- DL manuals

- Panasonic

- Air Conditioner

- CS-A18BD3P

- Service Manual

Panasonic CS-A18BD3P Service Manual

1

SERVICE INFORMATION

3

2

FEATURES

4

3

SPECIFICATION (HEAT PUMP TYPE)

7

4

SPECIFICATION (COOLING ONLY TYPE )

8

5

TECHNICAL DRAWING

9

6

CIRCUIT DIAGRAM

11

7

OPERATING INSTRUCTION

22

8

REFRIGERATION CYCLE

24

9

OPERATION RANGE

25

10 PIPE LENGTH

26

11 OPERATING CHARACTERISTIC

28

12 FAN PERFORMANCE

29

13 SAFETY DEVICE

30

© 2002 Matsushita Industrial Corporation Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-A18BD3P CU-A18BBP5

CS-A18BD3P CU-C18BBP5

14 COMPONENT SPECIFICATION

31

15 CAPACITY AND POWER CONSUMPTION

33

16 DISCHARGE AND SUCTION PRESSURE

36

17 POSITION OF THE CENTRE GRAVITY

37

18 SOUND DATA

38

19 TWIN AND TRIPLE

39

20 WIRING MISTAKE PREVENTION

45

21 TEST OPERATION AND SELF DIAGNOSIS

46

22 SETTING OF SAVE ENERGY AND THERMISTOR SWITCH

50

23 GROUP CONTROL

51

24 TROUBLE SHOOTING

52

25 EMERGENCY OPERATION

58

26 CONTROL

59

AIR CONDITIONER

CONTENTS

Page

Page

ORDER NO. MAC0208031C8

Summary of CS-A18BD3P

Page 1

1 service information 3 2 features 4 3 specification (heat pump type) 7 4 specification (cooling only type ) 8 5 technical drawing 9 6 circuit diagram 11 7 operating instruction 22 8 refrigeration cycle 24 9 operation range 25 10 pipe length 26 11 operating characteristic 28 12 fan performance 29 13...

Page 2

27 installation (indoor unit) 70 28 installation (outdoor unit) 87 29 replacement parts 97 2.

Page 3: 1 Service Information

1 service information caution: ● pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70°f (30 - 40°c) higher. Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°f (370 ± 10°c)...

Page 4: 2 Features

2.1. Variety of excellent features 2.1.1. Compact design, height 27 cm • • • • the height has been reduced to 27 cm (for 2.0hp to 6.0hp), the equipment can be installed in limited spaces. 2.1.2. Versatile installation • • • • the indoor unit is designed in order that air will also enter from below, ...

Page 5

2.2. Greatly improved workability increases system renewal capability 2.2.1. Pipes that are one size larger can also be connected for renewal • • • • if renewing the system, existing refrigerant pipes can be utilized so that only the indoor units need to be replaced. • • • • for example, liquid and ...

Page 6

2.3.5. Twin and triple operation • • • • simultaneous air conditioning of wide spaces and corners is possible. Indoor units of different horsepowers and models can even be used in combination. • • • • master unit and slave-units can be set automatically in twin and triple systems. No address setting...

Page 7

Electrical data (50hz) 3 specification (heat pump type) 3.1 cs-a18bd3p / cu-a18bbp5 item / model indoor unit outdoor unit main body cs-a18bd3p cu-a18bbp5 cooling capacity kw 5.00 (btu/h) (17,100) heating capacity kw 5.60 (btu/h) (19,100) refrigerant charge-less m 10 standard air volume for high medi...

Page 8

Electrical data (50hz) 4 specification (cooling only type ) 4.1 cs-a18bd3p / cu-c18bbp5 item / model indoor unit outdoor unit main body cs-a18bd3p cu-c18bbp5 cooling capacity kw 5.00 (btu/h) (17,100) refrigerant charge-less m 10 standard air volume for high m 3 /min hi 17 - medium and low speed cfm ...

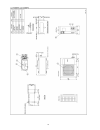

Page 9: 5 Technical Drawing

5 technical drawing cs-a18bd3p outside dimensions 9.

Page 10

10

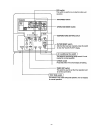

Page 11: 6 Circuit Diagram

6 circuit diagram 11.

Page 12

12.

Page 13

13.

Page 14

14.

