- DL manuals

- Panasonic

- Air Conditioner

- CS-F14DD3E5

- Service Manual

Panasonic CS-F14DD3E5 Service Manual

1

SERVICE INFORMATION

3

1.1.

Example of trouble at test operation

3

1.2.

Caution of test operation

3

1.3.

Caution during automatic address setting

3

1.4.

Caution during installation

3

1.5.

Operation range

3

2

FEATURES

4

2.1.

Hide-away type

4

2.2.

Outdoor unit

4

2.3.

A brand-new control method using the latest in technology

5

3

SPECIFICATION

6

3.1.

CS-F14DD3E5 CU-B14DBE5

6

3.2.

CS-F18DD3E5 CU-B18DBE5

7

4

DIMENSIONS

8

© 2006 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-F14DD3E5 CU-B14DBE5

CS-F18DD3E5 CU-B18DBE5

4.1.

CS-F14DD3E5 CS-F18DD3E5

8

4.2.

CU-B14DBE5 CU-B18DBE5

9

5

REFRIGERATION CYCLE

10

5.1.

CS-F14DD3E5 CU-B14DBE5 CS-F18DD3E5 CU-

B18DBE5

10

6

BLOCK DIAGRAM

11

6.1.

CS-F14DD3E5 CS-F18DD3E5

11

6.2.

CU-B14DBE5

11

6.3.

CU-B18DBE5

12

7

WIRING DIAGRAM

13

7.1.

CS-F14DD3E5 CS-F18DD3E5

13

7.2.

CU-B14DBE5

14

7.3.

CU-B18DBE5

15

8

WIRED REMOTE CONTROL OPERATING INSTRUCTIONS 16

8.1.

Name and function of each part

16

Air Conditioner

CONTENTS

Page

Page

ORDER NO. MAC0602013C2

Summary of CS-F14DD3E5

Page 1

1 service information 3 1.1. Example of trouble at test operation 3 1.2. Caution of test operation 3 1.3. Caution during automatic address setting 3 1.4. Caution during installation 3 1.5. Operation range 3 2 features 4 2.1. Hide-away type 4 2.2. Outdoor unit 4 2.3. A brand-new control method using ...

Page 2

8.2. Remote control - display 17 8.3. Remote control - panel 18 8.4. How to set remote control day and time 19 8.5. How to select the timer 19 8.6. Daily timer setting 20 8.7. Weekly timer setting 21 9 operation detail 23 9.1. Cooling operation 23 9.2. Heating operation 24 9.3. Soft dry operation 24...

Page 3: 1 Service Information

1 service information notice of address setting for new duct / new outdoor unit. The new duct type / new outdoor models are possible to have address setting for twin control by automatic when main power supply is switched on. (manual address setting is also possible by using dip switch on indoor uni...

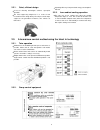

Page 4: 2 Features

2.1. Hide-away type 2.1.1. Compact design • the height has been reduced to 25 cm, the equipment can be installed in limited spaces. 2.1.2. Versatile installation • the indoor unit is designed in order that air will also enter from below, for easier installation under different conditions. • the equi...

Page 5

2.2.1. Quiet, efficient design • a host of silencing technologies achieves super-quiet operation. • the noise-suppressing winglet fan is a result of new research into vane design theory. The unique curved shape suppresses the generation of vortexes, thus reduces air flows noise. 2.3.1. Twin operatio...

Page 6: 3 Specification

3 specification 3.1. Cs-f14dd3e5 cu-b14dbe5 item / model indoor unit outdoor unit main body cs-f14dd3e5 cu-b14dbe5 cooling capacity kw 3.8 btu/h 13,000 heating capacity kw 4.3 btu/h 14,700 refrigerant charge-less m 20 standard air volume for high speed m 3 /min hi 17 hi 54 cfm hi 600 hi 1907 externa...

