- DL manuals

- Oki

- Printer

- OKIPAGE 8iM

- Maintenance Manual

Oki OKIPAGE 8iM Maintenance Manual

Summary of OKIPAGE 8iM

Page 1

41260201th draft 1 / 106 okipage 8im led page printer maintenance manual oda/oel draft version.

Page 2

41260201th draft 2 / rev.No. Date no. Corrected items page description of change person in change 1 issue e2 nagahashi.

Page 3: Preface

41260201th draft 3 / preface this maintenance manual describes the field maintenance methods for led page printers. This manual is written for use by service persons. Please note that you should refer to the printer handbook for the handling and operating methods of the equipment..

Page 4: Contents

41260201th draft 4 / contents 1. Configuration ......................................................................................... 6 1.1 system configuration ............................................................................... 6 1.2 printer configuration ...............................

Page 5

41260201th draft 5 / 4.2 adjustment when replacing a part .......................................................... 59 4.2.1 setting led head drive time ......................................................................... 59 4.2.2 uploading and downloading eeprom data ............................

Page 6

41260201th draft 6 / electro-photographic processor paper feed mechanism engine unit hopper plate main high-voltage power supply board sub high-voltage powersupply board power supply unit main control board figure 1-1 1. Configuration 1.1 system configuration the okipage 8im consists of a control bl...

Page 7

41260201th draft 7 /106 i/d unit (type 6) upper cover assy top cover assy heat assy main control board high-voltage power supply board (p6l) high-voltage power supply board (p2h) 1.2 printer configuration the printer unit consists of the following five hardware components: • electro-photographic pro...

Page 8

41260201th draft 8 /106 1.3 specification (1) type desktop (2) outside dimensions height 6.7” (170 mm) (excludes protruding width 12.8” (324 mm) portion) depth 8.1” (207 mm) (3) weight 4.2 kg (with image drum cartridge and toner cartridge) (4) development method dry non-magnetic development system e...

Page 9

41260201th draft 9 /106 (12) temperature and humidity temperature during operation in storage 10 to 32 ˚c –10 to +43 ˚c 20 to 80% rh (relative humidity) 10 to 90% rh (relative humidity) no condensation is permissible. Humidity caution: temperature and humidity in storage are measured with the okipag...

Page 10

41260201th draft 10 /106 1.4 safety standards 1.4.1 certification label the safety certification label is affixed to the following location of the okipage 8im 1.4.2 warning label warning labels are affixed to the locations that may cause bodily injury. During maintenance, do work with enough care wh...

Page 11

41260201th draft 11/106 2. Operation description the okipage 8im consists of a main control board, two high-voltage power supply board, a power supply unit, and an electro-photographic processor. The okipage 8im receives print data from a higher-level interface and sequentially stores it in memory. ...

Page 12

41260201th draft 12 /106 cpu (nx8) dram 2mb eprom 64kb serial i/f parallel i/f usb i/f macintosh i/f dram bus (data : 4) (address : 11) high voltage power unit p6l high voltage power unit p2h eeprom 1kb motor driver mtd2005f osc 16mhz hc125 ls373 rst cn10 cn1 id unit cn7 motor head2 head1 cn8 plunge...

Page 13

41260201th draft 13 /106 2.1 main control board the main control board consists of a one-chip cpu, a program rom, a dram, an eeprom, a host interface circuit, and a mechanism driving circuit. The mechanism driving circuit consists of a led head, a main motor, and an electromagnetic clutch. (1) one-c...

Page 14

41260201th draft 14 /106 used to generate a logic circuit and a high voltage. Used to drive the motor and electromagnetic clutch. Output voltage application +5 v +26v output application ch db sb cb tr voltage –1.3 kv –265 v/+265 v –550 v/ 0 v +400 v/–1.35 kv +500 v ~ +3.5 kv/–750 v voltage to be app...

Page 15

41260201th draft 15 /106 figure 2-2 (2) sensors the high-voltage power supply board consists of the high-voltage power supply circuit that supplies power to the electro-photographic processor system and the photosensor that detects a paper feeding system and toners. Figure 2-2 shows the sensor layou...

Page 16

41260201th draft 16 /106 2.4 electro-photographic processor the electro-photographic processor prints out the image data to be sent from the main control board on sheets of paper. Figure 2-3 shows the layout drawing of the electro-photographic processor. (1) image drum unit the image drum unit makes...

