- DL manuals

- Panasonic

- Air Conditioner

- CS-E12PKEA

- Service Manual

Panasonic CS-E12PKEA Service Manual

© Panasonic Corporation 2012.

Order No: PAPAMY1212049CE

Indoor Unit

Outdoor Unit

CS-E9PKEA

CS-E12PKEA

CS-E15PKEA

CS-E18PKEA

CU-E9PKEA

CU-E12PKEA

CU-E15PKEA

CU-E18PKEA

Destination

Europe

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

WARNING

Summary of CS-E12PKEA

Page 1

© panasonic corporation 2012. Order no: papamy1212049ce indoor unit outdoor unit cs-e9pkea cs-e12pkea cs-e15pkea cs-e18pkea cu-e9pkea cu-e12pkea cu-e15pkea cu-e18pkea destination europe precaution of low temperature in order to avoid frostbite, be assured of no refrigerant leakage during the install...

Page 2: Table of Contents

2 table of contents 1. Safety precautions .............................................3 2. Specifications .....................................................5 3. Features.............................................................14 4. Location of controls and components..........15 4.1 indoor u...

Page 3: 1. Safety Precautions

3 1. Safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. • the caution items state...

Page 4

4 warning 20. During pump down operation, stop the compressor before remove the refrigeration piping. (removal of compressor while compressor is operating and valves are opened will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.) 21. After co...

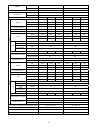

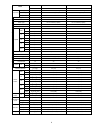

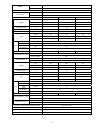

Page 5: 2. Specifications

5 2. Specifications indoor cs-e9pkea model outdoor cu-e9pkea performance test condition eurovent phase, hz single, 50 power supply v 230 min. Mid. Max. Kw 0.85 2.50 3.00 btu/h 2900 8530 10200 capacity kcal/h 730 2150 2580 running current a – 2.40 – input power w 170 515 710 annual consumption kwh – ...

Page 6

6 indoor cs-e9pkea model outdoor cu-e9pkea type hermetic motor (rotary) motor type brushless (4 poles) compressor output power w 900 type cross-flow fan material asg33 motor type dc / transistor (8-poles) input power w 44.9 output power w 40 cool rpm 630 qlo heat rpm 690 cool rpm 700 lo heat rpm 740...

Page 7

7 indoor cs-e9pkea model outdoor cu-e9pkea pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) standard length m (ft) 5.0 (16.4) length range (min – max) m (ft) 3 (9.8) ~ 15 (49.2) i/d & o/d height different m (ft) 5.0 (16.4) additional gas amount g/m (oz/ft) 20 (0.2) piping length for ad...

Page 8

8 indoor cs-e12pkea cs-e15pkea model outdoor cu-e12pkea cu-e15pkea performance test condition eurovent eurovent phase, hz single, 50 single, 50 power supply v 230 230 min. Mid. Max. Min. Mid. Max. Kw 0.85 3.50 4.00 0.98 4.20 5.00 btu/h 2900 11900 13600 3340 14300 17100 capacity kcal/h 730 3010 3440 ...

Page 9

9 indoor cs-e12pkea cs-e15pkea model outdoor cu-e12pkea cu-e15pkea type hermetic motor (rotary) hermetic motor (rotary) motor type brushless (4 poles) brushless (4 poles) compressor output power w 900 900 type cross-flow fan cross-flow fan material asg33 asg33 motor type dc / transistor (8-poles) dc...

Page 10

10 indoor cs-e12pkea cs-e15pkea model outdoor cu-e12pkea cu-e15pkea pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 12.70 (1/2) standard length m (ft) 5.0 (16.4) 5.0 (16.4) length range (min – max) m (ft) 3 (9.8) ~ 15 (49.2) 3 (9.8) ~ 15 (49.2) i/d & o/d height different ...

Page 11

11 indoor cs-e18pkea model outdoor cu-e18pkea performance test condition eurovent phase, hz single, 50 power supply v 230 min. Mid. Max. Kw 0.98 5.00 6.00 btu/h 3340 17100 20500 capacity kcal/h 840 4300 5160 running current a – 6.4 – input power w 280 1.44k 1.99k annual consumption kwh – 720 – w/w 3...