Page 7

3.2. Cs-f18dd3e5 cu-b18dbe5 item / model indoor unit outdoor unit main body cs-f18dd3e5 cu-b18dbe5 cooling capacity kw 5.0 btu/h 17,100 heating capacity kw 5.6 btu/h 19,100 refrigerant charge-less m 20 standard air volume for high speed m 3 /min hi 17 hi 57 cfm hi 600 hi 2013 external static pressur...

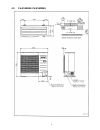

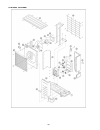

Page 8: 4 Dimensions

4 dimensions 4.1. Cs-f14dd3e5 cs-f18dd3e5 8.

Page 9

4.2. Cu-b14dbe5 cu-b18dbe5 9.

Page 10: 5 Refrigeration Cycle

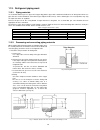

5 refrigeration cycle 5.1. Cs-f14dd3e5 cu-b14dbe5 cs-f18dd3e5 cu-b18dbe5 10

Page 11: 6 Block Diagram

6 block diagram 6.1. Cs-f14dd3e5 cs-f18dd3e5 6.2. Cu-b14dbe5 11.

Page 12

6.3. Cu-b18dbe5 12.

Page 13: 7 Wiring Diagram

7 wiring diagram 7.1. Cs-f14dd3e5 cs-f18dd3e5 13.

Page 14

7.2. Cu-b14dbe5 14.

Page 15

7.3. Cu-b18dbe5 15.

Page 16

Remote the off/on button cannot be used. Local all wired remote control buttons can be used. Time/time setting display check display fan speed display operation mode selection display filter reset display (appears after the cumulative running time reaches approximately 2,500 hours of operation.) tem...

Page 17

8.2. Remote control - display 17.

Page 18

8.3. Remote control - panel 18.

Page 19

8.4. How to set remote control day and time • the day and time need to be set when you turn on the power for the first time or after a long time has elapsed since the power was last turned on. • the day and time become the standard time for all the timer operations. • set the day and time accurately...

Page 20

Clock display (to set current day and time) note: • the above display is shown if no valid timer setting is made. • if valid timer setting is made. − timer and setting will be displayed. − if you want to check the current time and day, press “mode button” once. (however, after a few seconds, the dis...

Page 21

Final display of daily timer: 8.7. Weekly timer setting • display • how to set weekly timer − you can set the timer for 1 week (monday to sunday) with 6 programs per day. − on-timer can be set together with your desired temperature. However, this temperature will be used continuously. − cannot set 2...

Page 22

For example, if you want to set: a - monday to friday: same time, 1st program on 9:00 & 2nd program off 16:00. B - only wednesday: additional 3rd program off 12:30 & 4th program on 13:30. C - only saturday: 1st program on 10:00 with 20°c & 2nd program off 14:00. D - sunday: holiday. No need to set a...

Page 23: 9 Operation Detail

9 operation detail 9.1. Cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • cooling operation time diagram. 23.

Page 24

9.2. Heating operation • heating operation can be set using remote control. • this operation is applied to warm up the room temperature reaches the setting temperature set on the remote control. • heating operation time diagram. 9.3. Soft dry operation • soft dry operation can be set using remote co...

Page 25

9.6. Normal control 9.6.1. Cooling indoor fan control • manual fan speed operation starts at high, medium or low speed set by remote control. • auto fan speed when operation starts, or shifting to thermostat on condition from thermostat off condition, indoor fan operates as below. Thermostat & compr...

Page 26

9.6.3. Cooling outdoor fan control • during cooling operation, outdoor fan speed changes according to outdoor pipe temperature. • the fan speed is controlled by the timing of turning the outdoor fan on and off within an interval. • when outdoor pipe temperature increases, internal timing also increa...

Page 27

9.7.4. Energy save control • during cooling operation, press "economy" button at remote control to enable energy saving operation. • the air conditioner judges the stable condition, where the different between indoor suction temperature and setting temperature is 1°c for 30 minutes and moderately sh...

