- DL manuals

- Panasonic

- Air Conditioner

- CS-C18CKV

- Service Manual

Panasonic CS-C18CKV Service Manual

1

Features

2

2

Functions

3

3

Product Specifications

6

4

Dimensions

10

5

Refrigeration Cycle Diagram

12

6

Block Diagram

13

7

Wiring Diagram

15

8

Operation Details

17

8.1.

Indoor Fan Speed Control

17

8.2.

Cooling Mode Operation

18

8.3.

Soft Dry Mode Operation

22

8.4.

Air Circulation Mode Operation

24

8.5.

Automatic Mode Operation

24

8.6.

Powerful Mode Operation

25

8.7.

Random Auto Restart Control

25

© 2003 Matsushita Industrial Corp. Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-C18CKV CU-C18CKV

CS-C24CKV CU-C24CKV

8.8.

Airflow Direction Control

26

8.9.

Delay ON Timer Control

27

8.10. Remote Control Signal Receiving Sound

27

8.11. Ionizer Operation

28

9

Operating Instructions

32

10 Installation Instructions

40

10.1. Safety Precautions

40

10.2. INDOOR UNIT

43

10.3. OUTDOOR UNIT

46

11 3-way Valve

50

11.1. Air Purging of the Piping and Indoor Unit

51

12 Servicing Information

57

12.1. Indoor Electronic Controllers Removal Procedures

57

12.2. Cross Flow Fan and Indoor Fan Motor Removal

Procedures

58

Air Conditioner

CONTENTS

Page

Page

Order No. MAC0311039C3

Summary of CS-C18CKV

Page 1

1 features 2 2 functions 3 3 product specifications 6 4 dimensions 10 5 refrigeration cycle diagram 12 6 block diagram 13 7 wiring diagram 15 8 operation details 17 8.1. Indoor fan speed control 17 8.2. Cooling mode operation 18 8.3. Soft dry mode operation 22 8.4. Air circulation mode operation 24 ...

Page 2: 1 Features

13 troubleshooting guide 61 13.1. Refrigeration cycle system 61 14 technical data 63 15 exploded view 65 16 replacement parts list 66 17 exploded view 67 18 replacement parts list 68 • • • • high efficiency • • • • compact design • • • • comfort environment − − − − ionizer control for generate negat...

Page 3: 2 Functions

2 functions remote control operation off / on off / on i room temperature setting temp. Operation mode selection • auto automatic operation mode • cool cooling operation mode • dry soft dry operation mode • fan air circulation mode mode time time / timer setting • hours and minutes setting. Clock se...

Page 4

Indoor unit random auto restart control • operation is restarted randomly after power failure at previous setting mode. Anti-freezing control • anti-freezing control for indoor heat exchanger. (cooling and soft dry) ionizer control • ionizer control for generate negative ion in discharge air. Indoor...

Page 5

Outdoor unit • to protect compressor from reverse rotation when there is a instantaneous power failure. 60 secs. Forced operation control • once the compressor is activated, it does not stop within the first 60 secs. However, it stops immediately with remote control stop signal. Overload protector •...

Page 6: 3 Product Specifications

3 product specifications unit cs-c18ckv cu-c18ckv power source phase, voltage, cycle single, 220, 60 hz cooling capacity kw (btu/h) 5.30 (18,100) moisture removal l/h (pint/h) 2.9 (6.1) airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 12.8 (450) 26.5 (930) in...

Page 7

Unit cs-c18ckv cu-c18ckv refrigerant (r-22) g (oz) — 1,240 (43.8) thermostat electronic control mechanical control protection device — o.L.P. Capillary tube length mm — 650 flow rate l/min — 20.9 inner diameter mm — 1.9 air filter material style p.P. Honeycomb — capacity control capillary tube compr...