Page 17

41260201th draft 17 /106 figure 2-3 layout drawing of electro-photographic processor exit roller heat roller (ø 19.910) 6.85 10 off on 26.50 outlet sensor cleaning roller (ø 9.000) charge roller (ø 9.000) 6.77 led head drum roller (ø 16.000) developing roller (ø 14.000) 17.23 12.72 23.18 20.32 64.60...

Page 18

41260201th draft 18 /106 main motor electromagnetic clutch off on hopping roller non-rotation rotation non-rotation regist gear drum gear operation warm-up hopping prinitng non-rotation rotation rotation rotation rotation rotation normal rotation reverse rotation off (3) pulse motor (main) this puls...

Page 19

41260201th draft 19 /106 figure 2-4 schematic drawing of okipage8im paper feeding exit roller heat roller transfer roller cleaning roller ch roller drum roller developing roller outlet sensor paper sensor hopping roller tray printing feed roller manual feed sensor manual printing 2 roller to be driv...

Page 20

41260201th draft 20 /106 2.5 electro-photographic process (1) electro-photographic process the electro-photographic process is outlined below. 1 charging the surface of the opc drum is charged negatively and uniformly by applying the dc voltage to the ch roller. 2 exposure light emitted from the led...

Page 21

41260201th d ra ft 21 / 10 6 figure 2-5 flow for electro-photographic process control signal exposure transfer paper supply charging paper delivery paper feeding fusing cleaning development paper sensor led head power supply charge roller power supply transfer roller cleaning roller paper eject roll...

Page 22

41260201th draft 22 /106 2.5.1 explanation of each process operation (1) hopping as shown in the figure below, the clutch for hopping is turned on/off according to current on/ off to a coil. When the clutch is off when the clutch is on when the clutch is on, the hopping gear engages with the clutch ...

Page 23

41260201th draft 23 /106 b" b' b hopping gear gear a pulse motor (main) planetary gear idle gear triple gear transfer gear regist gear a" a' a hopping gear gear a pulse motor (main) planetary gear idle gear triple gear transfer gear regist gear rotate the pulse motor (main) in the a direction. The p...

Page 24

41260201th draft 24 /106 led head charge roller led head image drum paper opc drum high- voltage power supply charge roller opc drum high- voltage power supply (3) charging charging is performed by applying dc voltage to the charge roller that is in contact with the surface of the opc drum. (4) expo...

Page 25

41260201th draft 25 /106 opc drum transfer roller paper high-voltage power supply 2 the toner applied to the developing roller is thin-coated by the developing blade. 3 a toner adheres to the exposure part of the opc drum in the contact part between the opc drum and developing roller. This causes th...

Page 26

41260201th draft 26 /106 cleaning roller opc drum transfer roller high-voltage power supply separation claw heater heater roller thermistor pressure spring back-up roller (7) fusing the transferred unfused toner image is fused to a sheet of paper because heat and pressure are applied when it passes ...

Page 27

41260201th draft 27 /106 2.6 paper jam detection the okipage 8im monitors the paper status when the power supply is on and during printing. In the following cases, the okipage 8im interrupts the printing process as a paper jam. Printing can be recovered by opening the cover, removing the jammed pape...

Page 28

41260201th draft 28 /106 off reverse rotation off on pulse motor (main) electromagnetic clutch off on manual feed sensor off on paper sensor off on operation mode warm-up paper feed printing outlet sensor normal rotation timing chart for paper feed (tray feed).

Page 29

41260201th draft 29 /106 2.7 toner low detection • hardware configuration of toner sensor the figure below shows the hardware configuration of the toner sensor. Hardware configuration of toner sensor image drum unit agitation bar (iron) magnet toner sensor lever.

Page 30

41260201th draft 30 /106 • toner detection method (1) toner sensor monitoring conditions are shown in the figure below. T1 t magnet draw-in toner sensor caution: the toner sensor is not monitored when the drum is inactive. (a) when the toner-low state continues twice, toner low occurs. (this state i...