Page 28

9.7.8. Time delay safe control • the compressor will not start for three minutes after stop of operation. 9.7.9. Outdoor fan remaining heat removal control • when compressor stops, outdoor fan operates at high speed for 1 minute to remove the remaining heat. 9.7.10. Crank case heater control • crank...

Page 29

• press test run button for 1 second. Sw1 located at outdoor printed circuit board. • during pump down operation, push the test run button again for 1 second to stop the pump down operation. • the pump down operation runs for 10 minutes. 9.8. Protection control 9.8.1. Outdoor low-pressure protection...

Page 30

9.8.5. Ct disconnection detection control • ct disconnection detection control detects if the ct sensor works normally. • the ct disconnection detection activates when: − ct input value is maintained at compressor shutdown status (1.5a or less) consecutively for 2 seconds when the compressor is oper...

Page 31

9.8.11. Low-pressure switch disconnection error detection control • low-pressure switch disconnection is detected when low-pressure switch input continuously open for 1 minute while compressor shutdown. • during this error, low-pressure switch error is displayed. 9.9. Test run • test run is necessar...

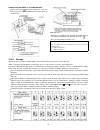

Page 32

10.1. Pipe length 10 installation instruction 10.1.1. Correction of capacities correction of capacities according to the connecting pipe length. The data of rated capacities (marked on the name plate) are based on 7.5 metres connecting pipe and horizontal installation. Cs-f14dd3e5, cs-f18dd3e5 pipin...

Page 33

10.2. Position of the centre gravity model name outside dimensions net weight centre of gravity width (mm) depth (mm) height (mm) kg x (mm) y (mm) z (mm) cu-b14dbe5 900 320 795 55 560 150 320 cu-b18dbe5 900 320 795 57 560 150 320 33.

Page 34

This mark means “caution” or “warning”. This mark means “earth”. 10.3. Indoor unit installation duct type air conditioners installation instructions precautions in terms of safety carry out installation work with reliability after thorough reading of this “precautions in terms of safety”. • precauti...

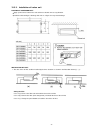

Page 35

No. Parts name q’ty 1 thermal insulator for refrigerant pipe 2 2 hose clip for thermal insulator 5 3 m10 flange washer 4 4 m10 flat washer 4 5 thermal insulator for drainage hole 1 6 duct flange r 1 7 duct flange l 1 8 screws 4 • (6) and (7) should be installed when the duct will be installed at the...

Page 36

4. The indoor unit must be away from heat and steam sources, but avoid installing it near an entrance. 5. The indoor unit must allow easy draining. 6. The indoor unit must allow easy connection to the outdoor unit. 7. Place the indoor unit easy water drainage. (suitable dimension “h” is necessary to...

Page 37

10.3.3. Installation of indoor unit position of supension bolt • apply a joint-canvas between the unit and duct to absorb unnecessary vibration. • install the unit learning to a drainage hole side as a figure for easy water drainage. Installation of duct 1. The duct of the air inlet could be install...

Page 38

2. The panel bottom could be changed into the air inlet (case of (c)) as shown in the illustration below. 3. When the duct of air inlet will be installed, install the duct flange side r & l to the air inlet with accessories as shown in the illustration. 4. The filter could be removed from any one of...

Page 39

1. Brazing for piping. A. Execute brazing before tightening the flare nut. B. Brazing must be executed while blowing nitrogen gas. (this prevents generation of oxidized scale in copper pipe.) 2. When there is a lot of brazings for long piping, install a strainer midway of the piping. (the strainer i...

Page 40

10.3.6. Heat insulation caution be sure to perform heat insulation on the drain, liquid and gas piping. Imperfection in heat insulation work leads to water leakage. 1. Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over 120°c). 2. Precautions in h...

Page 41

10.3.7. Electrical wiring as to main power source and cable size of outdoor unit, read the installation manual attached to the outdoor unit. The units must be installed in accordance with applicable national and local regulations. Warning the units installed by a professional installer must be suppl...

