- DL manuals

- Panasonic

- Air Conditioner

- CS-C12ATP5

- Service Manual

Panasonic CS-C12ATP5 Service Manual

1

Functions

2

2

Product Specifications

5

3

Dimensions

15

4

Refrigeration Cycle Diagram

17

5

Block Diagram

18

6

Wiring Diagram

19

7

Operation Details

21

8

Operating Instructions

23

9

Installation Instructions

27

© 2001 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-C12ATP5 CU-C12ATP5

CS-C18ATP5 CU-C18ATPT5

CS-C24ATP5 CU-C24ATPT5

CS-C18ATP6 CU-C18ATPT6

CS-C24ATP6 CU-C24ATPT6

10 Servicing Information

38

11 Troubleshooting Guide

39

12 Technical Data

41

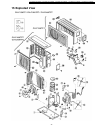

13 Exploded View

45

14 Replacement Parts List

46

15 Exploded View

47

16 Replacement Parts List

48

17 Electronic Parts List

49

18 Electronic Circuit Diagram

50

Room Air Conditioner

CONTENTS

Page

Page

Order No. MAC0112082C0

Summary of CS-C12ATP5

Page 1

1 functions 2 2 product specifications 5 3 dimensions 15 4 refrigeration cycle diagram 17 5 block diagram 18 6 wiring diagram 19 7 operation details 21 8 operating instructions 23 9 installation instructions 27 © 2001 matsushita air-conditioning corp. Sdn. Bhd. (183914d). All rights reserved. Unauth...

Page 2: 1 Functions

1 functions remote control transmitter remote control operation start/stop operation mode selection indoor fan speed selection room temperature setting / time setting sleep mode auto-control ● starts/stops when the button is pressed timer operation selection ● 12 hours on/off dual timer setting time...

Page 3

Indoor unit sensing the room temperature ● room temperature sensor (thermistor) starting current control ● indoor fan is delayed for 1.6 seconds at the starting time delay safety control ● restarting is inhibited for apporox. 3 minutes circuit protection control ● 30 seconds forced operation of the ...

Page 4

Outdoor unit overload protector 4 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 5: 2 Product Specifications

2 product specifications unit cs-c12atp5 cu-c12atp5 cooling capacity kw btu/h kcal/h 3.45; 3.45; 3.50 11,700; 11,700; 11,900 2,970; 2,970; 3,050 moisture removal l/h pint/h 2.0 4.2 power source phase v cycle single 220; 230; 240 50 airflow method outlet intake side view top view air volume indoor ai...

Page 6

Unit cs-c12atp5 cu-c12atp5 air circulation type sirocco propeller fan material stylac 181 aes + glass fiber 12% motor type induction (4-poles) induction (6-poles) input w 45.6 58.6 rated output w 20 20 fan speed low rpm 980 — medium rpm 1,055 — high rpm 1,100 730 heat exchanger description evaporato...

Page 7

Unit cs-c18atp5 cu-c18atpt5 cooling capacity kw btu/h kcal/h 5.15; 5.20; 5.30 17,500; 17,700; 18,000 4,430; 4,470; 4,560 moisture removal l/h pint/h 2.9 6.1 power source phase v cycle single 220; 230; 240 50 airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 10...

Page 8

Unit cs-c18atp5 cu-c18atpt5 air circulation type sirocco propeller fan material stylac 181 ce10g15 jsr motor type induction (4-poles) induction (4-poles) input w 66.00 136.8 (high) rated output w 40 65 fan speed low rpm 1,160 610 medium rpm 1,250 — high rpm 1,340 960 heat exchanger description evapo...

Page 9

Unit cs-c18atp6 cu-c18atpt6 cooling capacity kw btu/h kcal/h 5.30 18,100 4,560 moisture removal l/h pint/h 2.9 6.1 power source phase v cycle single 220 60 airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 10.4 (354) — indoor air (me) m 3 /min (cfm) 10.7 (379)...

Page 10

Unit cs-c18atp6 cu-c18atpt6 air circulation type sirocco propeller fan material stylac 181 ce10g15 jsr motor type induction (4-poles) induction (4-poles) input w 61.27 93.60 (high) rated output w 70 95 fan speed low rpm 1,050 575 medium rpm 1,125 — high rpm 1,215 765 heat exchanger description evapo...

