no 1: yes setting this switch to “0”, ignores telephone line congestion tones. 5 1 4 0 ring back tone wait time (seconds) 3.0 3.3 3.6 3.9 switch 5: 0 0 1 1 switch 4: 0 1...

Page 69

3-42 unique switch b:6 - transmission switch initial setting adjust usage/comments 7 1 available *, # and space upon f-code sub/sep registration 0: no 1: yes determines if checking the * (asterisk), # (sharp) and space upon f-code sub/sep registration. 6 1 available *, # and space upon f-code commun...

Page 70

3-43 unique switch b:8 - transmission switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 factory use only 2 0 factory use only 1 0 factory use only 0 0 transmission when disable to detect first nsf in feeder transmissi...

Page 71

3-44 unique switch c:1 - reception switch initial setting adjust usage/comments 7 0 t1 timer adjustment when the unit switches to fax by on-hook transfer, the unit will seize the telephone line and attempt to handshake. Switch 7 5 6 4 settings 6 1 0 0 0 0 0 s 0 0 0 1 2 s 0 0 1 0 4 s 0 0 1 1 6 s 0 1 ...

Page 72

3-45 unique switch c:2 - reception switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 jbig reception (only for okioffice 1600) 0: no 1: yes determines how documents from the remote fax are received. 2 0 receive the jun...

Page 73

3-46 unique switch d:0 - modem switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 1 3429 baud symbol rate when communicating at v.34 (only for okioffice 1600) 0: no 1: yes if the error frame often occurs because of the symbol rate is too high, setting this switc...

Page 74

3-47 unique switch d:2 - modem switch initial setting adjust usage/comments 7 1 v8 handshake in feeder tx (only for okioffice 1600) 0: no 1: yes determine if the handshaking will be done with v.8 recommendation in feeder transmission. 6 0 factory use only 5 0 factory use only 4 1 factory use only 3 ...

Page 75

3-48 unique switch d:5 switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 1 2 0 1 1 0 0 dtmf output level attenuation for second phone line (only for okioffice 1600) see table below. Unique switch d:5 … dtmf output level...

Page 76

3-49 unique switch d:7 - modem switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 3 0 the delay before post- message is transmitted (only for okioffice 1600) if retraining occurs due to the low reception signal level and few delay of the t...

Page 77

3-50 unique switch e:2 - scanner switch initial setting adjust usage/comments 7 0 factory use only 6 1 factory use only note: initial setting for okioffice 1600 is “0”. 5 0 continuous lighting of the lamp for ccd adjustment (only for okioffice 1600) 0: no 1: yes setting at “1”, the lamp continues to...

Page 78

3-51 unique switch e:5 - scanner switch initial setting adjust usage/comments 7 1 6 0 5 0 4 1 leading edge document margin adjustment (adf) (only for okioffice 1600) adjusts the leading edge margin from the mirror carriage passes end sensor to the start of the scanning position, which was set in mac...

Page 79

3-52 unique switch e:7 - scanner switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 4 0 3 0 2 0 1 0 0 0 right edge document margin adjustment upon scanning using fbs adjusts the right edge margin when scanning document by fbs. Each setting changes by 1 mm. Swi...

Page 80

3-53 unique switch e:9 - scanner switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 4 0 3 0 2 * 1 * 0 * trailing edge document margin adjustment upon scanning using fbs adjusts the trailing edge margin when scanning document by fbs. Each setting changes by 1 m...

Page 81

3-54 unique switch f:0 - printer switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 smoothing in h-fine resolution in receive mode (only for okioffice 1600) 0: no 1: yes 2 1 smoothing in s-fine resolution in receive mo...

Page 82

3-55 unique switch f:2 - printer switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 4 0 3 0 2 0 1 0 0 0 led print head exposure time adjustment for lists, test patterns and pcl printing 1 step = 1.74 µ s note: this setting effects after turning the power switc...

Page 83

3-56 unique switch f:6 - printer switch initial setting adjust usage/comments 7 1 factory use only 6 0 factory use only 5 0 4 0 3 0 2 0 1 0 0 0 led print head exposure time adjustment for copies and receiving documents 1 step = 1.74 µ s note: this setting effects after turning the power switch off/o...

Page 84

3-57 unique switch g:0 - remote reception switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 1 factory use only 2 0 use numeric keypad on the fax using second phone (only for okioffice 1200) 0: no 1: yes determines if us...

Page 85

3-58 unique switch g:8 ∼∼∼∼ g:9 --- factory use only unique switch h:0 - operation switch initial setting adjust usage/comments 7 0 first dialing symbol when pressing dialing options key 0: “ − ” 1: “ − ! ” when set to “0”, “ − ” will appear first when pressing dialing options key. When set to “1”, ...

Page 86

3-59 unique switch h:3 - operation switch initial setting adjust usage/comments 7 0 priority of consumable order sheet printing 1: print immediately 0: print after the current printing job completed when the drum cartridge has reached its design life, or the toner cartridge is empty, the machine pri...

