- DL manuals

- Paloma

- Water Heater

- PH2-20R DVSN

- Engineering handbook

Paloma PH2-20R DVSN Engineering handbook

R

Tankless Gas Water Heaters

High Effi ciency Condensing Models

PHH-25ROFN & PHH-32ROFN (Outdoor Natural Gas Models)

PHH-25ROFP & PHH-32ROFP (Outdoor L.P. Gas Models)

PHH-25RDVN & PHH-32RDVN (Indoor Direct Vent Natural Gas Models)

PHH-25RDVP & PHH-32RDVP (Indoor Direct Vent L.P. Gas Models)

Engineering Handbook

DESIGN

CERTIFIED

®

CERTIFIED

R

Mid Effi ciency Models

PH2-20R OFN, PH2-25R OFN & PH2-28R OFN (Outdoor Natural Gas Models)

PH2-20R OFP, PH2-25R OFP & PH2-28R OFP (Outdoor L.P. Gas Models)

PH2-20R DVSN, PH2-25R DVSN & PH2-28R DVSN

(Indoor Direct Vent Natural Gas Models)

PH2-20R DVSP, PH2-25R DVSP & PH2-28R DVSP

(Indoor Direct Vent L.P. Gas Models)

Outdoor Water Heater

PH2-20, 25 & 28ROF

Indoor Direct Vent Water Heater

PH2-20, 25 & 28RDVS

Outdoor Water Heater

PHH-25ROF & PHH-32ROF

Indoor Direct Vent Water Heater

PHH-25RDV & PHH-32RDV

Summary of PH2-20R DVSN

Page 1

R tankless gas water heaters high effi ciency condensing models phh-25rofn & phh-32rofn (outdoor natural gas models) phh-25rofp & phh-32rofp (outdoor l.P. Gas models) phh-25rdvn & phh-32rdvn (indoor direct vent natural gas models) phh-25rdvp & phh-32rdvp (indoor direct vent l.P. Gas models) engineer...

Page 3

Svc 820-tankless gas trouble shooting manual page

Page 5

Svc 820-tankless gas trouble shooting manual page

Page 7

Svc 820-tankless gas trouble shooting manual page

Page 9: Error Code

Svc 820-tankless gas trouble shooting manual page

Page 11

Svc 820-tankless gas trouble shooting manual page

Page 13

Svc 820-tankless gas trouble shooting manual page

Page 15

Svc 820-tankless gas trouble shooting manual page

Page 17

Svc 820-tankless gas trouble shooting manual page

Page 19: Control Board

Svc 820-tankless gas trouble shooting manual page

Page 21

Svc 820-tankless gas trouble shooting manual page

Page 23: P1 - Warning Code

Svc 820-tankless gas trouble shooting manual page

Page 25: 03 - Error Code

Svc 820-tankless gas trouble shooting manual page

Page 27: Dip #2 Setting:

