- DL manuals

- Panasonic

- Air Conditioner

- CS-C18HKD

- Service Manual

Panasonic CS-C18HKD Service Manual

© 2007 Panasonic HA Air-Conditioning (M) Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0710040C8

Air Conditioner

Indoor Unit Outdoor Unit

CS-C18HKD CU-C18HKD

CS-C24HKD CU-C24HKD

TABLE OF CONTENTS

PAGE

PAGE

1 Safety Precautions----------------------------------------------- 2

2 Specifications ----------------------------------------------------- 4

2.1. CS-C18HKD CU-C18HKD ----------------------------- 4

2.2. CS-C24HKD CU-C24HKD ----------------------------- 6

3 Features ------------------------------------------------------------- 8

4 Location of Controls and Components ------------------- 9

4.1. Indoor Unit--------------------------------------------------- 9

4.2. Outdoor Unit ------------------------------------------------ 9

4.3. Remote Control -------------------------------------------- 9

5 Dimensions ------------------------------------------------------- 10

5.1. Indoor Unit & Remote Control ------------------------ 10

5.2. Outdoor Unit----------------------------------------------- 11

6 Refrigeration Cycle Diagram -------------------------------- 12

7 Block Diagram --------------------------------------------------- 13

8 Wiring Connection Diagram--------------------------------- 14

8.1. CS-C18HKD CU-C18HKD ---------------------------- 14

8.2. CS-C24HKD CU-C24HKD ---------------------------- 15

9 Electronic Circuit Diagram----------------------------------- 16

Summary of CS-C18HKD

Page 1

© 2007 panasonic ha air-conditioning (m) sdn. Bhd. (11969-t). All rights reserved. Unauthorized copying and distribution is a violation of law. Order no. Mac0710040c8 air conditioner indoor unit outdoor unit cs-c18hkd cu-c18hkd cs-c24hkd cu-c24hkd table of contents page page 1 safety precautions----...

Page 2: 1 Safety Precautions

2 10 printed circuit board ------------------------------------------ 17 10.1. Indoor unit (main printed circuit board) ----------- 17 10.2. Indoor unit (power printed circuit board) --------- 19 10.3. Indicator panel -------------------------------------------- 20 11 installation instruction ------...

Page 3

3 4. Install at a strong and firm location which is able to withstand the set's weight. If the strength is not enough or installation is not properly done, the set will drop and cause injury. 5. For electrical work, follow the local national wiring standard, regulation and the installation instructi...

Page 4: 2 Specifications

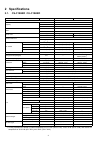

4 2 specifications 2.1. Cs-c18hkd cu-c18hkd 1. Cooling capacities are based on indoor temperature of 27 qc d.B. (80.6qf d.B.), 19.0qc w.B. (66.2qf w.B.) and outdoor air temperature of 35 qc d.B. (95qf d.B.), 24qc w.B. (75.2qf w.B.) item unit indoor unit outdoor unit performance test condition new ji...

Page 5

5 note: • specification are subject to change without prior notice for further improvement. Item unit power source (phase, voltage, cycle) ø single single v 220 230 hz 50 50 input power w 1.72k 1.76k starting current a 40 40 running current cooling a 8.2 8.3 maximum current cooling a 12.2 12.2 power...

Page 6: 2.2.

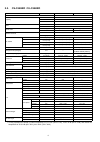

6 2.2. Cs-c24hkd cu-c24hkd 1. Cooling capacities are based on indoor temperature of 27 qc d.B. (80.6qf d.B.), 19.0qc w.B. (66.2qf w.B.) and outdoor air temperature of 35 qc d.B. (95qf d.B.), 24qc w.B. (75.2qf w.B.) item unit indoor unit outdoor unit performance test condition new jis capacity kw 7.0...

Page 7

7 note: • specification are subject to change without prior notice for further improvement. Item unit power source (phase, voltage, cycle) ø single single v 220 230 hz 50 50 input power kw 2.35 2.41 starting current a 65 65 running current cooling a 11.5 11.6 maximum current cooling a 15.1 15.1 powe...

Page 8: 3 Features

8 3 features • e-ion air purifying system with patrol sensor - active e-ions are released to catch dust particles and bring them back the large positively charged filter - patrol sensor color changes to indicate the dirt level in the air • long installation piping - cs/cu-c18/24hk, long piping up to...

Page 9: 4.1.

9 4 location of controls and components 4.1. Indoor unit 4.2. Outdoor unit 4.3. Remote control.

Page 10: 5 Dimensions

10 5 dimensions 5.1. Indoor unit & remote control 5.1.1. Cs-c18hkd cs-c24hkd.

Page 11: 5.2.

11 5.2. Outdoor unit 5.2.1. Cu-c18hkd 5.2.2. Cu-c24hkd.

