- DL manuals

- Paccar

- Trucks

- Peterbilt 587

- Owner's Manual

Paccar Peterbilt 587 Owner's Manual

Summary of Peterbilt 587

Page 2

© 2010 paccar inc - all rights reserved this manual illustrates and describes the operation of features or equipment which may be either standard or optional on this vehicle. This manual may also include a description of features and equipment which are no longer available or were not ordered on thi...

Page 3: Part 1: Introduction

Part 1: introduction how to find what you want (r05/10) y53-6032 – 1 – part 1: introduction t his manual contains useful information for the safe and efficient operation of your peterbilt model 587. It also pro- vides information on maintaining your vehicle in the best condition, with an outline for...

Page 4

A special word about repairs part 1: introduction – 2 – y53-6032 (r05/10) a special word about repairs your peterbilt dealer’s service center is the best place to have your vehicle repaired. You can find peterbilt dealers all over the country with the equipment and trained personnel to get you back ...

Page 5

Part 1: introduction safety signals (r05/10) y53-6032 – 3 – another place to learn more about trucking is a local truck driving school. Contact one near you to find out what kinds of instruction it offers. Federal agencies such as the national highway traffic safety administration and the federal mo...

Page 6

Vehicle safety part 1: introduction – 4 – y53-6032 (r05/10) note provides general information: for example, the note may suggest how to operate the vehicle more efficiently. Example: note: pumping the accelerator will not assist in starting the engine. Vehicle safety make sure your peterbilt is in t...

Page 7

Part 1: introduction vehicle safety (r05/10) y53-6032 – 5 – program or truck driving school. If you have not been trained, get the proper training before you drive. Only qualified drivers should drive this vehicle. Safe driving is only possible with the proper concentration on the driving task. Keep...

Page 8

Part 2: getting into & out of the cab and frame access – 6 – y53-6032 (r05/10) part 2: getting into & out of the cab and frame access be careful whenever you get into or out of your vehicle’s cab. Always maintain at least three points of contact with your hands on the grab handles and your feet on t...

Page 9

Part 2: getting into & out of the cab and frame access door lock and keys (r05/10) y53-6032 – 7 – vehicle without external grab handle door lock and keys doors can be locked from the inside by using the lock but- ton. Close the door then push the button down to lock. Doors automatically unlock when ...

Page 10

Door lock and keys part 2: getting into & out of the cab and frame access – 8 – y53-6032 (r05/10) to lock both doors press the lock button. The doors will lock and the parking lights will come on for 2 seconds. If the doors are open they will not lock. The range of the rke system should be approxima...

Page 11

Part 2: getting into & out of the cab and frame access climbing onto the deck plate (r05/10) y53-6032 – 9 – climbing onto the deck plate when you are climbing onto and off the deck plate, main- tain at least three points of contact with your hands on the grab handles and your feet on the steps. Note...

Page 12

Climbing onto the deck plate part 2: getting into & out of the cab and frame access – 10 – y53-6032 (r05/10) hold handles as you step up three points of contact three points of contact as you reach the deck area three points of contact as you step to the deckplate y53-6032.Book page 10 monday, may 2...

Page 13

Part 3: getting to your engine hood hold downs (r05/10) y53-6032 – 11 – part 3: getting to your engine hood hold downs hood hold downs keep a hood from opening unexpect- edly. Caution: a hood not latched securely could open during operation and cause vehicle damage. Be sure to latch the hood securel...

Page 14

Hood tilt part 3: getting to your engine – 12 – y53-6032 (r05/10) 2. Locate the hood anti-blowdown device mounted to the driver side hood dampener. Warning! The hood uses two struts to con- trol movement during opening and closing. Do not tilt the hood with one or both struts disconnected. Replace d...

Page 15

Part 3: getting to your engine hood tilt (r05/10) y53-6032 – 13 – 4. To close the hood, disengage the hood antiblowdown device by pushing it in the upward direction. The device will move about 1/4” up the shaft. You may feel a click when the device disengages. Caution: attempting to close a hood wit...

Page 16

Your instrument panel part 4: controls and displays – 14 – y53-6032 (r05/10) part 4: controls and displays this part explains the location of the various features on your vehicle and describes their function. For information on using these features in driving, see the paragraphs below. Your instrume...

Page 17

Part 4: controls and displays your instrument panel (r05/10) y53-6032 – 15 – typical cab instruments and controls left side 1. Hazard switch 10. Oil pressure 2. Ignition switch 11. Primary air pressure 3. Headlight light switch 12. Secondary air pressure 4. Id/clearance lamps switch 13. Fuel 5. Volt...

Page 18

Your instrument panel part 4: controls and displays – 16 – y53-6032 (r05/10) right side 1. Parking brake valve 12. Optional 2. Trailer air supply valve 13. Engine brake 3. Heater/ac control panel 14. Engine brake sel 4. Engine fan switch 15. Interaxle differential lock switch 5. Floor light switch 1...

Page 19

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 17 – instruments and controls menu control switch (mcs) the mcs is used to navigate the driver information dis- play unit. The menu control switch is located on the d panel as shown in the illustration below. The mcs has the ...

Page 20

Instruments and controls part 4: controls and displays – 18 – y53-6032 (r05/10) warning lights and indicator symbols will be shown in both areas 1 and 2. Area 3 includes the turn and high beam indicator symbols. 1. Driver information display: the display can show up to six warning lights. Warnings d...

Page 21

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 19 – refer to “warning light / indicator symbols” on page 20 for information on each symbol. Completing this sequence will indicate a successful self test. Have your instrumentation system checked by a qualitfied service tech...

Page 22

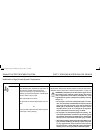

Instruments and controls part 4: controls and displays – 20 – y53-6032 (r05/10) warning light / indicator symbols the following is a list of warning light / indicator symbols. Reading left to right, the table header identifies • the symbol name • the appearance of the symbol • the symbol color when ...

Page 23

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 21 – 10. Dump truck, body up yellow 24 11. Dump truck, trailer body up yellow 25 12. Emissions, diesel particu- late filter (dpf) yellow 25 13. Emissions, high exhaust system temperture (hest) yellow 25 14. Emissions, malfunc...

Page 24

Instruments and controls part 4: controls and displays – 22 – y53-6032 (r05/10) 28. Park brake red 28 29. Power take-off (pto) green 28 30. Power take-off (pto), pump mode green 28 31. Refrigerator green 28 32. Seat belt, fasten red 28 33. Suspension dump yellow 28 34. Tire inflation yellow 29 35. T...

Page 25

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 23 – warning light/indicator symbol descriptions 1. Active warnings, exclamation point illuminates when a red warning is active. Use the mcs knob to view the warnings that are active. Refer to the preceeding figure , “warning...

Page 26

Instruments and controls part 4: controls and displays – 24 – y53-6032 (r05/10) 6.Anti-lock brake system (abs), trailer illuminates during the instrumentation sys- tem self test and the tractor/truck is con- nected with a abs equipped trailer. Illuminates during normal operating condi- tions to indi...

Page 27

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 25 – 11.Dump truck, trailer body up illuminates when trailer dump body is up. 12.Emissions, diesel particulate filter (dpf) illuminates when diesel particulate trap is plugged. This warning will also illuminate when regenerat...

Page 28

Instruments and controls part 4: controls and displays – 26 – y53-6032 (r05/10) to the skin. Allow adequate cooling time before working on or near any part of the exhaust sys- tem. 14.Emissions, malfunction indicator lamp illuminates when an engine emissions failure has occurred. The vehicle can be ...

Page 29

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 27 – 20. Engine, overspeed illuminates when engine rpm is exceeded. 21. Engine, retarder (brake) illuminates when the engine retarder (com- pression brake or exhaust brake) switch is turned on. (engine retarders are an option...

Page 30

Instruments and controls part 4: controls and displays – 28 – y53-6032 (r05/10) 26. Lights, high beam illuminates when the high beams are on. This icon will flash with audible alarm if the headlamps are left on when the door is open. In addition, this icon will flash, but without an audible alarm, i...

Page 31

Part 4: controls and displays instruments and controls (r05/10) y53-6032 – 29 – 34. Tire inflation illuminates when tire pressures need to be checked. (tire pressure monitoring system is an option) 35. Transmission, auxiliary illuminates to indicate auxiliary transmission is in neutral. 36. Transmis...