Svc 820-tankless gas trouble shooting manual page

Page 29: 10 – Warning Code

Svc 820-tankless gas trouble shooting manual page

Page 31: Blower Motor

Svc 820-tankless gas trouble shooting manual page

Page 33: 11 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 35

Svc 820-tankless gas trouble shooting manual page

Page 37

Svc 820-tankless gas trouble shooting manual page

Page 39

Svc 820-tankless gas trouble shooting manual page

Page 41

Svc 820-tankless gas trouble shooting manual page

Page 43: 12 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 45

Svc 820-tankless gas trouble shooting manual page

Page 47: 13 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 49

Svc 820-tankless gas trouble shooting manual page

Page 51

Svc 820-tankless gas trouble shooting manual page

Page 53: 15 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 55

Svc 820-tankless gas trouble shooting manual page

Page 57

Svc 820-tankless gas trouble shooting manual page

Page 59: 29 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 61

Svc 820-tankless gas trouble shooting manual page

Page 63

Svc 820-tankless gas trouble shooting manual page

Page 65

Svc 820-tankless gas trouble shooting manual page

Page 67

Svc 820-tankless gas trouble shooting manual page

Page 69

Svc 820-tankless gas trouble shooting manual page

Page 71

Svc 820-tankless gas trouble shooting manual page

Page 73

Svc 820-tankless gas trouble shooting manual page

Page 75

Svc 820-tankless gas trouble shooting manual page

Page 77

Svc 820-tankless gas trouble shooting manual page

Page 79

Svc 820-tankless gas trouble shooting manual page

Page 81

Svc 820-tankless gas trouble shooting manual page

Page 83

Svc 820-tankless gas trouble shooting manual page

Page 85

Svc 820-tankless gas trouble shooting manual page

Page 87

Svc 820-tankless gas trouble shooting manual page

Page 89

Svc 820-tankless gas trouble shooting manual page

Page 91: 90 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 93: 99 – Error Code

Svc 820-tankless gas trouble shooting manual page

Page 95: Notes:

Svc 820-tankless gas trouble shooting manual page

Page 96

R tankless gas water heaters high effi ciency condensing models phh-25rofn & phh-32rofn (outdoor natural gas models) phh-25rofp & phh-32rofp (outdoor l.P. Gas models) phh-25rdvn & phh-32rdvn (indoor direct vent natural gas models) phh-25rdvp & phh-32rdvp (indoor direct vent l.P. Gas models) mid effi...

Page 97

- do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. To do so may result in an explosion or fire. - what to do if you smell gas * do not try to light any appliance. * do not touch any electrical switch; do not use any phone in your buil...

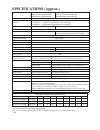

Page 98: Specifications (Approx.)

Specifications (approx.) model ph2-20r ofn, ph2-20r ofp, ph2-25r ofn, ph2-25r ofp ph2-28r ofn, ph2-28r ofp ph2-20r dvsn, ph2-20r dvsp ph2-25r dvsn, ph2-25r dvsp ph2-28r dvsn, ph2-28r dvsp purpose domestic hot water supply rated gas input (btu/hr.) 11,000 (min.) ~ 150,000 (max.) (ph2-20r series) modu...

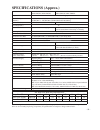

Page 99: Specifications (Approx.)

Specifications (approx.) model phh-25rofn, phh-25rofp phh-32rofn, phh-32rofp phh-25rdvn, phh-25rdvp phh-32rdvn, phh-32rdvp purpose domestic hot water supply rated gas input (btu/hr.) 11,000 (min.) ~ 157,000 (max.) (phh-25r series) modulating 11,000 (min.) ~ 199,900 (max.) (phh-32r series) modulating...

Page 100: External Dimensions

External dimensions (remote control) combustion indica t o r power on/off indica t o r power on/off butt on priority indica t or tempera ture adjustment butt on led displa y power on/off priority ° f 7/8” (21mm) 4 3/4” (120mm) 4 3/4” (120mm) 1 7/8” 46mm) 3 1/4” (83.5mm) 13 7/8” (350 mm) 12 15/16” (3...

Page 101: External Dimensions

External dimensions (remote control) combustion indica t o r power on/off indica t o r power on/off butt on priority indica t or tempera ture adjustment butt on led displa y power on/off priority ° f 7/8” (21mm) 4 3/4” (120mm) 4 3/4” (120mm) 1 7/8” 46mm) 3 1/4” (83.5mm) (phh-25rof & phh-32rof outdoo...

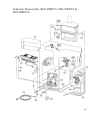

Page 102: Schematic Construction

- 102 - schematic construction (ph2-20rof, ph2-25rof & ph2-28rof outdoor models) no. Name of parts no. Name of parts no. Name of parts 1 gas connection 11 bypass pipe 21 film type ohl 2 gas control valve assy. 12 heat exchanger 22 pc board 3 lower burner assy. 13 heat transfer coil 23 fan assembly 4...

