- DL manuals

- Panasonic

- Air Conditioner

- CS-E12DKDW

- Service Manual

Panasonic CS-E12DKDW Service Manual

1 Features

3

2 About Lead Solder (PbF)

4

2.1.

DISTINCTION OF PbF P.C. BOARD

4

2.2.

CAUTION

4

3 Functions

5

3.1.

Wall Type

5

3.2.

Duct Type

8

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights

reserved.

Unauthorized

copying

and

distribution is a violation of law.

CS-ME7DKEG CS-ME10DD3EG

CS-ME10DTEG CS-E15DB4EW

CS-ME7DKRG CS-ME7DKDG

CS-E9DKEW CS-E9DKRW

CS-E9DKDW CS-E12DKEW

CS-E12DKRW CS-E12DKDW

CS-E15DKEW CS-E15DKRW

CS-E15DKDW CS-E18DKEW

CS-E18DKRW CS-E18DKDW

CS-E15DD3EW CS-E18DD3EW

CS-E15DTEW CS-E18DTEW

CS-E18DB4EW

3.3.

Ceiling Floor Type

11

3.4.

Mini-Cassette Type

13

4 Product Specifications

15

4.1.

Wall Type

15

4.2.

Duct Type

16

4.3.

Ceiling Floor Type

17

4.4.

Mini-Cassette Type

18

Multi Air Conditioner

Please file and use this manual together with the Service Manuals for the following models:

Indoor unit models: CS-ME7CKPG, CS-ME10CKPG, CS-ME12CKPG, CS-ME14CKPG and CS-ME18CKPG;

Outdoor unit models: CU-2E15CBPG, CU-2E18CBPG, CU-3E23CBPG and CU-4E27CBPG (Order No.

RAC0209005C2); Indoor unit models: CS-ME7CB1P, CS-ME10CB1P, CS-ME12CB1P, CS-ME14CB1P, CS-

ME10CD3P and CS-ME14CD3P; Outdoor unit models: CU-3E23CBPG and CU-4E27CBPG (Order No.

RAC0312001A8)

CONTENTS

Page

Page

Order No. RAC0503011C2

Summary of CS-E12DKDW

Page 1

1 features 3 2 about lead solder (pbf) 4 2.1. Distinction of pbf p.C. Board 4 2.2. Caution 4 3 functions 5 3.1. Wall type 5 3.2. Duct type 8 © 2005 matsushita electric industrial co., ltd. All rights reserved. Unauthorized copying and distribution is a violation of law. Cs-me7dkeg cs-me10dd3eg cs-me...

Page 2

4.5. Outdoor units: cu-2e15cbpg / cu-2e18cbpg 19 4.6. Outdoor units: cu-3e23cbpg / cu-4e27cbpg 20 5 dimensions 24 5.1. Wall type 24 5.2. Duct type 26 5.3. Ceiling floor type 28 5.4. Mini-cassette type 29 6 refrigeration cycle diagram 30 6.1. Cu-2e15cbpg / cu-2e18cbpg 30 6.2. Cu-3e23cbpg / cu-4e27cbp...

Page 3: 1 Features

1 features • • • • product − − − − a single outdoor unit enable air conditioning of up to two separate rooms for cu-2e15cbpg and cu-2e18cbpg. − − − − a single outdoor unit enable air conditioning of up to three separate rooms for cu-3e23cbpg. − − − − a single outdoor unit enable air conditioning of ...

Page 4

• • • • serviceability − − − − self diagnosis − − − − test run at both cooling and heating rated frequency • • • • built-in drain pump (cassette and duct type) − − − − a drain pump is built in. The pipe can rise to 200m above the drain outlet. 2 about lead solder (pbf) 2.1. Distinction of pbf p.C. B...