Page 11

Unit cs-c24atp5 cu-c24atpt5 cooling capacity kw btu/h kcal/h 6.30; 6.30; 6.35 21,500; 21,500; 21,600 5,420; 5,420; 5,440 moisture removal l/h pint/h 3.6 7.6 power source phase v cycle single 220; 230; 240 50 airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 10...

Page 12

Unit cs-c24atp5 cu-c24atpt5 air circulation type sirocco propeller fan material stylac 181 ce10g15 jsr motor type induction (4-poles) induction (4-poles) input w 66.00 141.7 (high) rated output w 40 80 fan speed low rpm 1,160 685 medium rpm 1,250 — high rpm 1,340 1,053 heat exchanger description eva...

Page 13

Unit cs-c24atp6 cu-c24atpt6 cooling capacity kw btu/h kcal/h 6.45 22,200 5,550 moisture removal l/h pint/h 4.0 8.4 power source phase v cycle single 220 60 airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 10.5 (370) — indoor air (me) m 3 /min (cfm) 11.2 (395)...

Page 14

Unit cs-c24atp6 cu-c24atpt6 air circulation type sirocco propeller fan material stylac 181 ce10g15 jsr motor type induction (4-poles) induction (4-poles) input w 61.27 108.3 (high) rated output w 70 118 fan speed low rpm 1,050 660 medium rpm 1,125 — high rpm 1,215 895 heat exchanger description evap...

Page 15: 3 Dimensions

3 dimensions 15 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 16

16 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 17

4 refrigeration cycle diagram 17 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 18: 5 Block Diagram

5 block diagram 18 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 19: 6 Wiring Diagram

6 wiring diagram 19 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 20

20 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 21: 7 Operation Details

Time delay safety control automatic restarting control compressor forced operation control 7 operation details 7.1. Cooling mode operation when selecting the cooling (cool) mode operation, the unit will operate according to the setting by the remote control and the operation is as the following. 3 m...

Page 22

Time delay safety control automatic restarting control compressor forced operation control 7.3. Cooling mode with sleep mode auto operation when selecting the cooling (cool) combined with the sleep mode auto operation (sleep), the operation shows as the following. --- intermittent indoor fan operati...

Page 23: 8 Operating Instructions

8 operating instructions ■ installation precautions ! Warning ● this room air conditioner must be earthed. Improper grounding could cause electric shock. ● ensure that the drainage piping is connected properly. Otherwise, water will leak out. ● do not install the unit in a potentially explosive atmo...

Page 24

Name of each part ■ remote control ● remote control signal. • make sure it is not obstructed. • maximum distance : 10 m. • signal received sound. One short beep or one long beep. ● notes for remote control. • do not throw or drop. • do not get it wet. • certain type of fluorescent lamps may affect s...

Page 25

● operation details cool – cooling operation • to set the room temperature at your preference cooling comfort. Auto – automatic operation • sense indoor temperature to select the optimum mode. • temperature is not displayed on the remote control during auto operation. Dry – soft dry operation • a ve...

Page 26

■ pre-season inspection ● clean the air filters, re-insert and operate the air conditioners. ● is the discharged air cold / warm? Operation is normal if 15 minutes after the start of operation, the difference between the air intake and outlet vents temperature is:- ● are the air intake or outlet ven...

Page 27

9 installation instructions required tools for installation works 1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 55 n.M (5.5 kgf.M) 65 n.M (6.5 kgf.M) 3. Electric drill, hole core drill (ø70...

Page 28

1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in ins...

Page 29

Installation parts provided 1. Suspension bolts (m10 × 600...4 pcs.) 2. Nut, washer (m10...16 pcs.) 3. Spring washer (m10...8 pcs) 4. Bolt with washer (m8...4 pcs) 5. Remote control holder fixing screw (m3 × 12...2 pcs.) 6. Adjusting bolts (...2 pcs.) 7. Bolt/nut-wall installation (m12 × 25...Each 2...

Page 30

Installation on the ceiling • measure and mark the position for the suspension bolts and the piping hole. • drill the hole for anchor nut on the ceiling. • drill the piping hole slightly tilted to the outdoor side with a Ø 70 hole-core drill. • insert the nuts and washers onto the suspension bolts f...

Page 31

Installation on the floor • measure and mark the position for the floor brackets and the piping hole. • drill the hole for the anchor nut. • drill the piping hole with a Ø 70 hole-core drill (either the left or the right). • secure the floor mount brackets on the wall with two m4 screw. 9.2.3. To dr...

