© panasonic ha air-conditioning (m) sdn. Bhd. 2010. Unauthorized copying and distribution is a violation of law. Order no: phaam1006051c3 indoor unit outdoor unit cs-c18kks cs-c24kks cu-c18kks cu-c24kks table of contents 1. Safety precautions.............................................3 2. Specific...

2 13. Protection control............................................49 13.1 restart control (time delay safety control).. ....................................................................49 13.2 7 minutes time save control .....................49 13.3 60 seconds forced operation ....................

3 caution warning warning 1. Safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. •...

4 caution warning 20. After completion of installation or service, confirm there is no leakage or refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 21. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when refrigerant contacts w...

5 2. Specification indoor cs-c18kks cs-c24kks model outdoor cu-c18kks cu-c24kks performance test condition saso (t3) saso (t1) saso (t3) saso (t1) phase, hz single, 60 single, 60 power supply v 220 220 kw 4.40 5.10 5.60 6.50 btu/h 15000 17400 19100 22200 capacity kcal/h 3780 4390 4820 5590 running c...

6 control device capillary tube capillary tube refrigerant oil cm 3 atmos nm56m or suniso 4gdid (650) atmos m60 or suniso 4gdid (1130) refrigeration cycle refrigerant type g (oz) r22, 1.27k (44.8) r22, 1.61k (56.8) height(i/d / o/d) mm (inch) 290 (11-7/16) 750 (29-17/32) 290 (11-7/16) 750 (29-17/32)...

7 3. Features • e-ion air purifying system with patrol sensor o active e-ions are released to catch dust particles and bring them back the large positively charged filter. O patrol sensor color changes to indicate the dirt level in the air • long installation piping o cs/cu-c18kk, cs/cu-c24kk, long ...

8 4. Location of controls and components 4.1 indoor unit 4.2 outdoor unit 4.3 remote control.

9 5. Dimensions 5.1 indoor unit.

10 5.2 outdoor unit.

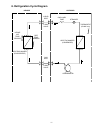

11 6. Refrigeration cycle diagram indoor outdoor liquid side gas side capillary tube heat exchanger (condenser) thermostat (c24kk only) heat exchanger (evaporator) compressor 2-way valve pipe temp. Sensor intake air temp. Sensor 3-way valve strainer.

12 7. Block diagram.

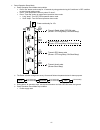

13 8. Wiring connection diagram 8.1 cs-c18kks cu-c18kks resistance of outdoor fan motor windings resistance of compressor windings model cu-c18kks model cu-c18kks connection cwa951401j connection 2ks252f5aa04 blue-yellow 59.47 Ω c-r 1.959 Ω yellow-red 60.95 Ω c-s 3.083 Ω note: resistance at 20°c of ...

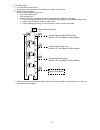

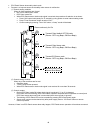

14 8.2 cs-c24kks cu-c24kks resistance of outdoor fan motor windings resistance of compressor windings model cu-c24kks model cu-c24kks connection cwa951399j connection 2j39s236a1a yellow-blue 59.47 Ω c-r 0.933 Ω yellow-orange 80.58 Ω c-s 1.584 Ω yellow-red 60.95 Ω note: resistance at 20°c of ambient ...

15 9. Electronic circuit diagram 9.1 cs-c18kks cu-c18kks.

16 9.2 cs-c24kks cu-c24kks.

17 10. Printed circuit board 10.1 indoor unit 10.1.1 main printed circuit board.

18 10.1.2 power printed circuit board.

19 10.1.3 indicator printed circuit board 10.1.4 receiver printed circuit board 10.1.5 high voltage power supply printed circuit board.

20 11. Installation instruction 11.1 select the best location 11.1.1 indoor unit • do not install the unit in excessive oil fume area such as kitchen, workshop and etc. • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a...