Page 5: 3 Functions

3 functions 3.1. Wall type 3.1.1. Remote control 5 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 6

3.1.2. Indoor unit 6 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 7

7 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 8

3.2. Duct type 3.2.1. Remote control 8 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 9

3.2.2. Indoor unit 9 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 10

10 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 11

3.3. Ceiling floor type 3.3.1. Remote control 11 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 12

3.3.2. Indoor unit 12 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 13

3.4. Mini-cassette type 3.4.1. Remote control 13 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 14

3.4.2. Indoor unit 14 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

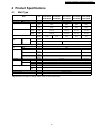

Page 15: 4 Product Specifications

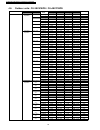

4 product specifications 4.1. Wall type cs-me7dkeg cs-e9dkew cs-e12dkew cs-e15dkew cs-e18dkew model unit cs-me7dkrg cs-e9dkrw cs-e12dkrw cs-e15dkrw cs-e18dkrw cs-me7dkdg cs-e9dkdw cs-e12dkdw cs-e15dkdw cs-e18dkdw item wall type power source outdoor power single 230v 50hz air volume cooling m 3 /min ...

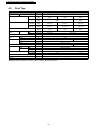

Page 16

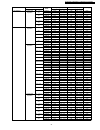

4.2. Duct type model unit cs-me10dd3eg cs-e15dd3ew cs-e18dd3ew item duct type power source outdoor power single 230v 50hz air volume cooling m 3 /min (cfm) high: 7.0 (250) high: 7.8 (280) high: 10.3 (360) heating m 3 /min (cfm) high: 8.9 (310) high: 12.6 (440) noise level cooling (power) db(a) (db) ...

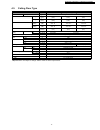

Page 17

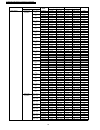

4.3. Ceiling floor type model unit cs-me10dteg cs-e15dtew cs-e18dtew item ceiling floor type power source outdoor power single 230v 50hz air volume cooling m 3 /min (cfm) high: 9.3 (330) high: 11.7 (410) high: 12.1 (430) heating m 3 /min (cfm) high: 9.3 (330) high: 12.0 (420) high: 12.5 (440) noise ...

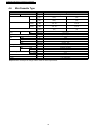

Page 18

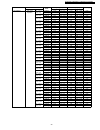

4.4. Mini-cassette type model unit cs-e15db4ew cs-e18db4ew item mini-cassette type power source outdoor power single 230v / 240v, 50hz air volume cooling m 3 /min (cfm) high: 10.5 (370) high: 11.0 (390) heating m 3 /min (cfm) high: 10.8 (380) high: 11.5 (405) noise level cooling (power) db(a) (db) h...

Page 19

4.5. Outdoor units: cu-2e15cbpg / cu-2e18cbpg outdoor unit indoor unit combination operation mode capacity (kw) power input (kw) current (a) operation class (kw) rating mini - max rating mini - max cu-2e15cbpg one-room operation 2.2 cooling 2.20 1.1 - 2.9 0.52 0.22 - 0.75 2.45 heating 3.20 0.7 - 4.8...

Page 20

4.6. Outdoor units: cu-3e23cbpg / cu-4e27cbpg outdoor unit indoor unit combination operation mode capacity (kw) power input (kw) current (a) operation class (kw) rating mini - max rating mini - max cu-3e23cbpg one-room operation 2.2 cooling 2.20 1.9 - 2.7 0.45 0.38 - 0.62 2.25 heating 3.20 1.7 - 4.1...

Page 21

Outdoor unit indoor unit combination operation mode capacity (kw) power input (kw) current (a) operation class (kw) rating mini - max rating mini - max cu-3e23cbpg three-room operation 2.8 + 2.8 + 3.2 cooling 6.80 2.7 - 8.2 1.96 0.49 - 2.79 8.60 heating 8.60 3.2 - 9.0 1.92 0.51 - 2.76 8.45 2.8 + 2.8...

Page 22

Outdoor unit indoor unit combination operation mode capacity (kw) power input (kw) current (a) operation class (kw) rating mini - max rating mini - max cu-4e27cbpg three-room operation 2.2 + 2.8 + 5.0 cooling 8.00 2.8 - 8.3 2.46 0.49 - 2.80 10.80 heating 9.40 3.5 - 10.4 2.08 0.56 - 3.15 9.15 2.2 + 3...

Page 23

Outdoor unit indoor unit combination operation mode capacity (kw) power input (kw) current (a) operation class (kw) rating mini - max rating mini - max cu-4e27cbpg four-room operation 2.2 + 2.2 + 2.8 + 5.0 cooling 8.00 2.9 - 8.9 2.11 0.52 - 2.88 9.30 heating 9.40 4.1 - 10.5 2.09 0.70 - 3.10 9.20 2.2...

