- DL manuals

- Panasonic

- Air Conditioner

- CS-A18BB4P

- Service Manual

Panasonic CS-A18BB4P Service Manual

1

SERVICE INFORMATION

3

2

FEATURES

4

3

SPECIFICATION (HEAT PUMP TYPE )

7

4

SPECIFICATION (COOLING ONLY TYPE )

9

5

TECHNICAL DRAWING

10

6

CIRCUIT DIAGRAM

12

7

OPERATING INSTRUCTION

24

8

REFRIGERATION CYCLE

26

9

OPERATION RANGE

27

© 2002 Matsushita Industrial Corporation Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-A18BB4P CU-A18BBP5

CS-A18BB4P CU-C18BBP5

10 PIPE LENGTH

28

11 OPERATING CHARACTERISTIC

30

12 FAN PERFORMANCE

31

13 SAFETY DEVICE

32

14 COMPONENT SPECIFICATION

33

15 CAPACITY AND POWER CONSUMPTION

34

16 DISCHARGE AND SUCTION PRESSURE

37

17 POSITION OF THE CENTER GRAVITY

38

AIR CONDITIONER

CONTENTS

Page

Page

ORDER NO. MAC0208026C8

Summary of CS-A18BB4P

Page 1

1 service information 3 2 features 4 3 specification (heat pump type ) 7 4 specification (cooling only type ) 9 5 technical drawing 10 6 circuit diagram 12 7 operating instruction 24 8 refrigeration cycle 26 9 operation range 27 © 2002 matsushita industrial corporation sdn. Bhd. (11969-t). All right...

Page 2

18 reaching distance 39 19 sound data 40 20 twin and triple 42 21 wiring mistake prevention 47 22 test operation and self diagnosis 48 23 setting of save energy and thermistor switch 52 24 group control 53 25 troubleshooting 54 26 emergency operation 59 27 control 60 28 wired remote control installa...

Page 3: 1 Service Information

1 service information caution: ● pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70°f (30 - 40°c) higher. Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°f (370 ± 10°c)...

Page 4: 2 Features

2.1. Variety of excellent features • • • • compact design compact design 240 mm height, 840 mm width and 840 mm depth. • • • • automatic restart function when the electric power resumes after a power failure, the unit will automatically restarts the operation in the pre- failure mode. • • • • auto f...

Page 5

− − − − maximum piping length of 25m for all models. 2.3. A brand-new control method using the latest in technology • • • • easier power supply wiring connection power supply wiring and other wiring tasks can be carried out more easily. − − − − twin non-polar wires used to connect indoor and outdoor...

Page 6

2.6. Group control equipment 6.

Page 7

3 specification (heat pump type ) 3.1. Cs-a18bb4p / cu-a18bbp5 item / model indoor unit outdoor unit main body cs-a18bb4p cu-a18bbp5 panel cz-bt01p remote cz-rd51p (wired) control cz-rl51p (wireless) cooling capacity kw 5.0 btu/h 17,100 heating capacity kw 5.6 btu/h 19,100 refrigerant charge-less m ...

Page 8

Electrical data (50hz) item / model cs-a18bb4p, cu-a18bbp5 condition by jis b 8615 volts v 220 230 240 phase single single single power consumption kw cool 1.90 1.90 1.90 heat 1.88 1.88 1.88 running current a cool 8.7 8.5 8.4 heat 8.6 8.4 8.3 starting current a 38 40 42 power factor % cool 99 97 94 ...

Page 9

4 specification (cooling only type ) 4.1. Cs-a18bb4p / cu-c18bbp5 item / model indoor unit outdoor unit main body cs-a18bb4p cu-c18bbp5 panel cz-bt01p remote cz-rd51p (wired) control cz-rl01p (wireless) cooling capacity kw 5.00 btu/h 17,100 refrigerant charge-less m 10 standard air volume for high, ...

Page 10: 5 Technical Drawing

5 technical drawing 10

Page 11

11.