Page 32

Driver information display part 4: controls and displays – 30 – y53-6032 (r05/10) driver information display warning! Do not look at the driver informa- tion display for prolonged periods while the vehicle is moving. Only glance at the monitor briefly while driving. Failure to focus to the vehicle’s...

Page 33

Part 4: controls and displays driver information display (r05/10) y53-6032 – 31 – in addition to a blank screen, the following are menu items and the information available within each menu selec- tions. Note: some driver information display functions are only accessible when the vehicle is parked. O...

Page 34

Driver information display part 4: controls and displays – 32 – y53-6032 (r05/10) d. Trip information note: when accessing the trip information menu, push the mcs on this menu (bullet). To exit, push the mcs again. To reset the trip values, press the trip odometer reset but- ton on the main gauge in...

Page 35

Part 4: controls and displays driver information display (r05/10) y53-6032 – 33 – 7. Transmission sw version 8. Abs (antilock braking system) make 9. Abs model 10. Abs sw version 11. Cecu (cab electronic control unit) software version 12. Cecu hardware version f. Diagnostic display (accessible only ...

Page 36

Driver information display part 4: controls and displays – 34 – y53-6032 (r05/10) • display format 12 hour (am/pm) or 24 hour (military) • home/local time • alarm on/off • alarm time • units of measure • language (english, spanish or french) to set clock display format: 1. When in the settings menu,...

Page 37

Part 4: controls and displays steering column-mounted controls (r05/10) y53-6032 – 35 – 4. Rotate the mcs knob to change the minutes. Press the mcs. 5. Rotate the mcs to toggle am/pm. Press the mcs 6. Rotate the mcs to select exit. Press the mcs to exit the settings function. To turn alarm on/off: 1...

Page 38

Steering column-mounted controls part 4: controls and displays – 36 – y53-6032 (r05/10) high beam headlamps note: the headlamps must be “on” for the high beam switch to operate. To switch your headlamps to lower or higher beam, gently pull the turn signal lever towards the steering wheel, until you ...

Page 39

Part 4: controls and displays steering column-mounted controls (r05/10) y53-6032 – 37 – windshield wipers/washer your vehicle is equipped with a two-speed, intermittent windshield wiper system. A seven-position rotary wiper switch (located on the turn signal lever) operates the wind- shield wipers a...

Page 40

Steering column-mounted controls part 4: controls and displays – 38 – y53-6032 (r05/10) lever is released, the wipers will shut off automatically or resume the wiper’s setting speed. To activate the wipers for one swipe without activating the washer (“mist” function), push the turn signal lever in (...

Page 41

Part 4: controls and displays steering column-mounted controls (r05/10) y53-6032 – 39 – hazard flasher the four-way hazard flasher switch is on the turn signal body, just underneath the turn signal lever. It will operate with the key switch in the on or off position. Use your hazard flasher whenever...

Page 42

Steering column-mounted controls part 4: controls and displays – 40 – y53-6032 (r05/10) electric horn your peterbilt has an electric horn. To sound the horn, press on the bar in the center of the steering wheel electric horn bar air horn your vehicle has an air horn in addition to an electric horn. ...

Page 43

Part 4: controls and displays tilt-telescoping steering column (r05/10) y53-6032 – 41 – see the index, under brake safety and emergency for more complete information on when and how to use your trailer brake warning! It is dangerous to use air-applied trailer brakes for parking or holding a vehicle....

Page 44

Dash-mounted features part 4: controls and displays – 42 – y53-6032 (r05/10) ignition switch your ignition switch has four positions: • acc (accessory): with your key in this position you can play the radio or use other accessories, but your engine won’t start. • off: in this position all systems ar...

Page 45

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 43 – brightness if the engine is running and the headlamp switch is turned off. The daytime running lights are turned off auto- matically while the parking brake is engaged. If the head- lamp switch is turned on, the drl system ...

Page 46

Dash-mounted features part 4: controls and displays – 44 – y53-6032 (r05/10) fog/ driving lights switch if your vehicle has fog/driving lights, turn them on or off with the control panel switch shown above. Note: state requirements vary as to when high beams and fog lights can and cannot be used tog...

Page 47

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 45 – • on (i) position: – press once: light will turn on at high intensity. – press again: light will shift to low intensity. – press a third time: light will turn off. Air suspension deflate switch (dump valve) this vehicle may...

Page 48

Dash-mounted features part 4: controls and displays – 46 – y53-6032 (r05/10) engine fan switch the engine fan switch allows you to control the engine fan manually or automatically. With the ignition key switch on and the fan switch in the on position, the engine fan will be on regardless of engine t...

Page 49

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 47 – mirror heat switch mirror heat is controlled by the control panel switch shown above. If the vehicle is equipped with this switch, mirror heat can be switched on to help remove frost and ice from the mirror glass. Power mir...

Page 50

Dash-mounted features part 4: controls and displays – 48 – y53-6032 (r05/10) warning! Convex mirrors can distort images and make objects appear smaller and farther away than they really are. You could have an accident resulting in death or personal injury if you are too close to another vehicle or o...

Page 51

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 49 – will prompt you to press the service brake pedal if it has not been pressed since the vehicle has been started. Engine brake when an engine brake is energized, the power-producing diesel engine is converted into a power-abs...

Page 52

Dash-mounted features part 4: controls and displays – 50 – y53-6032 (r05/10) warning! Using the engine brake when operating on surfaces with poor traction (such as wet or icy, slippery roads or gravel) could cause an accident involving death or personal injury. Two-speed rear axle (range) switch if ...

Page 53

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 51 – warning! Do not engage the differential lock if the vehicle is moving or if the tires are slip- ping. Otherwise, the vehicle may move in an unexpected direction, and could cause an accident involving death or personal injur...

Page 54

Dash-mounted features part 4: controls and displays – 52 – y53-6032 (r05/10) fifth wheel lock (slider adjustment) switch vehicles having an air slide fifth wheel have a fifth wheel slider lock controlled by a switch on the instrument panel. By placing the switch in the unlock position, you can slide...

Page 55

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 53 – parking brake valve and trailer air supply valve your parking brake valve is a yellow diamond-shaped knob located below the right instrument panel. It controls the parking brakes. To apply all parking brakes, pull the yello...

Page 56

Dash-mounted features part 4: controls and displays – 54 – y53-6032 (r05/10) warning! Before operating your vehicle after it has been parked, do not forget to push in the parking brake valve to release the parking brakes. Failure to release your parking brakes before putting the vehicle into motion ...

Page 57

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 55 – note: do not stay in the vehicle with the engine running or idling for more than 10 minutes with the vehicle’s heater / ac ventilation system in recirc or at low fan speed. Even with the ventilation system on, running the e...

Page 58

Dash-mounted features part 4: controls and displays – 56 – y53-6032 (r05/10) • a rocker switch (e) on the lower center portion to send power to the “bunk” or sleeper control panel. • a rocker switch (f) in the lower right portion to select either fresh or recirculated air mode. The sleeper control p...

Page 59

Part 4: controls and displays dash-mounted features (r05/10) y53-6032 – 57 – and safe driving, it is extremely important for you to follow the instructions pertaining to the function and use of the ventilation/heating and defogging/defrosting system. If in doubt, consult your dealer. Maximum heating...

Page 60

Dash-mounted features part 4: controls and displays – 58 – y53-6032 (r05/10) note: when the air conditioner isn’t in regular use, operate it for at least 15 minutes at least once a month or every 5,000 miles(8,000 km), whichever comes first. This will lubricate the seals in the air conditioning syst...

Page 61

Part 4: controls and displays gauges (r05/10) y53-6032 – 59 – glove compartment to open your glove compartment, pull the latch. To close it, push the cover up and press to latch it. The glove compartment can be locked. Turn your glove box key clockwise (right) to lock and counterclockwise (left) to ...

Page 62

Gauges part 4: controls and displays – 60 – y53-6032 (r05/10) note: all of the warning lights and alarms for functions monitored by the multiplex instrumenta- tion system instrument system are contained within the individual gauges of the system. The alarms for other controls or systems that you may...