Page 24: 5 Dimensions

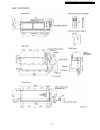

5 dimensions 5.1. Wall type 24 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 25

25 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 26

5.2. Duct type 26 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 27

27 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 28

5.3. Ceiling floor type 28 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 29

5.4. Mini-cassette type 29 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 30

6 refrigeration cycle diagram 6.1. Cu-2e15cbpg / cu-2e18cbpg 30 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 31

6.2. Cu-3e23cbpg / cu-4e27cbpg 31 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 32: 7 Block Diagram

7 block diagram 32 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 33: 8 Wiring Diagram

8 wiring diagram 8.1. Wall type 33 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 34

8.2. Duct type 34 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 35

8.3. Ceiling floor type 35 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 36

8.4. Mini-cassette type 36 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 37: 9 Operation Details

9 operation details 9.1. Wall type 9.1.1. Basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomp...

Page 38

Table (d): indoor air temperature shifting 1. Target room temperature shift value (dgetadst) • • • • to offset the absolute gap between detection temperature with actual room temperature. • • • • the heat exchanger unit’s temperature is different based on operation mode, it becomes the action operat...

Page 39

1. Operation modes which can be selected using the remote control unit: automatic, cooling, dry, heating, fan operation mode. 2. Types of operations modes which can be performed simultaneously • • • • cooling operation and cooling, dry or fan operation • • • • heating operation and heating operation...

Page 40

9.1.1.3. Cooling operation 9.1.1.3.1. Thermostat control • • • • compressor is off when intake air temperature - internal setting temperature • • • • compressor is on after waiting for 3 minutes, if the intake air temperature - internal setting temperature > compressor off point. 9.1.1.4. Soft dry o...

Page 41

9.1.1.6. Automatic operation this mode can be set using remote control and the operation is decided by remote control setting temperature, indoor intake air temperature and outdoor air temperature. During operation mode judgment, indoor fan motor (with speed of lo-) and outdoor fan motor are running...

Page 42

Notes: 9.1.1.7. Indoor fan motor operation a. Basic rotation speed (rpm) • • • • required rotation speed for fan is set to respond to the remote control setting (10 rpm unit) [cooling, dry, fan] remote control — — o o o o o — — — tab (rpm) pshi shi hi me+ me me- lo lo- slo sslo cs-me7dkeg 1320 1320 ...

Page 43

B. Indoor fan control i. Indoor fan control operation outline 1. Cooling / dry 43 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 44

2. Heating ii. Auto fan speed 1. Cooling model no. A no. B no. C powerful program cs-me7dkeg, cs-e9dkew 1110 1130 1150 cs-e12dkew 1230 1250 1270 cs-e15dkew 1300 1320 1340 cs-e18dkew 1390 1410 1430 normal program cs-me7dkeg, cs-e9dkew 1050 1070 1090 cs-e12dkew 1170 1190 1210 cs-e15dkew 1240 1260 1280...

Page 45

2. Heating note: a. Up: • • • • if move from lo, the fan speed will be shifted to maximum 1,520 rpm. • • • • if move from maximum, the fan speed no change. • • • • in up zone, 10 rpm is added for every 10 seconds until maximum 1,520 rpm. B. Down: • • • • the fan speed will be decreased one step ever...

Page 46

D. Deodorizing control i. Control condition control at cooling/dry operation and auto fan speed. No deodorizing control is performed during on timer standby operation and during anti-freezing control prevention. Ii. Operation the odor status is arranged as below and it is shifted as follows. * when ...

Page 47

Horizontal airflow 1. Automatic horizontal airflow direction can be set using remote control; the vane swings left and right within the angles as stated below. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as figure 1 below. Operation mode vane an...

Page 48

2. When quiet operation is stopped, operation is shifted to normal operation with previous setting. 3. When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed. 4. When operation mode is changed, quiet operation is shifted to quiet operation of the new mode. 5. D...

Page 49

9.1.1.11. Powerful mode operation when the powerful mode is selected, the internal setting temperature will shift to achieve the setting temperature quickly. (a) cooling operation (b) soft dry operation (c) heating operation 9.1.1.12. Delay on timer control delay on timer can be set using remote con...

