- DL manuals

- Panasonic

- Air Conditioner

- CS-E15EKEA

- Service Manual

Panasonic CS-E15EKEA Service Manual

© 2005 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0511088C2

Air Conditioner

CS-E15EKEA CU-E15EKEA

CS-E18EKEA CU-E18EKEA

CS-E21EKEA CU-E21EKEA

TABLE OF CONTENTS

PAGE

PAGE

1 Safety Precautions----------------------------------------------- 3

2 Specifications ----------------------------------------------------- 5

2.1. CS-E15EKEA CU-E15EKEA -------------------------- 5

2.2. CS-E18EKEA CU-E18EKEA -------------------------- 7

2.3. CS-E21EKEA CU-E21EKEA -------------------------- 9

3 Features ------------------------------------------------------------ 11

4 Location of Controls and Components ------------------12

4.1. Indoor Unit--------------------------------------------------12

4.2. Outdoor Unit -----------------------------------------------13

4.3. Remote Control -------------------------------------------13

5 Dimensions--------------------------------------------------------14

5.1. Indoor Unit & Remote Control -------------------------14

5.2. Outdoor Unit----------------------------------------------- 16

6 Refrigeration Cycle Diagram -------------------------------- 17

7 Block Diagram --------------------------------------------------- 18

8 Wiring Connection Diagram--------------------------------- 19

8.1. Indoor Unit ------------------------------------------------- 19

8.2. Outdoor Unit----------------------------------------------- 20

9 Printed Circuit Board ------------------------------------------ 21

9.1. Indoor Unit ------------------------------------------------- 21

9.2. Outdoor Unit----------------------------------------------- 25

10 Installation Instruction ---------------------------------------- 27

10.1. CS-E15EKEA --------------------------------------------- 27

10.2. CS-E18EKEA CS-E21EKEA ------------------------- 33

Summary of CS-E15EKEA

Page 1

© 2005 panasonic ha air-conditioning (m) sdn bhd (11969-t). All rights reserved. Unauthorized copying and distribution is a violation of law. Order no. Mac0511088c2 air conditioner cs-e15ekea cu-e15ekea cs-e18ekea cu-e18ekea cs-e21ekea cu-e21ekea table of contents page page 1 safety precautions-----...

Page 2

2 11 operation and function -------------------------------------- 39 11.1. Basic function -------------------------------------------- 39 11.2. Airflow direction ------------------------------------------ 39 11.3. Quiet operation (cooling mode/cooling area of soft dry mode) ------------------------...

Page 3: 1 Safety Precautions

3 1 safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. • the caution items stated...

Page 4

4 3. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the furniture. 4. Pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70°f (30 - 40°c) higher. Please use a high t...

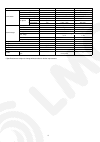

Page 5: 2 Specifications

5 2 specifications 2.1. Cs-e15ekea cu-e15ekea unit cs-e15ekea cu-e15ekea performance test condition eurovent cooling capacity kw kcal/h btu/h 4.40 (0.90 - 5.00) 3,780 (770 - 4,300) 15,000 (3,070 - 17,100) heating capacity kw kcal/h btu/h 5.50 (0.90 - 7.10) 4,730 (770 - 6,110) 18,800 (3,070 - 24,200)...

Page 6

6 • specifications are subject to change without notice for further improvement. Air circulation type cross-flow fan propeller fan material asht-18 p.P motor type transistor (8-poles) transistor (8-poles) rate output w 30 40 fan speed lo (cool/heat) rpm 980 / 1,160 — me (cool/heat) rpm 1,220 / 1,360...

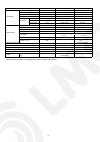

Page 7: 2.2.

7 2.2. Cs-e18ekea cu-e18ekea unit cs-e18ekea cu-e18ekea performance test condition eurovent cooling capacity kw kcal/h btu/h 5.30 (0.90 - 6.00) 4,560 (770 - 5,160) 18,100 (3,070 - 20,500) heating capacity kw kcal/h btu/h 6.60 (0.90 - 8.00) 5,680 (770 - 6,880) 22,500 (3,070 - 27,300) moisture removal...