Page 63

Part 4: controls and displays gauges (r05/10) y53-6032 – 61 – or in kilometers on a metric speedometer. The maximum distance that can be shown on the odometer is “1 999 999” before it rolls over to zero. The trip odometer displays how far the vehicle has gone on a particular trip. The trip odometer ...

Page 64

Gauges part 4: controls and displays – 62 – y53-6032 (r05/10) engine hours / outside air temperature the lcd display in the lower part of the tachometer con- tains the engine hour meter and the outside air tempera- ture display. The engine hour meter will display the total number of hours the engine...

Page 65

Part 4: controls and displays gauges (r05/10) y53-6032 – 63 – air application gauge this gauge will show you how much air pressure is being applied from your foot brake valve or trailer brake hand valve. Primary (secondary) air pressure gauge (air reservoir) the air pressure gauge indicates the amou...

Page 66

Gauges part 4: controls and displays – 64 – y53-6032 (r05/10) warning! The air pressure warning light and the audible alarm indicate a dangerous situa- tion. There is not enough air pressure in the reservoirs for repeated braking and the brake system has failed. If air pressure falls below 60 psi (4...

Page 67

Part 4: controls and displays gauges (r05/10) y53-6032 – 65 – • if your oil pressure suddenly drops while you are driv- ing, bring the vehicle to a stop as soon as possible in a safe location off the road and turn off the engine. Wait a few minutes to allow oil to drain into the oil pan, and then ch...

Page 68

Gauges part 4: controls and displays – 66 – y53-6032 (r05/10) pressure to escape. Then push down and turn for final removal. The cooling system may overheat if the coolant level is below normal or if there is a sudden loss of coolant (such as a worn hose splitting). It may also temporarily overheat ...

Page 69

Part 4: controls and displays gauges (r05/10) y53-6032 – 67 – caution: use ultra low sulfur diesel fuel only. Failure to do so may damage the engine and components of the diesel particulate filter (dpf). The fuel gauge shows the approximate amount of fuel in the fuel tanks. Besides empty and full, t...

Page 70

Gauges part 4: controls and displays – 68 – y53-6032 (r05/10) transmission temperature gauge your transmission temperature gauge indicates the tem- perature of the oil in your transmission. Watch this gauge to know when your transmission is overheating. If it is, have it checked by an authorized ser...

Page 71

Part 4: controls and displays gauges (r05/10) y53-6032 – 69 – these gauges indicate the temperature of the lubricant in your vehicle’s axle(s). These temperatures will vary with the kind of load you are carrying and the driving condi- tions you encounter. Maximum axle temperature may vary, depending...

Page 72

Gauges part 4: controls and displays – 70 – y53-6032 (r05/10) voltmeter the voltmeter displays the voltage at which your batteries are being charged while the engine is operating. Note: even with a healthy charge/start system, the voltmeter may fall well below 12v during engine cranking. If voltage ...

Page 73

Part 4: controls and displays gauges (r05/10) y53-6032 – 71 – caution: continued operation with the air fil- ter re-striction gauge reading 25” h 2 o may cause damage to the engine. Inspect the filter and replace if necessary. Holes in the paper ele- ment render an air cleaner useless and may cause ...

Page 74

Gauges part 4: controls and displays – 72 – y53-6032 (r05/10) appliances in the cab you may decide to equip your vehicle with a radio, a refrig- erator, or other appliances and conveniences. Be sure they are compatible with your truck’s electrical system. Secure them in the cab so they can’t fly loo...

Page 75

Part 4: controls and displays gauges (r05/10) y53-6032 – 73 – peterbilt navigation system your vehicle may be equipped with a peterbilt navigation system. This system is a global positioning satellite (gps)-linked computer. It receives input from multiple sources to locate your vehicle. Read and und...

Page 76

Gauges part 4: controls and displays – 74 – y53-6032 (r05/10) note: the map database is the most current available at the time of production. The database is designed to provide you with route suggestions and does not take into account the relative safety of a suggested route or of factors that may ...

Page 77

Part 5: seat and restraint systems seat (r05/10) y53-6032 – 75 – part 5: seat and restraint systems seat for information on the features and adjustment of the seat, see the seat manufacturer’s literature included with the vehicle. Warning! Do not drive or ride with your seat back in the reclined pos...

Page 78

Seat belts and their proper use part 5: seat and restraint systems – 76 – y53-6032 (r05/10) person in crash, unbelted shoulder belt your combination shoulder-lap belt needs proper adjust- ment: • the lap portion should be worn as low on the hips as possible properly worn belt 02998 y53-6032.Book pag...

Page 79

Part 5: seat and restraint systems seat belts and their proper use (r05/10) y53-6032 – 77 – improperly worn belt the shoulder portion should fit snugly across your body. It should always be worn over the shoulder next to the door. It you put the belt under your arm, it can’t protect you properly war...

Page 80

Seat belts and their proper use part 5: seat and restraint systems – 78 – y53-6032 (r05/10) . Incorrect (under arm) warning! Do not wear the shoulder belt under your arm or otherwise out of position. In a crash your body would move too far for- ward, increasing the chance of death or head and neck i...

Page 81

Part 5: seat and restraint systems seat belts and their proper use (r05/10) y53-6032 – 79 – warning! Do not twist the belt in the process of putting it on. A twisted belt will not work as well to protect you. In a crash, the full width of the belt would not be protecting you. A twisted belt could cu...

Page 82

Seat belts and their proper use part 5: seat and restraint systems – 80 – y53-6032 (r05/10) . Pregnant woman with belt properly worn sleeper bunk restraints if your cab is equipped with a sleeper, be sure to use the restraint device. You may have belts which either are over the bunk or cover the ope...

Page 83

Part 5: seat and restraint systems seat belts and their proper use (r05/10) y53-6032 – 81 – • the upper rear wall: access to the bunk is easiest when these connections are buckled and the front buckle is detached. • the side walls: the tenting straps are attached to the side wall sills with easy-to-...

Page 84

Seat belts and their proper use part 5: seat and restraint systems – 82 – y53-6032 (r05/10) some other safety restraint tips: • don’t wear belts over rigid or breakable objects in or on your clothing. Such things might be eyeglasses, pens, keys, etc. These could cause injury in an acci- dent. • dama...

Page 85

Part 5: seat and restraint systems inspection of the restraint system (r05/10) y53-6032 – 83 – tether adjustment warning! Failure to adjust tether belts prop- erly can cause excessive movement of the seat in an accident. This could lead to death or greater injuries to you. Tether belts should be adj...

Page 86

Inspection of the restraint system part 5: seat and restraint systems – 84 – y53-6032 (r05/10) the typical three-point seat systems in passenger cars may seem very similar to the three-point seat belt system in heavy duty vehicles, but there are some key differences that all users of this system sho...

Page 87

Part 5: seat and restraint systems inspection of the restraint system (r05/10) y53-6032 – 85 – age to the buckle, latch plate, retractor hardware or any other obvious problem should be replaced immediately, regardless of mileage. Warning! It is important to remember that any time a vehicle is involv...

Page 88

Inspection of the restraint system part 5: seat and restraint systems – 86 – y53-6032 (r05/10) 1. Check the web wear in the system. The webbing must be closely examined to determine if it is coming into contact with any sharp or rough surfaces on the seat or other parts of the cab interior. These ar...

Page 89

Part 5: seat and restraint systems inspection of the restraint system (r05/10) y53-6032 – 87 – warning! Replace the entire belt system (retractor and buckle side) if replacement of any one part is necessary. Unexposed damage to one or more components could prevent the system from functioning properl...

Page 90: Part 6: Driver’S Checklist

Safe vehicle operation part 6: driver’s checklist – 88 – y53-6032 (r05/10) part 6: driver’s checklist safe vehicle operation to keep your vehicle in top shape, and to maintain its high level of safety for you, your passengers, and your load, make a thorough inspection every day before you drive. You...

Page 91

Part 6: driver’s checklist safe vehicle operation (r05/10) y53-6032 – 89 – warning! Do not drink and drive. Your reflexes, perceptions, and judgment can be affected by even a small amount of alcohol. You could have a serious—even fatal—acci- dent if you drive after drinking. Please do not drink and ...