Page 8

Unit cs-c24ckv cu-c24ckv power source phase, voltage, cycle single, 220, 60 hz cooling capacity kw (btu/h) 7.03 (24,000) moisture removal l/h (pint/h) 4.0 (8.5) airflow method outlet intake side view top view air volume indoor air (lo) m 3 /min (cfm) 13.9 (492) 27.4 (970) indoor air (me) m 3 /min (c...

Page 9

Unit cs-c24ckv cu-c24ckv capillary tube length mm — 1,170 flow rate l/min — 21.1 inner diameter mm — 2.4 air filter material style p.P. Honeycomb — capacity control capillary tube compressor capacitor µf, vac — 60 µf, 370vac fan motor capacitor µf, vac — 5.0 µf, 400vac note: • • • • specifications a...

Page 10: 4 Dimensions

4 dimensions 10 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 11

11 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 12

5 refrigeration cycle diagram 12 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

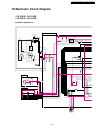

Page 13: 6 Block Diagram

6 block diagram 13 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 14

14 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

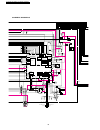

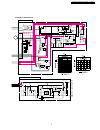

Page 15: 7 Wiring Diagram

7 wiring diagram cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv 15.

Page 16

Cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv 16.

Page 17: 8 Operation Details

8 operation details 8.1. Indoor fan speed control • • • • auto fan speed control when set to auto fan speed, the fan speed is adjusted between maximum and minimum setting as shown in the table. • • • • manual fan speed control basic fan speed adjustment (3 settings, from lo to hi) can be carried out...

Page 18

Cooling in operation according to remote control setting. Time delay safety control (3 minutes) 7 minutes time save control anti-freezing control • • • • if the temperature of the indoor heat exchanger falls continuously below 2°c for 4 minutes or more, the compressor turns off to protect the indoor...

Page 19

Automatic fan speed mode 2. Qlo fan speed (transistor motor) 3. Qlo fan speed (induction motor) when automatic fan speed is selected at remote control during cooling operation. • • • • fan speed rotates in the range of hi to me. • • • • deodorizing control. 19 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24c...

Page 20

Cooling operation time diagram quiet operation control (for cooling mode or cooling region of soft dry mode) • • • • purpose of this operation is to provide quite cooling operation compare to normal operation. • • • • when the quiet mode is set at the remote control, quiet mode led illuminates, the ...

Page 21

• • • • manual fan speed:- − − − − rpm control during lo cool − − − − rpm control during hi & me cool • • • • auto fan speed:- • • • • quiet mode operation will stop if:- − − − − quiet mode button is pressed again. − − − − stopped by on/off switch. − − − − timer off activates. − − − − powerful mode ...

Page 22

Time delay safety control anti-freezing control compressor reverse rotation protection control anti-dew formation control automatic fan speed mode 8.3. Soft dry mode operation • • • • the unit starts cooling operation until the room temperature reaches the setting temperature set on the remote contr...

Page 23

Soft dry operation time diagram quiet operation control • • • • same as quiet operation control for cooling mode operation. 23 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 24

Standard for determining operation mode 8.4. Air circulation mode operation • • • • fan operation only. Indoor fan speed selection by remote control and setting refer to indoor fan speed control. − − − − manual fan speed follow remote control setting − − − − auto fan speed 8.5. Automatic mode operat...

Page 25

• • • • the mode judging temperature and standard setting temperature can be increased by 2°c, by open the circuit of jx1 at indoor electronic controller. 8.6. Powerful mode operation • • • • purpose of this operation is to obtain the setting temperature quickly. • • • • when the powerful mode is se...

Page 26

Vertical airflow direction auto-control • • • • when set an airflow direction auto-control with remote control, the louver swings up and down as shown in the diagram. • • • • the louver does not swing when the indoor fan motor stops during operation at the upper limit. • • • • when stopped with remo...

Page 27

Horizontal airflow direction manual control • • • • when the manual airflow direction selection button is pressed, the automatic airflow is released and the airflow direction vane move left and right in the range shown in the diagram. The louver can be adjusted by pressing the button to the desired ...

