- DL manuals

- Pacific

- Scrubber

- S Series

- Parts & Operating Manual

Pacific S Series Parts & Operating Manual

This operator’s book has important information for the use and safe operation of this machine. Read this book carefully before

starting the machine. Keep this book near the machine, protected from liquids and other substances that can cause damage to it.

If you do not follow the instructions, you can cause an injury or damage equipment, furniture or buildings.

For new books, please download your copy from our website www.pacificfloorcare.com or write to:

Pacific Floorcare

®

2259 S. Sheridan Drive

Muskegon, MI 49442-6252

Carefully inspect all components to ensure that there is no concealed freight damage. If such damage is discovered, file a

“CONCEALED DAMAGE REPORT” immediately with the delivering carrier.

The contents of this manual are based on the latest product information available at the time of publication. Pacific Floorcare

reserves the right to make changes or improvements without being obliged to apply changes to the machines previously sold.

Thank you for purchasing a Pacific Floorcare product. Warranty registration will allow us to better serve you over the lifetime of

the product. For quick and easy registration, go to: www.pacificfloorcare.com/Register Product.

PLEASE READ THIS BOOK

S-SERIES, 22-GALLON MID-SIZE

AUTO SCRUBBERS

PARTS & OPERATING MANUAL

Summary of S Series

Page 1

This operator’s book has important information for the use and safe operation of this machine. Read this book carefully before starting the machine. Keep this book near the machine, protected from liquids and other substances that can cause damage to it. If you do not follow the instructions, you ca...

Page 2

Safety precautions this machine is intended for commercial use. Only use recommended pads or brushes and commercially approved floor cleaning chemical intended for machine application. The following symbols will be used to warn you of hazards or unsafe practices which could result in personal injury...

Page 3

Note: do not allow the brush/pad to operate while the machine is stationary to avoid damage to the floor. Caution: do not bump into shelves or scaffoldings, especially where there is a risk of falling objects. Caution: before leaving or servicing a machine, stop it on a level surface. Note: before l...

Page 4

Machine preparation unpacking & battery installation unpacking the machine 1. Remove the outer packaging. 2. The machine is fastened to the pallet with tie down brackets. Remove the brackets with a 3/8-inch socket head tip in a cordless screwdriver. 3. The machine is also held in place with four cle...

Page 5

5 machine preparation battery power level indicators the battery power level gage is located on the upper control panel. The gage has a series of leds to indicate the amount of power left in the batteries. When the batteries have a full charge, all leds are lit. As the batteries are discharged, the ...

Page 6

6 charging the batteries with an on-board charger before using your s-series mid-size scrubber for the first time, fully charge your batteries. Machine preparation using your on-board charger the on-board charger has charging indication leds - the red led means it has just started the charging cycle...

Page 7

Machine preparation setting the dip switches on your on-board charger for your battery type both the on-board and off-board chargers are able to charge wet, lead acid or maintenance-free agm batteries. As your unit leaves pacific floorcare’s factory, the charger is set up to match the type of batter...

Page 8

8 machine preparation using your off-board charger charging the batteries with an off-board charger before using your s-series mid-size scrubber for the first time, fully charge your batteries. Anderson connector located on lower, rear panel anderson connector located on charger cable off-board char...

Page 9

Machine preparation setting the dip switches on your off-board charger for your battery type the off-board charger is able to charge wet, lead acid or maintenance-free agm batteries. As your unit leaves pacific floorcare’s factory, the charger is set up to match the type of battery chosen in the ori...

Page 10

It is easy to gage the solution level by watching the fog-free solution sight gage at the rear of the machine. Additionally, marks on the tank provide solution level indicators as a guide. 10 to prepare the machine for cleaning, the unit must be filled with cleaning solution. Rear hose fill port not...

Page 11

11 machine preparation solution tank - auto-off solution fill system option 1 if your machine is equipped with the auto-off solution fill system option, connect the male end of the quick-connector to your 1/2-inch inner diameter fill hose. Once your fill hose is set up, leave the faucet for that hos...

Page 12

12 connect the cleaning pad to the disk pad drivers by centering them on the drivers. Machine preparation attaching cleaning pads to your pad drivers - disk head depress position “a” for 1 second then depress position “b” 1 if using floor pads with your pad drivers: 1 2 3 place your pad drivers on a...

Page 13

13 the pad drivers or brushes are attached by using the automatic on/off system. This valuable ingenuity removes the need for operators to kneel or strain to attach the pad drivers or brushes. First, start by placing the pad drivers or brushes on the floor in front of the s-series mid-size scrubber....

Page 14

14 attaching a pad to your orbital pad driver the orbital unit can be used for daily cleaning; however it specializes in chemical-free finish removal for low-cost finish maintenance programs. The following directions show how to prepare the machine for both applications. For cleaning, the orbital un...

Page 15

15 machine preparation connecting the squeegee and adjusting squeegee height prior to shipping from the factory, the squeegee assembly is removed from the unit. To connect your squeegee assembly to the machine: the squeegee blade assembly height is factory set at the optimum water recovery position ...