Page 15

15.

Page 16

16.

Page 17

17.

Page 18

18.

Page 19

19.

Page 20

20

Page 21

21.

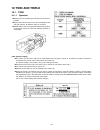

Page 22: 7 Operating Instruction

7 operating instruction 7.1. Wired remote control name and function of each part 22.

Page 23

23.

Page 24: 8 Refrigeration Cycle

8 refrigeration cycle 8.1. Heating model cs-a18bd3p / cu-a18bbp5 8.2. Cooling model cs-a18bd3p / cu-c18bbp5 24.

Page 25: 9 Operation Range

9 operation range power supply the applicable voltage range for each unit is given in “ the following table”. The working voltage among the three phases must be balanced within 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the rated volta...

Page 26: 10 Pipe Length

Correction of cooling and heating capacities according to the connecting pipe length. The data of cooling capacities (marked on the name plate) are based on 5 metres connecting pipe and horizontal installation. (cooling) equivalent length = actual pipe length + number of elbow x ele + number of oil ...

Page 27

10.3. Piping installation by existing piping it is possible to use the existing piping by adjusting the refrigerant gas volume. Please do correct piping installation referring to the table below. Standard piping specification heat pump type cooling only type liquid piping gas piping gas charge-less ...

Page 28

11 operating characteristic 11.1. Operating characteristic heat pump model model main power compressor motor indoor unit outdoor unit source fan motor fan motor voltage frequency s.C. R.C.(a) ipt(kw) r.C. Ipt r.C. Ipt (v) (hz) (a) cool/heat cool/heat (a) (kw) (a) (kw) cs-a18bd3p 220 50 38 7.9 / 7.9 ...

Page 29: 12 Fan Performance

12 fan performance ● ● ● ● cs-a18bd3p fan performance curve 29.

Page 30: 13 Safety Device

13 safety device ● ● ● ● indoor unit indoor unit model cs-a18bd3p for fan motor protection internal off °c 135 protector (49f) on °c 85 for control protection fuse cut a 3.15 ● ● ● ● outdoor unit outdoor unit heat pump model 50hz cu-a18bbp5 cooling only 50hz cu-c18bbp5 model for refrigerant cycle, o...

Page 31: 14 Component Specification

14 component specification compressor model heat pump model 50hz cu-a18bbp5 cooling only model 50hz cu-c18bbp5 compressor model 2k32c225cua compressor type no. Of cylinders rotary 1 revolution r/min 2,900 piston displacement m 3 /h 7.27 motor type kw starting method direct on-line starting rated out...

Page 32

Evaporator models (cooling only model) cs-a18bd3p tube material copper tube outer diameter mm 9.53 thickness mm 0.28 row 3 no. Of tubes/row 10 fin material aluminium thickness mm 0.11 fin pitch no./inch 14 fin surface louvre-fin total face area g 0.218 evaporator fan type sirocco fan no./unit 2 evap...

Page 33

● ● ● ● cooling capacity curve example cs-a28bd3p / cu-c28bbp8 • • • • calculation of the actual cooling capacity and power consumption for the following cooling conditions: indoor temperature of 18°c (wet-bulb temperature) and outdoor temperature of 40°c (dry-bulb temperature). Calculation method •...

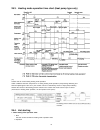

Page 34

15.2. Performance data cs-a18bd3p/cu-a18bbp5, cs-c18bd3p/cu-c18bbp5 model cooling performance ambient temperature air entering condenser (°c d.B.) return 25°c 30°c 35°c 40°c 45°c air tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw kw kw kw kw kw 17 6.84...

Page 35

● ● ● ● heating capacity curve on using capacity and electrical characteristics curves> • • • • heating capacity when the unit is frosted over or while being defrosted will vary depending on outdoor temperature (´cw8) and the amount c frost. Heating capacity performance must be compensated because i...

Page 36

16 discharge and suction pressure 16.1. Saturation temperature of discharge and suction pressure 36.

Page 37

17 position of the centre gravity model name outside dimensions net weight centre of gravity width (mm) depth (mm) height (mm) kg x (mm) y (mm) z (mm) cu-a18bbp5 800 300 685 56 560 160 360 cu-c18bbp5 800 300 685 52 560 160 360 37.

Page 38: 18 Sound Data

18 sound data 38.