21 11.2 indoor unit 11.2.1 how to fix installation plate the mounting wall shall be strong and solid enough to prevent if from the vibration. The centre of installation plate should be at more than c at right and left of the wall. The distance from installation plate edge to ceiling should more than...

22 11.2.3 indoor unit installation piping piping intake grille shock absorber use shock absorber during pull out the piping to protect the intake grille from damage. Do not turn over the unit without it ’s shock absorber during pull out the piping. It may cause intake grille damage caution ! ! 11.2....

23 11.2.4 connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 x 2.5mm 2 (2.0 ~ 2.5hp) flexible cord, type designation ...

24 11.2.5 wire stripping and connecting requirement 11.2.5.1 cutting and flaring the piping 1 please cut using pipe cutter and then remove the burrs. 2 remove the burrs by using reamer. If burrs are not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering t...

25 caution 11.3 outdoor unit 11.3.1 install the outdoor unit • after selecting the best location, start installation to indoor/outdoor unit installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10mm). 2 when installing at roof, please consider strong w...

26 11.3.3 evacuation of the equipment for environmental protection, manufacturer strongly recommends to use evacuation method. 1 connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. O be sure to connect the end of the charging hose with t...

27 11.3.4 air purging of the piping and indoor the remaining air in the refrigerant cycle which contains moisture may cause malfunction on the compressor. 1 remove the caps from the 2-way and 3-way valves. 2 remove the service-port cap from the 3-way valves. 3 to open the valve, turn the valve stem ...

28 11.3.6 pipe insulation 1 please carry out insulation at pipe connection portion as mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2 if drain hose or connecting piping is in the room (where dew may form), p...

29 12. Operation control 12.1 cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature to the setting temperature set on the remote control. • the remote control setting temperature, which takes the reading of intake air tem...

30 12.2 soft dry operation • soft dry operation can be set using remote control. • soft dry operation is applied to dehumidify and to perform a gentle cooling to the room. • this operation starts when the intake air temperature sensor reaches the setting temperature on the remote control. • when ope...

31 12.3 automatic operation • automatic operation can be set using remote control. • this operation starts to operate with indoor fan at slo speed for 20 seconds to judge the intake air temperature. • after judged the temperature, the operation mode is determined by referring to the below standard. ...

32 12.4 indoor fan speed control • indoor fan speed can be set using remote control. 12.4.1 fan speed rotation chart fan speed (rpm) speed cs-c18kks cs-c24kks shi 1370 1500 hi 1200 1350 me 1110 1230 hlo 1080 1190 clo 1020 1110 lo- 850 970 slo 670 750 qhi 1110 1150 qme 1020 1050 qlo 930 960 12.4.2 au...

33 • auto fan speed during cooling operation: 1 indoor fan will rotate alternately between off and on as shown in below diagram. 2 at the beginning of each compressor starts operation, indoor fan speed increases gradually for deodorizing purpose. 3 for the first time the compressor operates, indoor ...

34 12.5 outdoor fan speed control • there is only one speed for outdoor fan motor. (applicable for cu-c18kk) • there is 2 speeds for outdoor fan motor. Outdoor fan speed can be changed to hi or lo according to outdoor temperature. (applicable for cu-c24kk). • for cooling and soft dry operation, when...

35 12.7 horizontal airflow direction control 12.7.1 auto control • when the horizontal airflow is set to auto using the remote control, the vanes swings left and right as shown in the diagram. • when stopped with remote control, the discharge vanes are reset and stop at the reset position. • during ...

36 12.9 quiet operation (for cooling operation or cooling region of soft dry operation) • to provide quiet cooling operation condition. • once the quiet operation is set at the remote control, the quiet led illuminated. The sound level will reduce around 2db(a) for lo fan speed or 3db(a) for hi/me f...

37 12.10 timer control 12.10.1 on timer • when the on timer is set by using the remote control, the unit will start to operate slightly before the set time, so that the room will reach nearly to the set temperature by the set time. • for cooling and soft dry operation, the operation will start 15 mi...