Page 12

12 indoor cs-e18pkea model outdoor cu-e18pkea type hermetic motor (rotary) motor type brushless (4 poles) compressor output power w 900 type cross-flow fan material asg33 motor type dc / transistor (8-poles) input power w 94.8 output power w 40 cool rpm 880 qlo heat rpm 860 cool rpm 900 lo heat rpm ...

Page 13

13 indoor cs-e18pkea model outdoor cu-e18pkea pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 12.70 (1/2) standard length m (ft) 5.0 (16.4) length range (min – max) m (ft) 3 (9.8) ~ 20 (65.6) i/d & o/d height different m (ft) 15.0 (49.2) additional gas amount g/m (oz/ft) 20 (0.2) piping length f...

Page 14: 3. Features

14 3. Features • inverter technology o wider output power range o energy saving o quick cooling o quick heating o more precise temperature control • environment protection o non-ozone depletion substances refrigerant (r410a) • long installation piping o long piping up to 15 meters (0.75 ~ 1.75hp) an...

Page 15

15 4. Location of controls and components 4.1 indoor unit 4.2 outdoor unit 4.3 remote control.

Page 16: 5. Dimensions

16 5. Dimensions 5.1 indoor unit 5.1.1 cs-e9pkea cs-e12pkea cs-e15pkea.

Page 17

17 5.1.2 cs-e18pkea.

Page 18

18 5.2 outdoor unit 5.2.1 cu-e9pkea cu-e12pkea 5.2.2 cu-e15pkea cu-e18pkea.

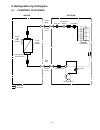

Page 19

19 6. Refrigeration cycle diagram 6.1 cu-e9pkea cu-e12pkea indoor outdoor intake air temp. Sensor pipe temp. Sensor liquid side 2-way valve 3-way valve gas side cooling heat exchanger (evaporator) heating compressor 4-ways valve condenser muffler muffler strainer expansion valve.

Page 20

20 6.2 cu-e15pkea cu-e18pkea indoor outdoor intake air temp. Sensor pipe temp. Sensor pipe temp. Sensor air temp. Sensor liquid side 2-way valve 3-way valve gas side cooling heat exchanger (evaporator) heating compressor condenser process tube strainer expansion valve 4-ways valve tank sensor dis. T...

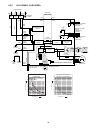

Page 21: 7. Block Diagram

21 7. Block diagram 7.1 cs-e9pkea cu-e9pkea cs-e12pkea cu-e12pkea fus e 1 0 3 ry -p w r ry -p wr 2 3 1 ms 3 ~ ct1 0 1 4- w a ys va lv e sc u m sc fus e 1 0 1 ic 1 9 c1 0 3 fu s e 3 0 1 te mp . Fus e si n g le ph as e pow e r su pp ly 1ø 23 0v 50 h z te mp . Fus e u l n 2 no ise f ilt er fus e 1 0 4 ...

Page 22

22 7.2 cs-e15pkea cu-e15pkea cs-e18pkea cu-e18pkea f u se3 fu s e 2 db 2 db 1 fu s e 1 p n u v w q1 3 2 ms 3 ~ 4- w a y s va lv e ry-c cr3 m c t 400 re a c t o r th1 ntc ry-ho t sc ry -a c r y -p w r pt c 2 db 3 th 2 nt c pt c 1 nois e f ilt er ry -p wr ry -p wr 2 1 m sc fu s e 3 0 1 te mp . Fu s e ...

Page 23

23 8. Wiring connection diagram 8.1 indoor unit fan motor cn-fm (wht) y 7 4 1 b w bl r m fuse301 t3.15a l250v ry-pwr ry-pwr2 y/g y/g temp. Fuse 102°c (3a) temp. Fuse 102°c (3a) evaporator 1 2 3 ac304 (red) ac303 (wht) g301 (grn) grounding terminal l w r g g p bl br terminal board grounding terminal ...

Page 24

24 8.2 outdoor unit 8.2.1 cu-e9pkea cu-e12pkea resistance of compressor windings model cu-e9pkea / cu-e12pkea connection 5rd102xbe21 ( Ω ) u-v 1.897 u-w 1.907 v-w 1.882 note: resistance at 20°c of ambient temperature..

