Summary of 20A

Page 1

Operation & maintenance manual st 20a systems.

Page 2

I © 1995 pace incorporated, laurel md. All rights reserved. Printed in the u.S.A. Pace incorporated retains the right to make changes to specifications contained herein at any time, without notice. Contact your local authorized pace distributor or pace incorporated to obtain the latest specification...

Page 3: Manual Number 5050-0355

System quick start the st 20a systems are very easy to operate. St 20a-sp systems (using sp-2a sodr-pen handpiece) can be quickly set up for use in standard soldering operations. To begin operation of a st 20a-sp system quickly, perform the "set-up" and "operation" procedures detailed on pages 7-11 ...

Page 4: Table of Contents

2 table of contents title page general information ................................................................................................ 3 introduction .................................................................................................. 3 specifications ........................

Page 5: General Information

3 general information introduction thank you for purchasing the pace model st 20a soldering system. This manual will provide you with the information necessary to properly set up, operate and maintain the system. Please read this manual thoroughly before using the system. The st 20a systems utilize ...

Page 6: Specifications

4 specifications system power source power requirements the system power sources are available in either the 115 vac, 230 vac or 100 vac version as listed below. Pps 15a (st 20a system) - operates on 97-127 vac, 50/60hz, 90 watts maximum at 115 vac, 60hz pps 15ae (st 20ae system) - operates on 197-2...

Page 7: Parts Identification

5 parts identification general information sp-2a handpiece (standard with st 20a-sp systems) tt-65 handpiece (standard with st 20a-tt systems) ps-50 prepset (standard with st 20a-ps systems).

Page 8: Safety

6 the following are safety precautions which personnel must understand and follow when using or servicing this product. 1. To prevent personnel injury, adhere to safety guidelines in accordance with osha and other applicable safety standards. 2. Sensatemp handpiece heaters and installed tips are hot...

Page 9: Set-Up

7 set-up set up the st 20a system using the following steps and associated drawings. If you have purchased a system which includes the tt-65 thermotweez handpiece or the ps 50 prep-set system, refer to their operation & maintenance manuals for applicable set-up instructions for those items. 1. Store...

Page 10: Set-Up

8 set-up tip & tool stand if your system has been shipped with a tip & tool stand, perform the following procedure. 1. Place 4 rubber feet (packed with small accessories) on the bottom corners of any enclosed tip & tool stand. 2. If your system has been shipped with a tt tip & tool stand (for tt-65 ...

Page 11: Set-Up

9 set-up 3. The tip & tool stand may be used as “free standing” or may be attached to either side of the power source. Attach the stand using the following procedure. A) insert the 2 enclosed mounting screws (head first) into the 2 power source mounting slots shown. Slide the screws toward the rear ...

Page 12: Set-Up

10 set-up pacelink the pacelink receptacle on the front panel of the power source allows the operator to activate the auto snap-vac and controllable pressure features of a st 60 system power source. If an air handpiece (sx-70, tp-65 or tj-70) is connection to the st 20a, actuation of its finger swit...

Page 13: Handpiece Connection

11 handpiece connection connect the handpiece (or ps 50) connector plug into the power receptacle in the following manner. 1. Turn the locking ring fully counterclockwise with the connector key end facing the power source. 2. Align the connector key with the receptacle keyway. 3. Insert the connecto...

Page 14: Operation

12 sodr-pen tip selection & use 1. Heat transfer: maximize thermal transfer by selecting the shortest, fattest tip with the largest surface contact area which appropriately fits the work. Keep the tip clean and freshly tinned and clean the work of oxides or other residues. When soldering, angle the ...

Page 15: Operation

13 3. Tip temperature: use the lowest tip temperature which will achieve rapid yet controllable melt of the entire joint(s). Begin with a temperature of 316°c (600°f) and adjust as necessary to suit the particular application and operator skill level. Lower tip temperatures reduce the risk of damage...

Page 16: Operation

14 operation available tips shown below is a partial listing of available single point tips plus illustrations of different tip configurations. Contact your local authorized pace distributor for the tip & applications catalog which contains a complete list of tips. Table i. Single point tips flatpac...

Page 17: Operation

15 operation note periodically, clean the heater bore with a properly sized wire brush (3/16" o.D. For sp-2a and 1/8" o.D. For sp-1a) to insure optimum heat transfer and proper tip grounding. Sodr-pen tip installation for maximum productivity and proper fit, install tips into your sodr-pen when the ...

Page 18: Operation

16 operation temperature selection variable temperature control adjust the variable temperature control knob to the desired temperature setting. Notice that the control dial has a white graphic scale denoting temperature in °c (celsius) and a yellow graphic scale denoting temperature in °f (fahrenhe...

Page 19: Operation

17 operation led operation the tri-colored (red, green and yellow) led on the power source front panel indicates system status (by color illumination) and power receptacle output status (led off, on or flashing). Following is an explanation of these status indicators. Refer to the illustration at th...

Page 20: Calibration

18 calibration the st 20a system can be checked for calibration according to pace requirements. Also, a temperature setting normally used by the operator can be adjusted to the precise temperature indicated on the dial/display. No internal adjustments can be made to the power supply. To verify calib...

Page 21: Corrective Maintenance

19 corrective maintenance power source most malfunctions are simple and easy to correct. Refer to table ii below to clear these malfunctions. Symptom probable cause solution no power to system. Blown fuse check handpiece using table iii . Replace the fuse (located in the ac receptacle/fuse holder) w...

Page 22: Corrective Maintenance

20 corrective maintenance sodr-pen heater replacement insure that the installed heater assembly of your sodr-pen handpiece is defective by referring to table iii. If replacement becomes necessary, follow the procedure below. 1. Disconnect the sodr-pen from the power source. 2. Unscrew, remove and di...

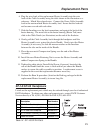

Page 23: Replacement Parts

21 replacement parts table iv. Sp-1a/sp-2a parts item # description part number 1 sp-1a sodr-pen handpiece 6025-0013-p1 2 sp-1a heater assembly (37 watt) 6010-0085-p1 3 sp-2a sodr-pen handpiece 6025-0014-p1 4 sp-2a heater assembly (54 watt) 6010-0086-p1 5 heater set screw 1348-0547-p10 6. Plug the w...

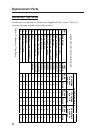

Page 24: Replacement Parts

22 replacement parts ac c e sso r y t r ay it em s ( p a c ki n g l ist ) q uant it y s u p p l ie d -s p s y st em s (with sp-2a so d r- p e n ) -t t s y s te m s (with tt-65 the rm otw e e z ) -p s s y st em s (with ps 50 prep-set) item no. D esc r ipt io n pa r t nu m b e r st 2 0 a s t 20a j st ...

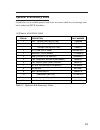

Page 25: Optional & Accessory Items

23 optional & accessory items listed below are available optional and accessory items which may be through your local authorized pace distributor. Optional & accessory items item no. Description part number 1 fuse, 1.0 amp time lag (pps 15a) 1159-0246 0.5 amp time lag (pps 15ae) 1159-0213 1.25 amp t...

Page 26

24.

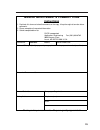

Page 27: Instructions

25 manual improvement & comment form instructions 1. 2. 3. Duplicate this form and submit comments on the copy. Keep the original to make future comments. Please complete all requested information. Submit completed form to: pace incorporated applications engineering fax: (301) 604-8782 9893 brewers ...