Page 31

41260201th draft 31 /106 i/d unit existence detection time t time remarks 3.04 sec. As the toner sensor monitors at intervals of 40 msec. The fractional part should be rounded down. Invalid condition valid condition in the case of 31 pages or more in total drum counter in the case of 30 pages or les...

Page 32

41260201th draft 32 /106 power on abnormal toner sensor waveform i/d unit not installed displayed/informed status_a status_b normal printing abnormal toner sensor waveform normal toner sensor waveform toner sensor error di splayed/informed normal printing cover open/close cover open/close normal nor...

Page 33

41260201th draft 33 /106 manual light medium- light medium medium- heavy heavy ohp light medium- light medium medium- heavy heavy ohp media type tray feeding tray paper size excutive letter legal 14 legal 13 a4 jis b5 a5 a6 monarch com-10 dl c5 com-9 domestic postcard and envelop equivalent 8 8 8 8 ...

Page 34

41260201th draft 34 /106 3. Parts replacement this chapter explains how to replace parts, assemblies, and units in the field. The replacement procedures to be explained here include dismounting, not mounting. When mounting parts, assemblies, and units, reverse the dismounting steps. 3.1 precautions ...

Page 35

41260201th draft 35 /106 [maintenance tools] table 3-1 lists the maintenance tools necessary for parts replacement. Table 3-1 maintenance tools no. No. 1-100 philips screwdriver q'ty use remarks maintenance tools 1 2 3 4 5 6 7 no. 2-100 philips screwdriver no. 3-100 philips screwdriver no. 5-200 scr...

Page 36

41260201th draft 36 /106 figure 3-1 hopper plate guide side (r) guide side (l) spur gear (a) upper cover 3.2 parts layout this section explains the layout of main parts. [upper cover assy].

Page 37

41260201th draft 37 /106 [base frame unit] figure 3-2 i/d unit (type 6) power sensor e pulse motor (main) hopping roller roller holder magnet h (hopping shaft) hopping shaft assy side plate m registration roller heat assy idle gear heat paper holder paper guide (r) transfer roller pressure roller (b...

Page 38

41260201th draft 38 /106 high voltage power supply board p6l base plate assy power supply unit main control board [base plate unit] figure 3-3.

Page 39

41260201th draft 39 /106 3.3 replacing parts this section explains how to replace parts and assemblies. 3.3.1 hopper plate (1) remove two claws and dismount hopper plate 1 . 1.

Page 40

41260201th draft 40 /106 3.3.2 led head and head spring (1) open top cover assy 1 . (2) dismount the left clamp and led head 2 . Then, dismount flat cable assy 3 . (3) dismount two head springs 4 . 2 1 4 4 3.

Page 41

41260201th draft 41 /106 3.3.3 transfer roller (1) open top cover assy 1 and dismount i/d unit (type 6) 2 . (2) remove the washer tr 6 (make sure to do it) 1 1 1 1 1 : insert a flat-tip driver between the claw and the guide gear t 7 in a way of pushing gear t 5 so that it hits the left side and rota...

Page 42

41260201th draft 42 /106 3.3.4 how to remove cover upper assy (1) unscrew screws on the rear part. (2) open cover top assy. Inserting a screwdriver head into a slot marked with ∆ on the plate base edge, turn the screwdriver and lift cover upper assy upward. Repeat the same procedure for another slot...

Page 43

41260201th draft 43 /106 7 9 8 6 0 1 2 5 4 3 3.3.5 upper cover assy (1) turn off the power switch and unplug the ac cord from the ac socket. (2) disconnect interface cable 1 . (3) open top cover assy 2 and dismount i/d unit (type 6) 3 . (4) move paper guide (l) 4 and paper guide (r) 5 on the rear of...

Page 44

41260201th draft 44 /106 3.3.6 high-voltage power supply board (p2h) (1) dismount upper cover assy. (see section 3.3.5.) (2) remove three screws 1 and remove the cover 2 and draw out high-voltage power supply board(p2h) 3 . (3) disconnect all the cables 4 from high-voltage power supply board(p2h) 3 ...

Page 45

41260201th draft 45 /106 3.3.7 top cover assy and flat cable assy (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the led head. (see section 3.3.2.) (3) press the right clamp outward and dismount the engagement and top cover assy 1 . (tension spring 2 also comes off at the same ...