Page 50

9.1.1.14. Auto restart control • • • • if there is a power failure, operation will automatically be restarted when the power is resumed. It will start with the previous operation mode and airflow direction. (timer delay safety control is valid.) 1. Control start conditions • • • • the 24-hour timer ...

Page 51

9.1.1.16. Auto operation switch 1. When the switch is pressed between 0 to 5 seconds, auto mode operation starts to function. 2. When the switch is pressed between 5 to 8 seconds, the unit is forced to operate in cooling mode. 3. When the switch is pressed between 8 to 11 seconds, the unit will ente...

Page 52

B. Operation mode + ionizer operation. 1. Ionising operation start condition when air conditioner unit is in “on” condition (heat, cool, dry, fan, auto mode) and an ion operation button at remote control is pressed. Ionizer on & ion led illuminates. (3 → 4) power led also illuminates. 2. Ionising op...

Page 53

9.1.1.17.2. Ionizer operation case study case 1 9.1.2. Anti-freezing control 1. When indoor heat exchanger temperature is lower than 2°c continuously for six minutes, compressor will stop operating. 2. Compressor will resume its operation three minutes after the indoor heat exchanger is higher than ...

Page 54

1. Operation modes which can be selected using the remote control unit: automatic, cooling, dry, heating, fan operation mode. 2. Types of operations modes which can be performed simultaneously • • • • cooling operation and cooling, dry or fan operation • • • • heating operation and heating operation...

Page 55

9.2.2. Indoor fan control • • • • the following shows how fan speed changes depending on the setting made with the fan speed button and other operating conditions. • • • • actual fan speed may differ from that you set with remote control. 55 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 56

9.2.3. Drain pump control basic operation • • • • the drain pump starts 50 seconds after the indoor unit starts or the thermostat comes on (i.E., 10 seconds after the fan motor starts). The drain pump stops 30 seconds after the indoor unit stops or the thermostat turns off. • • • • the drain pump re...

Page 57

9.2.4. Auto restart control • • • • if there is a power failure, operation will automatically be restarted when the power is resumed. It will start with the previous operation mode and airflow direction. (timer delay safety control is valid.) 1. Control start conditions • • • • the 24-hour timer mus...

Page 58

9.2.5. Other indoor unit operation functions 9.2.5.1. Auto button proceed with operation when the air conditioner is stopped. (when the auto button is pressed during operation, the air conditioner is stopped.) 1. Emergency operation press the auto button and release it within 5 seconds to perform em...

Page 59

• • • • under various setting mode, after select the transmission code combination of remote control, press any button of remote control to transmit a signal to indoor unit. The transmission code will be stored in eeprom. • • • • after signal is received, the various setting mode is cancelled and re...

Page 60

9.3. Ceiling floor type 9.3.1. Basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer mainta...

Page 61

Table (d): indoor air temperature shifting 1. Target room temperature shift value (dgetadst) • • • • to offset the absolute gap between detection temperature with actual room temperature. • • • • the heat exchanger unit’s temperature is different based on operation mode, it becomes the action operat...

Page 62

1. Operation modes which can be selected using the remote control unit: automatic, cooling, dry, heating, fan operation mode. 2. Types of operations modes which can be performed simultaneously • • • • cooling operation and cooling, dry or fan operation • • • • heating operation and heating operation...

Page 63

9.3.1.3. Cooling operation 9.3.1.3.1. Thermostat control • • • • compressor is off when intake air temperature - internal setting temperature • • • • compressor is on after waiting for 3 minutes, if the intake air temperature - internal setting temperature > compressor off point. 9.3.1.4. Soft dry o...

Page 64

9.3.1.6. Automatic operation this mode can be set using remote control and the operation is decided by remote control setting temperature, indoor intake air temperature and outdoor air temperature. During operation mode judgment, indoor fan motor (with speed of lo-) and outdoor fan motor are running...

Page 65

9.3.1.7. Indoor fan motor operation a. Basic rotation speed (rpm) • • • • required rotation speed for fan is set to respond to the remote control setting (10 rpm unit) [cooling, dry, fan] remote control — — o o o o o — — — tab (rpm) pshi shi hi me+ me me- lo lo- slo sslo cs-me10dteg 900 900 830 790 ...