Page 103: Schematic Construction

- 103 - schematic construction no. Name of parts no. Name of parts no. Name of parts 1 gas connection 11 bypass pipe 21 film type ohl 2 gas control valve assy. 12 heat exchanger 22 heat exchanger thermistor 3 lower burner assy. 13 heat transfer coil 23 pc board 4 flame rod 14 fin 24 fan assembly 5 m...

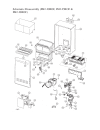

Page 104: Schematic Construction

- 104 - schematic construction (phh-25rof & phh-32rof outdoor models) no. Name of parts no. Name of parts no. Name of parts 1 front cover 11 gas control valve assy. 21 water control valve assy. 2 back cover 12 fan assembly 22 water supply pipe 3 heat exchanger 13 film type ohl 23 bypass pipe 4 fin 1...

Page 105: Schematic Construction

- 105 - schematic construction no. Name of parts no. Name of parts no. Name of parts 1 front cover 11 gas control valve assy. 21 water control valve assy. 2 back cover 12 fan assembly 22 water supply pipe 3 heat exchanger 13 film type ohl 23 bypass pipe 4 fin 14 igniter 24 turbulence coil 5 heat tra...

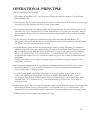

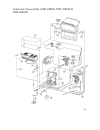

Page 106: Operational Principle

- 106 - operational principle no. Name of parts no. Name of parts no. Name of parts 1 hot water tap 11 solenoid valve 2 21 film type ohl 2 water flow servo 12 solenoid valve 3 22 fan 3 water flow sensor 13 solenoid valve 4 23 fan motor 4 water inlet thermistor 14 proportional gas control valve 24 dr...

Page 107: Operational Principle

- 107 - operational principle air intake exhaust outlet hot water outlet water inlet gas inlet (ph2-20rdvs, ph2-25rdvs & ph2-28rdvs direct vent models) no. Name of parts no. Name of parts no. Name of parts 1 hot water tap 11 solenoid valve 2 21 film type ohl 2 water flow servo 12 solenoid valve 3 22...

Page 108: Operational Principle

- 108 - operational principle when supplying hot water 1) by opening the hot water top (1), the water fl ows through the water flow sensor (3) to the heat heat exchanger (20). 2) the frequency signal is given from the water flow sensor (3) and when the pc board (7) senses the signal that reached a c...

Page 109: Operational Principle

- 109 - operational principle no. Name of parts no. Name of parts no. Name of parts 1 hot water tap 11 solenoid valve 2 21 film type ohl 2 water flow servo 12 solenoid valve 3 22 fan 3 water flow sensor 13 solenoid valve 4 23 fan motor 4 water inlet thermistor 14 proportional gas control valve 24 dr...

Page 110: Operational Principle

- 110 - operational principle (phh-25rdv & phh-32rdv direct vent models) no. Name of parts no. Name of parts no. Name of parts 1 hot water tap 11 solenoid valve 2 21 film type ohl 2 water flow servo 12 solenoid valve 3 22 fan 3 water flow sensor 13 solenoid valve 4 23 fan motor 4 water inlet thermis...

Page 111: Operational Principle

- 111 - operational principle when supplying hot water 1) by opening the hot water top (1), the water fl ows through the water flow sensor (3) to the primary heat exchanger (20). 2) the frequency signal is given from the water flow sensor (3) and when the pc board (7) senses the signal that reached ...

Page 112: Capacity

- 112 - capacity hot water capacity curve: ph2-20r residential use 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 85 100 120 130 140 inlet water temperature : 40°f (ph2-20r) water flow rate (gpm) outlet t e mperature (°f) 6.4 gpm when maximum temperature is set at 140°f when maximum temperature i...

Page 113: Capacity

- 113 - capacity hot water capacity curve: ph2-25r residential use 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 85 100 120 130 140 inlet water temperature : 40°f (ph2-25r) water flow rate (gpm) outlet t e mperature (°f) 8.4 gpm when maximum temperature is set at 140°f when maximum temperature i...