Page 46

41260201th draft 46 /106 3.3.8 paper holder (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount paper holder 1 . (3) unlock and dismount paper guide (l) 2 and paper guide (r) 3 . (4) remove the claw and dismount hopper spring 4 . (5) remove the claw and dismount stopper spring 5 . 1...

Page 47

41260201th draft 47 / 106 3.3.9 side plate m and idle gear perform parts replacement while making the base frame assy stand so that side plate m will face upward. (1) dismount the upper cover assy. (see section 3.3.5.) (2) remove two screws 1 and two claws, then dismount plate side m 2 . (3) dismoun...

Page 48

41260201th draft 48 /106 1 2 1 3 3.3.10 heat assy this section explains how to dismount the heat assy and parts in the assy. (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) remove two screws 1 , disconnect conne...

Page 49

41260201th draft 49 /106 3.3.11 drive shaft e (eject) and eject roller (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount top cover assy. (see section 3.3.7.) (3) remove two screws 1 from heat assy (section3.3.10), lift the heat assy, and dismount idle gear e (a) 2 and idle gear e ...

Page 50

41260201th draft 50 /106 3.3.12 pressure roller b (back up roller) (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) dismount the heat assy. (see section 3.3.10.) (4) dismount the engagement with the left ground, ...

Page 51

41260201th draft 51 /106 3.3.13 separator guide (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) remove four screws 1 . (4) dismount inlet 2 from base frame 3 . 2 > insert a screwdriver into the hole on the side ...

Page 52

41260201th draft 52/106 1 1 3 1 1 2 6 8 9 4 a 4 4 b b a screw driver (-) screw driver clamp lever cn2.

Page 53

41260201th draft 53 /106 3.3.14 pulse motor (main) (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) dismount side plate m. (see section 3.3.9.) (4) dismount the base frame. (see section 3.3.13.) (5) remove two sc...

Page 54

41260201th draft 54 /106 3.3.15 hopping shaft assy (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) dismount the base frame. (see section 3.3.13.) (4) dismount the paper holder assy. (see section 3.3.8.) (5) dism...

Page 55

41260201th draft 55 /106 3.3.16 regist roller (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount idle gear r 3 and gear r 4 . (3) move regist roller 1 to the right and dismount it by lifting. (two regist bearings 2 also come off at the same time. Take care not to lose them.) 2 1 3 ...

Page 56

41260201th draft 56 / 106 3.3.17 paper sensor e, paper sensor exit and toner sensor assy (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the high-voltage power supply board (p2h). (see section 3.3.6.) (3) dismount the base frame. (see section 3.3.13.) (4) dismount the paper hold...

Page 57

41260201th draft 57 / 106 1 1 2 5 5 6 8 5 0 c a a 9 9 b 7 3 4 3.3.18 base plate (1) dismount the upper cover assy. (see section 3.3.5.) (2) dismount the base frame. (see section 3.3.13.) (3) remove two screws 1 , disconnect connector 2 , and dismount power supply unit 3 . (4) dismount insulation she...

Page 58

41260201th draft 58/106 4. Adjustment this chapter explains adjustment necessary when a part is replaced. This adjustment is made by changing the parameters values set in eeprom on the main control board. The printer driver or maintenance utility can be used to change these values. Only servicemen a...

Page 59

41260201th draft 59 / 106 this three digits indicate the luminous intensity of the led head character 4.2 adjustment when replacing a part the table below lists the parts that requires adjustment when they are replaced. Luminous intensity display 020 155 figure 4-2 part to be replaced adjustment led...

Page 60

41260201th draft 60 / 106 4.2.2 uploading and downloading eeprom data when the main control board is replaced, eeprom data must be reflected on a new main control board. Use “eeprom operations” in the option tab of the maintenance utility to reflect eeprom data on the new main control board. (see ap...

Page 61

41260201th draft 61 /106 5. Periodical maintenance 5.1 periodical replacement parts table 5-1 lists the part and unit to be replaced periodically. Table 5-1 routine replacement parts toner cartridge (type 6) part name replacement time part to be checked simultaneously remarks ep unit (type 6) when "...

Page 62

41260201th draft 62 / 106 led head cleaner led lens array figure 5-2 (1) set the led head cleaner in the led lens array, as shown in the figure below, and slide the cleaner left and right several time to clean the head. Caution: do not press the led head cleaner against the led lens array..