Page 66

B. Indoor fan control i. Indoor fan control operation outline 1. Cooling / dry 66 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 67

2. Heating ii. Auto fan speed 1. Cooling model no. A no. B no. C powerful program cs-me10dteg 790 810 830 cs-e15dtew 940 960 980 cs-e18dtew 990 1010 1030 normal program cs-me10dteg 730 750 770 cs-e15dtew 880 900 920 cs-e18dtew 930 950 970 quiet program cs-me10dteg 710 730 750 cs-e15dtew 860 880 900 ...

Page 68

2. Heating note: a. Up: • • • • if move from lo, the fan speed will be shifted to maximum 1,520 rpm. • • • • if move from maximum, the fan speed no change. • • • • in up zone, 10 rpm is added for every 10s until maximum 1,520 rpm. B. Down: • • • • the fan speed will be decreased one step every 10 se...

Page 69

9.3.1.8. Airflow direction 1. There is one type of airflow, vertical airflow (directed by horizontal vane). 2. Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat exchanger temperature and intake air temperature) and manual (angles of direction ca...

Page 70

9.3.1.9. Quiet operation (cooling mode/cooling area of dry mode) a. Purpose to provide quiet cooling operation compare to normal operation. B. Control condition a. Quiet operation start condition • • • • when “quiet” button at remote control is pressed. Quiet led illuminates. B. Quiet operation stop...

Page 71

C. Control contents a. Fan speed manual 1. Fan speed is changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of hi, me, lo for 3db. 2. Fan speed for quiet operation is -1 step from setting fan speed. 3. Fan speed auto indoor fm rpm depends on pipe temp sensor...

Page 72

9.3.1.13. Delay off timer control delay off timer can be set using remote control, the unit with timer set will stop operate at set time. 9.3.1.14. Auto restart control 1. When the power supply is cut off during the operation of air conditioner, the compressor will re-operate within three to four mi...

Page 73

9.3.1.17. Anti-freezing control 1. When indoor heat exchanger temperature is lower than 2°c continuously for six minutes, compressor will stop operating. 2. Compressor will resume its operation three minutes after the indoor heat exchanger is higher than 10°c. 3. At the same time, indoor fan speed i...

Page 74

9.4. Mini-cassette type 9.4.1. Basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer mainta...

Page 75

Table (d): indoor air temperature shifting 1. Target room temperature shift value (dgetadst) • • • • to offset the absolute gap between detection temperature with actual room temperature. • • • • the heat exchanger unit’s temperature is different based on operation mode, it becomes the action operat...

Page 76

1. Operation modes which can be selected using the remote control unit: automatic, cooling, dry, heating, fan operation mode. 2. Types of operations mode which can be performed simultaneously • • • • cooling operation and cooling, dry or fan operation • • • • heating operation and heating operation ...

Page 77

9.4.1.3. Cooling operation 9.4.1.3.1. Thermostat control • • • • compressor is off when intake air temperature - internal setting temperature • • • • compressor is on after waiting for 3 minutes, if the intake air temperature - internal setting temperature > compressor off point. 9.4.1.4. Soft dry o...

Page 78

9.4.1.6. Automatic operation this mode can be set using remote control and the operation is decided by remote control setting temperature, indoor intake air temperature and outdoor air temperature. During operation mode judgment, indoor fan motor (with speed of lo-) and outdoor fan motor are running...

Page 79

9.4.1.7. Indoor fan motor operation a. Basic rotation speed (rpm) • • • • required rotation speed for fan is set to respond to the remote control setting (10 rpm unit) [cooling, dry, fan] remote control — — o o o o o — — — tab (rpm) pshi shi hi me+ me me- lo lo- slo sslo cs-e15db4ew 600 600 560 520 ...

Page 80

B. Indoor fan control i. Indoor fan control operation outline 1. Cooling / dry 80 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 81

2. Heating ii. Auto fan speed 1. Cooling model no. A no. B no. C powerful program cs-e15db4ew 540 560 580 cs-e18db4ew 605 625 645 normal program cs-e15db4ew 480 500 520 cs-e18db4ew 545 565 585 quiet program cs-e15db4ew 460 480 500 cs-e18db4ew 525 545 565 81 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e...