Page 39: 19 Twin And Triple

19.1. Twin 19.1.1. Operation • • • • simultaneous air conditioning of wide spaces and corners is possible. • • • • master units and slave-units can be set automatically in twin and triple systems. No address setting is necessary. • • • • multiple indoor units can be operated simultaneously with a si...

Page 40

Automatic address setting for twin system procedure: turn on the power supply for the indoor and outdoor units. Operation: automatic address setting will start 10 to 30 seconds after the power supply is turned on, and will be completed after about 1 minute. If the power supplies for the indoor unit ...

Page 41

• • • • be sure to set dip switch 1-8 to on when setting twin/triple addresses. If dip switch 1-1 is set to on without setting 1- 8 to on also, group addresses will be set instead, and the remote control open circuit error code (f26) will be displayed. Automatic address resetting for twin systems fu...

Page 42

● ● ● ● installing branch pipes 42.

Page 43

19.3. Refrigerant charging • • • • for twin- and triple-type systems the pipe length is the total of the branch pipe (l) and the junction pipes (ia → t ib → t ic in order from the thickest diameter)). At the point where the pipe length exceeds 30 m, determine the amount of refrigerant for the remain...

Page 44

19.4. Wiring 44.

Page 45

20 wiring mistake prevention improved quality of installation work through adoption of an “connection error prevention” circuit which prevents wiring mistakes connection errors with the control wires and the power supply wires will not only contribute to burning-out of the control circuit board, but...

Page 46

21.1. Test operation • • • • always be sure to use a properly-insulated tool to operate the switch on the circuit board. (do not use your finger or a metallic object). • • • • never turn on the power supply until all installation work has been completed. • • • • turn on the circuit breaker before te...

Page 47

21.3. Test operation using the wired remote control 47.

Page 48

48.

Page 49

● ● ● ● self-diagnosis error code table 49.

Page 50

22 setting of save energy and thermistor switch 22.1. Energy save setting open the cover remote control unit and confirm the presence of the [ rp1] marking. Energy save setting method should be different for with [ rp1] marking and without [rp1] marking. 50

Page 51: 23 Group Control

23 group control 1 setting group for 1 remote control unit • • • • when using a remote control thermostat, the thermostat setting is used for all indoor units in the group. • • • • during group control, up to a maximum of 16 indoor units can be connected. (do not mix heat pump units and cooling only...

Page 52: 24 Trouble Shooting

If test operation does not proceed correctly carry out test operation after approximately 6 hours have passed since the power was turned on (crankcase heater is energized). If operation is started by using the remote control within 1 minute of turning on the power, the outdoor unit settings will not...

Page 53

1. The main power is turned on while the transmission wires between the indoor unit(s) are not connected (open circuit at section a) symptom: nothing abnormal appears on the remote control display. If operation is then started in this condition, the combination of the 160c outdoor unit and the 40u i...

Page 54

1. The main power is turned on while the transmission wires between the indoor unit and the outdoor unit are not connected (open circuit at section a) symptom: operation of indoor unit no. 1 and indoor unit no. 3 is possible. However, “check” flashes in the remote control unit display for 3-5 minute...

Page 55

1. Automatic address setting (no need to have dip-switch set) if the wiring connected properly as above example, the address is set automatically by the main power supply. An indoor unit with remote control will be set as the master. If the power source is installed to indoor units and outdoor separ...

Page 56

1. Automatic address setting (no need to have dip-switch set) if the wiring connected properly as above example, the ac numbers are set automatically by the main power supply. An indoor unit with remote control will be set as the master. If the power source is installed to indoor units and outdoor s...

Page 57

Procedures of deleting memory at twin/triple control system 1. Set the “off” position for main power supply switch. 2. Set the “on” position for no. 8 pin of dip switch (dsw1) on indoor unit p.C. Board. 3. Take main power supply switch “on” for one minute, and then main power supply switch off. 4. S...

Page 58: 25 Emergency Operation

Emergency operation • • • • emergency operation of outdoor unit emergency operation can be carried out by setting the dsw1 switch on the printed circuit board inside the outdoor unit to the emergency position. However, emergency operation is only carried out when an abnormality is detected by the in...