Page 25

25 8.2.2 cu-e15pkea cu-e18pkea resistance of compressor windings model cu-e15pkea / cu-e18pkea connection 5rd132xba21 ( Ω ) u-v 1.897 u-w 1.907 v-w 1.882 note: resistance at 20°c of ambient temperature..

Page 26

26 9. Electronic circuit diagram 9.1 indoor unit.

Page 27

27 9.2 outdoor unit 9.2.1 cu-e9pkea cu-e12pkea sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 -10 0 10 temperature ( o c) r esi st an ce ( k Ω ) 20 30 40 50 1 2 1 2 outdoor air sensor outdoor heat exchanger sensor compressor temp. Sensor (thermistor) characteristics 70 60 50 40 30 20 10 ...

Page 28

28 9.2.2 cu-e15pkea cu-e18pkea to indoor unit ac-wht (white) cn-dcfm (white) ljp117 (green) fg01 (green) grn ylw/grn control board control board control board cabinet side plate blk wh t grn ac-blk (black) com3 (red) red gry l2-i (gray) gry l2-o (gray) reactor blu electro-magnetic coil (4-ways valve...

Page 29: 10. Printed Circuit Board

29 10. Printed circuit board 10.1 indoor unit 10.1.1 main printed circuit board 10.1.2 indicator printed circuit board.

Page 30

30 10.2 outdoor unit 10.2.1 cu-e9pkea cu-e12pkea.

Page 31

31 10.2.2 cu-e15pkea cu-e18pkea.

Page 32: 11. Installation

32 11. Installation instruction 11.1 select the best location 11.1.1 indoor unit • do not install the unit in excessive oil fume area such as kitchen, workshop and etc. • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a...

Page 33

33 11.2 indoor unit the mounting wall shall be strong and solid enough to prevent it from vibration. Dimension model c d e f g h e9****, e12****, e15**** 490 mm 82 mm 439 mm 432 mm 43 mm 95 mm e18**** 590 mm 82 mm 539 mm 532 mm 169 mm 219 mm the centre of installation plate should be at more than ○ ...

Page 34

34 11.2.2 indoor unit installation 11.2.2.1 for the right rear piping 11.2.2.2 for the right and right bottom piping 11.2.2.3 for the embedded piping (this can be used for left rear piping and bottom piping also.).

Page 35

35 11.2.3 connect the cable to the indoor unit the power supply cord, indoor and outdoor unit connection cable can be connected without removing the front grille. 1 install the indoor unit on the installing holder that mounted on the wall. 2 open the front panel and grille door by loosening the scre...

Page 36

36 7 remove the tapes and connect the power supply cord and connection cable between indoor unit and outdoor unit according to the diagram below. 8 secure the power supply cord and connection cable onto the control board with the holder. 9 close grille door by tighten with screw and close the front ...

Page 37

37 11.2.3.2 cutting and flaring the piping 1 please cut using pipe cutter and then remove the burrs. 2 remove the burrs by using reamer. If burrs are not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3 please make flare after inserting the ...

Page 38

38 11.3 outdoor unit 11.3.1 install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2 when installing at roof, please consider stron...

Page 39

39 11.3.3 evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1 connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. O be sure to connect...

Page 40

40 11.3.4 connect the cable to the outdoor unit 1 remove the control board cover from the unit by loosening the screw. 2 connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 (1.0 ~ 1.75hp) or 4 × 2.5 mm 2 (2.0hp) flexible cord, type designatio...

Page 41: 12. Operation

41 12. Operation control 12.1 basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer maintai...

Page 42

42 12.1.5 automatic operation • this mode can be set using remote control and the operation is decided by remote control setting temperature, remote control operation mode and indoor intake air temperature. • during operation mode judgment, indoor fan motor (with speed of lo-) is running for 30 seco...

Page 43

43 [heating] • according to indoor pipe temperature, automatic heating fan speed is determined as follows. B. Feedback control • immediately after the fan motor started, feedback control is performed once every second. • during fan motor on, if fan motor feedback ≥ 2550 rpm or counter increase, fan ...

Page 44

44 12.4 airflow direction • there are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by vertical vanes). • control of airflow direction can be automatic (angles of direction is determined by operation mode, heat exchanger temperature and intake ...

Page 45

45 12.4.2 horizontal airflow • automatic horizontal airflow direction can be set using remote control; the vane swings left and right within the angles as stated below. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as figure 1 below. It does not s...