Page 87

3-60 unique switch i:7 - miscellaneous switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 0 factory use only 4 0 factory use only 3 0 factory use only 2 0 factory use only 1 0 print “year” on activity journal and tcr 0: no 1: yes 0 0 print last 25-digit of remot...

Page 88

3-61 unique switch j:5 - miscellaneous switch initial setting adjust usage/comments 7 0 factory use only 6 0 factory use only 5 1 factory use only 4 0 factory use only 3 0 factory use only 2 0 priority of printing the check message on a5(portrait) 0: no 1: yes when set to “1”, a5(portrait) sized pap...

Page 89: 3.8 Printer Maintenance Mode

3-62 3.8 printer maintenance mode in case of followings, use this mode. • when replaced the fuser unit or transfer roller. • when “please call service” message appear in the lcd, access this mode to determine the cause of the “please call service” error message. When you replace the fuser unit or tr...

Page 90: 3.10 Test Modes

3-63 3. The kind of printer error will be displayed. If happens two or more troubles, the number of troubles is displayed on the right upper of the lcd. For example, when “heater error” and “drum fuse error” has occurred, the lcd shows 2. Service call :2 heater error how many troubles 4. Press to sh...

Page 91

3-64 3.10.1 life monitor the life monitor displays the current software version, the total number of pages scanned, printed, and transmitted, the number of drums replaced and the total page count on the current drum. Note: the all ram clear setting does not clear the life monitor. To clear, see belo...

Page 92

3-65 3.10.2 printer test the printer test mode offers seven different test patterns as shown below. Pattern a pattern b pattern c pattern d pattern e pattern f pattern g 1. Press program key, *, 9, , then press enter. Pattern 2. Press one-touch a, b, c, d, e, f or g to select the desired pattern. Pa...

Page 93

3-66 3.10.3 feeder test the feeder test discharges all documents in the automatic document feeder at a constant speed and displays the document total in the lcd. 1. Load test documents into the automatic document feeder. 2. Press program key, *, 9, two times, then press enter. Feeder test 3. Press s...

Page 94: Unique Switch Settings

3-67 3.11 print machine parameters, memory switch and unique switch settings this function instructs the unit to print a list of the machine parameter, memory switch and unique switch settings. The list shows the default and current settings for each. After printing, the unit returns to standby. 1. ...

Page 95

3-68 3.12.3 lcd test this mode displays two test patterns in lcd. 1. Press program key, *, b(02). Then press one-touch c. Lcd test pressing start, all dots turn on. Next pressing start, all dots turn off. Finally pressing start, the alphabetical characters are shown in the lcd. Abcdefghijklmnopqrst ...

Page 96

3-69 3.12.5 sram check this mode is used to test the sram memory where user programmed parameters such as date, time, tti, etc are stored. Note: when this test is executed, an all ram clear will be performed by the unit. The all ram clear erases all user settings and resets all memory switches, mach...

Page 97

3-70 the machine starts checking and the result(ok/ng) will be shown in the display. For example, if the check area is “0” and one additional memory, you will see: dram check ok:12 ng: 3. Press stop to exit the test mode. 3.12.7 rtc(real time clock) test this test mode is not applicable to field ser...

Page 98: 3.13 Line Tests

3-71 3.13 line tests this mode offers several internal tests and ability to monitor certain unit output functions. Included are relay tests, modem signal output monitoring, and dtmf output monitoring. 1. Press program key, *, c(03) to enter the test mode. The tests are contained within three main me...

Page 99

3-72 3.13.2 tonal signal test the tonal signal test permits the unit’s output tones to be monitored. Note: to monitor the tones, an external monitoring device must be connected to the telephone line jack. 1. Press program key, *, c (03). Board number? 2. Press the numeric keypad 0 (zero) to select t...

Page 100

3-73 13 12000 bps 13 7200 bps 14 14400 bps 14 9600 bps 15 16800 bps 15 12000 bps 16 19200 bps 16 14400 bps 17 21600 bps 17 16800 bps 18 4800 bps 18 19200 bps 19 7200 bps 19 21600 bps 20 9600 bps 20 24000 bps 21 12000 bps 21 26400 bps 22 14400 bps 22 28800 bps 23 16800 bps 23 31200 bps 24 19200 bps 2...

Page 101

3-74 7. To select another tonal signal, repeat steps 4-6. Otherwise, proceed to step 8. 8. To exit the tonal signal test mode, press stop under not tests. 9. Press stop again to return to standby mode. 3.13.3 dtmf output test the dtmf output test permits the unit’s dtmf tones to be monitored. Note: ...

Page 102: 3.15 Consumable Order Sheet

3-75 3.14 mirror carriage transfer mode important: the fax machine is shipped with mirror carriage locking plate for protecting the machine’s mirror carriage during shipping. When installing the fax, loosen the screw which secures the mirror carriage locking plate, and then slide the plate. After un...

Page 103

3-76 to enter spaces, punctuation and symbols, use the characters shown on the one-touch keypad you want. Note: if you make a mistake, press cancel to erase to the left. To change just one character, press to move left, or to move right. Press cancel to erase the character. Then re-enter the charact...