Page 12

12 6 refrigeration cycle diagram.

Page 13: 7 Block Diagram

13 7 block diagram.

Page 14: 8 Wiring Connection Diagram

14 8 wiring connection diagram 8.1. Cs-c18hkd cu-c18hkd resistance of outdoor fan motor windings note: resistance at 20 qc of ambient temperature. Resistance of compressor windings note: resistance at 20 qc of ambient temperature. Model cu-c18hkd connection cwa951116j blue-red 230 : yellow-red 255 :...

Page 15: 8.2.

15 8.2. Cs-c24hkd cu-c24hkd resistance of outdoor fan motor windings note: resistance at 20 qc of ambient temperature. Resistance of compressor windings note: resistance at 20 qc of ambient temperature. Model cu-c24hkd connection cwa951352j blue-yellow 99.6 : yellow-red 126.8 : yellow-orange 158.7 :...

Page 16

16 9 electronic circuit diagram.

Page 17: 10 Printed Circuit Board

17 10 printed circuit board 10.1. Indoor unit (main printed circuit board) top view.

Page 18

18 bottom view.

Page 19

19 10.2. Indoor unit (power printed circuit board).

Page 20: 10.3. Indicator Panel

20 10.3. Indicator panel top view bottom view.

Page 21: 11 Installation Instruction

21 11 installation instruction 11.1. Select the best location 11.1.1. Indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where drainage can be easil...

Page 22: 11.2. Indoor Unit

22 11.2. Indoor unit 11.2.1. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 550 mm at right and left of the wall. The distance from installation plate edge to ceiling should more tha...

Page 23

23 3. For the embedded piping (this can be used for left rear piping and left bottom piping also.).

Page 24

24 11.2.4. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 u 2.5 mm 2 flexible cord, type designation 245 iec 57 o...

Page 25: 11.3. Outdoor Unit

25 11.3. Outdoor unit 11.3.1. Install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2. When installing at roof, please consider s...

Page 26

26 11.3.3. Evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. • be sure to conne...

Page 27

27 11.3.4. Connect the cable to the outdoor unit 1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 x 2.5 mm 2 flexible cord, type designation 245 iec 57 or heavier cord. 3. Sec...

Page 28: 12 Operation Control

28 12 operation control 12.1. Cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • the remote control setting temperature, which takes the reading of intake ai...

Page 29: 12.2. Soft Dry Operation

29 12.2. Soft dry operation • soft dry operation can be set using remote control. • soft dry operation is applied to dehumidify and to perform a gentle cooling to the room. • this operation starts when the intake air temperature sensor reaches the setting temperature on the remote control. • when op...

Page 30: 12.3. Automatic Operation

30 12.3. Automatic operation • automatic operation can be set using remote control. • this operation starts to operate with indoor fan at slo speed for 25 seconds to judge the intake air temperature. • after judged the temperature, the operation mode is determined by referring to the below standard....

Page 31

31 12.4.2. Automatic fan speed control • when set to auto fan speed, the fan speed is adjusted between maximum and minimum setting as shown in the table. - fan speed rotates in the range of hi, me and lo-. - deodorizing control will be activated. • auto fan speed during cooling operation: 1. Indoor ...

Page 32

32 12.4.3. Manual fan speed control • manual fan speed adjustment can be carried out by using the fan speed selection button at the remote control. • there are 3 types of fan speed settings: lo, me, hi. 12.5. Outdoor fan speed control • there is only one speed for outdoor fan motor (c18hk). • there ...

Page 33: 12.8. Powerful Operation

33 12.7. Horizontal airflow direction control 12.7.1. Auto control • when the horizontal airflow direction is set to auto using the remote control, the vanes swings left and right as shown in the diagram. • when stopped with remote control, the discharge vane is reset, and stop at the reset position...

Page 34: 12.9. Quiet Operation

34 12.9. Quiet operation (for cooling operation or cooling region of soft dry operation) • to provide quiet cooling operation condition. • once the quiet mode is set at the remote control, the quiet mode led illuminated. The sound level will reduce around 2 db (a) for lo fan speed or 3 db(a) for hi/...

Page 35: 12.10. Timer Control

35 12.10. Timer control 12.10.1. On timer • when the on timer is set by using the remote control, the unit will start to operate slightly before the set time, so that the room will reach nearly to the set temperature by the set time. • for cooling and soft dry operation, the operation will start 15 ...

Page 36: 12.13. Patrol Operation

36 12.13. Patrol operation • to monitor air dirtiness level by using patrol sensor and to maintain air freshness by activates e-ion operation. • patrol operation start condition - when the unit operation is started with “off/on” button. - when the unit stops, “patrol” button is pressed, patrol indiv...