38 12.13 patrol operation • to monitor air dirtiness level by using patrol sensor and to maintain air freshness by activates e-ion operation • patrol operation starts condition o when the unit operation is started with “off/on” button o when the unit stops, “patrol” operation is selected, patrol ind...

39 • patrol sensor control o first 2 minutes from patrol function activates is stabilization time, during stabilization time, no air dirtiness level is monitored. The air dirtiness level is set to clean, patrol led turns blue color. O after that, patrol sensor starts to record the resistance value a...

40 • airflow direction (horizontal, vertical) control o during any operation mode combines with patrol operation, airflow direction follows respective operation mode. O during patrol individual operation if e-ion starts, only auto air swing is allowed. Even if “air swing” button is pressed, no signa...

41 • patrol operation demo mode o patrol operation demo mode start condition press “set” button continuously for 15 seconds by using pointer during air conditioner is off condition to enter internal setting mode. Press “timer decrement" button to select “pt demo”. Press “timer set” button to toggle ...

42 12.14 e-ion operation • this operation provides clean air by producing negative ions to attract dust captured at the positively charged active e-ion filters. • e-ion operation start condition o during unit running at any operation mode, if “e-ion” operation is selected, combination operation (ope...

43 • e-ion check mode o e-ion abnormality check mode o purpose is to improve sensor serviceability when sensor is malfunction. (1) control starting condition when all of the conditions are formed not in patrol demo mode. E-ion operation on. When e-ion check mode signal is received; the procedure of ...

44 • error detection control when e-ion indicator blink, it indicates error listed below: o active e-ion air purifying system pcb main connector open: judgment method • during e-ion operation (include during patrol operation), active e-ion air purifying system main connector to pcb is opened. Troubl...

45 12.15 eco patrol operation • a pyoelectric infrared sensor is used to detect injection strength variation of infrared at setting area to determine the presence or absence of human and its activity level. Human detection area is shown in figure below: • eco patrol operation – human presence/absenc...

46 • eco patrol demo mode press “set” button continuously for 15 seconds by using pointer during air conditioner is off condition to enter internal setting mode. Press “timer decrement" button to select “ec demo”. Press “timer set” button to toggle eco patrol demo mode. • short "beep": turn on eco p...

47 • during eco patrol operation, the internal setting temperature and fan speed are adjusted in order to provide comfort and energy saving. • eco patrol start condition. Press eco patrol button to select eco1 and eco2. • eco patrol stop condition. Press eco patrol button again. Off timer activates....

48 • eco patrol sensor abnormality check mode • purpose is to improve sensor serviceability when sensor is malfunction. (1) control starting condition when all of the conditions are formed not in eco patrol demo mode. Eco patrol mode on. When eco patrol sensor check mode signal is received; the proc...

49 13. Protection control 13.1 restart control (time delay safety control) • when the thermo-off temperature (temperature which compressor stops to operate) is reach during:- o cooling operation – the compressor stops for 3 minutes (minimum) before resume operation. O soft dry operation – the compre...

50 compressor starts for ≥ 5 minutes ▲ t ≤ 2.5°c for 2 minutes compressor off compressor restart ▲ t = intake air temperature – indoor heat exchanger temperature 13.5 freeze prevention control • to protect indoor heat exchanger from freezing and to prevent higher volume of refrigerant in liquid form...

51 14. Servicing mode 14.1 auto off/on button auto off/on button pressed auto off/on button pressed auto off/on button pressed 5 sec 5 sec auto operation test run operation (forced cooling operation) stop various setting mode stop 1 auto operation mode the auto operation will be activated immediatel...

52 14.2 remote control button 14.2.1 set button • to check current remote control transmission code and store the transmission code to eeprom: o press “set” button for more than 10 seconds o press “timer set” button until a “beep” sound is heard as confirmation of transmission code change. • to chan...