Page 59: 26 Control

26 control 26.1. Description of basic functions 26.1.1. Cooling mode operation time chart (*1) outdoor unit fan start control during cooling at the start of cooling mode and drying mode operation, the outdoor unit heat exchanger outlet temperature is detected in order to set the fan speed. Operation...

Page 60

• • • • the 10-minute countdown is cleared if the compressor stops or if the temperature at the outdoor unit outlet rises to 13.5°c or higher. 26.2. Freezing prevention control 1. Operation during cooling mode operation, after 9 minutes have passed since the compressor turned on, the outdoor units s...

Page 61

26.3. Heating mode operation time chart (heat pump type only) (*2) outdoor unit fan control during heating mode operation under conditions when the compressor is on during heating mode operation (except during defrosting and when the liquid bypass valve is on), the outdoor unit fan is controlled by ...

Page 62

“preheat” appears on the remote control display. (other displays remain unchanged.) at the indoor unit, the indoor unit fan stops. In addition, during hot starting, the louvre stays at the horizontal position (angle 0°). 3. Cancelling after 1 minute has passed since heating mode operation started, o...

Page 63

26.5. Indoor unit fan control when thermostat is off during heating mode operation when the thermostat of the indoor unit turns off during heating mode operation, the indoor unit fan operates for 2 minutes at low and then stops. In addition, 5 minutes after the thermostat of the indoor unit turns of...

Page 64

(the fan operates at low speed for the remainder of the 30 seconds in (1), and then hot start commences.) 26.7. Defrost mode operation time chart 1. Start and completion of defrosting a. Start during heating mode operation (including automatic heating), after the 45-minute defrosting cycle time has ...

Page 65

65.

Page 66

66.

Page 67

4.Thermostat characteristic during cooling mode and heating mode operation. The thermostat on/off characteristic in both operation modes are given in the table below. 67.

Page 68

26.9. Indoor unit fan control 1. Fixing at lo, med or hi when lo, med or hi is set, the relay switches and operation is carried out at that setting. 2. Automatic fan speed when set to auto, the indoor unit fan operation changes as shown in the table below. 26.10. Forced operation during restart the ...

Page 69

69.

Page 70

27 installation (indoor unit) 70

Page 71

71.

Page 72

72.

Page 73

73.

Page 74

74.

Page 75

75.

Page 76

76.

Page 77

77.

Page 78

78.

Page 79

79.

Page 80

80

Page 81

81.

Page 82

82.

Page 83

83.

Page 84

84.

Page 85

85.

Page 86

86.

Page 87

28 installation (outdoor unit) 87.

Page 88

88.

Page 89

89.

Page 90

90

Page 91

91.

Page 92

92.

Page 93

93.

Page 94

94.

Page 95

95.

Page 96

96.

Page 97: 29 Replacement Parts

29 replacement parts 29.1. Indoor unit cs-a18bd3p 97.

Page 98

Cs-a18bd3p ref. No. Parts name parts number quantity per 1 unit cs-a18bd3p 1 cabinet (bottom) p02-t06820 1 2 drain pan p42-t02900 1 3 evaporator p45-t05610 1 4 distributor ass’y. P45-t07xxx 1 5 cabinet (top) p42-t02930 1 6 filter guide ass’y. P42-t02920 1 7 filter p03-t01390 1 8 duct flange ass’y. (...

Page 99

29.2. Outdoor unit cu-c18bbp5 99.

Page 100

Cu-a18bbp5 100

Page 101

Cu-c18bbp5 ref. No. Part name & description qty part no. 1 base pan ass’y 1 cwd50k2076b 2 compressor 1 2k32c225cua 3 anti-vibration bushing 4 cwh50055 4 nut for comp. Mount. 3 cwh4582065 5 condenser complete 1 cwb32c1241 6 tube ass’y (capillary tube) 1 cwh35k029b 7 condenser side plate 1 cwe04111b 8...

Page 102

Cu-a18bbp5 ref. No. Part name & description qty part no. 1 base pan ass’y 1 cwd50k2070b 2 compressor 1 2k32c225cua 3 anti-vibration bushing 4 cwh50055 4 nut for comp. Mount. 3 cwh4582065 5 condenser complete 1 cwb32c1240 6 tube ass’y (capillary tube) 1 cwt01c2585 7 pipe holder rubber 1 cwg251022 8 c...