Page 32

(ii) secure the indoor unit onto the installation bracket with four m8 bolts with washer. • engage the lower flange of the hanging bracket on the unit with the hooks. • secure the unit to the installation bracket with four m8 bolts. • (refer to the diagram below) 2b. For installation on the floor. (...

Page 33

2. For the left side piping. Attach the edge protector onto the edge of the knock- out hole. • align the center of the pipings and sufficiently tighten the flare nut with fingers. • finally tighten the flare nut with torque wrench until the wrench clicks. When tightening the flare nut with torque wr...

Page 34

At the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut. (ø10 mm). 2. When installing at roof, please consider strong wind. Please fasten the installation stand firmly with bolt or ...

Page 35

1. Remove the service port caps from both 3-way valves. 2. Connect the manifold gauge set to the service port of liquid side 3-way valve. 3. Connect the charging cylinder to the manifold gauge set and open the valve of the cylinder. 4. Open the low pressure side valve of the manifold gauge for appro...

Page 36

9.3.6. Connect the cable to the outdoor unit 1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 (c12at) × 1.5 mm 2 or 5 (a12at) × 1.5 mm 2 or 3 (c18at/c24at) × 2.5 mm 2 or 5 (a1...

Page 37

In case of the outdoor unit is installed upper position of the indoor unit. 1. Tape the pipings, and connecting cable from down to up. 2. From the pipings gathered by taping along the exterior wall and the trap is required to prevent water from entering the room. 3. Fix the pipings onto the wall by ...

Page 38: 10 Servicing Information

Pump-down terminal • the thermostat will be switched on (even if the room temperature is low) when the pump-down terminal is short-circuited (by using) alligator-type clips or a similar method), thus permitting easy pump-down when the unit is to be moved to another place. For charging the wireless r...

Page 39: 11 Troubleshooting Guide

11.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air te...

Page 40

11.1.1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode condition of the air conditoner low pressure high pressure electric current during operation insufficient refrigerant (gas leakage) clogged capillary tube or strainer short circuit in the...

Page 41: 12 Technical Data

12 technical data 41 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 42

240v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 3.47 2.63 1.19 3.24 2.52 1.28 3.02 2.43 1.37 2.74 2.30 1.48 19.0°c 3.50 1.30 19.5°c 3.81 2.76 1.21 3.56 2.65 1.31 3.31 2.55 1.40 3.01 2.43 1.51 22.0°c 4.15 2.86 1.24 3.88 2.75 1.33 3.61 2.65 1.42...

Page 43

240v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 5.26 3.99 2.01 4.91 3.82 2.16 4.57 3.67 2.31 4.16 3.49 2.49 19.0°c 5.30 2.19 19.5°c 5.77 4.17 2.04 5.40 4.01 2.20 5.02 3.86 2.35 4.56 3.67 2.54 22.0°c 6.29 4.33 2.08 5.88 4.16 2.24 5.47 4.01 2.39...

Page 44

220v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 5.26 3.99 1.90 4.91 3.82 2.04 4.57 3.67 2.18 4.16 3.49 2.35 19.0°c 5.30 2.07 19.5°c 5.77 4.17 1.93 5.40 4.01 2.08 5.02 3.86 2.22 4.56 3.67 2.40 22.0°c 6.29 4.33 1.97 5.88 4.16 2.12 5.47 4.01 2.26...

Page 45: 13 Exploded View

13 exploded view 45 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 46: 14 Replacement Parts List

14 replacement parts list ref no. Description & name qty. Cs-c24atp5 cs-c18atp5 cs-c18atp6 cs-c12atp5 cs-c24atp6 1 chassy complete 1 cwd52k195b ← ← ← ← 2 particular plate for base 1 cwd90811 ← ← ← ← 3 particular piece 2 cwd93592 ← ← ← ← 4 particular plate 1 cwd90821 ← ← ← ← 5 bracket fan motor 1 cwd...

Page 47: 15 Exploded View

15 exploded view 47 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 48: 16 Replacement Parts List

16 replacement parts list ref no. Description & name qty. Cu-c24atpt5 cu-c18atpt5 cu-c18atpt6 cu-c12atp5 cu-c24atpt6 1 chassy assy 1 cwd50k514b ← cwd50k515b cwd50k548a cwd50k514b 2 sound proof board 1 cwh15223 ← ← - cwh15223 3 fan motor bracket 1 cwd54145 ← ← cwd54155 cwd54145 4 supporter - fm brack...