Page 16

16 machine preparation recovery tank preparation & plastic bag holder picking up larger debris during the cleaning process your s-series mid-size scrubber has been designed with two hooks molded into the handle that can be used to hang a plastic bag to put larger pieces of debris that you come acros...

Page 17

17 machine operation operational controls the machine operation and controls were designed to minimize operator training and decrease the need for adjustments during operation. Additionally, once in operation, pacific floorcare’s goal was to provide an ergonomic, easy to use system. Due to this focu...

Page 18

Machine operation on-board chemical injection system if your s-series mid-size scrubber is equipped with the on-board chemical injection system, the following instructions will walk you through the easy process of setting up and operating this system. Chemical injection chemical mix ratio dial being...

Page 19

Machine operation on-board chemical injection system once the chemical mix ratio is selected, set your desired solution flow rate to low, medium or high based on your cleaning needs and the chemical injection system will automatically mix your chemical for you. A solid green led indicates the system...

Page 20

20 machine operation operational controls once the machine is powered on and the solution flow is set, it takes three simple steps to operate the machine: lower the scrub deck, lower the squeegee and engage the activation trigger. These steps are visually shown on the lower control panel by the s-se...

Page 21

21 machine operation operational controls lowering the scrub deck the scrub deck is lowered using the foot pedal at the rear of the unit. Self-adjusting head shroud with bristle skirt the disk scrub head is equipped with a self-adjusting shroud with bristle skirt that virtually eliminates overspray ...

Page 22

22 machine operation operational controls activating the scrubber activating the handle trigger speed control adjustment reverse switch is easily reached with fingertip to begin scrubbing, engage the handle trigger. The trigger activates solution flow, the brush motor and traction drive. This unique...

Page 23

23 machine operation operational controls transport mode the scrub deck and squeegee must be in the raised position for transport. Squeegee assembly in raised/ storage position the scrub deck is raised into transport position by placing your foot on the foot pad and depressing the lever until it cle...

Page 24

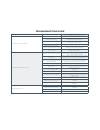

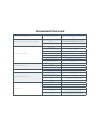

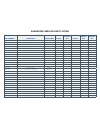

Maintenance schedule for service maintenance daily weekly monthly every six months 100 hours 200 hours clean squeegee assembly. Check blades for wear or damage. Check if adjustment needed to squeegee height x clean out recovery tank inside and out and float shut off assembly. Check both for damage. ...

Page 25

25 maintenance end of shift once you’ve completed your daily scrubbing, project work or finish maintenance, proper end of use maintenance can greatly extend the machine’s life, improve performance, enhance sanitization and lower the machine’s long-term operational costs. There are four key areas we ...

Page 26

26 maintenance end of shift squeegee assembly the squeegee system is crucial to high-performance cleaning. It is the last thing that touches the floor so proper maintenance is important for making it perform at its peak. To flip or replace squeegee blades, release over-center latch remove the blade ...

Page 27

27 maintenance end of shift battery maintenance based on research and experience, batteries are the number one nuisance issue and drive a high cost of ownership if not properly maintained. With the s-series mid-size scrubber, you can select from two types of batteries: wet, lead acid or sealed, main...

Page 28

28 maintenance end of shift batteryshield tm automatic wet battery protection system if your scrubber is equipped with batteryshield technology, your scrubber will provide you “real time” notification when your wet batteries need to be watered. After your machine is charged and you turn the key swit...

Page 29

29 maintenance end of shift pad driver and brush maintenance this portion of maintenance is simple and quick, but key to keeping your s-series mid-size scrubber performing at peak levels. Remove the pad drivers or brushes to check for wear. Depress position “a” for 1 second then depress position “b”...

Page 30

30 periodic maintenance changing batteries to change the batteries in your s-series mid-size scrubber, move the machine to an area with a level surface, turn off the power switch and remove the key. If using an off-board charger, make sure that it is located near your machine and that your location ...

Page 31

31 periodic maintenance checking the isolators on your s-28 orbital unit your s-28 orbital scrubber is equipped with an hour meter that is located on the upper control panel. After 300 hours, it is time to check the eight isolators located in the scrub head of the unit. Using a flashlight, do a visu...

Page 32

32 periodic maintenance inspecting the hepa filter your s-series mid-size scrubber is equipped with a hepa filter. You can locate the hepa filter by lifting the recovery water tank, opening it as far as it will go using the side handle. 1 recovery tank shown in fully open position 1 hepa filter vacu...

Page 33

33 transporting your unit your s-series mid-size scrubber was designed so that it could easily be transported on a route cleaning program. The machine has a tie down holes on each side of the main frame. It can also be strapped down to a trailer or truck bed using tie down straps inserted between th...

Page 34

34 troubleshooting operator top five troubleshooting list because cleaning equipment can encounter a wide array of environments and debris, various issues can arise that can be quickly fixed with some easy troubleshooting by the operator. Because there are so many scenarios, we’ve generated the top ...