Page 12: 6 Circuit Diagram

6 circuit diagram 12.

Page 13

13.

Page 14

14.

Page 15

15.

Page 16

16.

Page 17

17.

Page 18

18.

Page 19

19.

Page 20

20

Page 21

21.

Page 22

22.

Page 23

23.

Page 24: 7 Operating Instruction

7 operating instruction 7.1. Wired remote control (optional parts) notes: • • • • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • • • • the illustration above is for explanatory purposes only. The appearance will be diff...

Page 25

7.2. Wireless remote control (optional parts) notes: • • • • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • • • • the illustration above is for explanatory purpose only. The appearance will be different during actual op...

Page 26: 8 Refrigeration Cycle

8 refrigeration cycle cs-a18bb4p / cu-a18bbp5 cs-a18bb4p / cu-c18bbp5 26.

Page 27: 9 Operation Range

9 operation range power supply the applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the rated voltag...

Page 28: 10 Pipe Length

10 pipe length ■ ■ ■ ■ correction of cooling capacity and heating capacities correction of cooling and heating capacities according to the connecting pipe length. The data of cooling capacities (marked on the name plate) are based on 5 meters connecting pipe and horizontal installation. For other pi...

Page 29

Attention ■ ■ ■ ■ refrigerant additional charge 1. Piping installation by standard piping • • • • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of 10m. (refer to the following table) but when the piping length exceeds 10m, additi...

Page 30

11 operating characteristic model main power source compressor motor indoor unit fan motor outdoor unit fan motor voltage frequency s.C. R.C. (a) ipt (kw) r.C. Ipt r.C. Ipt (v) (hz) (a) cool/heat cool/heat (a) (kw) (a) (kw) cooling only model cs-a18bb4p 220 50 38 7.9 / - 1.74 0.30 0.06 0.50 0.10 cu-...

Page 31: 12 Fan Performance

12 fan performance cs-a18bb4p item / model indoor unit outdoor unit cs-a18bb4p cu-a18bbp5, cu-c18bbp5 mode hi me lo hi air volume m 3 /min 17 15 14 43 running current a 0.38 0.31 0.27 0.50 power consumption kw 0.08 0.07 0.06 0.11 fan speed r/min 425 385 335 660 31.

Page 32: 13 Safety Device

13 safety device indoor unit heat pump model indoor unit cs-a18bb4p cooling only model for fan motor protection, off °c 135 internal protector (49f) on °c 85 for control protection, fuse cut a 3.15 outdoor unit outdoor unit heat pump model 50hz cu-a18bbp5 cooling only model 50hz cu-c18bbp5 for refri...

Page 33: 14 Component Specification

14 component specification compressor model heat pump model 50hz cu-a18bbp5 cooling only model 50hz cu-c18bbp5 60hz compressor model 50hz 2k32c225cua 60hz compressor type (no. Of cylinders) rotary 1 revolution r/min 2,900 piston diplacement m 3 /h 7.27 motor type starting method direct on-line start...

Page 34

15 capacity and power consumption 15.1. Heating performance model heating capacities are based on conditions below. Cs-a18bb4p heating capacity 5.0 kw 1 phase, 50hz, 220v indoor temperature 20°c d.B. Outdoor temperature 7°c d.B. 6°c w.B. Standard air volume 14m 3 /min inlet air outdoor temperature (...

Page 35

15.2. Cooling performance model cooling capacities are based on conditions below. Cs-a18bb4p cooling capacity 5.0 kw 1 phase, 50hz, 220v indoor temperature 27°c d.B. 19°c w.B. Outdoor temperature 35°c d.B. Standard air volume 14m 3 /min entering temperature air entering condenser (°c d.B.) air 25 30...