Page 63

41260201th draft 63 /106 6. Troubleshooting procedures 6.1 troubleshooting tips (1) check the basic check points written in the user’s manual. (2) gather detailed failure information as much as possible from the customer. (3) check the printer under the condition close to that under which the failur...

Page 64

41260201th draft 64 / 106 trouble trouble indicated by the message displayed on the status monitor. Image problem (or trouble not displayed on the status monitor) perform detailed troubleshooting according to the troubleshooting flow. (see section 6.5.2.) troubleshoot according to section 6.5.3. Tro...

Page 65

Opel code category status message display content remedy 41260201th rev.1 65 / table 6-1 warming-up status online (ready) status power save status the toner amount of the toner cartridge is small. The i/d unit is not installed or the toner sensor is faulty. Life of i/d drum the paper is in the manua...

Page 66

Opel code category status message display content remedy 41260201th rev.1 66 / table 6-1 (cont'd) 30 00 31 00 32 00 33 00 42 00 4f 00 40 01 40 10 60 10 60 30 paper of improper size was fed. 2.52" (64 mm) l 15.77" (400.56 mm) a paper jam occurred when sheets of paper were being supplied. A paper jam ...

Page 67

Opel code category status message display content remedy 41260201th rev.1 67 / table 6-1 (cont'd) 60 40 60 60 60 80 60 91 60 92 60 c0 60f0 an error occurred during eeprom check. An error occurred during option ram check. A heater timeout error occurred. The thermistor is open. A thermistor short occ...

Page 68

41260201th draft 68 / 106 6.5.2 status message troubleshooting some failures cannot be corrected according to the status message trouble list. Troubleshoot these failures according to the following troubleshooting flowcharts: caution: when replacing the main control board troubleshooted according to...

Page 69

41260201th draft 69 / 106 1 the okipage 8im malfunctions after the power supply has been turned on. • turn the power supply off, then on again. • is the led lamp on? • no is the ac cable connected correctly? • no connect the ac cable correctly. • yes is +5 v supplied between cn1 pin 7 and cn1 pin 13...

Page 70

41260201th draft 70 / 106 [jam error] 2 -1 paper input jam • does a paper input jam occur when the power supply is turned on? • yes is the jammed paper on paper sensor? • yes remove the jammed paper. • no is paper sensor (manual feed/paper) operating normally? • no replace paper sensor (manual feed ...

Page 71

41260201th draft 71 / 106 [jam error] 2 -2 paper feed jam • does a paper feed jam occur when the power supply is turned on? • yes is the jammed paper on paper sensor (paper/outlet)? • yes remove the jammed paper. • no is paper sensor (outlet/paper) operating normally? • no replace paper sensor (outl...

Page 72

41260201th draft 72/106 3 paper size error • is the paper of the specified size being use? • no use paper of the specified size. • yes is paper sensor (paper) operating normally? • no replace paper sensor (paper) or clean the inlet sensor on the high-voltage power supply board(p2h). • yes is the pap...

Page 73

41260201th draft 73 / 106 4 heat assy error • turn the power supply off, then on again. • does the halogen lamp of the heat assy go on? • no is the halogen lamp or thermostat disconnected? • yes replace the heat assy. • no replace the power supply unit. • yes are the cn2 connectors of main control b...

Page 74

41260201th draft 74 / 106 a light or blurred images entirely b dark background density c blank paper d black vertical stripes e cyclical defect f white vertical belts or streaks figure 6-3 image problems 6.5.3 image troubleshooting this section explains how to troubleshoot when an image problem is o...

Page 75

41260201th draft 75 / 106 1 an image is light or blurred entirely. • is the toner low? (is "toner low" being displayed?) • yes supply a toner. • no is the specified paper being used? • no use the specified paper. • yes is the lens of the led head dirty? • yes clean the led head. • no is the led head...

Page 76

41260201th draft 76 / 106 2 dark background density • has the opc drum being exposed to external light? • yes set the opc drum in the okipage 8im and wait for about 30 minutes. • no is the heat roller of the heat assy dirty? • yes clean the heat roller. • no is the terminal of the i/d unit in correc...