Page 104: 3.16 Dram Clear

3-77 2. Press . Reset order sheet / /enter 3. Press enter. Reset order sheet check enter/cancel 4. To clear the information of consumable order sheet, press enter. To finish the operation without clearing, press cancel. 3.16 dram clear note: perform a dram clear whenever a memory upgrade is installe...

Page 105: 3.19 Set Service Code

3-78 3.19 set service code this is the code which, one can protect the life monitor clear operation. If it is not necessary to protect to the life monitor clear operation, abort this operation without entering the service code. 1. Press program key, *, j (10). Set service code old passcode :**** 2. ...

Page 106: 3.21 Jp1, Jp2 Battery Backup

3-79 9. Enter previous value of the fuser replaced count, then press enter. Fuser life 0000000000 10. Enter previous value of the fuser life, then press enter. Transfer rplcd count 0000000000 11. Enter previous value of the transfer replaced count, then press enter. Transfer life 0000000000 12. Ente...

Page 107: 3.22 Update The Software

3-80 3.22 update the software here’s instruction to update the software version of the flash rom. Important: to update the software, it needs the flash rom writer and three of the latest versions of ep- roms — rom0, rom1 and rom2. 1. Turn off the power switch. 2. Remove the access cover on the rear ...

Page 108: Section4

4-1 section4 troubleshooting procedures 4.1 troubleshooting outline before troubleshooting a unit check the following: • is the power cord correctly connected to the machine? • is the telephone handset and the telephone line cord connected correctly? • is there paper in the paper cassette? • are all...

Page 109: 4.2 Recording Paper Jam

4-2 4.2 recording paper jam symptom: recording paper did not exit paper cassette properly or jam occurred in print area. Suggested corrective action: 1. Verify that the recording paper conforms to the type specified for use in the machine and that has not been damaged or exposed to moisture. 2. Make...

Page 110: 4.5 Mirror Carriage Error

4-3 4.4 document feeder multi-feeding or skew symptom: two or more pages of a multi-page document are fed at once. The document is fed on the skew. Slight skewing may sometimes occur. Suggested corrective action: 1. Verify that the original documents conform to the specifications designed for use in...

Page 111: 4.8 Cannot Transmit

4-4 4.8 cannot transmit symptom: the unit will not transmit suggested corrective action: 1. Verify the telephone line cord is properly installed and plugged into the correct type of wall jack. 2. Check for dial tone at the unit and wall jack. If no dial tone is present at the unit, check the ncu pcb...

Page 112: 4.11 Clearing Jammed Paper

4-5 4.11 clearing jammed paper if the original document jams 1. If an original document jams in the adf while scanning the document into the memory for faxing or copying, the lcd will show: document jam contstor enter/cancl if you do wish to continue the operation, press enter and proceed to step 2....

Page 113

4-6 to remove the document: 1. Open the scanner cover. 2. Lift the original document from the machine. Note: if you cannot remove the original document, open the inner cover as shown at right, then remove the document. 3. Gently close the scanner cover, making sure both sides are snapped down secure...

Page 114

4-7 if a printout jams inside your machine to clear a printout jammed inside your machine: important: gently close the top cover so that you don’t catch your hands, possibly injuring them. 1. Open the top cover. 2. Open the printer cover. 3. Remove the toner and drum cartridge. Important: shield the...

Page 115

4-8 4. Remove the jammed paper. Important: the fuser unit becomes very hot. Do not touch the fuser unit when you are removing a paper jam. Note: avoid getting “unfixed” toner on your hands and clothes. Open the side cover. Pulling up the jam release lever to remove the jammed paper. 5. Reset the ton...

Page 116

4-9 4.12. The image quality problems the following provides guidelines for troubleshooting the printer engine and actions to be taken. Before removing any portions of the machine or making any internal adjustments, be sure power to the unit is off. Suggested corrective actions should be performed in...

Page 117

4-10 4.12.3 printout too light symptom: printed image is faint or does not print solid. Poor development • remove the toner cartridge and shake it a few times to redistribute the toner inside. If the problem persists, replace the toner cartridge. • replace the high voltage unit. • clean the led prin...

Page 118

4-11 4.12.6 uneven print density symptom: image graduates from dark to light across page. Poor development • remove the toner cartridge and shake it a few times to redistribute the toner inside. If the problem persists, replace the toner cartridge. • replace the high voltage unit. • clean the led pr...

Page 119

4-12 4.12.8 white (black) line symptom: white or black strip appears vertically through image. Poor development • replace the toner cartridge. Defective drum • replace the drum cartridge. Improper charging • replace the drum cartridge. Improper fusing • replace the fusing unit. Poor image transfer •...

Page 120: 4.13 Lcd Error Messages

4-13 4.13 lcd error messages your fax machine’s lcd messages can help you spot problems. Lcd error messages (alphabetic list) what you see on the lcd what it means/what to do all commands in use your fax machine has all of its 99 possible delayed commands (automatic redialing counts as one) stored i...