Page 114: Capacity

- 114 - capacity hot water capacity curve: ph2-25r commercial setting 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 100 110 120 130 140 inlet water temperature : 40°f (ph2-25r commercial setting) water flow rate (gpm) outlet t e mperature (°f) 150 160 170 180 185 85 8.4 gpm when maximum temperat...

Page 115: Capacity

- 115 - capacity hot water capacity curve: ph2-28r residential use 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 85 100 120 130 140 inlet water temperature : 40°f (ph2-28r) water flow rate (gpm) outlet t e mperature (°f) 9.5 gpm when maximum temperature is set at 140°f when maximum temperature i...

Page 116: Capacity

- 116 - capacity hot water capacity curve: ph2-28r commercial setting 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 100 110 120 130 140 inlet water temperature : 40°f (ph2-28r commercial setting) water flow rate (gpm) outlet t e mperature (°f) 150 160 170 180 185 85 9.5 gpm when maximum temperat...

Page 117: Capacity

- 117 - capacity hot water capacity curve: phh-25r residential use °f °f water pressure & water flow rate: w a ter flow rate (gpm) water pressure (psi) 3.3 3.8 4.3 4.8 5.3 5.8 6.1 inlet water temperature: 70 inlet water temperature: 40 (6.1) (3.8) 22 35 45 60 105 120 135 (at the outlet hot water tem...

Page 118: Capacity

- 118 - capacity hot water capacity curve: phh-25r commercial setting °f °f water pressure & water flow rate: w a ter flow rate (gpm) water pressure (psi) 3.3 3.8 4.3 4.8 5.3 5.8 6.1 inlet water temperature: 70 inlet water temperature: 40 (6.1) (3.8) 22 35 45 60 105 120 135 (at the outlet hot water ...

Page 119: Capacity

- 119 - capacity hot water capacity curve: phh-32r residential use °f °f water pressure & water flow rate: w a ter flow rate (gpm) water pressure (psi) 3.7 4.2 4.7 5.2 5.7 6.2 6.7 inlet water temperature: 70 inlet water temperature: 40 (6.7) (4.2) 29 40 50 60 105 120 135 (at the outlet hot water tem...

Page 120: Capacity

- 120 - capacity hot water capacity curve: phh-32r commercial setting °f °f water pressure & water flow rate: w a ter flow rate (gpm) water pressure (psi) 3.7 4.2 4.7 5.2 5.7 6.2 6.7 inlet water temperature: 70 inlet water temperature: 40 (6.7) (4.2) 29 40 50 60 105 120 135 (at the outlet hot water ...

Page 121

Wiring diagram for ph2-20r, ph2-25r & ph2-28r 31-93618 0 ver t/ja une g/y :green/y ell ow , ac 120v o:orange,orange co de de c ouleur co lo r c ode min but ton bout on min. G/y org w bout on m ax. Bl bl bl led gg ma x but to n adjuster but to n bl bout on de rÉgla ge bl 1 2 3 4 5 a for indoor,direc ...

Page 122

- 122 - wiring diagram for phh-25 & phh-32 flame rod 2 Électrode de dÉtection de flamme 2 31-98419 2 neutralizer w ater le vel electrode r r Électrode de nivea u d’ ea u de neutr alisant 2 1 p g rÉsist ance vert/ja une g/y : green/ yell ow , ac 120v o: orange , orange usu all y disc onnected normale...

Page 123

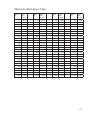

Thermistor resistance chart temp ºf resis- tance k ohm temp ºf resis- tance k ohm temp ºf resis- tance k ohm temp ºf resis- tance k ohm 32 23.73 77 8.494 122 3.485 167 1.598 33.8 22.706 78.8 8.177 123.8 3.371 168.8 1.552 35.6 21.733 80.6 7.873 125.6 3.262 170.6 1.508 37.4 20.806 82.4 7.583 127.4 3.1...