Page 8

8 • specifications are subject to change without notice for further improvement. Air circulation type cross-flow fan propeller fan material asht-18 p.P motor type transistor (8-poles) transistor (8-poles) rate output w 30 40 fan speed lo (cool/heat) rpm 1,170 / 1,240 — me (cool/heat) rpm 1,330 / 1,3...

Page 9: 2.3.

9 2.3. Cs-e21ekea cu-e21ekea unit cs-e21ekea cu-e21ekea performance test condition eurovent cooling capacity kw kcal/h btu/h 6.30 (0.90 - 7.10) 5,420 (770 - 6,110) 21,500 (3,070 - 24,200) heating capacity kw kcal/h btu/h 7.20 (0.90 - 8.50) 6,190 (770 - 7,310) 24,600 (3,070 - 29,000) moisture removal...

Page 10

10 • specifications are subject to change without notice for further improvement. Air circulation type cross-flow fan propeller fan material asht-18 p.P motor type transistor (8-poles) transistor (8-poles) rate output w 30 40 fan speed lo (cool/heat) rpm 1,170 / 1,270 — me (cool/heat) rpm 1,355 / 1,...

Page 11: 3 Features

11 3 features • product - four modes of operation selection - powerful mode operation - on timer and off timer - ionizer mode operation - quiet mode operation - automatic air swing and manual adjusted by remote control for horizontal and vertical airflow - supersonic air purifying system with super ...

Page 12: 4.1.

12 4 location of controls and components 4.1. Indoor unit 4.1.1. Cs-e15ekea 4.1.2. Cs-e18ekea cs-e21ekea.

Page 13: 4.2.

13 4.2. Outdoor unit 4.3. Remote control.

Page 14: 5 Dimensions

14 5 dimensions 5.1. Indoor unit & remote control 5.1.1. Cs-e15ekea.

Page 15

15 5.1.2. Cs-e18ekea cs-e21ekea.

Page 16: 5.2.

16 5.2. Outdoor unit.

Page 17

17 6 refrigeration cycle diagram if piping length is over common length, additional refrigerant should be added as shown in the table. Model piping size rated length (m) common length (m) max. Elevation (m) max. Piping length (m) additional refrigerant (g/m) gas liquid e15ekea 1/2” 1/4” 7.5 7.5 5 15...

Page 18: 7 Block Diagram

18 7 block diagram.

Page 19: 8 Wiring Connection Diagram

19 8 wiring connection diagram 8.1. Indoor unit.

Page 20: 8.2.

20 8.2. Outdoor unit.

Page 21: 9 Printed Circuit Board

21 9 printed circuit board 9.1. Indoor unit 9.1.1. Main printed circuit board.

Page 22

22.

Page 23

23 9.1.2. Power printed circuit board.

Page 24

24.

Page 25: 9.2.

25 9.2. Outdoor unit.

Page 26

26.

Page 27: 10 Installation Instruction

27 10 installation instruction 10.1. Cs-e15ekea 10.1.1. Select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circula- tion. • a place where air circulation in the room is good. • a place where drainage...

Page 28

28 10.1.3. Indoor unit 10.1.3.1. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 680 mm at right and 570 mm at left of the wall. The distance from installation plate edge to ceiling s...

Page 29

29 3. For the embedded piping (this can be used for left rear piping & left bottom piping also.).

Page 30

30 10.1.3.4. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 flexible cord, type designation 245 iec 57...

Page 31

31 10.1.4. Outdoor unit 10.1.4.1. Install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizon- tally by bolt nut (ø10 mm). 2. When installing at roof, please cons...

Page 32

32 10.1.4.3. Evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. • be sure to con...

Page 33

33 10.2. Cs-e18ekea cs-e21ekea 10.2.1. Select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circula- tion. • a place where air circulation in the room is good. • a place where drainage can be easily do...

Page 34

34 10.2.3. Indoor unit 10.2.3.1. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 550 mm at right and left of the wall. The distance from installation plate edge to ceiling should more...

Page 35

35 3. For the embedded piping (this can be used for left rear piping & left bottom piping also.).

Page 36

36 10.2.3.4. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 flexible cord, type designation 245 iec 57...