Page 92

Safe vehicle operation part 6: driver’s checklist – 90 – y53-6032 (r05/10) 7. Check the power steering fluid reservoir; top up as necessary. 8. Check the steering components (pitman arm, dra- glink, power steering hoses, etc.) 9. Drain the fuel/water separator. Checking the luggage compartment 1. Ch...

Page 93

Part 6: driver’s checklist safe vehicle operation (r05/10) y53-6032 – 91 – 8. Visually inspect the fuel tank mounting hardware. Are the tank straps tight? Is the webbing in place? 9. Check the air cleaner and exhaust system. Are they tight and secure? 10. Check the trailer connections. Are they secu...

Page 94

Safe vehicle operation part 6: driver’s checklist – 92 – y53-6032 (r05/10) 5. Check mirror adjustment. 6. Operate air-powered devices to circulate lubricants. Note: the above items should be checked daily, as a minimum. They are in addition to, not in place of federal motor carrier safety regula- ti...

Page 95

Part 7: starting & operating the vehicle normal temperature starting procedure (05/10) y53-6032 – 93 – part 7: starting & operating the vehicle since each vehicle is custom-equipped, all engine opera- tion instructions in this manual are general. You will want to consult the manual for your engine t...

Page 96

Cold temperature starting procedure part 7: starting & operating the vehicle – 94 – y53-6032 (05/10) minutes before trying again. If the engine still won’t start after a couple of tries, check the manual override shut- down valve and fuel lines for possible fuel starvation or air leaks. Starting fai...

Page 97

Part 7: starting & operating the vehicle engine warmup (05/10) y53-6032 – 95 – engine warmup the purpose of engine warmup is to allow oil film to be established between pistons and liners, shafts and bear- ings while your engine gradually reaches operating tem- perature. Warmup procedure 1. After yo...

Page 98

Engine warmup part 7: starting & operating the vehicle – 96 – y53-6032 (05/10) warning! Exhaust fumes from the engine contain carbon monoxide, a colorless and odorless gas. Do not breathe the engine exhaust gas. A poorly maintained, damaged or corroded exhaust system can allow carbon monoxide to ent...

Page 99

Part 7: starting & operating the vehicle transmission warmup (05/10) y53-6032 – 97 – notes: • keep the engine exhaust system and the vehi- cle’s cab/sleeper ventilation system properly maintained. It is recommended that the vehi- cle’s exhaust system and cab/sleeper be inspected – by a competent tec...

Page 100

Putting the vehicle in motion part 7: starting & operating the vehicle – 98 – y53-6032 (05/10) warning! To reduce the chance of personal injury and/or vehicle damage from overheated engines, which can result in a fire, never leave the engine idling without an alert driver present. If the engine shou...

Page 101

Part 7: starting & operating the vehicle putting the vehicle in motion (05/10) y53-6032 – 99 – shifting the transmission you will find a shift pattern either on a decal in your cab or on a medallion in the shift knob. Check to be sure you know the correct sequence for your particular transmis- sion....

Page 102

Putting the vehicle in motion part 7: starting & operating the vehicle – 100 – y53-6032 (05/10) the total stroke of the clutch pedal is about 10 inches. The first 1 3/4 to 2 inches is free travel. After that is the release stroke, the part that fully releases the clutch. The last 1/2 to 1 inch engag...

Page 103

Part 7: starting & operating the vehicle putting the vehicle in motion (05/10) y53-6032 – 101 – caution: be careful not to apply the clutch brake while the vehicle is moving. The pur- pose of the clutch brake is to stop the trans- mission so that you can shift into a starting gear without grinding. ...

Page 104

Putting the vehicle in motion part 7: starting & operating the vehicle – 102 – y53-6032 (05/10) switch in unlock position warning! Do not engage the differential lock while operating on dry pavement; it could lead to an accident involving death or per- sonal injury. You will not be able to safely st...

Page 105

Part 7: starting & operating the vehicle putting the vehicle in motion (05/10) y53-6032 – 103 – warning! Do not use the differential lock at speeds greater than 25 mph (40 kph); it could lead to an accident involving death or per- sonal injury. A vehicle with the differentials locked will be difficu...

Page 106

Putting the vehicle in motion part 7: starting & operating the vehicle – 104 – y53-6032 (05/10) 3. Off-highway: when you are driving on rough terrain and secondary roads, or under a very heavy load, keep the axle in the low range. Shift your transmis- sion to maintain the road speed you want. 4. Whe...

Page 107

Part 7: starting & operating the vehicle putting the vehicle in motion (05/10) y53-6032 – 105 – when you are driving with poor traction, lock the differen- tial. When you have the differential locked, drive with the axle in low range only. Interaxle in lock always unlock the interaxle differential b...

Page 108

Putting the vehicle in motion part 7: starting & operating the vehicle – 106 – y53-6032 (05/10) if your vehicle must be towed follow these directions to ensure your vehicle is not dam- aged when towing is required. 1. Lift driving wheels off the ground or remove the drive- line and axle shafts befor...

Page 109

Part 7: starting & operating the vehicle putting the vehicle in motion (05/10) y53-6032 – 107 – a. Remove the air line and firmly cap illustration of driver-controlled main differential lock b. Remove the caging bolt from its storage hole. C. Screw the caging bolt into the air line hole. When fully ...

Page 110

Anti-lock braking system operating information part 7: starting & operating the vehicle – 108 – y53-6032 (05/10) • if you don’t desire to use the recovered vehicle’s brakes, ensure that you cage the spring brakes before attempting to move the vehicle. 4. Install recovery hitches and rigging. Caution...

Page 111

Part 7: starting & operating the vehicle anti-lock braking system operating information (05/10) y53-6032 – 109 – warning! • the brake system is a critical vehicle safety system. For the safety of you and others around you, have the vehicle submitted for periodic preventive maintenance checks as well...

Page 112

Anti-lock braking system operating information part 7: starting & operating the vehicle – 110 – y53-6032 (05/10) trailer abs warning lamp trucks, tractors, and trailers built on and after march 1, 2001 are equipped with power line communication (plc) per u.S. Fmvss 121, including a plc trailer abs w...

Page 113

Part 7: starting & operating the vehicle anti-lock braking system operating information (05/10) y53-6032 – 111 – caution: • the center pin of the 7-way trailer light line may be constantly powered for abs. Make sure it will not accidently turn on trailer equipment. • do not splice into the non-switc...

Page 114

Anti-lock braking system operating information part 7: starting & operating the vehicle – 112 – y53-6032 (05/10) during operation, the ecu of the bendix advanced abs system constantly compares performance models to the vehicle’s actual movement, using the wheel speed sen- sors of the abs system, as ...

Page 115

Part 7: starting & operating the vehicle anti-lock braking system operating information (05/10) y53-6032 – 113 – yaw stability yaw stability counteracts the tendency of a vehicle to spin about its vertical axis. During operation, if the friction between the road surface and the tires is not sufficie...

Page 116

Anti-lock braking system operating information part 7: starting & operating the vehicle – 114 – y53-6032 (05/10) yaw control example important safety information about the stability system esp may reduce the vehicle speed automati- cally to minimize unexpected deceleration and reduce the risk of a c...

Page 117

Part 7: starting & operating the vehicle anti-lock braking system operating information (05/10) y53-6032 – 115 – warning! Exercise extreme care when tow- ing doubles or triples with a vehicle equipped with electronic stability program. Excessive speed and aggressive maneuvers, such as sharp turns, s...

Page 118

Anti-lock braking system operating information part 7: starting & operating the vehicle – 116 – y53-6032 (05/10) truck chassis modifications the esp system was specifically calibrated and validated only for your vehicle’s original factory-built configuration. If your vehicle’s chassis components are...

Page 119

Part 7: starting & operating the vehicle brake safety and emergency (05/10) y53-6032 – 117 – the wheel spin control warning lamp will briefly illumi- nate and then go out when the ignition switch is first turned on. The wheel spin control warning lamp will illu- minate whenever the asr or atc system...

Page 120

Brake safety and emergency part 7: starting & operating the vehicle – 118 – y53-6032 (05/10) warning! Unless you have an anti-lock brak- ing system, always avoid completely depress- ing the service brake pedal, if possible, even during emergency braking. Depressing the brake pedal too aggressively c...