Page 124: Adjustment

- 124 - adjustment adjustment of burner control assembly (pc board) the content on this page is intended for use by qualifi ed service personnel only. Pcb replacement procedure warning: you will need to perform this procedure when you replace the pcb. Without this adjustment, the water heater may no...

Page 125

- 125 - adjustment of burner manifold settings on the new pcb. Note: always start from “minimum” when adjusting the burner manifold pressure setting. The display is on remote control. Always connect the remote control to monitor this procedure. 13. Reconnect power to water heater. 14. Adjustment of ...

Page 126

- 126 - adjusting of burner manifold setting on the new pcb if the old pcb was completely broken or you could not get the value number [01 - 39]. Note: during the adjustment procedure if [ee] is displayed on the led of remote control, adjust again with caution. This means there was an error in the a...

Page 127

- 127 - 13. Adjustment of maximum manifold setting a. Open the hot water tap fully and make the maximum fl ow. B. Press and hold down the adjusting button (sw3). C. While holding the adjusting button (sw3); momentarily push the maximum button (sw2) on the pcb. (note: it becomes to the maximum settin...

Page 128

[how to check test point gas pressure] when press the maximum button (sw2) or minimum button (sw1), the combustion is fi xed at maximum or minimum and then the led of remote control displays as follows. 1 __ l __ minimum combustion 1st step combustion 4 __ h __ maximum combustion 4th step combustion...

Page 129

- 129 - high altitude dip switch adjustment for high altitude installation above 3,280 feet (1,000 m): warning: improper adjustment, alternation, service or maintenance can cause property damage, personal injury, or death. When the water heater is installed above 3,280 feet (1,000m) or when the burn...

Page 130

- 130 - instruction for changing the setting to 85ºf (29ºc): warning: improper adjustment, alternation, service or maintenance can cause property damage, personal injury, or death. Minimum temperature adjustment by the remote control (umc-117) follow the instruction below if it is determined that a ...

Page 131

- 131 - instruction for changing the setting back to 120ºf (49ºc): warning: improper adjustment, alternation, service or maintenance can cause property damage, personal injury, or death. Adjustment to limit maximum water temperature setting to 120ºf (49ºc) by the main remote control (umc-117) follow...

Page 132: 185ºf (85ºc):

- 132 - instruction for changing the setting to 140ºf (60ºc) or 185ºf (85ºc): warning: improper adjustment, alternation, service or maintenance can cause property damage, personal injury, or death. Maximum temperature adjustment by the main remote control (umc-117) required adjustment for up to 140º...

Page 133

Tankless water heater duonex™ 2-unit system installation instructions it is very important that all persons who are expected to install, operate or adjust this duonex™ system and/or water heater read these instructions along with those instructions provided with the tankless water heater. Recognize ...

Page 134

Typical two unit manifold - figure 2 review the use and care manual provided with the water heater for complete information and installation instructions. Danger - water temperature setting safety and energy conservation are factors to be considered when selecting the water temperature setting of a ...

Page 135

1. Make sure power is disconnected and turn off gas and water to both water heaters, then remove the front cover from each water heater. 2. Feed one end of the duonex tm cable through a grommeted hole in the bottom of the fi rst heater. 3. Plug the cable into the connector marked “f” on the right of...

Page 136

140°f (60°c) maximum temperature adjustment the factory default temperature setting is 120°f (49°c). Follow these instructions to set the system to allow up to 140°f (60°c) operation. Note: only the umc-117 main remote control thermostat can be used for 140°f (60°c) operation. Do not execute the fol...

Page 137: Safety Precautions

1 mic-185 manifold controller operation and installation manual safety precautions ● read these instructions and the water heater instruction manual entirely before installing or operating the manifold controller and the water heater. ● use this manifold controller only for its intended purpose as d...

Page 138: D A N G E R

2 important safety information read all instructions before using. Safety and energy conservation are factors to be considered when selecting the water temperature setting of a water heater. Water temperatures above 125°f (52°c) can cause severe burns or death from scalding. Be sure to read and foll...