Page 37

37 10.2.4. Outdoor unit 10.2.4.1. Install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2. When installing at roof, please consid...

Page 38

38 10.2.4.3. Evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. • be sure to con...

Page 39: 11 Operation and Function

39 11 operation and function 11.1. Basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer ma...

Page 40

40 1. Automatic vertical airflow direction can be set using remote control; the vane swings up and down within the angles as stated above. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as figure 1 below. When the air conditioner is stopped using r...

Page 41

41 1. When one of the following conditions is satisfied, quiet operation stops: a. Powerful button is pressed. B. Stop by off/on switch. C. Timer “off” activates. D. Quiet button is pressed again. 2. When quiet operation is stopped, operation is shifted to normal operation with previous setting. 3. ...

Page 42: 11.5. On Timer Control

42 c. Control contents a. Fan speed manual 1. Fan speed is changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of hi, me, lo for 3db. 2. Fan speed for quiet operation is -100 rpm from setting fan speed. 3. Fan speed auto • if fm lo -100 rpm reduce from norma...

Page 43: 11.6. Off Timer Control

43 11.6. Off timer control off timer can be set using remote control, the unit with timer set will stop operate at set time. 11.7. Auto restart control 1. When the power supply is cut off during the operation of air conditioner, the compressor will re-operate within three to four minutes (there are ...

Page 44: 12 Protection Control

44 12 protection control 12.1. Protection control for all operations 12.1.1. Time delay safety control 1. The compressor will not start for three minutes after stop of operation. 2. This control is not applicable if the power supply is cut off and on again or after 4-way valve deices condition. 12.1...

Page 45

45 12.1.5. Compressor overheating prevention control instructed frequency for compressor operation will be regulated by compressor top temperature. The changes of frequency are as below figure. 12.2. Protection control for cooling & soft dry operation 12.2.1. Outdoor air temperature control the comp...

Page 46

46 • control contents: outdoor fan speed (switch to zone a and b minimum fan speed). Outdoor total current (zone c) higher than the specified. • cancellation condition: when one of above is not satisfied. 12.2.3. Freeze prevention control 1. When indoor heat exchanger temperature is lower than 2 °c ...

Page 47

47 12.3.3. Overload protection control the compressor operating frequency is regulated in accordance to indoor heat exchanger temperature as shown in below figures..

Page 48: 13 Servicing Mode

48 13 servicing mode 13.1. Auto switch operation the below operations will be performed by pressing the “auto” switch. 1. Auto operation mode the auto operation will be activated immediately once the auto switch is pressed. 2. Test run operation (for pump down/servicing purpose) the test run operati...

Page 49: 13.3. Indication Panel

49 13.3. Indication panel note: • if power led is blinking, the possible operations of the unit are hot start, during deice operation, operation mode judgment, or delay on timer sampling. • if timer led is blinking, there is an abnormality operation occurs. • if ionizer, led is blinking, there is an...

Page 50: 14 Troubleshooting Guide

50 14 troubleshooting guide 14.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

Page 51

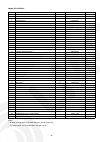

51 14.2. Relationship between the condition of the air conditioner and pressure and electric current • carry out the measurements of pressure, electric current, and temperature fifteen minutes after an operation is started. Cooling mode heating mode condition of the air conditoner low pressure high ...

Page 52

52 14.3. Breakdown self diagnosis function 14.3.1. Self diagnosis function (three digits alphanumeric code) • once abnormality has occurred during operation, the unit will stop its operation, and timer or both timer and ion leds blink. (the unit does not stop under ion abnormality.) • although timer...

Page 53: 14.4. Error Codes Table

53 14.4. Error codes table note: “o” - frequency measured and fan speed fixed. The memory data of error code is erased when the power supply is cut off, or press the auto switch until “beep” sound heard following by pressing the “check” button at remote control. Although operation forced to stop whe...

Page 54

54 15 disassembly and assembly instructions 15.1. Indoor electronic controller and control board • caution! When handling electronic controller, be careful of electrostatic discharge. • be sure to return the wiring to its original position. • there are many high voltage components within the heat si...

Page 55

55.