Page 36

Entering temperature air entering condenser (°c d.B.) air 25 30 35 40 43 temperature ipt ipt ipt ipt ipt d.B. W.B. Kw kw kw kw kw 17 1.48 1.62 1.75 1.92 2.00 23 19 1.56 1.68 1.84 1.96 2.07 22 1.60 1.73 1.89 1.98 2.14 17 1.50 1.62 1.76 1.93 2.00 25 19 1.59 1.71 1.87 2.01 2.11 22 1.62 1.75 1.91 2.03 2...

Page 37

16 discharge and suction pressure 37.

Page 38

17 position of the center gravity model name outside dimensions net weight centre of gravity width (mm) depth (mm) height (mm) kg x (mm) y (mm) z (mm) cu-a18bbp5 800 300 685 56 560 160 360 cu-c18bbp5 800 300 685 52 560 160 360 38.

Page 39: 18 Reaching Distance

18 reaching distance 39.

Page 40: 19 Sound Data

19 sound data 40

Page 41

41.

Page 42: 20 Twin And Triple

20.1. Twin and triple operation • • • • simultaneous air conditioning of wide spaces and corners is possible. Indoor units with different horsepowers can even be used in combination. • • • • the master unit and slave units are set automatically when the power is turned on. At this time, the indoor u...

Page 43

20.1.2. Automatic address setting for twin and triple systems procedure: turn on the power supply for the indoor and outdoor units. Operation: automatic address setting will start 10 to 30 seconds after the power supply is turned on, and will be completed after about 1 minute. If the power supplies ...

Page 44

• • • • the indoor units will not run for approximately 1 minute while automatic twin/triple address resetting is being carried out. Note: • • • • do not turn off the power supply for at least 1 minute after automatic twin/triple address resetting has been carried out. 20.2. Piping connections • • •...

Page 45

20.3. Refrigerant charging • • • • for twin and triple-type systems the pipe length is the total of the branch pipe (l) and the junction pipes (la → lb → lc in order from the thickest diameter). At the point where the pipe length exceeds 30 m, determine the amount of refrigerant for the remaining li...

Page 46

20.4. Wiring 46.

Page 47

21 wiring mistake prevention improved quality of installation work through adoption of an “connection error prevention” circuit which prevents wiring mistakes connection errors with the control wires and the power supply wires will not only contribute to burning-out of the control circuit board, but...

Page 48

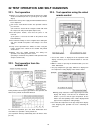

22.1. Test operation • • • • always use a properly-insulated tool to operate the switch on the circuit board. (do not use your finger or any metallic object). • • • • never turn on the power supply until all installation work has been completed. • • • • turn on the circuit breaker before test operat...

Page 49

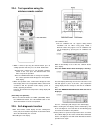

22.4. Test operation using the wireless remote control 1. Within 1 minute of pressing the off/on button, press to cooling operation and then press the test run button. • • • • if more than 1 minute passes, test operation cannot be started. In this case, press the off/on button once more to repeat th...

Page 50

How to display the past error message if the “check” display on the wired remote control is not flashing, press the check button continuously for 5 seconds or more to display the problem details for the last problem or the problem before that. You can then switch between the displays for the previou...

Page 51

51.

Page 52

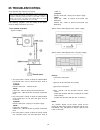

23.1. Energy save setting • • • • upper and lower limit can be set for the setting temperature during cooling and heating operation. (the factory shipment setting has an upper limit of 31°c and a lower limit of 16°c.) 1. While operation is stopped, press the temp up and temp down buttons simultaneou...

Page 53: 24 Group Control

Setting group for 1 remote control unit • • • • when using a remote control thermostat, the thermostat setting is used for all indoor units in the group. • • • • during group control, up to a maximum of 16 indoor units can be connected. (do not mix heat pump units and cooling-only units.) • • • • do...

Page 54: 25 Troubleshooting

If test operation does not proceed correctly carry out test operation after approximately 12 hours have passed since the power was turned on (crankcase heater is energized). If operation is started by using the remote control within 1 minute of turning on the power, the outdoor unit settings will no...