Page 121

Part 7: starting & operating the vehicle brake safety and emergency (05/10) y53-6032 – 119 – red / yellow controls warning! • do not leave the cab without applying the parking brake. The truck could roll and cause an accident involving death or personal injury. Always apply the parking brake before ...

Page 122

Brake safety and emergency part 7: starting & operating the vehicle – 120 – y53-6032 (05/10) your vehicle could result in excessive heat build-up in the brake system, resulting in a fire. Note: today’s diesel electronic engines have significant torque and startability power at low rpm. Combinations ...

Page 123

Part 7: starting & operating the vehicle brake safety and emergency (05/10) y53-6032 – 121 – manually releasing spring brakes there may be an occasion when you need to tow the vehi- cle but the air system does not produce enough operating pressure to release the parking brakes. For these situa- tion...

Page 124

Brake safety and emergency part 7: starting & operating the vehicle – 122 – y53-6032 (05/10) to release spring brakes manually 1. Remove the cap from the spring chamber. 2. Remove the release stud assembly from the side pocket; remove the release nut and washer from the release stud. : 02936a 02936b...

Page 125

Part 7: starting & operating the vehicle brake safety and emergency (05/10) y53-6032 – 123 – 3. Slide out the release stud 4. Insert the release stud through the opening in the spring chamber where the cap was removed. Insert it into the pressure plate. Turn the release stud 1/4-turn clockwise in th...

Page 126

Brake safety and emergency part 7: starting & operating the vehicle – 124 – y53-6032 (05/10) 5. Assemble the release stud washer and nut on the release stud. 6. With a wrench, turn the release stud assembly nut until the compression spring is 90% - 95% caged. While doing this, check to make sure the...

Page 127

Part 7: starting & operating the vehicle brake safety and emergency (05/10) y53-6032 – 125 – retarders various retarders are available which function against the engine, driveline, or transmission. These are devices that use your engine’s power to slow down your vehicle. They save wear and tear on y...

Page 128: Functionality / Notification

Exhaust after-treatment system part 7: starting & operating the vehicle – 126 – y53-6032 (05/10) driving bobtail or with an unloaded trailer we recommend that you do not use your engine retarder to slow down when you are bobtailing or pulling an empty trailer. Warning! Using an engine retarder can c...

Page 129

Part 7: starting & operating the vehicle exhaust after-treatment system (05/10) y53-6032 – 127 – "passive" regeneration and is transparent to the opera- tion of the vehicle. Occasionally, the exhaust gases are too cool for passive regeneration. When this occurs, the ats will regenerate the dpf by in...

Page 130

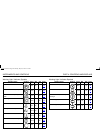

Exhaust after-treatment system part 7: starting & operating the vehicle – 128 – y53-6032 (05/10) notification of high exhaust system temperature: indicator information what to do on-steady the high exhaust temperature (hest) warning lamp will illuminate, regardless of ats status, as the vehicle's ex...

Page 131

Part 7: starting & operating the vehicle exhaust after-treatment system (05/10) y53-6032 – 129 – notification that regeneration is required: indicator information what to do on steady the dpf status indicator symbol will illu- minate when the soot level in the dpf is above the desired level and it n...

Page 132

Exhaust after-treatment system part 7: starting & operating the vehicle – 130 – y53-6032 (05/10) blinking on steady on steady (caterpillar engine) the dpf status indicator symbol will blink when the soot level in the dpf continues to stay above the desired level the soot level in the dpf is now at f...

Page 133: Dpf Regeneration

Part 7: starting & operating the vehicle exhaust after-treatment system (05/10) y53-6032 – 131 – dpf regeneration carefully read the following instructions to regenerate the dpf. If you have any problems or difficulties contact your nearest peterbilt authorized dealer for assistance. The after-treat...

Page 134

Exhaust after-treatment system part 7: starting & operating the vehicle – 132 – y53-6032 (05/10) warning! Never initiate an regeneration in a closed building or enclosure. Always park your vehicle outside and ensure no one is in the immediate vicinity. Failure to do so could ignite an explosion or h...

Page 135: Stop An Automatic Or Parked

Part 7: starting & operating the vehicle exhaust after-treatment system (05/10) y53-6032 – 133 – note: acknowledgment that a parked regener- ation has initiated will vary by engine. The most predominant acknowledgement to you will be an increase in engine rpm and overall engine noise. Note: the time...

Page 136

Stopping the engine part 7: starting & operating the vehicle – 134 – y53-6032 (05/10) warning! Never allow an automatic regen- eration to automatically start while inside a building such as a service bay, shop or build- ing of any kind. Any time you are parking your vehicle inside a building or encl...

Page 137

Part 7: starting & operating the vehicle stopping the engine (05/10) y53-6032 – 135 – 100°f (55°c) above the temperature reached during oper- ation. A sudden rise in temperature like this could cause the bearings to seize or the oil seals to loosen. Refuel before the final stop air space in your fue...

Page 138

Setting ride height part 7: starting & operating the vehicle – 136 – y53-6032 (05/10) 2. If you are parked on a steep grade, block the wheels . Blocked wheels 3. Drain water from the air reservoirs. While the engine and air supply system are still warm, drain moisture from the air reservoirs. Open t...

Page 139

Part 7: starting & operating the vehicle setting ride height (05/10) y53-6032 – 137 – is equipped with a peterbilt rear air suspension, and if it becomes necessary to reset the ride height, you may tem- porarily set it by following the next procedure. Proper ride height measurement and values are sh...

Page 140

Setting ride height part 7: starting & operating the vehicle – 138 – y53-6032 (05/10) 1. Ensure the air supply and delivery plumbing of the height control valve is consistent with the following illustrations: typical height control valve (top view) typical height control valve (rear view looking for...

Page 141

Part 7: starting & operating the vehicle setting ride height (05/10) y53-6032 – 139 – warning! The rear of a vehicle will drop about 3 1/2 inches (88 mm) when the air springs are deflated. Ensure that no persons or objects that could be killed, injured or damaged are under the vehicle before deflat-...

Page 142

Driving tips and techniques part 7: starting & operating the vehicle – 140 – y53-6032 (05/10) warning! Your brakes could fail if you con- tinue driving with deflated air springs. Air escaping from the system will lower the air pressure, which could cause a spring brake to engage. The spring brake ma...

Page 143

Part 7: starting & operating the vehicle driving tips and techniques (05/10) y53-6032 – 141 – cause a serious accident due to mechanical failures which could cause death or personal injury. Coasting with the transmission in neutral is also expen- sive. It causes premature failure or damage to the cl...

Page 144

Driving tips and techniques part 7: starting & operating the vehicle – 142 – y53-6032 (05/10) refer to the engine operation and maintenance manual for optimum engine rpm. • if the engine rpm exceeds the maximum governed speed, apply the service brake or shift to a higher gear to lower engine rpm. • ...

Page 145

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 143 – part 8: maintenance and service preventive maintenance schedule your preventive maintenance program begins with the daily checks you perform. See “part 6: driver’s checklist” for these. If you check your peterb...

Page 146

Preventive maintenance schedule part 8: maintenance and service – 144 – y53-6032 (r05/10) • disconnect the battery ground strap when- ever you work on the fuel system or the electrical system. When you work around fuel, do not smoke or work near heaters or other fire hazard. Keep an approved fire ex...

Page 147

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 145 – notes: • where questions or discrepancies develop between these recommendations and compo- nent supplier recommendations, consult the supplier for specific recommendations. • maintenance requirements of specifi...

Page 148

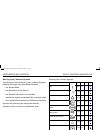

Preventive maintenance schedule part 8: maintenance and service – 146 – y53-6032 (r05/10) table 2 preventative maintenance schedule system component maintenance task recommended pm interval i a b c d e frame fifth wheel check the kingpin lock and plate for wear and function; lubricate (nlgi #2 greas...

Page 149

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 147 – front suspension shock absorbers inspect for leaking, body damage, and damaged or worn bushings. Replace as required. X shock absorbers check for proper function. X u-bolts (on highway) check the general condit...

Page 150

Preventive maintenance schedule part 8: maintenance and service – 148 – y53-6032 (r05/10) drive axle (dana) lube filter (on highway) change. X lube filter (off highway) change. X magnetic drain plug and breather (on highway) clean or replace. X magnetic drain plug and breather (off highway) clean or...