Page 56

56 15.2. Indoor cross flow fan and fan motor.

Page 57

57.

Page 58

58 15.3. Outdoor electronic controller removal procedure 1. Remove the top panel and front panel fig. 10 2. Remove the outdoor electronic controller fig. 11 fig. 12 caution! When handling electronic controller, be careful of electrostatic discharge..

Page 59: 16 Technical Data

59 16 technical data 16.1. Operation characteristics 16.1.1. Cs-e15ekea cu-e15ekea cooling characteristic at different outdoor air temperature [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 60

60

Page 61

61 heating characteristic at different outdoor air temperature [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 62

62.

Page 63

63 cooling characteristic at different piping length [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 64

64.

Page 65

65 heating characteristic at different piping length [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 66

66.

Page 67

67 16.1.2. Cs-e18ekea cu-e18ekea cooling characteristic at different outdoor air temperature [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 68

68.

Page 69

69 heating characteristic at different outdoor air temperature [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 70

70

Page 71

71 cooling characteristic at different piping length [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 72

72.

Page 73

73 heating characteristic at different piping length [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 74

74.

Page 75

75 16.1.3. Cs-e21ekea cu-e21ekea cooling characteristic at different outdoor air temperature [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 76

76.

Page 77

77 heating characteristic at different outdoor air temperature [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 78

78.

Page 79

79 cooling characteristic at different piping length [condition] indoor room temperature : 27/19 °c remote control setting : hi fan, cool 16 °c compressor frequency : rated cooling voltage : 230 v.

Page 80

80

Page 81

81 heating characteristic at different piping length [condition] indoor room temperature : 20 °c remote control setting : hi fan, heat 30 °c compressor frequency : rated heating voltage : 230 v.

Page 82

82.

Page 83

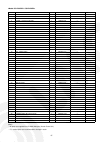

83 16.2. Sensible capacity chart ● cs-e15ekea cu-e15ekea ● cs-e18ekea cu-e18ekea ● cs-e21ekea cu-e21ekea outdoor temp. ( °c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0 °c 4.36 3.31 1.25 4.08 3.17 1.35 3.79 3.05 1.44 3.45 2.90 1.56 19.0 °c 4.40 1.37 19.5 °c 4.79 3....

Page 84: 17.1. Cs-E15Ekea

84 17 exploded view and replacement parts list 17.1. Cs-e15ekea note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 85

85 (note) • all parts are supplied from phaam, malaysia (vendor code: 061). • “o” marked parts are recommended to be kept in stock. Ref no. Part name & description qty. Cs-e15ekea remarks 1 chassy complete 1 cwd50c1431 2 fan motor 1 cwa981149j o 3 cross flow fan complete 1 cwh02c1045 4 bearing ass’y...

Page 86

86 17.2. Cs-e18ekea cs-e21ekea note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 87

87 (note) • all parts are supplied from phaam, malaysia (vendor code: 061). • “o” marked parts are recommended to be kept in stock. Ref no. Part name & description qty. Cs-e18ekea cs-e21ekea remarks 1 chassy complete 1 cwd50c1382 ← 2 fan motor 1 cwa981149j ← o 3 cross flow fan complete 1 cwh02c1010 ...

Page 88

88 17.3. Cu-e15ekea cu-e18ekea cu-e21ekea note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 89

89 ref. No. Description & name qty. Cu-e15ekea cu-e18ekea cu-e21ekea remarks 1 chassy ass’y 1 cwd50k2085 ← ← 2 anti-vibration bushing 3 cwh50077 ← ← 3 compressor 1 5cs130xad04 ← ← o 4 nut-compressor mount 3 cwh56000j ← ← 5 sound proof material 1 cwg302302 ← ← 6 fan motor bracket 1 cwd541084 cwd54105...

Page 90

90 (note) • all parts are supplied from phaam, malaysia (vendor code: 061). • “o” marked parts are recommended to be kept in stock. [phaam] printed in malaysia sfyw0605 - 01 56 drain hose 1 cwh5850080 ← ← 57 packing 1 cwb81012 ← ← 58 sound proof material 1 cwg302290 cwg302270 ← 59 sound proof materi...