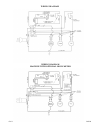

Pacific Steamex DYNAMO Repair Manual

REPAIR MANUAL

DYNAMO

&

TRIUMPH 440

03/01

The contents of this manual are based on the latest product

information available at the time of publication. Pacific

Steamex reserves the right to make changes or

improvements to its machines without notice.

FOR YOUR CONVENIENCE, RECORD THE

FOLLOWING INFORMATION:

MODEL_______________________________

SERIAL NUMBER______________________

PART NUMBER________________________

DATE PURCHASED_____________________

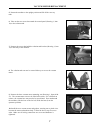

This Repair Manual is a supplement to the Operating &

Maintenance Instructions. Refer to the Operating &

Maintenance Instructions for the preparation, operation and

standard maintenance instructions. If you do not follow

the instructions, you can cause an injury or damage

equipment, furniture or buildings.

Maintenance and repairs must be done by authorized

personnel only. To prevent injury, always unplug the

machine before doing any repairs.

For new books write to:

Pacific Steamex, Inc.

2259 S. Sheridan

Muskegon, MI 49442-6252