Page 121

4-14 what you see on the lcd what it means/what to do drum near end your drum will need to be replaced soon. Enter no. (0-32) you tried to enter a call group number greater than 32. Your machine can maintain 32 call groups, numbered 1-32 (call group 0 covers all the groups). Determine the correct ca...

Page 122

4-15 what you see on the lcd what it means/what to do mirror carriage error the mirror carriage of your machine has become inoperable. Mirror locked the transport mode is not turned off. Turn off the transport mode. No command you pressed review commands to review upcoming commands, but your fax mac...

Page 123

4-16 what you see on the lcd what it means/what to do please replace drum your drum cartridge has reached the limit of its design life. Your machine cannot print until the drum cartridge is replaced. Please replace the drum cartridge. Please replace toner your toner cartridge is empty. Your machine ...

Page 124

4-17 what you see on the lcd what it means/what to do select paper size you tried to make a copy in the following conditions: • paper size selection is set to “auto”. • the bypass tray has the paper other than a4, a5 or f4. • paper cassette(s) runs out of paper. Press paper size to select your desir...

Page 125: 4.14 Error Codes

4-18 4.14 error codes if an error occurs during a communication, a check message will be printed. The following provides an explanation of the information found on check messages. • a possible solution to the problem • the date and time of the attempted communication • the sending location (if the r...

Page 126

4-19 r.4.4 the receiving fax machine has reached its memory capacity. R.5.1 dcn was received instead of rr during ecm communication. R.5.2 line noise or other problems prevented ecm reception. R.8.4 a compatibility error occurred. R.8.10 line noise or other problems prevented line probing. R.8.11 th...

Page 127

4-20 communication error messages the error messages on check message printouts indicate the following: here’s a brief summary: error message possible meanings check condition of remote fax. • remote machine malfunctioned • no handshake signals from remote machine • wrong phone number reached repeat...

Page 128: 4.15 Service Call Error

4-21 4.15 service call error when certain machine problems occur these message will appear in the lcd. 4.15.1 call for service symptom: “call for service” is in the lcd. Suggested corrective action: 1. Verify the lamp turns on when the book cover open and close. 2. Verify the mirror carriage moves n...

Page 129

4-22 the errors messages and an explanation of each are outlined below. Heater error symptom: fuser heater malfunction. Suggested corrective action: 1. Check the connectors from the power supply to the main control pcb and to the fuser unit. 2. Check the heater lamp. If it comes on, see step 3; if i...

Page 130

4-23 rx motor error symptom: rx motor malfunction suggested corrective action: 1. Verify the rx motor rotates when the power is on. 2. Check the connection between rx motor and the connect printer pcb (p1308). (see page 2-1.) 3. Replace the rx motor if it doesn’t rotate. 4. If the problem is not cor...

Page 131: 4.16 Lcd Failure

4-24 4.16 lcd failure symptom: no display in the lcd. Suggested corrective action: 1. Verify that the power cord is correctly connected and the power switch is on. 2. Check for a blown fuse or open circuit on the unit’s internal power supply. 3. Check the dc output voltages from the power supply uni...

Page 132: 4.18 Cleaning The Unit

4-25 4.18 cleaning the unit use a mild cleaning solution on a lint-free cloth to wipe the machine’s cover, handset and paper cassette tray. Never spray cleaner directly onto the fax machine as the spray could damage components inside the fax. Curing frequent jams in the adf if you’re having trouble ...

Page 133

4-26 cleaning the fbs glass, contact glass and white pad 1. Open the platen cover. 2. Get a soft, lint-free cloth and moisten it with isopropyl alcohol. Important: make sure the cloth doesn’t have any rough areas. Otherwise, it could scratch the glass surface of the fbs. 3. Using the cloth, gently c...

Page 134: Section5

5-1 section5 maintenance & adjustment 5.1 maintenance schedule ...............................................................................................................5-2 5.2 re/disassemble ..........................................................................................................

Page 135: 5.1 Maintenance Schedule

5-2 5.1 maintenance schedule scanner section maintenance cycle (pages) parts name clean replace qty reference page separator roller * — 1 5-26 retard roller * — 1 5-27 other rollers * — — 5-28 to 5-31 contact glass & fbs glass * clean if dirty — 1 — document press sheet (white sheet) * clean if dirt...

Page 136: 5.2 Re/disassemble

5-3 5.2 re/disassemble before disassembling, disconnect the power cord and line cord. 5.2.1 covers............................................................................................................................................5-5 front cover .................................................

Page 137

5-4 fbs motor ........................................................................................................................................5-33 scanner assembly........................................................................................................................5-34 knob...

Page 138

5-5 5.2.1 covers platen cover right cover bypass tray top right cover top rear cover harness holder top left cover contact glass pane top front cover jam access cover cover opener front cover panel cover one-touch cover tx side cover r tx side cover f tx cover rx exit cover exit tray option cover a ...

Page 139

5-6 front cover 1. Open the top cover. 2. Remove the two front cover mounting screw. 3. Remove the front cover. Rear cover 1. Open the top cover. 2. Remove the five rear cover mounting screws. 3. Disconnect the speaker connector and remove the rear cover..