Page 82

2. Heating note: a. Up: • • • • if move from lo, the fan speed will be shifted to maximum 1,520 rpm. • • • • if move from maximum, the fan speed no change. • • • • in up zone, 10 rpm is added for every 10s until maximum 1,520 rpm. B. Down: • • • • the fan speed will be decreased one step every 10 se...

Page 83

D. Deodorizing control i. Control condition control at cooling/dry operation and auto fan speed setting. No deodorizing control is performed during on timer standby operation and during anti-freezing control prevention. Ii. Operation the odor status is arranged as below and it is shifted as follows....

Page 84

9.4.1.9. Quiet operation (cooling mode/cooling area of dry mode) a. Purpose to provide quiet cooling operation compare to normal operation. B. Control condition a. Quiet operation start condition • • • • when “quiet” button at remote control is pressed. Quiet led illuminates. B. Quiet operation stop...

Page 85

B. Quiet operation stop condition 1. When one of the following conditions is satisfied, quiet operation stops: a. Powerful button is pressed. B. Stop by off/on switch. C. Timer “off” activates. D. Quiet button is pressed again. 2. When quiet operation is stopped, operation is shifted to normal opera...

Page 86

9.4.1.12. Delay on timer control delay on timer can be set using remote control, the unit with timer set will start operate earlier than the setting time. This is to provide a comfortable environment when reaching the set on time. 60 minutes before the set time, indoor (at fan speed of lo-) and outd...

Page 87

4. When the switch is pressed between 11 to 16 seconds and together with the signal from remote control (timer decrement button for 5s), the unit can be changed to different controlling setting (4 type of transmission codes). 5. When the switch is pressed between 16 to 21 seconds, either “h14” error...

Page 88: 10 Self Diagnosis Display

• • • • once abnormality has been detected during operation, the unit will immediately stop its operation. (timer led blinks.) • • • • although timer led goes off when power supply is turned off, if the unit is operated under a breakdown condition, the led will light up again. • • • • in operation a...

Page 89

10.2. Error code symbol diagnosis diagnosis method h11 indoor / outdoor abnormal communication this trouble display appears when indoor/outdoor unit communication fails to be established after 30 seconds or more. 1. Measure the voltage of the indoor/outdoor unit communication cables, and check wheth...

Page 90

Symbol diagnosis diagnosis method h30 outdoor discharge pipe temp. Sensor disconnected discharge sensor • • • • when the condition temperature is higher than the discharge temperature + (plus) 6°c, a sensor disconnection is detected, operation stops, and the trouble display appears (the timer lamp b...

Page 91

Symbol diagnosis diagnosis method h99 indoor operating unit freezing the restriction on the compressor frequency is started when the indoor unit heat exchanger temperature is between 8°c and 12°c. Operation stops if a temperature below 0°c continues for 6 minutes. Three minutes later, operation is s...

Page 92

Symbol diagnosis diagnosis method f96 ipm (power transistor module) or compressor overheating when this trouble is detected from the electrical parts radiation fin temperature sensor and olp output during operation, operation stops, and it is restarted 3 minutes later. If the trouble occurs on 4 occ...

Page 93

11 installation instructions 11.1. Wall type 93 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 94

94 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 95

95 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 96

96 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 97

97 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 98

98 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 99

99 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 100

100 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 101

11.2. Duct type 101 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 102

102 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 103

103 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 104

104 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 105

105 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 106

106 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 107

107 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 108

108 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 109

109 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 110

11.3. Ceiling floor type 110 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 111

111 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 112

112 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 113

113 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 114

114 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 115

115 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 116

11.4. Mini-cassette type 116 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 117

117 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 118

118 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 119

119 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 120

120 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 121

121 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 122

122 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 123

123 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 124

124 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 125: 12 Operating Instructions

12 operating instructions 125 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 126

126 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 127

127 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 128

128 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 129

129 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 130

130 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 131

131 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 132

132 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 133

133 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 134

134 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 135

135 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 136

136 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 137

137 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 138

138 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 139

13 installation and servicing air conditioner using r410a 13.1. Outline 13.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone la...

Page 140

D. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine o...

Page 141

13.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) • • • • this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) • • • •...

Page 142

5. Charging hose • • • • the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. 6. Vacuum pump adaptor • • • • when using a ...