Page 151

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 149 – rear suspension u-bolts check the torque. Tighten to specified torque value as required (see page 207 ). X x frame & crossmember bolts check the torque. Tighten to specified torque value as required (see page 2...

Page 152

Preventive maintenance schedule part 8: maintenance and service – 150 – y53-6032 (r05/10) disc brakes (all) brake pads inspect; replace as required. X brake disc/rotor inspect for visible cracks, heat checking, galling, or scoring of surface. Check thickness minimum of 1.46” (37 mm). X caliper slidi...

Page 153

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 151 – hub, drum, & hubcap lms hubs (dana) with mineral lubricant clean the components and check for excessive wear or damage. Change the oil and seal (see page 185 ). 360,000 miles/ 576,000 km brake drums inspect for...

Page 154

Preventive maintenance schedule part 8: maintenance and service – 152 – y53-6032 (r05/10) main & aux- iliary trans- mission (meritor) transfer case check the oil level; refill as required (see page 169 ). X x drain lubricant while warm. Flush each unit with clean flushing oil. X air intake air intak...

Page 155

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 153 – cooling system (elc) check the freeze point (see page 191 ). X check for contamination using test strips (see page 192 ). X replace blank water filter if applicable. X perform lab analysis of coolant to determi...

Page 156

Preventive maintenance schedule part 8: maintenance and service – 154 – y53-6032 (r05/10) tires & wheels disc wheels inspect the wheel disc for any cracks or surface irregularities. Inspect the rim edge and bead seat area for damage. Replace any damaged wheels - do not attempt to repair. X demountab...

Page 157

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 155 – power steering steering linkage check all joints for excessive lash; replace as required (see page 207 ). X draglink tube clamp and ball socket check the torque; tighten to specified torque value as required. X...

Page 158

Preventive maintenance schedule part 8: maintenance and service – 156 – y53-6032 (r05/10) fuel & tanks fuel tank straps tighten to proper torque value of 45 - 70 lb. Ft. (61 - 95 n.M.); *check annu- ally once strap tension reaches a steady state; i.E., after 2 - 3 retorquings, the measured torque is...

Page 159

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 157 – battery battery box and tray check the box integrity. Clean the drain tube and check for acid leaks. Check condition of all equipment mounted under the box. X electrical & lights headlamps check the aim and adj...

Page 160

Preventive maintenance schedule part 8: maintenance and service – 158 – y53-6032 (r05/10) electrical & lights power supply harnesses (engine, transmission, etc.) check for worn or damaged insulation, corroded terminals, frayed wires, and oil or fluid leaks on the connectors or wiring. X power supply...

Page 161

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 159 – aftertreat- ment sys- tem diesel particulate filter clean filter. Refer to the engine maintenance manual diesel exhaust fluid tank check fittings for abrasion damage, leaks, tightness and fully engaged con- nec...

Page 162

Preventive maintenance schedule part 8: maintenance and service – 160 – y53-6032 (r05/10) engine basic engine the maintenance and service interval recommendations for the specific engine are the maintenance requirements specified in the engine manufac- turer’s operations and maintenance manual inclu...

Page 163

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 161 – lubricant specifications warning! Handle lubricants carefully. Vehicle lubricants (oil and grease) can be poisonous and cause death, injury or sickness. They can also damage the paint on the vehicle. In this se...

Page 164

Preventive maintenance schedule part 8: maintenance and service – 162 – y53-6032 (r05/10) warning! Never idle your vehicle for prolonged periods of time if you sense that exhaust fumes are entering the cab or sleeper. Investigate the cause of the fumes and correct it as soon as pos- sible. If the ve...

Page 165

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 163 – master lubrication index note: the responsibility for meeting these specifi- cations, the quality of the product, and its perfor- mance in service rests with the lubricant supplier. Table 3 lubricant symbol key...

Page 166

Preventive maintenance schedule part 8: maintenance and service – 164 – y53-6032 (r05/10) table 4 component lubrication index universal joints ep drive shaft splines cl wheel bearings (driven hubs) hd wheel bearings (nondriven hubs) cd50 wheel bearings (all grease-lubricated hubs) wb steering column...

Page 167

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 165 – fuller transmission lubrication fuller transmissions are designed so that the internal parts operate in a bath of oil circulated by the motion of gears and shafts. Grey iron parts have built-in channels where n...

Page 168

Preventive maintenance schedule part 8: maintenance and service – 166 – y53-6032 (r05/10) caution: exceeding the recommended oil change intervals may be harmful to the life of the transmission and the transmission oil cooler. Recommended lubricants table 5 recommended lubricants type grade (sae) amb...

Page 169

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 167 – spicer transmission lubrication it is extremely important to use the proper lubricants and maintain the correct oil levels in spicer units. This will ensure proper lubrication and operating temperatures in thes...

Page 170

Preventive maintenance schedule part 8: maintenance and service – 168 – y53-6032 (r05/10) oil changes caution: when adding oil, types and brands of oil should not be intermixed because of p o s s ib le i n c o m p a t i b i li t y, w h i c h c o u l d decrease the effectiveness of the lubrication or...

Page 171

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 169 – meritor axle lubrication note: axles utilized in 100% off-highway use are not eligible for meritor’s advanced lube rear drive axle program. Under meritor’s advanced lube rear drive axle program, the axles liste...

Page 172

Preventive maintenance schedule part 8: maintenance and service – 170 – y53-6032 (r05/10) • change the lubricant filter every 120,000 miles (192,000 km). Top off the lubricant level with a similar lubricant. Eaton/dana axle lubrication • the original mineral-based lubricant must be drained within 30...

Page 173

Part 8: maintenance and service preventive maintenance schedule (r05/10) y53-6032 – 171 – through the bearings when initially filling a hub. Maintain the differential oil level by adding oil until its surface is even with the bottom of the filler hole (see page 165 ). Oil-lubricated nondriven hubs u...

Page 174

Preventive maintenance schedule part 8: maintenance and service – 172 – y53-6032 (r05/10) replacement 1. Replace fluid per the chart below. 2. Bleed the system if necessary . Inspection note: before removing reservoir cover, wipe out- side of cover so that no dirt can fall into the reser- voir. 1. C...

Page 175

Part 8: maintenance and service servicing specific systems and units (r05/10) y53-6032 – 173 – servicing specific systems and units this section will help you keep your peterbilt vehicle in good running condition. There are a number of checks you can do, and you may be able to do some of the ser- vi...

Page 176

Brake adjustment part 8: maintenance and service – 174 – y53-6032 (r05/10) tem. All of the following areas are interrelated and must conform to original specifications: • tire size • drum brakes a. Cam radius b. Wedge angle c. Drum radius d. Brake linings e. Brake chambers f. Slack adjusters • disc ...

Page 177

Part 8: maintenance and service brake adjustment (r05/10) y53-6032 – 175 – • watch the rate of air pressure drop registered by the air gauge. The rate of drop should not be more than 3 psi (21 kpa) per minute. • if you find excessive leakage, a leakage test should be made at the air line connections...

Page 178

Brake adjustment part 8: maintenance and service – 176 – y53-6032 (r05/10) • proper running clearance is 0.08” (2 mm) of move- ment of the brake caliper (approximately the thickness of a nickel) in the inboard/outboard direction. • have a qualified mechanic provide further inspection if the caliper ...

Page 179

Part 8: maintenance and service tires, wheels, and rims (r05/10) y53-6032 – 177 – warning! Manual adjustment of automatic slack adjusters is a dangerous practice that could result in an accident involving death or injury. It gives the operator a false sense of security about the effectiveness of the...

Page 180

Tires, wheels, and rims part 8: maintenance and service – 178 – y53-6032 (r05/10) addition, keeping your tires in good condition is essential to the safe, efficient operation of your vehicle. Regular, fre- quent inspection and the right care will give you the assur- ance of safe and reliable tire op...

Page 181

Part 8: maintenance and service tires, wheels, and rims (r05/10) y53-6032 – 179 – overloaded tires overloading your truck is as damaging to your tires as underinflation. The following chart shows how neglect or deliberate abuse can affect the life of your tires. Warning! Do not exceed the load ratin...