Page 140

5-7 top front cover / top right cover / top left cover 1. Open the platen cover. 2. Remove the screw covers. 3. Remove the three top front cover mounting screws, and then remove the top front cover. 4. Remove the two top right cover mounting screws, and then remove the top right cover. 5. Remove the...

Page 141

5-8 tx cover 1. Open the scanner cover. 2. Remove the four tx cover mounting screws. 3. Remove the tx cover. Tx cover tx side cover f 1. Open the platen cover. 2. Remove the tx side cover f mounting screw. 3. Release the locking tab, and then remove the tx side cover f. Tx side cover f.

Page 142

5-9 tx side cover r 1. Open the platen cover. 2. Remove the three tx side cover r mounting screws. 3. Remove the tx side cover r. Tx side cover r exit tray 1. Open the cassette. 2. Remove the three exit tray mounting screws. 3. Remove the exit tray. Exit tray.

Page 143

5-10 option cover a 1. Remove the option cover a mounting screw. 2. Remove the option cover a. Option cover a rx exit cover 1. Remove the exit tray. 2. Remove the top left cover. 3. Remove the option cover a. 4. Remove the rx exit cover mounting screw, and then remove the rx exit cover. Rx exit cove...

Page 144

5-11 right cover 1. Remove the front cover. 2. Remove the rear cover. 3. Remove the two right cover mounting screws. 4. Slide the line cover and disconnect the harnesses of the tos sensor and the hpes sensor. 5. Then remove the right cover. Right cover line cover cover opener 1. Open the jam access ...

Page 145

5-12 panel cover perform the procedure of step 1 through 2 in “panel a, b, c and lcd,” page 5-18. Platen cover perform the procedure of step 1 through 5 in “connect scanner pcb,” page 5-19. Bottom corner cover perform the procedure of step 1 through 2 in “connect scanner pcb,” page 5-19. Bypass tray...

Page 146

5-13 5.2.2 pcbs main control pcb ncu ccd pcb psu hvps connect printer pcb panel a pcb panel b pcb panel c pcb connect scanner pcb battery pcb inverter pcb connect adf pcb.

Page 147

5-14 main control pcb note: before changing the main control pcb, back up the user data (such as one-touch dial numbers). Confirm the jp1 and jp2 on the main control pcb are set to on. 1. Remove the rear cover. 2. Remove four shield plate mounting screws. 3. Disconnect all connectors on the main con...

Page 148

5-15 ncu pcb 1. Remove the exit tray. 2. Remove the two ncu pcb mounting screws and f.G. Wire mounting screws. 3. Disconnect all connectors on the ncu pcb. 4. Remove the ncu pcb. Ncu pcb modular pcb 1. Remove the rear cover. 2. Remove four shield plate mounting screws, and then remove the shield pla...

Page 149

5-16 power supply unit (psu) 1. Remove the rear cover. 2. Remove two fan motor mounting screws, and then remove the fan motor. 3. Remove the duct mounting screw, and then remove the duct. Duct fan motor 4. Disconnect two connectors on the psu. 5. Remove the two f.G. Wires. 6. Remove three psu mounti...

Page 150

5-17 high voltage power supply (hvps) 1. Open the top cover. 2. Remove the front cover. 3. Disconnect the connector on the hvps and remove five hvps mounting screws, then remove the hvps. High voltage power supply connect printer pcb 1. Remove the rear cover. 2. Remove two pcb shield mounting screws...

Page 151

5-18 panel a, b, c and lcd 1. Remove the top front cover. 2. Remove three panel cover mounting screws, and then remove the panel cover. Panel cover 3. Disconnect two connectors between panel a and b, panel b and c. 4. Disconnect the film harness of the lcd. 5. Remove all panel pcb mounting screws. 6...

Page 152

5-19 7. Remove two lcd support mounting screws, and then remove the lcd. Lcd support lcd lcd spacer connect scanner pcb 1. Remove the top front cover, the top right cover and the top left cover. 2. Remove the bottom corner cover mounting screw, and then remove the bottom corner cover. 3. Remove the ...

Page 153

5-20 4. Open the top cover and remove the hinge screw as shown. Hinge screw 4. Remove the harness holder mounting screw, and then remove the harness holder. 5. Remove the platen cover assembly. Harness holder platen cover assembly 6. Remove two screw covers. Then remove four top rear cover mounting ...

Page 154

5-21 7. Disconnect all connectors on the connect scanner pcb, and then remove the connect scanner pcb. Connect scanner pcb battery pcb 1. Perform the procedure of step1 through 6 in “connect scanner pcb,” page 5.19. 2. Disconnect the connector on the battery pcb and remove the battery pcb mounting s...

Page 155

5-22 inverter pcb 1. Remove the top front cover and the top right cover. 2. Remove the fbs glass. 3. Remove two lens cover mounting screws, and then remove the lens cover. 4. Disconnect two connectors on the inverter pcb and remove two inverter pcb mounting screws, then remove the inverter pcb. Lens...