Page 143

8. Electronic scale for refrigerant charging • • • • because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement sca...

Page 144

13.3. Refrigerant piping work when working with refrigerant piping, the following points must be carefully observed: no moisture od dust must be allowed to enter the piping, and there must be no refrigerant leaks. 1. Procedure and precautions for flaring work a. Cut the pipe use a pipe cutter, and c...

Page 145

2. Procedure and precautions for flare connection fig. 11 relation between the flare nut structure and flaring tool end table 11 r410a flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a (mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut t...

Page 146

13.3.3. Storing and managing piping materials 1. Types of piping and their storage the following is a general classification of the refrigerant pipe materials used for acs. Because the gas pressure of r410a is approximately 1.6 times as high as that of r22, copper pipes with the thickness shown in t...

Page 147

Precautions • • • • be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. • • • • make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. • • • • the gas pressure back fl...

Page 148

13.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. • • • • ch...

Page 149

Vacuum pump. Wait for 1-2 minutes, then check to make sure that the needle of the low pressure gauge has not returned. See fig. 13 for the remaining steps of this procedure. 5. Set the refrigerant cylinder onto the electronic scale, then connect the hose the cylinder and to the connection port for t...

Page 150

13.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n 2 ) flow. 1. Atta...

Page 151: 14 Disassembly Of Parts

1. Remove the front grille. 2. Remove the indoor control board. Fig. 2 fig. 3 fig. 4 fig. 5 14 disassembly of parts 14.1. Wall type 14.1.1. Indoor control board removal procedures fig. 1 151 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 152

1. Remove main electronic controller fig. 6 1. Remove cross flow fan and fan motor. Fig. 8 fig. 9 fig. 7 fig. 10 14.1.2. Electronic controller removal procedures 14.1.3. Cross flow fan and fan motor removal procedures 152 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 153

14.2. Duct type 14.2.1. Detaching the upper and inner casing 14.2.2. Detaching the control board 153 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 154

14.2.3. Detaching the fan 14.2.4. Detaching the fan motor and drain motor 154 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 155

14.3.1. Front grille removal procedure 1. Remove the intake grille and air filter from the front grille (fig. 1). Fig. 1 2. Remove the front grille by removing the screws (fig. 2). Fig. 2 3. Fan motor and control board (fig. 3). Fig. 3 14.3.2. Fan motor removal procedure 1. Remove two air guider blo...

Page 156

1. Open the intake grille from the front grille by moving the catchers to center (fig. 1). Fig. 1 2. Remove the control board cover by removing the screws (fig. 2). Fig. 2 3. Release the following parts (fig. 3): • • • • cn-stm1(wht) connector • • • • cn-stm1(wht) connector • • • • cn-stm2(ylm) conn...

Page 157

5. Remove the front grille by removing the screw a and screw b, c & d half way open (fig. 5). Fig. 5 6. Remove the air guider and drain pan complete by removing the screws (fig. 6). Fig. 6 7. Remove the turbo fan by removing the bolt (fig. 7). Fig. 7 8. Remove the fan motor by releasing the fan moto...

Page 158: 15 Technical Data

15 technical data 15.1. Operation characteristics 158 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 159

159 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 160

160 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 161

161 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 162

162 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 163

163 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 164

16 electronic circuit diagram 16.1. Wall type 164 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 165

165 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 166

166 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 167

167 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 168

168 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 169

16.1.1. Circuit diagram (remote control) 169 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 170

16.1.2. Printed circuit board (indoor unit) 170 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 171

16.2. Duct type 16.2.1. Circuit diagram (indoor units: cs-me10dd3eg / cs-e15dd3ew / cs-e18dd3ew) 171 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 172

16.2.2. Printed circuit board (indoor unit) 172 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 173

16.3. Ceiling floor type 16.3.1. Circuit diagram (indoor units: cs-me10dteg / cs-e15dtew / cs-e18dtew) 173 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 174

174 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 175

175 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 176

176 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 177

16.3.2. Circuit diagram (remote control) 177 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 178

16.3.3. Printed circuit board (indoor unit) 178 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 179

16.4. Mini-cassette type 16.4.1. Circuit diagram (indoor units: cs-e15db4ew / cs-e18db4ew) 179 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 180