Page 77

41260201th draft 77 / 106 4 vertical black belt/stripe • replace the i/d unit. • has this error been recovered? • yes end caution: after replacing the i/d unit, reset the drum counter. (refer to "replacing the drum cartridge" in "user's manual".) • no replace the led head. • has this error been reco...

Page 78

41260201th draft 78 / 106 6 a blank paper is output. • is the contact plate of the transfer roller in correct contact with the high-voltage power supply board? • no contact the contact plate of the transfer roller correctly. • yes replace the transfer roller. • has this error been recovered? • yes e...

Page 79

41260201th draft 79 / 106 7 poor fusing • is the specified paper being used? • no use the specified paper. (xerox 4200 (20 lbs)) • yes is the bias spring normal? (tension: 3.25 kg) • no replace the bias spring. • yes are the heater connector of the heat assy and the cn1 connector of the power supply...

Page 80

41260201th draft 80 / 106 8 vertical white belt/stripe • is the lens of the led head dirty? • yes clean the led head. • no is the contact plate of the transfer roller in correct contact with the high-voltage power supply board(p2h)? (see figure 6-4 e .) • no contact the contact plate of the transfer...

Page 81

41260201th draft 81 / 106 figure 6-4 contents a : toner supply roller b : developing roller c : charge roller d : cleaning roller e : transfer roller f : heat roller a e f b c d.

Page 82

41260201th draft 82 / 106 figure 6-5 contents a : toner supply roller b : developing roller c : charge roller d : cleaning roller e : ground (drum) a b d c e.

Page 83

41260201th dr af t 83 / 10 6 main control board (hbx) power supply unit high-voltage power supply board p2h high-voltage power supply board p6l cn4 (parallel interface) head1(led head) head2(led head) 36 18 19 1 1 stb-n 2 pdata1-p 3 pdata2-p 4 pdata3-p 5 pdata4-p 6 pdata5-p 7 pdata6-p 8 pdata7-p 9 p...

Page 84

41260201th draft 84 / 106 7.2 pcb layout 7.2.1 main control board (hbx pcb) cn10 ic2 1 2 cn1 cn4 head2 19 1 1 12 head1 14 1 36 18 cn2 1 1 8 2 cn7 cn8 1 1 2 4 cn5 3 6 1 4 2 7 5 8.

Page 85

41260201th draft 85 / 106 7.2.2 high-voltage power supply board p2h ps2 ps1 ps4 sb db ch tr cvsw ps3 cn7 cn1 cn1 cn2 p6l.

Page 86

41260201th draft 86 /106 8. Parts list figure 8-1 cover assy upper 7 6 5 4 1 2.

Page 87

41260201th draft 87 / 106 1 cover-upper 2 40412602 1 blueberry cover-upper 2 40412603 1 strawberry cover-upper 2 40412604 1 tangerine cover-upper 2 40412605 1 lime cover-upper 2 40412606 1 grape 2 lens 2 40413201 1 3 4 guide side (l) 2pp4128-1256p001 1 5 guide side (r) 2pp4128-1257p001 1 6 gear spur...

Page 88

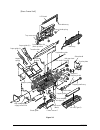

41260201th draft 88 / 106 figure 8-2 base frame unit d d e f c [ u r j e d i c b a 0 9 8 7 5 s o u t 6 3 3 1 2 i x g h f m k n p l l q s z k g w x t w v t o m t t r z y t v l a \ ] ^ b.

Page 89

41260201th draft 89 / 106 table 8-2 base frame unit 1 frame unit assy 40593201 1 2 high-voltage power supply board p2h 40607401 1 3 paper sensor e 3pp4083-1191p001 2 4 5 separator assy 40721301 1 6 compression spring s 40781701 1 7 toner sensor assy 3pa4083-1193g001 1 8 pulse motor 40496401 1 9 ep u...

Page 90

41260201th draft 90 / 106 40 paper holder 1pp4083-1231p001 1 41 paper sensor exit 3pp4083-1192p001 1 42 hopper spring 4pp4083-1247p001 1 43 top cover assy 40592119 1 44 head spring 4pp4083-6168p001 2 45 led head 40521101 1 46 flat cable assy 40591201 1 120v flat cable assy 40591202 1 230v 47 bias sp...