Page 35

35 troubleshooting operator top five troubleshooting list 2. Machine run time has decreased if the machine run time has decreased, there are three potential issues that must be checked: the charger may not be plugged in or working, the wet, lead acid batteries may need watering or the batteries need...

Page 36

36 troubleshooting operator top five troubleshooting list 3. Machine won’t dispense water first, when this issue occurs, check the solution tank sight gage for water level. If empty, fill the tank with cleaning solution. Check the solution flow adjustment knob and ensure that the knob is adjusted to...

Page 37

37 troubleshooting operator top five troubleshooting list 4. Recovery tank not draining if your recovery tank is not draining, there is a clog somewhere in the draining system. The two main areas of potential clogging are at the tank drain or at the restriction collar on the drain hose. Check for cl...

Page 38

38 troubleshooting operator top five troubleshooting list 5. Squeegee isn’t picking up water in tight turns the squeegee is designed to swing fully from left to right to the point where the squeegee system almost touches the casters. Should it be stopping well short of this, then it is likely that t...

Page 39

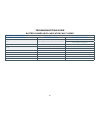

Troubleshooting guide issue potential cause proposed solution insufficient water to the brushes solution flow setting is too low make sure the solution control valve is open by adjusting the solution flow knob solution tank is empty check the sight gage for solution level. If low or empty, add water...

Page 40

Troubleshooting guide issue potential cause proposed solution machine isn’t cleaning satisfactorily pad or brush may be worn inspect & replace if necessary. Brushes should be replaced when the bristles reach a length of 3/4 in (19 mm) excessive foam is being produced in the recovery tank detergent u...

Page 41

Troubleshooting guide battery power level indicator fault codes transaxle drive units code (flashing led s ) potential cause proposed solution one low voltage shut-off. Brush motor shut down recharge batteries check battery connections two battery charge level getting low recharge batteries three tr...

Page 42

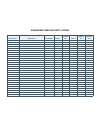

Sub-assembly description part number s-24 qty s-28 disk qty s-32 qty s-28 orbital qty options qty charger, on-board cord, 9 ft (3 m) 908128* 1 1 1 1 charger, on-board charger, on-board, 24vdc 852407 1 1 1 1 batteryshield ® sensor assy, batteryshield 878518 1 batteryshield ® relay, batteryshield 9116...

Page 43

Sub-assembly description part number s-24 qty s-28 disk qty s-32 qty s-28 orbital qty options qty head belt, v-groove 903046* 1 head bearing, .75-inch, sealed 902053 4 head guide, driver 853803* 1 1 1 head guide, pad 853804* 2 2 head guide, pad, plastic 873801* 2 head wheel, guide 859703 1 1 head mo...

Page 44

Sub-assembly description part number s-24 qty s-28 disk qty s-32 qty s-28 orbital qty options qty squeegee blade, rear, 35 in (889 mm) linatex 870701* 1 squeegee blade, rear, 35 in (889 mm) urethane 870707* --> 1 squeegee blade, front, 35 in (889 mm) linatex 870702* 1 squeegee blade, front, 35 in (8...

Page 45

45 frame assembly with urethane wheels.

Page 46

46 frame assembly with foam-filled wheels.

Page 47

47 solution tank assembly head switch location for all machines built prior to march 13, 2015 and before serial #102090

Page 48

48 on-board chemical injection assembly (optional).

Page 49

49 battery assembly.

Page 50

50 recovery tank assembly.

Page 51

51 squeegee assembly, s-24.

Page 52

Squeegee assembly, s-28 52.

Page 53

Squeegee assembly, s-32 53.

Page 54

54 squeegee linkage assembly.

Page 55

55 head lift assembly.

Page 56

56 head assembly (drawing 1 of 2), s-24.

Page 57

57 head assembly (drawing 2 of 2), s-24.

Page 58

58 head assembly, s-28 disk.

Page 59

59 head assembly, s-32.

Page 60

60 head assembly, lower, s-28 orbital.

Page 61

61 head assembly, upper, s-28 orbital.

Page 62

62 controls assembly, s-24.

Page 63

63 controls assembly, s-28 & s-32 disk.

Page 64

64 controls assembly, s-28 orbital.

Page 65

65 controls assembly, batteryshield tm & chemical injection system (optional).

Page 66

66 electronics assembly, s-24.

Page 67

67 electronics assembly, s-28 & s-32 disk.

Page 68

68 electronics assembly, s-28 orbital.

Page 69

69 electronics assembly, batteryshield tm.

Page 70

70 charger assembly, on-board.

Page 71

Wiring diagram, s-24.

Page 72

Wiring diagram, s-28 & s-32 disk.

Page 73

Wiring diagram, s-28 orbital.

Page 74

Wiring diagram, batteryshield (optional) 74.

Page 75

Wiring diagram, on-board chemical injection system (optional) 75.

Page 76

Warranty policy s-series mid-size auto scrubbers the pacific floorcare s-series mid-size auto scrubbers have been manufactured, tested and inspected in accordance with specific engineering requirements. These machines are warranted to be free from defects in workmanship and materials for periods as ...