Page 49: 17 Electronic Parts List

17 electronic parts list cwa73802 symbol description & name part no. Bz buzzer a48039 d1 diode a3154ra15-01kb db1 diode bridge a54cs1vb20e fuse fuse xba2c20tr0 ic1 integrated circuit a52mn15481y ic2 integrated circuit a52c056 ic3 integrated circuit a52mpa2003c ic4 integrated circuit a52sn74h4060 ic5...

Page 50

18 electronic circuit diagram schematic diagram 1/3 • cs-c12atp / cu-c12atp ry-c p l (ja) (c-fm) 3 1 3 5 cn-c cn-fm vh3-2(g) (olp) vh5-3(g) h m l 1 2 fan motor ssr 1 cr1 znr1 10dk erztceak471 znr2 erztceak471 ry-h ry-m 2n201lf fuse 2a w (w) t (bl) t (bl) vh2 tf cn-t cr2 + c16 25v 3300 µ – i o g 15 1...

Page 51

Schematic diagram 2/3 10k 2.2k ic3 µ pa2003c relay drive i o g 5 15 5v ic2 µ pa78m05 c1 25v 10 µ (su) c2 10v 22 µ (su) c17 0.01 µ 4 13 3 14 2 15 1 16 test nh2(w) q6 un4211 r20 5.6k r19 1m x2 512khz c5 100p (npo) c6 100p (npo) r21 300 Ω r22 300 Ω r24 300 Ω r23 300 Ω 5 7 8 9 10 11 12 13 14 15 16 17 18...

Page 52

Schematic diagram 3/3 c7 6.3v 47 µ k + – cn-rcv xh4 brown brown forced operation switch sm4 r4 5.1k r3 10 Ω c6 0.033 µ (ecqb) c5 4300p (ecqp) c4 16v 10 µ k l2 l1 r2 10k r1 1k pd1 pn3138 intake air temp sensor (20k Ω 3950) heat exchanger temp sensor (15k Ω 3950) fig. 1 1 1 2 3 3 9 7 4 2 5 6 8 4 stepp...

Page 53

Schematic diagram 1/3 • cs-c18atp / cu-c18atpt • cs-c24atp / cu-c24atpt ry-c p l (ja) (c-fm) 3 1 3 5 cn-c cn-fm vh3-2(g) (olp) vh5-3(g) h m l 1 2 fan motor ssr 1 cr1 znr1 10dk erztceak471 znr2 erztceak471 ry-h ry-m 2n201lf fuse 2a w (w) t (bl) t (bl) vh2 tf cn-t cr2 + c16 25v 3300 µ – i o g 15 12 12...

Page 54

Schematic diagram 2/3 10k 2.2k ic3 µ pa2003c relay drive i o g 5 15 5v ic2 µ pa78m05 c1 25v 10 µ (su) c2 10v 22 µ (su) c17 0.01 µ 4 13 3 14 2 15 1 16 test nh2(w) q6 un4211 r20 5.6k r19 1m x2 512khz c5 100p (npo) c6 100p (npo) r21 300 Ω r22 300 Ω r24 300 Ω r23 300 Ω 5 7 8 9 10 11 12 13 14 15 16 17 18...

Page 55

Schematic diagram 3/3 c7 6.3v 47 µ k + – cn-rcv xh4 brown brown forced operation switch sm4 r4 5.1k r3 10 Ω c6 0.033 µ (ecqb) c5 4300p (ecqp) c4 16v 10 µ k l2 l1 r2 10k r1 1k pd1 pn3138 intake air temp sensor (20k Ω 3950) heat exchanger temp sensor (15k Ω 3950) fig. 1 1 1 2 3 3 9 7 4 2 5 6 8 4 stepp...

Page 56

How to use electronic circuit diagram timer table test mode name time (when test point short-circuited) remarks time delay safety control 2 min. 58 sec. 0 sec. Circuit protection control 30 sec. 0 sec. Starting current control 1.6 sec. 0 sec. Automatic restarting control 7 min. 7 min. Sleep mode 5 m...

Page 57

18.1. Remote control 57 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 58

18.2. Print pattern indoor unit printed circuit board 58 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6.

Page 59

59 cs-c12atp5 cu-c12atp5 / cs-c18atp5 cu-c18atpt5 / cs-c24atp5 cu-c24atpt5 / cs-c18atp6 cu-c18atpt6 / cs-c24atp6 cu-c24atpt6 [macc] printed in malaysia.