Page 55

1. The main power is turned on while the transmission wires between the indoor unit(s) are not connected (open circuit at section a) symptom: nothing abnormal appears on the remote control display. If operation is started in this condition, the combination of the 50bb outdoor unit and the 14bb4 indo...

Page 56

1. The main power is turned on while the transmission wires between the indoor unit and the outdoor unit are not connected (open circuit at section a) symptom: operation of indoor unit no. 1 and indoor unit no. 3 is possible. However, “check” flashes in the remote control display for 3-5 minutes aft...

Page 57

1. Automatic address setting (don’t need to set dip-switch) if the wiring is connected properly as above example, the address is set automatically by the main power supply. An indoor unit with remote control will be set as the master. If the power source is installed to indoor units and outdoor unit...

Page 58

Reset the address by following the procedure: a. Make sure that dip-switches no. 1 to 4 and no. 8 are off, stop the operation. B. Simultaneously, push buttons “air swing auto”, “operation” and “a/c no.”. The address will be reset and new address will be set. Important: the address for the twin/tripl...

Page 59: 26 Emergency Operation

Emergency operation • • • • emergency operation of outdoor unit emergency operation can be carried out by setting the dsw1 switch on the printed circuit board of the outdoor unit to the emergency position. However, emergency operation is only carried out when an abnormality is detected by the indoor...

Page 60: 27 Control

27 control description of basic functions 27.1. Cooling mode operation time chart (*1) outdoor unit fan start control during cooling at the start of cooling mode and drying mode operation, the outdoor unit heat exchanger outlet temperature is detected in order to set the fan speed. Operation is carr...

Page 61

27.2. Drain pump control 1. Basic operation during cooling mode, dry mode or defrost mode operation, the drain pump turns on when the compressor turns on. (the drain pump turns on during freezing prevention control.) • • • • when the compressor turns off, the drain pump will still continue its opera...

Page 62

(when float switch is continuously off) 27.3. Freezing prevention control 1. Operation during cooling mode operation, after 9 minutes have passed since the compressor turned on, the outdoor unit will stop its operation when the temperature detected by the indoor unit pipe temperature sensor is 2°c o...

Page 63

27.4. Heating mode operation time chart (heat pump type) (*2) outdoor unit fan control during heating mode operation when the compressor is on during heating mode operation (except during defrosting and when the liquid bypass valve is on), the outdoor unit fan is controlled by means of input (cn2) i...

Page 64

27.5. Hot starting 1. When heating mode operation starts a. Start hot start control commences when heating mode operation starts. B. Operation “preheat” appears on the remote control display. (other displays remain unchanged.) the indoor unit fan stops. In addition, during hot starting, the louvre s...

Page 65

2. When defrosting is completed a. Start hot start control commences when defrosting is completed. B. Operation “preheat” appears on the remote control display. (other displays remain unchanged) the indoor unit fan stops. In addition, during hot starting, the louvre stays at the horizontal position ...

Page 66

27.7. Excess heat dissipation for indoor unit the indoor unit fan continue its operation for 30 seconds after heating mode operation turns off in order to dissipate excess heat. 1. When heating mode operation has stopped (low speed for 30 seconds) 2. When operation is set to a mode other than heatin...

Page 67

If p8 on the outdoor unit circuit board is shorted while the compressor is on during heating mode operation and the temperature detected by the outdoor unit heat exchanger outlet sensor is 25°c or lower, defrosting is carried out regardless of the current starting conditions. 2. Operation a. During ...

Page 68

3. Thermostat characteristics during automatic changeover operation a. Settings at the start of automatic changeover operation when operation changes from other modes to automatic changeover mode, operation starts at the temperature characteristics given in the table below. B. Thermostat characteris...

Page 69

27.10. Indoor unit fan control 1. Fixing at lo, med or hi when lo, med or hi is set, the relay switches and operation is carried out at that setting. 2. Automatic fan speed when set to auto, the indoor unit fan operation changes as shown in the table below. (indoor temperature) - (setting temperatur...