Page 46

46 12.6 quiet operation (heating) • purpose o to provide quiet heating operation compare to normal operation. • control condition o quiet operation start condition when “powerful/quiet” button at remote control is pressed. Powerful/quiet led illuminates. O quiet operation stop condition when one of ...

Page 47

47 12.8 timer control • to turn on or off the unit at a preset time. 12.8.1 on timer control.

Page 48

48.

Page 49

49 12.9 auto restart control • when the power supply is cut off during the operation of air conditioner, the compressor will re-operate within three to four minutes (there are 10 patterns between 2 minutes 58 seconds and 3 minutes 52 seconds to be selected randomly) after power supply resumes. • thi...

Page 50: 13. Protection

50 13. Protection control 13.1 protection control for all operations 13.1.1 restart control (time delay safety control) • the compressor will not turn on within 3 minutes from the moment operation stops, although the unit is turned on again by pressing off/on button at remote control within this per...

Page 51

51 13.1.4 compressor overheating prevention control • instructed frequency for compressor operation will be regulated by compressor discharge temperature. The changes of frequency are as below. • if compressor discharge temperature exceeds 107°c, compressor will be stopped, occurs 4 times per 20 min...

Page 52

52 13.2 protection control for cooling & soft dry operation 13.2.1 outdoor air temperature control • the compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in the diagram below. • this control will begin 1 minute after the compressor starts. • compresso...

Page 53

53 13.2.6 odor cut control • to reduce the odor released from the unit. O start condition auto fan speed is selected during cool or dry operation. During freeze prevention control and timer preliminary operation, this control is not applicable. O control content depends on compressor conditions: 1. ...

Page 54: 14. Servicing

54 14. Servicing mode 14.1 auto off/on button 1 auto operation mode the auto operation will be activated immediately once the auto off/on button is pressed. This operation can be used to operate air conditioner with limited function if remote control is misplaced or malfunction. 2 test run operation...

Page 55

55 4 remote control receiving sound off/on mode the remote control receiving sound off/on mode will be activated if the auto off/on button is pressed continuously for more than 16 seconds (4 “beep” sounds will occur at 16th seconds to identify the remote control receiving sound off/on mode is in sta...

Page 56: 15. Troubleshooting

56 15. Troubleshooting guide 15.1 refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

Page 57

57 15.1.1 relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditioner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refr...

Page 58

58 15.2 breakdown self diagnosis function 15.2.1 self diagnosis function (three digits alphanumeric code) • once abnormality has occurred during operation, the unit will stop its operation, and timer led blinks. • although timer led goes off when power supply is turned off, if the unit is operated u...

Page 59

59 15.3 error codes table diagnosis display abnormality / protection control abnormality judgment protection operation problem check location h00 no memory of failure — normal operation — — h11 indoor/outdoor abnormal communication after operation for 1 minute indoor fan only operation can start by ...

Page 60

60 diagnosis display abnormality / protection control abnormality judgment protection operation problem check location h41 abnormal wiring or piping connection — — wrong wiring and connecting pipe, expansion valve abnormality • check indoor/outdoor connection wire and connection pipe • expansion val...

Page 61

61 15.4 self-diagnosis method 15.4.1 h11 (indoor/outdoor abnormal communication) malfunction decision conditions • during startup and operation of cooling and heating, the data received from outdoor unit in indoor unit signal transmission is checked whether it is normal. Malfunction caused • faulty ...

Page 62

62 15.4.2 h12 (indoor/outdoor capacity rank mismatched) malfunction decision conditions • during startup, error code appears when different types of indoor and outdoor units are interconnected. Malfunction caused • wrong models interconnected. • wrong indoor unit or outdoor unit pcbs mounted. • indo...

Page 63

63 15.4.3 h14 (indoor intake air temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the indoor intake air temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector con...

Page 64

64 15.4.4 h15 (compressor temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor compressor temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector connectio...

Page 65

65 15.4.5 h16 (outdoor current transformer) malfunction decision conditions • an input current, detected by current transformer ct, is below threshold value when the compressor is operating at certain frequency value for 3 minutes. Malfunction caused • lack of gas • broken ct (current transformer) •...

