O op pe er ra at tiin ng g m ma an nu ua al l & & p pa ar rt ts s l liis st t 8 80 02 20 06 6 2 20 0″ ″ h he ea av vy y d du ut ty y f fl lo oo or r m mo od de el l d dr riil ll l p pr re es ss s read carefully and follow all safety rules and operating instructions before first use of this product. ...

D de es sc cr riip pt tiio on n palmgren drill presses feature a heavy cast iron base, column collar, work table and head. Work table height is adjustable using rack and pinion. Table can be tilted 45° both right and left, and rotates 360° on a vertical axis. Work table surface is precision ground w...

3 safety rules (continued) know how to use tool • use the right tool for the job. Do not force tool or attachment to do a job for which it was not designed. • disconnect tool when changing accessories such as bits, cut- ters and the like. • avoid accidental start-up. Make sure switch is in off posit...

4 installation (continued) grounding plug should be plugged directly into a properly installed and grounded 3-prong grounding-type receptacle, as shown (figure 1). Do not remove or alter grounding prong in any manner. In the event of a malfunction or breakdown, grounding provides a path of least res...

5 palmgren operating manual & parts list 80206 operation (continued) caution: the operation of any power tool can result in foreign objects being thrown into the eyes, which can result in severe eye damage. Always wear safety glasses complying with united states ansi z87.1 (shown on package) before ...

6 palmgren operating manual & parts list 80206 m ma aiin nt te en na an nc ce e warning: turn switch off and remove plug from power source outlet before maintaining or lubricating your drill press v-belt replace v-belt when worn. Lubrication refer to figures 5 and 6. The ball bearings are lubricated...

7 symptom spindle does not turn noisy spindle noisy operation bit burns or smokes excessive drill runout or wobble drill bit binds in workpiece possible causes 1. No power to drill press 2. Defective switch 3. Defective motor defective bearings 1. Incorrect bet tension 2. Dry spindle 3. Loose spindl...

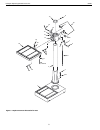

11 6 19 19 10 8 12 18 6 5 4 15 16 17 7 23 21 20 22 25 24 13 14 2 3 9 1 8 figure 5 - replacement parts illustration for base palmgren operating manual & parts list 80206.

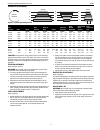

9 palmgren operating manual & parts list 80206 r re ep pl la ac ce em me en nt t p pa ar rt ts s l liis st t f fo or r b ba as se e ∆ not shown. * standard hardware item available locally. Ref. Part number for: no. Description 80206 qty. 1 base 18806.09 1 2 column assembly 18807.09 1 3 10-1.50 x 40m...

10 palmgren operating manual & parts list 80206 figure 6 - replacement parts illustration for head 35 62 66 67 68 81 65 23 53 74 14 73 13 13 29 59 36 20 30 80 79 4 51 52 61 71 72 39 7 50 6 9 8 28 43 48 13 5 3 3 3 2 1 22 33 34 75 60 26 11 37 46 46 44 54 49 38 42 42 69 12 27 32 25 21 31 41 56 47 19 19...

Ref. No. Description part no. Qty. 1 quill handle 17247.09 1 2 grip 17248.01 3 3 6-1.0 x 10mm socket head bolt * 6 4 spacer 17249.00 1 5 7 x 8 x 24mm key 18757.00 1 6 pinion 18813.00 1 7 10-1.5mm hex nut * 1 8 10-1.5 x 40mm dog point set screw 02576.00 1 9 jt3 chuck with key 15351.00 1 10 chuck key ...

W wa ar rr ra an nt ty y full two year warranty on palmgren drill press if within two full years from the date of purchase, this palmgren drill press fails due to a defect in material or workmanship, palmgren will repair it free of charge. To order parts for a non-warranty repair, please contact you...