Page 139

3 manifold control system components (optional kit) mics-180 expansion card for use when more than 6 tankless heaters are used in a manifold. Includes expansion board connecting wire harness mounting hardware mic-185 board (included with control system) the mic-185 manifold control system contains t...

Page 140: Typical Manifold System

4 typical manifold system a manifold system consists of the manifold controller referenced by this instruction, and a bank or 3 to 20 tankless water heaters. The tankless heaters are installed in a parallel manifold system where each unit if independently fed with cold water from a common water main...

Page 141: Manifold System Operation

5 section 1.2 - adjusting the temperature to adjust the system temperature higher, stop any hot water fl ow, and press the up button until you reach the desired temperature setting. See figure 1.2.A. Note: the temperature can only be raised above 112ºf if the water fl ow has been stopped, this is a ...

Page 142

6 the manifold control system is designed with system redundancy in mind. If a failure were to occur within a tankless water heater, the system will shut that unit down, bypass it, and display an error notifi cation on the remote control display. When an error occurs the remote will fl ash the error...

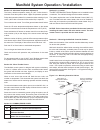

Page 143: Manifold System Installation

7 warning: field wiring connections and electrical grounding must comply with local codes, or in the absence of local codes, with the latest edition of the national electrical code, ansi/nfpa 70, or in canada, canadian electrical code, csa c22.1 part 1. Manifold system installation section 3.2 - ele...

Page 144: Manifold System Installation

8 manifold system installation figure 3.3.A - control cable installation at water heater number 4 dip switch in the “on” position control board layout for fi rst and second generation models control board layout for third generation models dip switch adjustment connector “f” wire clamp number 4 dip ...

Page 145: Manifold System Installation

9 manifold system installation figure 3.4.A - control cable installation at controller control cable connectors 7 - 13 wire clamp control cable connectors 14 - 20 control cable expansion card wiring harness main control board mounting screw support tab connect the other end of the wiring harness wit...

Page 146: Manifold System Installation

10 manifold system installation section 4 - system start up once the tankless water heaters have been setup and remote con- trol has been installed as instructed in section 3, you may begin the startup process. If the manifold control system has been previously powered up, turn off the power at the ...

Page 147: Mic-6 Manifold Controller

1 mic-6 manifold controller operation and installation manual safety precautions ● read these instructions and the water heater instruction manual entirely before installing or operating the manifold controller and the water heater. ● use this manifold controller only for its intended purpose as des...

Page 148: D A N G E R

2 important safety information read all instructions before using. Safety and energy conservation are factors to be considered when selecting the water temperature setting of a water heater. Water temperatures above 125°f (52°c) can cause severe burns or death from scalding. Be sure to read and foll...

Page 149

3 manifold control system components controller mounts inside tankless water heater cabinet, at the bottom right the mic-6 manifold control system contains the following: mic-6 controller card, (1) 1-feet mic-q-1 type q master control cable, (1) 10” ground wire, installation hardware, and this instr...

Page 150: Typical Manifold System

4 typical manifold system a manifold system consists of the manifold controller referenced by this instruction, and a bank or 3 to 6 tankless water heaters. The tankless heaters are installed in a parallel manifold system where each unit is independently fed with cold water from a common water main ...

Page 151: Manifold System Operation

5 section 1.2 - adjusting the temperature to adjust the system temperature higher, stop any hot water fl ow, and press the up button until you reach the desired temperature setting. See figure 1.2.A. Note: the temperature can only be raised above 112ºf if the water fl ow has been stopped, this is a ...

Page 152

6 the manifold control system is designed with system redundancy in mind. If a failure were to occur within a tankless water heater, the system will shut that unit down, bypass it, and display an error notifi cation on the remote control display. When an error occurs the remote will fl ash the heate...

