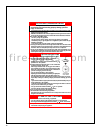

Pacific Energy The Oxford Installation And Operating Instructions Manual - Contents

2

Contents

CAUTION ....................................................................................... 3

SAFETY .......................................................................................... 3

MAINTENANCE ............................................................................. 3

CONTROL ASSEMBLY ................................................................. 4

GAS SUPPLY ................................................................................. 5

FLOOR PROTECTION ................................................................... 5

CLEARANCES ............................................................................... 5

INSTALLATION PRECAUTIONS .................................................. 6

STRAIGHT THROUGH WALL INSTALLATION ............................ 7

CORNER INSTALLATION ............................................................. 8

BASEMENT INSTALLATION ...................................................... 10

ATTACHMENT TO FLOOR ......................................................... 10

ALTERNATE VENTING ............................................................... 11

VENT TERMINAL INSTALLATION ............................................. 15

GLASS FRONT REMOVAL ......................................................... 16

LOG SET ...................................................................................... 17

GLOWING EMBERS .................................................................... 17

FIRST FIRE .................................................................................. 19

OPERATION ................................................................................ 19

PRIMARY AIR ADJUSTMENT ..................................................... 19

OPTIONAL WALL SWITCH OR THERMOSTAT ......................... 20

OPTIONAL BLOWER .................................................................. 20

REPLACEMENT PARTS ............................................................. 21

RATING LABEL ........................................................................... 23

f i r e - p a r t s . c o m