180 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 181

181 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 182

182 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 183

183 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 184

16.4.2. Circuit diagram (remote control) 184 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 185

16.4.3. Printed circuit board (indoor unit) 185 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 186

17 exploded view and replacement parts list 17.1. Wall type 17.1.1. Exploded view (indoor unit) 186 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 187

17.1.2. Replacement parts list (indoor unit) models: cs-me7dkeg / cs-me7dkrg / cs-me7dkdg / cs-e9dkew / cs-me9dkrw / cs-e9dkdw / cs-e12dkew /cs-e12dkrw / cs-e12dkdw ref. No. Part name & description qty. Cs-me7dkeg cs-me7dkrg cs-me7dkdg cs-e9dkew cs-e9dkrw cs-e9dkdw cs-e12dkew cs-e12dkrw cs-e12dkdw r...

Page 188

17.1.3. Exploded view (indoor unit) 188 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 189

17.1.4. Replacement parts list (indoor unit) models: cs-e15dkew / cs-e15dkrw / cs-e15dkdw ref. No. Part name & description qty. Cs-e15dkew cs-e15dkrw cs-e15dkdw remarks 1 chassy complete 1 cwd50c1431 ← ← ← ← ← ← ← ← 2 fan motor 1 cwa981149 ← ← ← ← ← ← ← ← 3 cross folw fan complete 1 cwh02c1031 ← ← ←...

Page 190

17.1.5. Exploded view (indoor unit) 190 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 191

17.1.6. Replacement parts list (indoor unit) models: cs-e18dkew / cs-e18dkrw / cs-e18dkdw ref. No. Part name & description qty. Cs-e18dkew cs-e18dkrw cs-e18dkdw remarks 1 chassy complete 1 cwd50c1382 ← ← ← ← ← ← ← ← 2 fan motor 1 cwa981149 ← ← ← ← ← ← ← ← 3 cross folw fan complete 1 cwh02c1010 ← ← ←...

Page 192

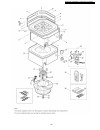

17.2. Duct type 17.2.1. Exploded view (indoor unit) 192 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 193

17.2.2. Replacement parts list (indoor unit) models: cs-me10dd3eg / cs-e15dd3ew / cs-e18dd3ew ref no. Part name & description qty. Cs-me10dd3eg cs-e15dd3ew cs-e18dd3ew remarks 1 float switch 1 cwa12161 ← ← ← ← ← ← ← ← 2 thermal fuse 1 cwa16c1038 ← ← ← ← ← ← ← ← 3 terminal board complete 1 cwa28k1045...

Page 194

17.3. Ceiling floor type 17.3.1. Exploded view (indoor unit) 194 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 195

17.3.2. Replacement parts list (indoor unit) models: cs-me10dteg / cs-e15dtew / cs-e18dtew ref no. Part name & description qty. Cs-me10dteg cs-e15dtew cs-e18dtew remarks 1 chassy complete 1 cwd50c1419 ← ← ← ← ← ← ← ← 2 fan motor 1 cwa921158 ← ← ← ← ← ← ← ← 3 supporter fan motor 2 cwd932270 ← ← ← ← ←...

Page 196

17.4. Mini-cassette type 17.4.1. Exploded view (indoor unit) 196 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 197

197 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 198

17.4.2. Replacement parts list (indoor unit) models: cs-e15db4ew / cs-e18db4ew ref no. Part name & description qty. Cs-e15db4ew cs-e18db4ew remarks 1 base pan ass’y 1 cwd52k1100 ← ← ← ← 2 inner polystyrene complete 1 cwg07c1047 ← ← ← ← 3 cabinet side plate ass’y 1 cwe041121 ← ← ← ← 4 cabinet side pl...

Page 199

17.4.3. Exploded view (indoor unit front grille) 199 cs-me7dkeg cs-me10dd3eg / cs-me10dteg cs-e15db4ew.

Page 200

17.4.4. Replacement parts list (indoor unit front grille) model: cz-bt12de (front grille complete) ref no. Part name & description qty. Part no. Remarks 1 front grille - complete 1 cwe11c3105 2 frone - front grille co. 1 cwe11c3353 4 a.S. Motor dc single 12v 250 ohm 2 cwa981105 5 bracket - a.S. Moto...