Page 156

5-23 connect adf pcb 1. Remove the tx side cover r. 2. Disconnect all connectors on the connect adf pcb. 3. Remove the ground wire. 4. Remove two connect adf pcb mounting screws, and then remove the connect adf pcb. Connect adf pcb ground wire.

Page 157

5-24 5.2.3 sensors txil home end aps ds1 ds2 pss tos pds pes hpes cover sw drum sw casop jcop txil refer to “txil(adf), ds1/ds2,” page 5-26. Home refer to “home sensor / end sensor,” page 5-33. End refer to “home sensor / end sensor,” page 5-33. Aps refer to “adf permit sensor,” page 5-29. Ds1 refer...

Page 158

5-25 5.2.4 scanning section tension pulley exit gear 24 separator gear 22 tension pulley gear 16/36 gear 26/30 geae 48 idler pulley 17 50/17 pulley g26 50/17 pulley belt installation of adf section fbs motor belt installation of fbs section.

Page 159

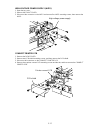

5-26 txil (adf) / ds1 / ds2 1. Remove the tx cover. 2. Remove the sensor you want to remove. Ds1 ds2 txil(adf) separator roller assembly 1. Remove the tx cover. 2. Remove the e-ring, and then remove the separator gear 22. 3. Remove two e-rings, and then remove the separator roller assembly. Separato...

Page 160

5-27 retard roller / torque limiter 1. Open the scanner cover. 2. Remove the retard cover. 3. Remove the retard roller assembly. Retard cover retard roller assembly 4. Remove two e-rings, and then remove the torque limiter with the bracket. Torque limiter.

Page 161

5-28 adf motor 1. Remove the tx side cover r. 2. Remove spring c, then remove seven motor bracket mounting screws. 3. Remove the motor bracket and adf motor. Motor bracket spring c pulley 50/17 g26 feed roller a 1. Remove the top side cover r and f. 2. Remove the adf motor. 3. Pull out the pulley 50...

Page 162

5-29 7. Remove the retard cover, retard roller assembly and torque limitor. 8. Remove the feed roller a from the inner guide a assembly. Inner guide a assembly feed roller a adf permit sensor (aps) 1. Remove the tx side cover f and r. 2. Remove the scanner cover assembly. 3. Remove two aps bracket m...

Page 163

5-30 4. Remove two inner guide b mounting screws, and then remove the inner guide b. 5. Release three tabs, and then remove the aps. Inner guide b aps feed roller b 1. Remove the tx side cover r and f. 2. Remove the adf motor. 3. Remove the scanner cover assembly. 4. Remove two inner guide b mountin...

Page 164

5-31 exit roller 1. Remove the tx side cover r. 2. Remove two e-rings, and then remove the exit gear 24 and the bearings. Exit gear 24 3. Open the platen cover. Remove two platen sheet mounting screws, and then remove the platen sheet as shown. Platen sheet.

Page 165

5-32 4. Remove five platen stay b mounting screws, and then remove the platen stay b. Platen stay b 5. Remove two press spring d. 6. Remove the exit roller. Exit roller.

Page 166

5-33 home sensor / end sensor 1. Remove the top front cover, the top right cover and the top left cover. 2. Remove the pane and the contact glass. 3. Remove the harness cover c mounting screw, and then remove the harness cover c. 4. Remove the end sensor. Remove the home sensor. Home sensor end sens...

Page 167

5-34 7. Loosen the rear angle mounting screw. Remove three fbs motor bracket mounting screws. Remove the belt. Remove the fbs motor with the bracket. Rear angle fbs motor brackect fbs motor scanner assembly 1. Remove the top front cover, the top right cover and the top left cover. 2. Remove the bott...

Page 168

5-35 6. Remove the belt retainer mounting screw. 7. Remove two lens cover mounting screws, and then remove the flat cable from the ccd pcb. Belt retainer lens cover flat cable ccd pcb 8. Slide out the guide rod as shown below. Then remove the scanner assembly. Guide rod scanner assembly.

Page 169

5-36 knob 1. Open the top cover. 2. Remove the spring. 3. Remove the small screw with a precision screwdriver. 4. Pull out the knob. Knob spring.

Page 170

5-37 5.2.5 printer section cover switch 1. Remove the rear cover. 2. Remove the connect printer pcb. 3. Remove two cover switch mounting screws, and then remove the cover switch. Cover switch casop 1. Remove the rear cover. 2. Remove the connect printer pcb. 3. Remove the psu. 4. Remove the casop mo...

Page 171

5-38 solenoid 1. Remove the rear cover. 2. Remove the connect printer pcb. 3. Remove the solenoid mounting screw, and then remove the solenoid. Solenoid rx motor 1. Remove the rear cover. 2. Remove the connect printer pcb. 3. Remove the psu. 4. Remove four rx motor mounting screws, and then remove t...