Page 182

Tires, wheels, and rims part 8: maintenance and service – 180 – y53-6032 (r05/10) warning! Do not mismatch wheel compo- nents. Equipment that does not exactly match original specifications or that is mismatched could cause the wheels to break and separate from the vehicle causing death or personal i...

Page 183

Part 8: maintenance and service tires, wheels, and rims (r05/10) y53-6032 – 181 – note: to prolong your tires’ life and make them safer, have their radial and lateral run-out checked at your dealer. And of course you should have your tires balanced any time you change a tire. Tire chains if you need...

Page 184

Tire load and inflation tables part 8: maintenance and service – 182 – y53-6032 (r05/10) tire load and inflation tables table 12 load range letters and corresponding ply rating ( g = 14 ply; h = 16 ply) single radial tires for vehicles in highway service tire size load range tire load limits at vari...

Page 185

Part 8: maintenance and service vehicle loading (r05/10) y53-6032 – 183 – vehicle loading warning! Do not exceed the specified load rat- ing. Overloading can result in loss of vehicle control, death or personal injury, either by caus- ing component failures or by affecting vehicle handling. Exceedin...

Page 186

Vehicle loading part 8: maintenance and service – 184 – y53-6032 (r05/10) load distribution: be sure any load you carry is distributed so that no axle has to support more than its load limit. Wheels and rims hub pilot mount system ball seat mount system hub, drum, and stud assembly • the hub pilot m...

Page 187

Part 8: maintenance and service vehicle loading (r05/10) y53-6032 – 185 – wheel nuts • hub pilot nut has a hex body and a flange for clamp- ing against wheel face. Hex size is 33 mm (same as 1- 5/16 in.). • inner and outer cap nuts mate with spherical cham- fers on wheels. Inner nut has 13/16 in. Sq...

Page 188

Vehicle loading part 8: maintenance and service – 186 – y53-6032 (r05/10) disc wheels to check the torque on disc wheels, follow the crisscross sequence shown. See the specifications chart for proper torque specification. Warning! Use the correct components and tools when working on wheels. Grooves ...

Page 189

Part 8: maintenance and service vehicle loading (r05/10) y53-6032 – 187 – crisscross sequence for demountable rims 02951 table 13 cap nut torque specifications (r12/01) wheel and nut configuration stud size torques for inner & outer cap nuts lb. Ft. N.M stud-piloted disc wheels 3/4”-16 inner 1 1/8”-...

Page 190

Your vehicle’s air system part 8: maintenance and service – 188 – y53-6032 (r05/10) your vehicle’s air system warning! Prior to the removal of any air sys- tem component, always block and hold the vehicle by a secure means other than the vehicle's own brakes. Depleting air system pressure may cause ...

Page 191

Part 8: maintenance and service your vehicle’s air system (r05/10) y53-6032 – 189 – truck and trailer brakes. That is why, when you push down on your brake pedal, you don’t feel the same amount of pressure on the pedal that you do when you apply the brakes on your car. All you are doing on your truc...

Page 192

Your vehicle’s air system part 8: maintenance and service – 190 – y53-6032 (r05/10) caution: don’t use penetrating oil, brake fluid, or wax-based oils in the air system. These fluids may cause severe damage to air system compo- nents . • maintain the air compressor to prevent excessive oil by-pass. ...

Page 193

Part 8: maintenance and service engine cooling system (r05/10) y53-6032 – 191 – of small amounts of moisture is normal and should not be considered as an indication that the dryer is not performing properly. • an outside air source may have been used to charge the air system, in which case this air ...

Page 194

Engine cooling system part 8: maintenance and service – 192 – y53-6032 (r05/10) elc condition (contamination and inhibitor concen- tration) perform a visual inspection of the elc. It should have no cloudiness or floating debris. Determine the chemical inhibitor concentration level by using an elc-sp...

Page 195

Part 8: maintenance and service engine cooling system (r05/10) y53-6032 – 193 – topping off warning! Removing the fill cap on a hot engine can cause scalding coolant to spray out and burn you badly. If the engine has been in operation within the previous 30 minutes, be very careful in removing the f...

Page 196

Engine cooling system part 8: maintenance and service – 194 – y53-6032 (r05/10) proper coolant level note: do not overfill a cooling system. Excess coolant may result in overflow, loss of antifreeze, and reduced corrosion protection. • the proper coolant level for a cold engine is at the base of the...

Page 197

Part 8: maintenance and service electrical (r05/10) y53-6032 – 195 – check the coolant level after each trip when the engine has cooled. Add coolant as necessary. You may find your coolant level is not up to the correct level soon after you have filled the radiator. This may be because all the trapp...

Page 198

Electrical part 8: maintenance and service – 196 – y53-6032 (r05/10) recharging batteries except for using small trickle chargers to maintain battery condition, you should have your vehicle’s batteries charged by a qualified service facility. To help reduce the risk of personal injuries, follow thes...

Page 199

Part 8: maintenance and service electrical (r05/10) y53-6032 – 197 – • before attempting any work on the batteries or electri- cal system, remove all jewelry. If metal jewelry or other metal comes in contact with electrical circuits, a short circuit may occur causing you to be injured— plus electric...

Page 200

Electrical part 8: maintenance and service – 198 – y53-6032 (r05/10) • do not charge a frozen battery; allow it to thaw out first. And always allow the battery to thaw gradually— do not apply direct heat. Gas trapped in the ice may cause an explosion. • never attempt to place the vehicle in motion, ...

Page 201

Part 8: maintenance and service electrical (r05/10) y53-6032 – 199 – warning! Batteries contain acid that can burn and gasses that can explode. Ignoring safety procedures can possible cause death or severe personal injury. • never jump start a battery near fire, flames, or electrical sparks. Batteri...

Page 202

Electrical part 8: maintenance and service – 200 – y53-6032 (r05/10) manufacturer. The jumper cables must be long enough so that the vehicles do not touch. • applying a higher voltage booster battery will cause expensive damage to sensitive electronic components, such as relays, and the radio. Impro...

Page 203

Part 8: maintenance and service electrical (r05/10) y53-6032 – 201 – 4. Attach one end of a jumper cable to the dead battery’s positive terminal. This will have a large red “+” or “p” on the battery case, post, or clamp. Attach the other end of the same cable to the positive terminal of the good bat...

Page 204

Electrical part 8: maintenance and service – 202 – y53-6032 (r05/10) 1. Ensure that the hood is properly adjusted. 2. Ensure that the hood is closed and completely latched. 3. Ensure that the tires are inflated to an on-highway set- ting. 4. Ensure that the headlamp surfaces are clean and dry. 5. Pa...

Page 205

Part 8: maintenance and service transmission and drive train (r05/10) y53-6032 – 203 – 9. Establish a second horizonal line, no more than 1 in. (2.5 cm) wide, below the h-h line. This is the a-a line. 10. Using a 10 mm socket, turn the headlamp’s adjuster until the aim zone visible in the beam patte...

Page 206

Fuel system part 8: maintenance and service – 204 – y53-6032 (r05/10) warning! A mixture of gasoline or alcohol with diesel fuel in the presence of an ignition source (such as a cigarette) could cause an explosion. You could be killed or seriously injured. Use only the recommended diesel fuel. Cauti...

Page 207

Part 8: maintenance and service fuel system (r05/10) y53-6032 – 205 – caution: do not overtighten the valve. Over- tightening can damage the threads. • after starting the engine, check for leaks around the filter. Emission components deisel exhaust fluid tank vehicles that comply with 2010 epa emiss...

Page 208

Fuel system part 8: maintenance and service – 206 – y53-6032 (r05/10) 2. Remove the pump protective plate mounted on the bottom of the def tank. 3. Using a 27 mm socket wrench (din3124), remove the filter cap that is screwed to the def supply pump. 4. Replace filter and reassemble the cap. Tighten t...

Page 209

Part 8: maintenance and service fuel system (r05/10) y53-6032 – 207 – steering guidelines for checking a steering system warning! A steering system that is not work- ing properly can cause an accident involving death or personal injury. You could lose con- trol of your vehicle if the steering is not...