Page 28

8.11. Ionizer operation purpose to provide fresh air effect to user by discharging minus ion to air. Control condition a. Ionizer only operation. 1. When air-conditioner unit is at “off” condition (standby) and ion operation button at remote control is pressed. Fan & ionizer on, ion led illuminates,...

Page 29

3. Ionizer operation status is not memorised by micon. After off, when operation is “on” again, air-conditioner operates without ionizer operation. However, during cool mode etc + ionizer operation, if there is a power failure & then power resume, air conditioner shall on at that mode + ionizer oper...

Page 30

Note: 1. 24 times checking: actual ion on for 10s & off for 30 min continuously for 24 times. 2. 24 times count will be cleared when either one of the following conditions happen. A) 24 times count over, b) ionizer cancel if press ion button or power reset, c) ion feedback signal is ok. 3. Error pro...

Page 31

31 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 32: 9 Operating Instructions

9 operating instructions ionizer direction louver temp auto on off auto dry fan cool fan auto reset clock mode fan speed off cancel on set 1 2 3 timer off on / quiet powerful air swing auto product overview outdoor unit indoor unit air intake piping air outlet your device can... Cooling dehumidifyin...

Page 33

Find on page preparations trouble- shooting safety precautions helpful information press button cooling dehumidifying air circulation switch off automatic operation according to the room temperature the system automatically chooses choose the right temperature to be comfortably cool! Room temperatur...

Page 34

Auto/cool/dry : 15 min. Vertical direction select automatic / manual start before «on» time horizontal direction fan speed (air volume) direction / volume automatic internal function super high fan speed (air volume) set temperature fast cooling provide quiet operation air flow sound produce negativ...

Page 35

Vacuum wash dry wipe gently wash gently... + dry filter cleaning see below open manually ionizer replace every 3 years! Clean with cotton bud benzine / thinner scouring powder dirty filters cause: unpurified air, low cooling capacity, more unpleasant smells, higher energy consumption! Indoor unit ca...

Page 36

Preparations refer page 39 indoor unit pre-season inspection insert batteries set clock installation: see enclosed installation instruction! Use year confirm press insert batteries / close open front panel plug in close front panel place air filters place purifying filters remove air filters open / ...

Page 37

Troubleshooting no problem operation delayed for 3 minutes after successful restart self protection procedure it sounds like water flowing... Caused by refrigerant flow inside mist seems to emerge from the indoor unit condensation effect due to cooling with setting “fan auto” indoor fan sometimes st...

Page 38

Safety precautions emergency! Immediately isolate from the mains supply (e.G. If there is a smell of burning) use only for... Cooling dehumidifying air circulation never use this unit for purposes other than those listed in these operating instructions. In particular, do not use it for the preservat...

Page 39

Safety precautions & features defect / suspicion of defect? —> attend defects before use! Do not repair yourself engage dealer / specialist defects off and unplug (connector or breaker) do not wash! Cleaning uninstalling and disposal of the unit only by dealer / specialist packaging recyclable waste...

Page 40

10 installation instructions required tools for installation works 1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 55 n.M (5.5 kgf.M) 65 n.M (6.5 kgf.M) 3. Electric drill, hole core drill (ø7...

Page 41

1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in ins...

Page 42

Applicable piping kit cz-4f5, 7, 10an (c18ck, a18ck, rs-c18ck) cz-52f5, 7, 10an (c24ck, a24ck, rs-c24ck) select the best location indoor unit • • • • there should not be any heat source or steam near the unit. • • • • there should not be any obstacles blocking the air circulation. • • • • a place wh...

Page 43

10.2.1. Select the best location (refer to “select the best location” section) 10.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 550 mm at right and left of the wall. The distan...

Page 44

3. For the embedded piping (this can be used for left rear piping & left bottom piping also.) 44 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 45

1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 × 2.5 mm 2 (c18ck, c24ck, rs/ru-c18/24ck) or 5 × 2.5 mm 2 (a18ck, a24ck) flexible cord, type designatio...