Page 66

66 15.4.6 h19 (indoor fan motor – dc motor mechanism locked) malfunction decision conditions • the rotation speed detected by the hall ic during fan motor operation is used to determine abnormal fan motor (feedback of rotation > 2550rpm or malfunction caused • operation stops due to short circuit in...

Page 67

67 15.4.7 h23 (indoor pipe temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the indoor heat exchanger temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector conne...

Page 68

68 15.4.8 h27 (outdoor air temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor air temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector connection. • f...

Page 69

69 15.4.9 h28 (outdoor pipe temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector connection. •...

Page 70

70 15.4.10 h30 (compressor discharge temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor discharge pipe temperature sensor are used to determine sensor errors. Malfunction caused • faulty conn...

Page 71

71 15.4.11 h32 (outdoor heat exchanger temperature sensor 2 abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor heat exchanger temperature sensor are used to determine sensor errors. Malfunction caused • faulty ...

Page 72

72 15.4.12 h33 (unspecified voltage between indoor and outdoor) malfunction decision conditions • the supply power is detected for its requirement by the indoor/outdoor transmission. Malfunction caused • wrong models interconnected. • wrong indoor unit and outdoor unit pcbs used. • indoor unit or ou...

Page 73

73 15.4.13 h34 (outdoor heat sink temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor heat sink temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector co...

Page 74

74 15.4.14 h36 (outdoor gas pipe sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor gas pipe temperature sensor are used to determine sensor errors. Malfunction caused • faulty connector connection. • fa...

Page 75

75 15.4.15 h37 (outdoor liquid pipe temperature sensor abnormality) malfunction decision conditions • during startup and operation of cooling and heating, the temperatures detected by the outdoor liquid pipe temperature sensor are used to determine sensor errors. Malfunction caused • faulty connecto...

Page 76

76 15.4.16 h97 (outdoor fan motor – dc motor mechanism locked) malfunction decision conditions • the rotation speed detected by the hall ic during fan motor operation is used to determine abnormal fan motor. Malfunction caused • operation stops due to short circuit inside the fan motor winding. • op...

Page 77

77 15.4.17 h98 (error code stored in memory and no alarm is triggered / no timer led flashing) malfunction decision conditions • indoor high pressure is detected when indoor heat exchanger is detecting very high temperature when the unit is operating in heating operation. • phenomena: unit is stoppi...

Page 78

78 15.4.18 h99 (indoor freeze prevention protection: cooling or soft dry) error code will not display (no timer led blinking) but store in eeprom malfunction decision conditions • freeze prevention control takes place (when indoor pipe temperature is lower than 2°c) malfunction caused • air short ci...

Page 79

79 15.4.19 f11 (4-way valve switching failure) malfunction decision conditions • when indoor heat exchanger is cold during heating (except deice) or when indoor heat exchanger is hot during cooling and compressor operating, the 4-way valve is detected as malfunction. Malfunction caused • indoor heat...

Page 80

80 15.4.20 f17 (indoor standby units freezing abnormality) malfunction decision conditions • when the different between indoor intake air temperature and indoor pipe temperature is above 10°c or indoor pipe temperature is below -1.0°c. Remark: when the indoor standby unit is freezing, the outdoor un...

Page 81

81 15.4.21 f90 (power factor correction protection) malfunction decision conditions • to maintain dc voltage level supply to power transistor. • to detect high dc voltage level after rectification. Malfunction caused • during startup and operation of cooling and heating, when power factor correction...

Page 82

82 15.4.22 f91 (refrigeration cycle abnormality) malfunction decision conditions • the input current is low while the compressor is running at higher than the setting frequency. Malfunction caused • lack of gas. • 3-way valve close. Troubleshooting.

Page 83

83 15.4.23 f93 (compressor rotation failure) malfunction decision conditions • a compressor rotation failure is detected by checking the compressor running condition through the position detection circuit. Malfunction caused • compressor terminal disconnect • faulty outdoor pcb • faulty compressor t...

Page 84

84 15.4.24 f95 (outdoor high pressure protection: cooling or soft dry) malfunction decision conditions • during operation of cooling or soft dry, when outdoor unit heat exchanger high temperature data is detected by the outdoor unit heat exchanger thermistor. Malfunction caused • outdoor heat exchan...

