1 safety precautions 3 2 specification 5 2.1. Cs-e18eku cu-e18eku 5 2.2. Cs-e21eku cu-e21eku 7 3 location of controls and components 9 3.1. Indoor unit 9 3.2. Outdoor unit 9 3.3. Remote control 9 4 dimension 10 4.1. Indoor unit & remote control 10 4.2. Outdoor unit 11 5 refrigeration cycle diagram 1...

12.2. Relationship between the condition of the air conditioner and pressure and electric current 35 12.3. Breakdown self diagnosis function 36 12.4. Error codes table 37 13 disassembly and assembly instructions 38 13.1. Indoor electronic controller and control board 38 13.2. Indoor cross flow fan a...

1 safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. • the caution items stated h...

1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in ins...

2 specification 2.1. Cs-e18eku cu-e18eku unit cs-e18eku cu-e18eku performance test condition csa cooling capacity kw btu/h 5.20 (1.30 - 5.80) 17,700 (4,400 - 19,700) heating capacity kw btu/h 6.30 (1.30 - 7.70) 21,400 (4,400 - 19,700) moisture removal l/h pint/h 1.8 3.8 power source (phase, voltage,...

Unit cs-e18eku cu-e18eku power cord length number of core-wire inch 70 - 29/32” (1.5mm 2 ) — — dimensions height inch (mm) 10 - 13/16 (275) 29 - 17/32 (750) width inch (mm) 39 - 9/32 (998) 34 - 7/16 (875) depth inch (mm) 9 - 1/16 (230) 13 - 19/32 (345) net weight lb (kg) 24 (11.0) 108 (49.0) compres...

2.2. Cs-e21eku cu-e21eku unit cs-e21eku cu-e21eku performance test condition csa cooling capacity kw btu/h 6.10 (1.30 - 6.85) 20,800 (4,400 - 23,400) heating capacity kw btu/h 6.90 (1.30 - 8.30) 23,400 (4,400 - 28,200) moisture removal l/h pint/h 2.6 5.5 power source (phase, voltage, cycle) ø v hz s...

Unit cs-e21eku cu-e21eku dimensions height inch (mm) 10 - 13/16 (275) 29 - 17/32 (750) width inch (mm) 39 - 9/32 (998) 34 - 7/16 (875) depth inch (mm) 9 - 1/16 (230) 13 - 19/32 (345) net weight lb (kg) 20 (9.0) 79 (36) compressor type — hermetic motor motor type — brushless (4-pole) rated output w —...

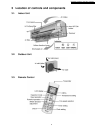

3 location of controls and components 3.1. Indoor unit 3.2. Outdoor unit 3.3. Remote control 9 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

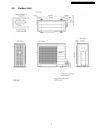

4 dimension 4.1. Indoor unit & remote control 10 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

4.2. Outdoor unit 11 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

5 refrigeration cycle diagram 12 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

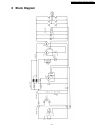

6 block diagram 13 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

7 wiring diagram 7.1. Cs-e18eku cs-e21eku 14 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

7.2. Cu-e18eku cu-e21eku 15 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

8.1. Indoor unit 8 printed circuit board 16 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

8.2. Outdoor unit 17 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

Indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where drainage can be easily done. • a place where noise prevention is taken into consideration. ...

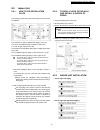

9.2.1. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The wall must be able to withstand the weight of the unit. The centre of installation plate should be at more than 21-21/32” at right and left of the wall. The distance from installati...

3. For the embedded piping (this can be used for left rear piping and left bottom piping also.) 20 cs-e18eku cu-e18eku / cs-e21eku cu-e21eku.

9.2.4. Indoor unit electrical wiring 1. Remove the control board metal cover. 2. Unscrew the conduit cover & fix the conduit connector to conduit cover with lock nut, then secure it against chassis. 3. Connecting wire between indoor unit and outdoor unit shall be ul listed or csa approved 4 × awg16 ...

1. Open the front panel. 2. Remove the air filter. 3. Put air purifying filter into place as shown in illustration at right. When reinstalling the front grille, first set the vertical airflow direction louvers to the horizontal position and then carry out above steps 2 - 3 in the reverse order. 9.2....

9.3.1. Install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø13/32”). 2. When installing at roof, please consider strong wind and earthqu...

9.3.3. Evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. • be sure to connect t...

1. Remove top panel. 2. Remove control board cover. 3. Remove plugs. 4. Fix the conduit connectors to the conduit holes with lock- nuts, then secure them. 5. Connecting wire between indoor unit and outdoor unit should be ul listed or csa approved 4 x awg16 wire. 6. Secure the wire onto the control b...

10 operation and control 10.1. Basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer mainta...

1. Automatic vertical airflow direction can be set using remote control; the vane swings up and down within the angles as stated above. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as figure 1 below. When the air conditioner is stopped using remo...

B. Quiet operation stop condition 1. When one of the following conditions is satisfied, quiet operation stops: a. Powerful button is pressed. B. Stop by off/on switch. C. Timer “off” activates. D. Quiet button is pressed again. 2. When quiet operation is stopped, operation is shifted to normal opera...

A. Powerful button is pressed. B. Stop by off/on switch. C. Timer “off” activates. D. Quiet button is pressed again. 2. When quiet operation is stopped, operation is shifted to normal operation with previous setting. 3. When fan speed is changed, quiet operation is shifted to quiet operation of the ...

10.1.5. On timer control on timer can be set using remote control, the unit with timer set will start operate earlier than the setting time. This is to provide a comfortable environment when reaching the set on time. 60 minutes before the set time, indoor (at fan speed of lo-) and outdoor fan motor ...

10.2. Protection control 10.2.1. Time delay safety control • compressor will not start for three minutes after stop of the operation. 10.2.2. 30 seconds forced operation • once compressor starts the operation, it will not stop its operation for 30 seconds. However, it can be stopped with the remote ...

10.2.7. Compressor protection control (refrigeration cycle abnormality) in cooling and dry operations 1. When compressor is operated continuously for 5 minutes in the maximum cooling power: a running current of 0.7 - 1.4a and “[indoor intake air temperature] - [indoor heat exchanger temperature]” 2....

11 servicing mode 11.1. Auto switch operation the below operations will be performed by pressing the “auto” switch. 1. Auto operation mode the auto operation will be activated immediately once the auto switch is pressed and release before 5 sec.. 2. Test run operation (for pump down/servicing purpos...