Page 91

41260201th draft 91 / 106 6 3 4 2 a 0 1 7 8 b c figure 8-3 base plate unit.

Page 92

41260201th draft 92 / 106 1 base plate assy 40592201 1 2 insulation sheet a 40722501 1 3 power supply unit 40455701 1 120v power supply unit 40455801 1 230v 4 main control board (hbx) 40535803 1 5 6 program rom 40780101 1 7 ac cord 3ys4011-1315p001 1 usa ac cord 3ys4011-1266p001 1 continental ac cor...

Page 93

41260201th draft 93 /106 appendix a local printing/ demo page printing the following operation enables the okipage 8im to print data by itself. With the cover open, turn on the ac switch and then close the cover. The following print patterns are printed..

Page 94

41260201th draft 94 /106 appendix b parallel interface (1) connector • printer side : 36-pin receptacle type: 57-40360 (daiichi denshi) or equivalent • cable side : 36-pin plug type: 57-30360 (daiichi denshi) or equivalent (2) cable • cable length : 6 feet (1.8 m) max. (ieee std 1284-1994 compliant ...

Page 95

41260201th draft 95 / 106 (3) parallel i/f signals • connector pin arrangement pin no. Signal name direction function (compatible mode) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 19 30 31 32 33 34 35 36 data strobe data bit - 1 data bit - 2 data bit - 3 data bit - 4 data bit - 5 data bit - 6 data bit...

Page 96

41260201th draft 96 / 106 (4) signal level • low : 0 v to +0.8 v • high : +2.4 v to 5.0 v (5) interface circuit a) receiving circuit b) sending circuit r = 3.3k Ω (1.0-k Ω strobe, i-prime) +5v r (6) timing charts a) data receiving timing (compatible mode) (open collector) +5v 3.3k Ω b) input prime t...

Page 97

41260201th draft 97 /106 appendix c macintosh interface 1) connector • printer side : 8-pin mini din receptacle type tcs7187-01-201 (made by hoshiden) or equivalent • cable side : 8-pin mini din plug type tcp7180-01-110 (made by hoshiden) or equivalent 2) cable apple system peripheral-8 cable (m0197...

Page 98

41260201th draft 98 / 106 5) connector pin arrangment 6) modes rs422 synchronous serial 8 6 5 4 3 2 1 7.

Page 99

41260201th draft 99 /106 appendix d usb interface (by usb printer cable) 1) connector • 1284 side : 36-pin plug • usb side : series a type plug 2) cable usb printer cable : made by in-system design, inc. 3) interface signal 4) timing chart and level 5) connector pin arrangment 6) modes satisfy the “...

Page 100

41260201th draft 100 / 106 appendix e maintenance utility manual overview this manual describes the details of gui for the maintenance utility corresponding to okipage 8im. However, as disable section is not used in this printer, its explanation will be omitted. 1 . Main menu dialog the following fi...

Page 101

41260201th draft 101 / 106 1.2 engine menu setting group this area shows the engine menu, the settings of which can be changed. The details of each item are as follows. Shown message print position setting item corrects the start position of print. Setting range -4.00mm ~ +3.5mm f/w default 0.00mm s...

Page 102

41260201th draft 102 / 106 1.3 engine counter reset group indicates the current value for each counter in this printer. And initiates each counter. The followings are the details for each item. Displays the number of rotations in build-in ep drum. Displays the total number of rotations after shipmen...

Page 103

41260201th draft 103 / 106 if the printer becomes other than manual feed mode, the following messages will appear. Button this button transmits a test printing file. When pressing the print file button, the select dialog box will open as shown in the following figure (windows api), ready for the ent...

Page 104

41260201th draft 104 / 106 2.2 option button this button rewrites the eeprom in this printer. Option menu items will be displayed classified into the following 3 types in functional unit. (1) eeprom operation displays and changes the engine menu settings. (2) h/w check performs a h/w check for the p...

Page 105

41260201th draft 105 / 106 button sends a ram check command to check the free space of the memory which is used for raster and receiving buffer including optional ram. This application, after sending a ram check command, will wait for the ram check end response from the printer with the dialog box o...

Page 106

41260201th draft 106 / 106 2.6 about button displays the version number of maintenance utility and virtual device driver and the information of firmware for this printer. 2.7 exit button terminates the maintenance utility..