Page 70

2. During initial operation when the off/on button is pressed to start the operation, the louvre moves through one full cycle, and then swings automatically (if auto has been set using the remote control) or moves to the setting angle (if manual has been set using the remote control). 3. When operat...

Page 71

28 wired remote control installation manual 71.

Page 72

72.

Page 73

73.

Page 74

74.

Page 75

75.

Page 76

29 wireless remote control installation manual 76.

Page 77

77.

Page 78

78.

Page 79

79.

Page 80

80

Page 81

81.

Page 82

82.

Page 83

30 installation (indoor unit) 83.

Page 84

84.

Page 85

85.

Page 86

86.

Page 87

87.

Page 88

88.

Page 89

89.

Page 90

90

Page 91

91.

Page 92

31 installation (outdoor unit) 92.

Page 93

93.

Page 94

94.

Page 95

95.

Page 96

96.

Page 97

97.

Page 98

98.

Page 99

99.

Page 100

100

Page 101

101.

Page 102: 32 Replacement Parts

32 replacement parts 32.1. Indoor unit 102.

Page 103

103.

Page 104

No. Part description qty. Cs-a18bb4p 1 base pan ass’y 1 cwd52k1034 2 inner polystyrene (top) 1 cwg071049 3 inner polystyrene (side) 1 cwg07c1016 4 cabinet side plate ass’y 1 cwe04k1001 5 cabinet side plate ass’y 1 cwe04k1002 6 fan motor 1 cwa921048 7 anti-vibration bushing 4 cwh501016 8 screw-fan mo...

Page 105

105.

Page 106

No. Part description part no. Qty. 1 front grille cwe121026 1 2 cover-air swing motor cwh811013 1 3 connector-shaft cwh081002 1 4 connector-shaft cwh081003 6 5 connector-shaft cwh081004 6 6 bearing cwh641006 8 7 vane cwe241103 4 8 connector-shaft cwh081005 2 9 connector-shaft cwh081006 2 10 air swin...

Page 107

32.2. Outdoor unit cu-a18bbp5 107.

Page 108

Cu-c18bbp5 108.

Page 109

Cu-a18bbp5 ref. No. Part name & description qty part no. 1 base pan ass’y 1 cwd50k2070b 2 compressor 1 2k32c225cua 3 anti-vibration bushing 4 cwh50055 4 nut for comp. Mount. 3 cwh4582065 5 condenser complete 1 cwb32c1240 6 tube ass’y (capillary tube) 1 cwt01c2585 7 pipe holder rubber 1 cwg251022 8 c...

Page 110

Cu-c18bbp5 ref. No. Part name & description qty part no. 1 base pan ass’y 1 cwd50k2076b 2 compressor 1 2k32c225cua 3 anti-vibration bushing 4 cwh50055 4 nut for comp. Mount. 3 cwh4582065 5 condenser complete 1 cwb32c1241 6 tube ass’y (capillary tube) 1 cwh35k029b 7 condenser side plate 1 cwe04111b 8...

Page 111

33 heating capacity performance data model power source inlet air outdoor temperature (°c w. B.) (cs-) external static pressure (pa) entering air -6 °c 0 °c 6 °c 12 °c air volume (m 3 /min) dry bulb (°c) h.C. Ipt h.C. Ipt h.C. Ipt h.C. Ipt a18bb4p 220v, 15 4.09 1.32 4.90 1.50 5.38 1.79 6.83 2.11 50h...

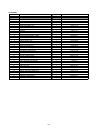

Page 112

34 cooling capacity performance data model power source entering temperature air entering condeser (°c d.B.) (cs-) air 25 °c 30 °c 35 °c 40 °c 43 °c temperature tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw kw kw kw kw kw a18bb4p 220v, 17 5.21 3.41 1....