Page 85

85 15.4.25 f96 (ipm overheating) malfunction decision conditions • during operating of cooling and heating, when ipm temperature data (100°c) is detected by the ipm temperature sensor. Multi models only o compressor overheating: during operation of cooling and heating, when the compressor ol is acti...

Page 86

86 15.4.26 f97 (compressor overheating) malfunction decision conditions • during operation of cooling and heating, when compressor tank temperature data (112°c) is detected by the compressor tank temperature sensor. Malfunction caused • faulty compressor tank temperature sensor • 2/3 way valve close...

Page 87

87 15.4.27 f98 (input over current detection) malfunction decision conditions • during operation of cooling and heating, when an input over-current (x value in total running current control) is detected by checking the input current value being detected by current transformer (ct) with the compresso...

Page 88

88 15.4.28 f99 (dc peak detection) malfunction decision conditions during startup and operation of cooling and heating, when inverter dc peak data is received by the outdoor internal dc peak sensing circuitry. Malfunction caused • dc current peak due to compressor failure. • dc current peak due to d...

Page 89

89 warning 16. Disassembly and assembly instructions high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 16.1 cs-e9pkea cs-e12pke...

Page 90

90 figure 3 figure 4 16.1.1.3 to remove discharge grille figure 5.

Page 91

91 16.1.1.4 to remove control board figure 6 16.1.1.5 to remove cross flow fan and indoor fan motor figure 7.

Page 92

92 figure 8 figure 9.

Page 93

93 figure 10

Page 94

94 16.2 cs-e18pkea 16.2.1 indoor electronic controllers, cross flow fan and indoor fan motor removal procedures 16.2.1.1 to remove front grille figure 4 16.2.1.2 to remove electronic controller figure 5.

Page 95

95 figure 6 figure 4 16.2.1.3 to remove discharge grille figure 5 16.2.1.4 to remove control board figure 6.

Page 96

96 16.2.1.5 to remove cross flow fan and indoor fan motor figure 7 figure 8.

Page 97

97 figure 9 figure 10

Page 98

98 16.3 outdoor electronic controller removal procedure 16.3.1 cu-e9pkea cu-e12pkea caution! When handling electronic controller, be careful of electrostatic discharge. 1 remove the 5 screws of the top panel. Fig. 1 2 remove the 8 screws of the front panel. Fig. 2 3 remove the screw of the terminal ...

Page 99

99 16.3.2 cu-e15pkea cu-e18pkea 1 remove the 4 screws of the top panel. Fig. 1 2 remove the 10 screws of the front panel. Fig. 2 3 remove the top cover of the electronic controller. Fig. 3 4 remove the control board. Fig. 4 5 remove the 8 screws of the electronic controller. Fig. 5 caution! When han...

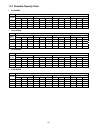

Page 100: 17. Technical

100 17. Technical data 17.1 operation characteristics 17.1.1 cs-e9pkea cu-e9pkea • cooling characteristic [condition] indoor temperature: 27/19°c piping length: 5m remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 101

101 • piping length characteristic [condition] indoor/outdoor temperature: 27/19°c, 35/24°c remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 102

102 • heating characteristic [condition] indoor temperature: 20/-°c piping length: 5m remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 103

103 • piping length characteristic [condition] indoor/outdoor temperature: 20/-°c, 7/6°c remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 104

104 17.1.2 cs-e12pkea cu-e12pkea • cooling characteristic [condition] indoor temperature: 27/19°c piping length: 5m remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 105

105 • piping length characteristic [condition] indoor/outdoor temperature: 27/19°c, 35/24°c remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 106

106 • heating characteristic [condition] indoor temperature: 20/-°c piping length: 5m remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 107

107 • piping length characteristic [condition] indoor/outdoor temperature: 20/-°c, 7/6°c remote condition: high fan speed, heat 30°c comp. Hz: f h.

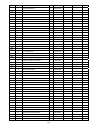

Page 108

108 17.1.3 cs-e15pkea cu-e15pkea • cooling characteristic [condition] indoor temperature: 27/19°c piping length: 5m remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 109

109 • piping length characteristic [condition] indoor/outdoor temperature: 27/19°c, 35/-°c remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 110

110 • heating characteristic [condition] indoor temperature: 20/-°c piping length: 5m remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 111

111 • piping length characteristic [condition] indoor/outdoor temperature: 20/-°c, 7/6°c remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 112

112 17.1.4 cs-e18pkea cu-e18pkea • cooling characteristic [condition] indoor temperature: 27/19°c piping length: 5m remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 113

113 • piping length characteristic [condition] indoor/outdoor temperature: 27/19°c, 35/-°c remote condition: high fan speed, cool 16°c comp. Hz: f c.