Page 210

Fasteners part 8: maintenance and service – 208 – y53-6032 (r05/10) regularly. Be sure someone with the proper training and the right tools checks and tightens the u-bolts on your peterbilt. The proper torque requirements are specified in the peterbilt maintenance manual for your vehicle. Warning! D...

Page 211

Part 8: maintenance and service fasteners (r05/10) y53-6032 – 209 – standard capscrew torque specifications the torque values in the previous tables are based on the use of clean and dry threads. Table 15 capscrew torque specifications sae grade number 5 8 capscrew body size (inches- thread) torque ...

Page 212

Engine accessories part 8: maintenance and service – 210 – y53-6032 (r05/10) frame fasteners • go around your vehicle as per the preventive mainte- nance schedule and tighten all frame fasteners with a torque wrench. • always use the torque values listed in frame fastener table. • always torque fast...

Page 213

Part 8: maintenance and service engine accessories (r05/10) y53-6032 – 211 – belt route for caterpillar engine 2. Slip the belt around the idler pulley attached to the automatic tensioner. 3. Release the automatic tensioner. 4. Check the belt alignment on each pulley. The belt must fall between the ...

Page 214

Air intake system part 8: maintenance and service – 212 – y53-6032 (r05/10) air intake system engine heat, vibration, and age combine to loosen air intake connections and cause cracks in the tubing and elbows. Leaks in the intake system allow abrasive dust to enter the engine and quickly cause expen...

Page 215

Part 8: maintenance and service exhaust system (r05/10) y53-6032 – 213 – warning! If your vehicle becomes disabled, the hot exhaust system could ignite dry grass, brush, spilled fuel, or other material that can cause fires which can lead to death, personal injury and property damage. Do not park or ...

Page 216

Anti-lock braking system (abs) part 8: maintenance and service – 214 – y53-6032 (r05/10) below are some general notes on repairing your anti-lock braking system: • the foundation brake system must be in proper work- ing order to ensure the best abs performance. • before welding anywhere on the vehic...

Page 217

Part 8: maintenance and service cab heater-air conditioner (r05/10) y53-6032 – 215 – warning! Although the brakes will continue to operate with a malfunction in either circuit, the vehicle should not be operated until the system is repaired, and both braking circuits, including all pneumatic and mec...

Page 218

Cab heater-air conditioner part 8: maintenance and service – 216 – y53-6032 (r05/10) notes:allow for the proper operation of the vehi- cle ventilation system: • keep the inlet grille at the base of the wind- shield clear of snow, ice, leaves, and other obstructions at all times. • keep the exhaust p...

Page 219

Part 8: maintenance and service cab heater-air conditioner (r05/10) y53-6032 – 217 – • check the evaporator core and condenser core for debris restricting air flow. Clean if necessary. Small particles may be removed with compressed air blown through the core in the opposite direction of normal air f...

Page 220

Appearance part 8: maintenance and service – 218 – y53-6032 (r05/10) appearance painted surfaces caution: do not aim the water jet directly at door locks or hatch. Tape the key holes to pre- vent water from seeping into the lock cylin- ders. Water in lock cylinders should be removed with compressed ...

Page 221

Part 8: maintenance and service appearance (r05/10) y53-6032 – 219 – stainless steel follow this procedure to clean and restore the finish of stainless steel components: 1. In a plastic pail mix 4 tsp of alum (a powder found in grocery stores or drugstores), with 32 oz. Of water (warm water will dis...

Page 222

Appearance part 8: maintenance and service – 220 – y53-6032 (r05/10) • always test a commercial cleaning agent on an inconspicuous area of the surface to be cleaned before using it. • never clean interior components with chemicals or solvents such as –gasoline –naphtha –acetone –turpentine –benzene ...

Page 223

Part 8: maintenance and service appearance (r05/10) y53-6032 – 221 – • remove soap with a clean, damp rag. • if a stronger cleaning solution is required, use a foam- type carpet shampoo. Vinyl and fabric upholstery caution: to avoid possible damage to the upholstery, do not use chemical solvents or ...

Page 224

Noise control system part 8: maintenance and service – 222 – y53-6032 (r05/10) • wash and protect painted and metal surfaces, and also weatherstripping, as outlined in the preceding “appearance” information. • operate the vehicle to circulate fluids and lubricants that have settled to the lowest par...

Page 225

Part 8: maintenance and service noise control system (r05/10) y53-6032 – 223 – (1) the removal or rendering inoperative by any person other than for maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise control prior to its...

Page 226

Noise control system part 8: maintenance and service – 224 – y53-6032 (r05/10) inspection & maintenance instructions for noise control system the following instructions are based on regular inspection of the noise control system. If, during regular inspection or maintenance of other systems or compo...

Page 227

Part 8: maintenance and service noise control system (r05/10) y53-6032 – 225 – piping check for rust, corrosion, and damage. If piping is perfo- rated at any point, temporary patching or lagging is acceptable until you can have permanent repairs made. On turbocharged engines check joints at the flan...

Page 228

Noise control system part 8: maintenance and service – 226 – y53-6032 (r05/10) blanket check for chafing, tears, etc. Patch it if necessary. Find the cause of the damage. If any component or accessory is causing wear or damage and can’t be relocated, put reinforcing pads on the blanket at the site o...

Page 229

Part 8: maintenance and service noise control system (r05/10) y53-6032 – 227 – air intake system • do all checks and maintenance chores listed in this manual under engine air intake system and air cleaner (see index). • check the induction tubing, elbow connections, clamps, brackets, and fasteners f...

Page 230

Noise control system part 8: maintenance and service – 228 – y53-6032 (r05/10) table 16 noise control system maintenance logs component recommended interval (miles) date & r.O. Number repair facility & location work performed date & r.O. Number repair facility & location work performed exhaust syste...

Page 231

Part 9: vehicle identification numbers (r05/10) y53-6032 – 229 – part 9: vehicle identification numbers each vehicle completed by peterbilt motors company uses a vehicle identification number (vin) that contains the model year designation of your peterbilt. The practice is in compliance with 49 cfr ...

Page 232

Federal safety standard certification label part 10: consumer information – 230 – y53-6032 (r05/10) part 10: consumer information federal safety standard certification label the national highway traffic safety administration regu- lations require a label certifying compliance with federal safety sta...

Page 233

Part 10: consumer information canadian consumer information (r05/10) y53-6032 – 231 – paign. However, nhtsa cannot get involved in individual problems between you, your dealer, and peterbilt motors company. Contacting nhtsa is possible through telephone, wriitten mail and email. Nhtsa also has a web...

Page 234

State of california part 10: consumer information – 232 – y53-6032 (r05/10) etc., may contaminate the environment if spilled or not dis- posed of properly. Contact your local government agency for information concerning proper disposal. State of california california proposition 65 warning diesel en...

Page 235: Part 11: Subject Index

Part 11: subject index (r05/10) y53-6032 – 233 – part 11: subject index a anti-lock brakes 109 , 213 appearance 218 appliances in the cab 72 b battery compartment cover 201 electrolyte 196 recharging 196 slow battery charging 198 belts, seat 77 brake operation 109 brake system electronic stability c...

Page 236

Part 11: subject index – 234 – y53-6032 (r05/10) d dash 14 def 67 , 205 defogging/defrosting system 57 deisel exhaust fluid 205 deisel exhaust fluid tank 205 door lock 218 driver information display 30 driver’s checklist 88 driving vehicle inspection 88 e electrical system batteries 197 battery char...

Page 237

Part 11: subject index (r05/10) y53-6032 – 235 – j jumper cables 199 k keys 7 keys and locks ignition switch 41 l lubrication axle 169 – 170 coasting 141 steering gear 171 transmission 165 –?? Types and brands 161 universal joint 171 wheel bearing 170 lubrication index 163 luggage compartment(s) 71 ...

Page 238

Part 11: subject index – 236 – y53-6032 (r05/10) engine cooling system 191 fasteners 208 steering 207 tires, wheels, and rims 177 transmission and drive train 203 shifting gears 141 , 142 standard capscrew torque specifications 209 starting and operating 93 anti-lock braking system 108 automated tra...

Page 239

Part 11: subject index (r05/10) y53-6032 – 237 – numerics 49 cfr 565, code of federal regulations 229 y53-6032.Book page 237 monday, may 24, 2010 3:37 pm.