Page 172

5-39 drive gear assembly 1. Perform the procedure of step 1 through 3 in “rx motor,” page 5.38. 2. Remove the solenoid. 3. Remove the four drive gear assembly mounting screws, then remove the drive gear assembly. Drive gear assembly tos 1. Open the top cover. 2. Remove the toner cartridge and drum c...

Page 173

5-40 pick up roller mp 1. Remove the front cover, the rear cover and the right cover. 2. Remove the bearing, and then remove the pick up roller mp. Pick up roller mp hpes 1. Remove the front cover, the rear cover and the right cover. 2. Remove the pick up roller mp. 3. Disconnect the connector of hp...

Page 174

5-41 image transfer roller 1. Remove the toner cartridge and the drum cartridge. 2. Remove the image transfer roller with transfer bracket using the precision screwdriver as shown. Image transfer roller fixing unit 1. Remove the toner cartridge and the drum cartridge. 2. Remove the rear cover. 3. Di...

Page 175

5-42 pds / thermistor 1. Remove the fixing unit. 2. Remove the fixing unit cover, and then remove the pds or the thermistor. Fxing unit cover pdf themistor exit roller p 1. Remove the fixing unit. 2. Disassemble the fixing unit to remove the exit roller p. Note: do not bend the plate spring at remov...

Page 176

5-43 pes 1. Pull out the cassette completely. 2. Remove the pes mounting screw under the cassette, and then remove the pes. Disconnect the connector. Pes paper pick up roller 1. Pull out the cassette completely. 2. Pull out the pick up roller. Paper pick up roller.

Page 177

5-44 feed roller bp 1. Remove the front cover, the rear cover and the right cover. 2. Remove four mp bracket mounting screws, and then remove the mp bracket. 3. Remove the feed b bearing, and then slide out the feed roller bp. Feed roller bp mp bracket.

Page 178

5-45 feed roller ap 1. Remove the rear cover and front cover. 2. Remove the power supply unit. 3. Remove the connect printer pcb. 4. Remove the drive gear assembly. 5. Remove the hvps. 6. Remove the main frame mounting screws. Main frame 7. Remove the e-rings at the both side of the feed roller ap a...

Page 179

5-46 pss 1. Remove the toner cartridge and the dram cartridge. 2. Remove the screw, and then remove the press spring b. Remove the release lever and the press roller bp. 3. Remove the pss cover and remove the screw. Pull out the pss and disconnect the connector. Pss press spring b release lever pres...

Page 180

5-47 led print head 1. Open the printer cover. 2. Remove the e-rings on the both side and pull out the led print head. Disconnect two connectors. Led print head jcop 1. Open the side cover. 2. Disconnect the connector of the jcop 3. Release the tab of the jcop, and then remove the jcop. Jcop.

Page 181

5-48 bypass tray 1. Open the side cover. 2. To remove the bypass tray, release the tab at the front side of the bypass tray first, then release the other. Bypass tray.

Page 182: 5.3 Adjustment

5-49 5.3 adjustment 5.3.1 adjustment of retard roller pressure when the bad document transportation or document separation is occurs even if the rollers dose not wear or uncleanness, adjust the retard roller pressure. Insert the precision screwdriver into the hole of the inner guide a as illustratio...

Page 183: Section 6

6-1 section 6 options 6.1 memory upgrade an optional 8 mb document memory upgrade is available for the okioffice 1200. An optional 8 mb or 24 mb document memory upgrade is available for the okioffice 1600. Packaging contents: (1) memory pcb ........................ 1 (2) spacer ........................

Page 184

6-2 8. Print the machine setting list (press program key, e, 1, 0, 1, enter). Check the memory amount printed on the upper left part of the machine setting list. Total memory printed memory amount 8 mb(standard) 8192 kb 8 mb + 8mb 16384 kb 8 mb + 24 mb (okioffice 1600 only) 32768 kb 9. Re-attach the...

Page 185

6-3 6.2 attaching an optional handset packaging contents: (1) telephone handset (with curl cord)................1 (2) handset holder ................................................1 (3) cord holder......................................................1 (4) screw .......................................

Page 186: 6.3 Rs-232C Interface

6-4 6.3 rs-232c interface packaging contents: (1) rs-232c pcb ................................................1 (2) connector pcb ...............................................1 (3) bracket ............................................................1 (4) connection cable..............................

Page 187

6-5 5. Open the top cover. 6. Remove five mounting screws holding the rear cover in place. Then remove the rear cover. 7. Remove the shield plate. 8. Connect the rs-232c pcb assembly to the main control pcb with the connection cable as shown below: 9. Insert the rs-232c pcb assembly into the slot. T...

Page 188

6-6 rs-232c interface cable the rs-232c port on your newly installed rs-232c interface has a db-25 (standard 25-pin serial) female receptacle which accepts a male db-25 cable plug. Your computer’s port may have either a db-25 or db-9 (9-pin) receptacle. If necessary, see the chart below for detailed...

Page 189: 6.3 Page Counter

6-7 6.3 page counter the mechanical counter shows the total number of pages the machine prints. Note: the mechanical counter must be installed by the engineer. Note: this device counts up to 999,999 pages. If more pages are printed, the counter resets to zero and begins counting the new pages from t...