Page 37

37 • patrol sensor control - first 2 minutes from patrol function activates is stabilization time, during stabilization time, no air dirtiness level is monitored. The air dirtiness level is set to clean, patrol led turns blue color. - after that, patrol sensor starts to record the resistance value a...

Page 38

38 • indicator - when patrol operation starts, patrol led is on with 3 different colors: - then e-ion operation starts based on dirtiness level, both patrol led and e-ion led are on • remote control receiving sound - normal operation Î patrol mode : beep - patrol mode Î stop : long beep - patrol mod...

Page 39: 12.14. E-Ion Operation

39 12.14. E-ion operation • this operation provides clean air by producing negative ions to attract dust captured at the positively charged active e-ion filters. • e-ion operation start condition - during unit running at any operation mode, if “e-ion” button is pressed, combination operation (operat...

Page 40

40 • indicator - when e-ion operation starts, e-ion indicator on. • remote control receiving sound - normal operation Î e-ion operation : beep - e-ion operation Î normal operation : beep - stop Î e-ion individual operation : beep - e-ion individual operation Î stop : long beep • power failure - duri...

Page 41

41 3. Active e-ion air purifying system breakdown error: • judgment method - when hi-feedback voltage (at microcontroller) supplied to filter during e-ion stop, e-ion air purifying system breakdown error shows immediately. - it is due to indoor pcb or filter’s high voltage power supply damage. - ope...

Page 42: 13 Operation Control

42 13 operation control 13.1. Restart control (time delay safety control) • when the thermo-off temperature (temperature which compressor stops to operate) is reached during:- - cooling operation - the compressor stops for 3 minutes (minimum) before resume operation. - soft dry operation - the compr...

Page 43: 13.6.

43 13.6. Compressor reverse rotation protection control • if the compressor is operating continuously for 5 minutes or longer and the temperature difference between intake air and indoor heat exchanger is 2.5 qc or less for continuous 2 minutes, compressor will stop and restart automatically. • time...

Page 44: 14 Servicing Mode

44 14 servicing mode 14.1. Auto off/on button 1. Auto operation mode the auto operation will be activated immediately once the auto off/on button is pressed. This operation can be use to operate air conditioner with limited function if remote control is misplaced or malfunction. 2. Test run operatio...

Page 45: 14.3. Remote Control Button

45 14.3. Remote control button 14.3.1. Set button • to check current remote control transmission code. - press for more than 10 seconds. • to change the air quality sensor sensitivity: - press and release with pointer. - press the timer decrement button to select sensitivity: 1. Low sensitivity 2. S...

Page 46: 15 Troubleshooting Guide

46 15 troubleshooting guide 15.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

Page 47

47 15.1.1. Relationship between the condition of the air conditioner and pressure and electric current • carry out the measurements of pressure, electric current, and temperature fifteen minutes after an operation is started. 15.1.2. Diagnosis methods of a malfunction of a compressor cooling mode co...

Page 48

48 16 disassembly and assembly instructions 16.1. Indoor electronic controllers and control board removal procedures warning • cautions! When handling electronic controller, be careful of electrostatic discharge. • be sure to return the wiring to its original position. • there are many high voltage ...

Page 49

49.

Page 50

50

Page 51

51.

Page 52

52.

Page 53: 17 Technical Data

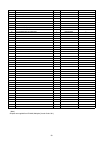

53 17 technical data 17.1. Thermostat characteristics cooling soft dry.

Page 54

54 17.2. Operation characteristics 17.2.1. Cs-c18hkd cu-c18hkd.

Page 55

55.

Page 56

56 17.2.2. Cs-c24hkd cu-c24hkd.

Page 57

57.

Page 58: 18.1. Indoor Unit

58 18 exploded view and replacement parts list 18.1. Indoor unit note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 59

59 (note) • all parts are supplied from phaam, malaysia (vendor code: 061). Ref. No. Part name & description qty. Cs-c18hkd cs-c24hkd 1 chassy complete 1 cwd50c1520 m 2 fan motor, dc 30w 3ph 1 arw61e8p30ac m 3 cross flow fan complete 1 cwh02c1010 m 4 screw - cross flow fan 1 cwh551146 m 5 bearing as...

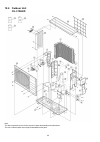

Page 60: 18.2. Outdoor Unit

60 18.2. Outdoor unit cu-c18hkd note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 61: 18.3. Outdoor Unit

61 18.3. Outdoor unit cu-c24hkd note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 62

62 (note) • all parts are supplied from phaam, malaysia (vendor code: 061). [phaam] printed in malaysia sfth0710-00 ref. No. Part name & description qty. Cu-c18hkd cu-c24hkd 1 chassy ass’y 1 cwd50k2072 cwd50k2100 2 compressor 1 2ks314d5fa04 2js438d3ga02 3 anti - vibration bushing 3 cwh50049 cwh50055...