Padamo Denmark ER Installation And Operation Instructions Manual

BLUE FLAME

VENT FREE HEATERS

INSTALLATION AND

OPERATION INSTRUCTIONS

P/N 88950 / REV. MARCH 2013

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

-

Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

-

WHAT TO DO IF YOU SMELL GAS:

••••• Do not try to light any appliance.

••••• Do not touch any electrical switch; do not use any

phone in your building.

••••• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

••••• If you cannot reach your gas supplier, call the fire

department.

-

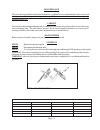

INSTALLATION AND SERVICE MUST BE

PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

R

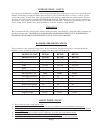

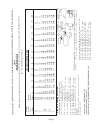

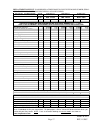

TYPE GAS

MODEL NUMBERS

NATURAL GAS

BFT101 BFT201 BFT301

PROPANE GAS

BFT102 BFT202 BFT302

This appliance may be installed in an aftermarket, permanently located, manufactured (mobile) home,

where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other gases.

Installation, maintenance, service, troubleshooting and repairs must be performed by a qualified service

agency. MR./MRS. HOMEOWNER, DO NOT attempt any of these procedures yourself as this could

expose you to property damage, personal injury or loss of life and will invalidate all warranties.

This unit is for residential use only and is not approved for installation in greenhouses,or

environments involving dusty, wet, corrosive, or explosive conditions. Such conditions will

invalidate the warranty and may create unsafe conditions.

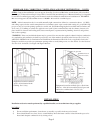

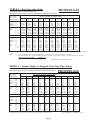

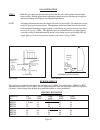

This is an unvented gas fired heater. It uses air (oxygen) from the room in which it is installed. Provisions

for adequate combustion and ventilation air must be provided. See Pg. 4 & 5.

INSTALLER: Leave this manual

with the appliance.

CONSUMER: Retain this

manual for future reference.

INSTALLER MUST SHOW

HOMEOWNER PROPER

LIGHTING AND OPERATION

OF HEATER. HAVE THEM

COMPLETE AND RETURN

THE WARRANTY CARD.