Page 153: Manifold System Installation

7 section 3.2 - manifold control cable installation the manifold controller communicated with each tankless water heater in the system through a communication cable. Each end of the cable connects to the control board and tankless water heater control board using a molex connector. The cable can onl...

Page 154: Manifold System Installation

8 manifold system installation disconnect the power from all tankless water heaters. Leave the power disconnected until all the tankless water heaters in the sys- tem have been connected to the manifold controller system. Route the manifold controller end of the communication cable , the one with th...

Page 155: D A N G E R

Tankless water heater commercial conversion installation instructions refer to the use and care manual provided with your tankless water heater for the proper installation procedures. It is very important that all persons who are expected to install, operate or adjust this commercial conversion and/...

Page 156

Chip installation and initiation chip installation 1. Make sure electrical power is disconnected and turn off gas and water to the water heater, then remove the front cover from the water heater. 2. Carefully remove the existing program chip, see figure 1 for location. Lightly grip the edges of the ...

Page 157: Or Duonex™ Installation

10. Press the up arrow temperature adjustment button several times to increase the temperature to a maximum of 185*, see figure 4. This will verify the unit has been successfully converted. If the temperature does not increase past 120 or 140, then the conversion failed, disconnect and restore power...

Page 158

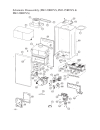

- 158 - schematic disassembly (ph2-20rdvs, ph2-25rdvs & ph2-28rdvs).

Page 159

- 159 - schematic disassembly (ph2-20rdvs, ph2-25rdvs & ph2-28rdvs).

Page 160

- 160 - schematic disassembly (ph2-20rdvs, ph2-25rdvs & ph2-28rdvs).

Page 161

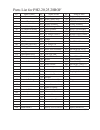

- 161 - parts list for ph2-20,25,28rdvs no. Name of parts no. Name of parts no. Name of parts 1 front cover assembly 402 quick fastener 751** program chip 410 water control assy. 10 upper block plate 411 drain valve a 756 120v cord assembly 412 bypass assembly 757 wiring assembly 26 f label packing ...

Page 162

- 162 - schematic disassembly (ph2-20rof, ph2-25rof & ph2-28rof).

Page 163

- 163 - schematic disassembly (ph2-20rof, ph2-25rof & ph2-28rof).

Page 164

- 164 - schematic disassembly (ph2-20rof, ph2-25rof & ph2-28rof).

Page 165

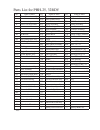

- 165 - parts list for ph2-20,25,28rof no. Name of parts no. Name of parts no. Name of parts 1 front cover assembly 402 quick fastener 751** program chip 410 water control assy. 755 power cord connector assy. 25 exhaust top assy. 411 drain valve a 756 120v cord assembly 412 bypass assembly 757 wirin...

Page 166

Schematic disassembly (phh-32rdv & phh-25rdv) - 166 -.

Page 167

Schematic disassembly (phh-32rdv & phh-25rdv) - 167 -.

Page 168

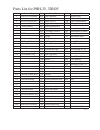

Parts list for phh-25, 32rdv no. Name of parts no. Name of parts no. Name of parts 1 front cover assembly 402 quick fastener 751** program chip 410 water control assy. 5 back cover support plate 411 drain valve a 756 120v cord assembly 6 front cover support plate 412 bypass assembly 757 wiring assem...

Page 169

- 169 - schematic disassembly (phh-32rof & phh-25rof).

Page 170

- 170 - matic disassembly (phh-32rof & phh-25rof).

Page 171

- 171 - parts list for phh-25, 32rof no. Name of parts no. Name of parts no. Name of parts 1 front cover assembly 402 quick fastener 751** program chip 410 water control assy. 5 back cover support plate 411 drain valve a 756 120v cord assembly 412 bypass assembly 757 wiring assembly 26 f label packi...

Page 172

Paloma industries, inc. 2151 eastman avenue oxnard, ca 93030 phone: (805) 278-5499 fax: (805) 278-5468 tech support center: (800) 432-8373 printed in usa 2011-08.