Page 114

114 • heating characteristic [condition] indoor temperature: 20/-°c piping length: 5m remote condition: high fan speed, heat 30°c comp. Hz: f h.

Page 115

115 • piping length characteristic [condition] indoor/outdoor temperature: 20/-°c, 7/6°c remote condition: high fan speed, heat 30°c comp. Hz: f h.

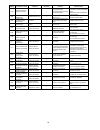

Page 116

116 17.2 sensible capacity chart • cu-e9pkea 230v outdoor temperature 30 °c 35 °c 40 °c 46 °c indoor wet bulb tc shc ip tc shc ip tc shc ip tc shc ip 17.0 °c 2.48 1.88 0.47 2.32 1.80 0.51 2.16 1.73 0.54 1.96 1.65 0.59 19.0 °c 2.50 0.52 19.5 °c 2.72 1.97 0.48 2.55 1.89 0.52 2.37 1.82 0.55 2.15 1.73 0...

Page 117

117 18. Exploded view and replacement parts list 18.1 indoor unit 18.1.1 cs-e9pkea cs-e12pkea cs-e15pkea note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 118

118 safety ref. No. Part name & description qty. Cs-e9pkea cs-e12pkea cs-e15pkea remark 1 chassis complete 1 cwd50c1730 ← ← 2 fan motor 1 arw7666accb ← ← o 3 cross - flow fan complete 1 cwh02c1135 ← ← 4 bearing assy 1 cwh64k1010 ← ← 5 screw - cross - flow fan 1 cwh551146 ← ← 6 evaporator 1 cwb30c428...

Page 119

119 safety ref. No. Part name & description qty. Cs-e9pkea cs-e12pkea cs-e15pkea remark 55 bag 1 cwg861515 ← ← 56 shock absorber (l) 1 cwg713484 ← ← 57 shock absorber (r) 1 cwg713485 ← ← 58 c.C.Case 1 cwg568509 ← ← (note) • all parts are supplied from papamy, malaysia (vendor code: 00029488). • “o” ...

Page 120

120 18.1.2 cs-e18pkea note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 121

121 safety ref. No. Part name & description qty. Cs-e18pkea remark 1 chassis complete 1 cwd50c1742 2 fan motor 1 arw7676accb o 3 cross - flow fan complete 1 cwh02c1136 4 bearing assy 1 cwh64k1010 5 screw - cross - flow fan 1 cwh551146 6 evaporator 1 cwb30c4217 7 flare nut (liquid) 1 cwt251030 8 flar...

Page 122

122 safety ref. No. Part name & description qty. Cs-e18pkea remark 53 installation instruction 1 cwf615635 54 remote control cable 1 cwa221109 55 bag 1 cwg861498 56 shock absorber (l) 1 cwg713484 57 shock absorber (r) 1 cwg713485 58 c.C.Case 1 cwg569437 (note) • all parts are supplied from papamy, m...

Page 123

123 18.2 outdoor unit 18.2.1 cu-e9pkea cu-e12pkea note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 124

124 safety ref. No. Part name & description qty. Cu-e9pkea cu-e12pkea remark 1 chassis complete 1 cwd52k1277 ← 2 sound proof material 1 cwg302742 ← 3 fan motor bracket 1 cwd541167 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 ars6411ac ← o 6 screw - fan motor mount 4 cwh55252j ← 7 propel...

Page 125

125 18.2.2 cu-e15pkea cu-e18pkea note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 126

126 safety ref. No. Part name & description qty. Cu-e15pkea cu-e18pkea remark 1 chassis complete 1 cwd52k1261 ← 2 anti - vibration bushing 3 cwh50077 ← 3 compressor 1 5rd132xba21 ← o 4 nut - compressor mount 3 cwh56000j ← 5 sound proof material 1 cwg302630 ← 6 fan motor bracket 1 cwd541153 ← 7 fan m...