- DL manuals

- Pacific

- Sander

- Wolverine PF7

- Owner's Manual & Operating Instructions

Pacific Wolverine PF7 Owner's Manual & Operating Instructions

Summary of Wolverine PF7

Page 1

Wolverine pf7 edger sander owners manual & operating instructions may 2010 ref. 69 part # 000510 from serial number 04453 (110 volt) pacific.

Page 2

North american safety instructions use and application warning: this floor sanding machine must be grounded. This floor-sanding machine shall be grounded while in use to protect the operator from electric shock. The machine is provided with a three-conductor cord and a moulded three-contact groundin...

Page 3

Contents warning mains cable wiring - plug spare parts specification safety set up preparation operation floor sanding technique floor types i i i 1 1 assembly and transport 2 installing abrasive disc 2 2 2,3 drum floor sander 4 edger sander 4 hand sanding 4 sanding plank & strip floors 4 parquet & ...

Page 4

Specification the pacific wolverine pf7 edger sander will sand hard and soft wood floors, cork and composition floors and any solid wood surface that requires rapid sanding and leveling to a fine finish. Ideal for confined areas such as closets and stair treads the will sand right up to the edge of ...

Page 5

Set up assembly and transport installing abrasive disc 1. Always carry the floor sander by the two handles with the bag frame in the up position and the power cable stowed around the bag frame. Protect the sanding disc with an abrasive disc and ensure that the clamp bolt is secure. Ensure that the f...

Page 6

Shoulder. Tilt the floor sander back so that the sanding disc does not touch the floor or work piece. 5. Switch on by pushing the on/off switch to (i) position and hold in place with your thumb. To switch off (o), release the pressure on the switch and it will automatically return to the off positio...

Page 7

Floor sanding technique pacific rhino pfs 8 drum sander pacific wolverine edger sander hand sanding - a powerful floor sander designed for the rapid leveling and sanding of all types of wood flooring excluding thin laminated or veneered floors. Load the sander with abrasive making sure that it is sk...

Page 8

Unsanded boards sanded boards level very uneven floors by sanding diagonally in both directions unsanded boards unsanded boards level uneven floors. Sand main floor area. Sand and blend edges in with main floor area . Floor sanding technique plank and strip floors parquet and wood block floor - sand...

Page 9

Floor sander abrasive guide 6 do not over-sand use only as heavy grade abrasive as it takes to do the job. Progress from first grade used through following grades to remove all visible sanding marks. Do not miss a grade. Abrasive grade floor type and condition grit p24 open coat (very coarse non-glo...

Page 10

Service & routine maintenance caution - maintenance and repairs must be carried out by authorized personnel only. To prevent injury, always remove the power cable from the power supply before undertaking any work on the machine. Do not operate this machine unless it is fully assembled and all guards...

Page 11

4. To replace the motor brushes ref.12. I. Remove the four screws ref.1 from the cover motor and lift the cover off. Ii. Remove the four spring brush ref.17 and set to one side. The springs are removed by pushing the spring tag in towards the brush and lifting out. Iii. Using a cross recess screwdri...

Page 12

9 floor sander abrasive (120 grit) face up to a solid flat board that is large enough to stand on and operate the edger. Place the board on a flat even floor and the edger on top of the board with the pad over the abrasive. Do not fit an abrasive disc. Caution - make sure that the clamp bolt (ref.59...

Page 13

Adjusting the castors the castors are set to achieve the correct contact area across the sanding pad as illustrated in the diagrams above. 1. To check the castor setting place a clean sheet of glass across the two castors and the sanding pad. Inserting a 0.005" feeler gauge (or a sheet of paper) bet...

Page 14

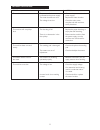

Trouble shooting fault cause action the machine does not run. The power cable is not connect the power cable to the connected to the power supply. Power supply. The motor brushes are worn. Replace the motor brushes. The voltage is too low. Check the main power complies with the machine's serial plat...

Page 15

12 wolverine pf7 parts diagram 42 5 37 40 9 8 6 30 56 57 52 69 250 1 4 2 10 11 65 16 12 17 7 13 14 65 15 22 23 24 25 18 19 20 21 26 27 28 29 31 32 33 34 35 25 36 60 62 100 59 58 55 41 54 53 20 45 51 48 50 47 46 27 49 48 39 44 61 43 p a cific service t ool wolverine pf7 edger sander owners manual & o...

Page 16

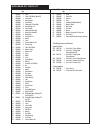

13 wolverine pf7 parts list 1 r010010 4 screw 2 r011610 1 switch 110/120 volt (bias off) 4 r010050 1 cover motor 5 r010070 1 housing motor 6 r010080 1 strain relief 7 r010100 1 cable main 110 volt (na) 8 r010140 2 handles pack of 2 9 r010150 4 screw handle 10 r010160 1 cable switch assembly 11 r0101...

Page 17

14 wolverine pf7 circuit diagram green black white.

Page 18

15 service & repair contact your reseller for the name of your local service agent. Service and repairs undertaken by non-approved service agents will void the product warranty. If you should have difficulty in obtaining service please contact pacific floor care at the following address. Pacific flo...