Page 46

How to take out front grille please follow the steps below to take out front grille if necessary such as when servicing. 1. Open the intake grille and remove the screw at the front of the front grille. 2. Set the vertical airflow direction louver to the horizontal position. 3. Slide down the 3 caps ...

Page 47

Cutting and flaring the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut ...

Page 48

1) checking a gas leakage 1. Remove the service-port cap from the 3-way valves. 2. Connect the manifold gauge set to the service port of liquid side 3-way valve. 3. Connect the charging cylinder to the manifold gauge set and open the valve of the cylinder. 4. Open the low pressure side valve of the ...

Page 49

Disposal of outdoor unit drain water • • • • if a drain elbow is used, the unit should be placed on a stand which is taller than 3 cm. • • • • if the unit is used in an area where temperature falls below 0°c for 2 or 3 days in succession, it is recommended not to use a drain elbow, for the drain wat...

Page 50: 11 3-Way Valve

11 3-way valve 3-way valve (liquid side) 3-way valve (gas side) works shaft position service port shaft position service port shipping closed closed closed close (with valve cap) (with cap) (with valve cap) (with cap) (installation and closed open closed open re-installation) (clockwise) (connected ...

Page 51

Required tools: hexagonal wrench, adjustable wrench, torque wrenches, wrench to hold the joints, gas leak detector, and charging set. 1. Recheck the piping connections. 2. Open the valve caps and service port caps for both 3-way valves. 3. Connect the charging cylinder to the manifold gauge as shown...

Page 52

1. Confirm that both the 3-way valves are set to the open position. • • • • remove the valve caps and confirm that the valve caps are in the raised position. • • • • be sure to use a hexagonal wrench to operate the valve stems. 2. Operate the unit for 10 to 15 minutes. 3. Stop operation and wait for...

Page 53

11.1.3. Re-air purging 1. Remove the cap nut from 3-way valves. • • • • remove the cap nut from 3-way valves after carefully checked whether the piping connection was properly and certainly done. 2. Confirm that valve in both 3-way valves are set to the close. 3. Connect the gas cylinder to the liqu...

Page 54

1. Confirm that both the 3-way valves are set to the open position. 2. Connect the manifold gauge to the gas side (low side) 3-way valve’s port. • • • • leave the valve on the manifold gauge closed. • • • • connect the manifold gauge to the service port. 3. Open the valves (low side) on the manifold...

Page 55

(no refrigerant in the refrigeration cycle) 1. Connect the vacuum pump to the manifold gauge’s centre hose. 2. Evacuation for approximately one hour. • • • • confirm that the gauge needle has moved toward -0.01 mpa. 3. Close the valve (low side) on the manifold gauge, turn off the vacuum pump, and c...

Page 56

11.1.6. Gas charging 1. Connect the charge hose to the gas charging cylinder. • • • • connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom of the cylinder. 2. Purge the air from the charge hose. • • • • open the valve at the bottom of the cylinder and press ...

Page 57: 12 Servicing Information

1. The electronic controller, a signal receiver and an indicator (fig. 3) can be seen by the below steps: • • • • open the intake grille and remove the screw at the front of the front grille. (fig. 1). • • • • remove the 3 caps and 3 screws at the bottom of the front grille. (fig. 1) • • • • remove ...

Page 58

1. In order to remove the cross flow fan and indoor fan motor, control board need to be taken out by releasing all the connectors as indicated below. A. Release the earth wire screw. (fig. 5) b. Release the intake air sensor. (fig. 5) c. Release the piping sensor. (fig. 5) d. Release the cn-rec/disp...

Page 59

6. Remove the bearing. (fig. 9) 7. Remove the screws at the left of the evaporator. (fig. 9) 8. Push up the evaporator and pull out the cross flow fan from shaft. By then, fan motor can be taken out. (fig. 10). Reminder - to reinstall the fan motor, put it back in place, adjust the position of the f...