Page 190: 6.4 Second Line Interface

6-8 6.4 second line interface (only for okioffice 1600) packaging contents: (1) second line interface — includes the ncu and modem pcbs...........................1 (2) screws ................................................................................................................4 (3) connect...

Page 191

6-9 5. Remove the ground wire mounting screw on the second phone line module. Then remove the ground wire. Note: keep the ground wire to re-attach it in step 13. 6. Remove two ncu pcb mounting screws and release two tabs as shown. Then remove the ncu pcb from the bottom chassis of the second phone l...

Page 192

6-10 9. Re-attach the ncu pcb and the modem pcb to the bottom chassis using two screws and six tabs. 10. Use the screws to re-attach the four angle plates to the bottom chassis. 11. Plug the connection cable into the p14a connector on the main control pcb. Remove the mounting screw on the lower left...

Page 193

6-11 14. Re-attach two ground wire to the second phone line module’s bottom chassis using the screw. Plug the connection cable into the p1(in) connector on the second phone line module’s modem pcb. 15. Use the four screws to re-attach the second phone line module cover. 16. Plug one end of the telep...

Page 194

6-12 6.5 printer controller board / network interface card packaging contents: here’s what should be in the printer controller board package: 3 1 2 6 7 5 4 8 9 10 11 1. Printer control pcb ..................................................................................................................

Page 195

6-13 attaching the printer controller board (and network interface card) note: make sure to turn off the fax machine and unplug the power cable before proceeding the following steps. Note: when it is absolutely necessary to touch the ics and other electrical components on the board, be sure to groun...

Page 196

6-14 2. Remove the rear cover and option cover a of the machine, and remove the shield plate. 3. Connect the connection cable b and connect option pcbs and connection cable c as shown below. Take notice of the pcbs’ direction. Frrite core connect option 1 pcb connect option 2 pcb connection cable b ...

Page 197

6-15 if you also install the nic pcb, secure it using a screw too. And then attach the o.P. Shield. O.P. Shield 11. Re-attach the shield plate and the rear cover you have removed in step 1. Note: be sure to ensure no wire is trapped when reattaching the shield plate and the rear cover. 12. Cut out t...

Page 198

6-16 13. Connect the bi-directional parallel printer cable to the printer interface port of printer control pcb. Note: attach the ferrite core included in the printer control kit’s carton box to the printer cable as shown. 14. Snap the plug’s wire clips onto the printer cable. 15. Connect the other ...

Page 199

6-17 6.6 attaching the 2-bin tray packaging contents: (1) 2-bin unit (with connection cable) .......................................................................1 (2) screws ................................................................................................................4 (3) paper...

Page 200

6-18 10. And then secure the 2-bin tray using the four screws. 11. Re-attach the pcb shield. 12. Re-attach the rx exit cover a. Rx exit cover a 13 re-attach the exit tray, top left cover, option cover a, pcb shield and rear cover. 14. Attach the paper tray of the 2-bin unit..

Page 201

6-19 references> rear cover 1. Open the top cover. 2. Remove the five rear cover mounting screws. 3. Disconnect the speaker connector and remove the rear cover. Top front cover / top right cover / top left cover 1. Open the platen cover. 2. Remove the screw covers. 3. Remove the three top front cove...

Page 202

6-20 option cover a 1. Remove the option cover a mounting screw. 2. Remove the option cover a. Option cover a exit tray 1. Open the cassette. 2. Remove the three exit tray mounting screws. 3. Remove the exit tray. Exit tray.

Page 203

6-21 rx exit cover 1. Remove the exit tray. 2. Remove the top left cover. 3. Remove the option cover a. 4. Remove the rx exit cover mounting screw, and then remove the rx exit cover. Rx exit cover 5. Separate the rx exit cover a from b. Rx exit cover a rx exit cover b.

Page 204: 6.7 Second Paper Cassette

6-22 6.7 second paper cassette packaging contents: (1) second cassette........................1 (2) screws (3 x 10 mm) ..................2 (3) ferrite core ................................1 note: when it is absolutely necessary to touch the ics and other electrical components on the board, be sure t...

Page 205

6-23 5. Release the tab of the harness door under the machine, and then remove the harness door. 6. Put the machine on the second cassette. 7. Pass the harness and the ground wire of the second cassette through the harness door. Then attach the ferrite core to the harness as illustration below. 8. C...

Page 206

6-24 10. Re-attach the rear cover of the machine. However, do not secure the two places of the rear side of the rear cover. These places will be secured with the screws (3 x 10 mm) included in the option cassette box. The remaining two screws (3 x 8 mm) will be used in step 12. Note: do not forget t...

Page 207

6-25 setting of the paper size default setting: a4 when you install the second cassette, you must set the paper size for it. 1 press program key, b, 1, 0, 1, enter. The lcd shows: 1st cassette :a4 ← / → /enter 2 press enter to go to the setting for the second cassette. The lcd shows: 2nd cassette :a...