53 15. Troubleshooting guide 15.1 refrigeration cycle system in order to diagnose malfunctions, ensure the air conditioner is free from electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compre...

54 15.1.1 relationship between the condition of the air conditioner and pressure and electric current cooling mode condition of the air conditioner low pressure high pressure electric current during operation insufficient refrigerant (gas leakage) Ô Ô Ô clogged capillary tube or strainer Ô Ô Ô short...

55 warning 16. Disassembly and assembly instructions high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 16.1 indoor electronic c...

56 16.1.3 to remove power electronic controller figure 3 figure 4 figure 5 figure 6.

57 16.1.4 to remove discharge grille figure 7 16.1.5 to remove control board figure 8 16.1.6 to remove cross flow fan and indoor fan motor figure 9.

58 figure 10 figure 11 figure 12.

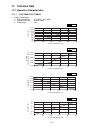

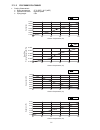

59 17. Technical data 17.1 operation characteristics 17.1.1 cs-c18kks cu-c18kks • cooling characteristic o room temperature: 27°c (dbt), 19°c (wbt) o operation condition: high fan speed o piping length: 5.0m gas s ide pi p in g pr es su re ( m pa ) c apa ci ty (k w ) outdoor temperature (ºc) outdoor...

60 • piping length characteristic o outdoor temperature: 35°c (dbt), 24°c (wbt) o operation condition: high fan speed o piping length: 5.0m c u rrent (a ) ga s s ide p iping p ressur e ( m p a ) ca p a ci ty ( kw) ou tle ta ir ( ºc ) 220v piping length (m) 220v piping length (m) piping length (m) 22...

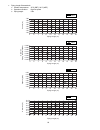

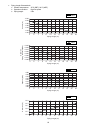

61 17.1.2 cs-c24kks cu-c24kks • cooling characteristic o room temperature: 27°c (dbt), 19°c (wbt) o operation condition: high fan speed o piping length: 5.0m c urr en t (a ) gas s ide p ipin g p ressu re ( m p a ) ca pa cit y ( kw) o u tlet a ir (ºc ) outdoor temperature (ºc) outdoor temperature (ºc...

62 • piping length characteristic o outdoor temperature: 35°c (dbt), 24°c (wbt) o operation condition: high fan speed o piping length: 5.0m c u rrent (a ) ga s s ide p iping p ressur e ( m p a ) ca p a ci ty ( kw) ou tle ta ir ( ºc ) 220v piping length (m) 220v piping length (m) piping length (m) 22...

63 18. Exploded view and replacement parts list 18.1 indoor unit note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

64 ref. No. Part name & description qty cs-c18kks cs-c24kks remark 1 chassy complete 1 cwd50c1654 ← 2 fan motor 1 l6cbyyyl0037 l6cbyyyl0039 o 3 cross flow fan complete 1 cwh02c1077 ← 4 bearing ass’y 1 cwh64k007 ← 5 screw - cross flow fan 1 cwh551146 ← 6 ion generator 1 cwh94c0028 ← 7 evaporator 1 cw...

65 50 drain hose 1 cwh851173 ← 51 bag complete - installation screw 1 cwh82c1705 ← 52 installation plate 1 cwh361098 ← 53 fulcrum 2 cwh621103 ← 54 operating instruction 1 cwf567115 ← 55 installation instruction 1 cwf614219 ← 56 installation instruction 1 cwf614220 ← 57 power supply cord 1 cwa20c2836...

66 18.2 outdoor unit note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

67 ref. No. Part name & description qty cu-c18kks cu-c24kks remark 1 chassy ass’y 1 cwd50k2115 cwd50k2100 2 sound proof material 2 cwg302408 ← 3 fan motor bracket 1 cwd541065 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 cwa951401j cwa951399j o 6 screw - fan motor mount 3 cwh55252j ← 7 p...