Page 60

• • • • remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happen, remove the cover of the remote control and you will find a resetting terminal, and by shorting it with...

Page 61: 13 Troubleshooting Guide

13.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air te...

Page 62

13.1.1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode condition of the air conditioner low pressure high pressure electric current during operation insufficient refrigerant (gas leakage) clogged capillary tube or strainer short circuit in th...

Page 63: 14 Technical Data

14 technical data 63 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 64

64 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 65: 15 Exploded View

15 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 65 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 66: 16 Replacement Parts List

16 replacement parts list ref. No. Part name & description qty. Cs-c18ckv cs-c24ckv remarks 1 chassy complete 1 cwd50c1293 ← ← ← ← 2 fan motor 1 cwa981056 ← ← ← ← 0 3 cross flow fan complete 1 cwh02c1010 ← ← ← ← 4 screw - cross flow fan 1 cwh4580304 ← ← ← ← 5 bearing ass’y 1 cwh64k007 ← ← ← ← 6 evap...

Page 67: 17 Exploded View

17 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 67 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 68: 18 Replacement Parts List

18 replacement parts list ref. No. Part name & description qty. Cu-c18ckv cu-c24ckv remarks 1 chassy ass’y 1 cwd50k515b cwd50k514b 2 sound proof board 1 cwh15223 ← ← ← ← 3 fan motor bracket 1 cwd54238 cwd54237 4 screw - fan motor bracket 4 cwh55027 ← ← ← ← 5 fan motor 1 cwa951132 cwa921079 0 6 screw...

Page 69

19 electronic circuit diagram schematic diagram 1/3 • cs-c18ck cu-c 18ck • cs-c24ck cu-c24ck 1 2 temperature fuse to outdoor power supply test wht ac01 (wht) blk ac02 (blk) 1 2 3 4 wht ac03 (wht) c13 0.01 µ r58 10k c22 0.01 µ r68 10k r59 1k receiver 1 3 (mx-3) indicator cn-rcv 2 (ph) cn-disp 6 5 4 3...

Page 70

Schematic diagram 2/3 r11 1k c01 0.01 µ r34 10k r20 r21 r22 r23 r24 r25 d07 d08 d09 d10 d11 d12 r18 r19 d05 d06 p72 p73 p74 p75 p64 p65 p66 p67 p40/a00 p41/a01 p42/a02 p43/a03 p44/a04 p45/a05 p46/a06 p47/a07 p50/a8 p51/a9 ry-pwr drive signal p52/a10 p53/a11 p54/a12 p55/a13 p56/a14 p57/a15 vss0 vdd0 ...

Page 71

Cn001 3 4 5 6 7 8 9 10 11 1 2 f001 z001 c002 l001 c003 c004 c005 d007 r030 r046 cn002 7 6 5 4 3 2 1 db004 th001 th002 r114 pc001 1 4 3 2 r002 zd005 r116 pc002 4 1 2 3 r001 r118 r117 c b e q102 r115 r007 r006 d002 d003 r005 r004 r008 r003 pc003 1 4 3 2 pc004 feedback 1 4 3 2 + zd001 c066 r011 r010 r0...

Page 72

How to use electronic circuit diagram timer table test mode name time (when test point remarks short-circuited) real timer 1 hr. 1 min. 10 min. 10 sec. 1 min. 1 sec. Time delay safety control 2 min. 58 sec. 0 sec. Forced operation 60 sec. 0 sec. Time save control 7 min. 42 sec. Anti-freezing 4 min. ...

Page 73

19.1. Remote control 73 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 74

19.2. Print pattern indoor unit printed circuit board 74 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv.

Page 75

19.3. Print pattern indoor unit printed circuit board 75 cs-c18ckv cu-c18ckv / cs-c24ckv cu-c24ckv [maico] printed in malaysia.