Page 42

Connecting the wires to the control box • remove two screws , remove the control box cover, and then connect the wires by following the procedure given in the illustration. • remove the control box for electrical connection between the indoor and outdoor unit. (remove two screws ). • use the cord cl...

Page 43

(remote controller address setting) (refer to the installation manual which is provided with the remote controller for details.) • two remote controllers (including the wireless remote controller) can be connected. However, remote control thermistor setting is not possible. • as for [master/slave] s...

Page 44

Is circulation of air adequate? Is draining smooth? Is heat insulation complete (refrigerant and drain piping)? Is there any leakage of refrigerant? Is remote controller switch operated? Is there any faulty wiring? Are the terminal screws loosened? M3... 69-98n.Cm {7-10kgf.Cm} m4... 157-196n.Cm {16-...

Page 45

This mark means “caution” or “warning”. This mark means “earth”. 10.4. Outdoor unit installation air conditioners outdoor unit installation instructions precautions in terms of safety carry out installation work with reliability after thorough reading of this “precautions in terms of safety”. • prec...

Page 46

Part name q’ty diagram application protective bushing 2 for protecting electrical wires banding strap 3 for tying electrical wires together heat pump-types only part name q’ty diagram application drain elbow as 1 for connecting the drain pipe (with ring seat) warnings wiring shall be connected secur...

Page 47

B. Prevention measure for refrigerant piping prevention measure for refrigerant piping is very important work to prevent water-dust-rubbish from getting in. All piping terminals need sealing such as shown below. Place period of work method of seal outside more than 1 month pinch less than 1 month pi...

Page 48

For the use of a gas cylinder without siphon inside, turn it upside down and use it. (we recommend manifold with sight glass.) caution do not use a “charge cylinder”. Caution as a rule, please collect all existing refrigerants in the system outside the system when the refrigerant leakage occurs by t...

Page 49

12. Be sure to leave enough space around the outdoor unit to maintain proper performance and to allow access for routine maintenance. • allow enough space from any obstacles as shown in fig. 1.2 below in order to prevent short-circuits from occurring. (if installing more than one outdoor unit, make ...

Page 50

• if a drain pipe needs to be installed, insert the accessory drain elbow into the mounting hole at the bottom of the outdoor unit, and connect a hose with an inside diameter of 15mm to this drain elbow. (the hose is not supplied.) if using the drain elbow, install the outdoor unit on a base which i...

Page 51

Caution use a material with good heat-resistant properties as the heat insulation for the pipes. Be sure to insulate both the gas-side and liquid-side pipes. If the pipes are not adequately insulated, condensation or water leakages may occur. 1.5 hp 2 hp (14 18 type) liquid-side pipes material that ...

Page 52

2.5 hp 6 hp (24 ~ 50 type) • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of 30m. If the equivalent pipe length used will be 30m or less, no additional charging will be necessary. • if the equivalent pipe length will be between ...

Page 53

Terminal screw tightening torque n.Cm {kgf.Cm} m3 69 ~ 98 {7 ~ 10} m4 157 ~ 196 {16 ~ 20} m5 196 ~ 245 {20 ~ 25} earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. • power supply specifica...

Page 54

10.4.10. Connecting power supply cables caution • for three phase model, never operate the unit by pressing the electromagnetic switch. • never correct the phase by switching over any of the wires inside the unit. 10.4.11. Precautions with regard to test operation • use only insulation tool to switc...

Page 55

Short circuit of the blow-out air smooth flow of the drain reliable thermal insulation leakage of refrigerant mistake in wiring reliable connection of the grand wire looseness in terminal screw, fastening torque m3... 69-98n.Cm {7-10kgf.Cm} m4... 157-196n.Cm {16-20kgf.Cm} m5... 196-245n.Cm {20-25kgf...

Page 56

10.5. Wired remote controller installation wired remote controller installation manual • before installing the wired remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installation manual provided with the indoor unit. • after installing the wired remote c...

Page 57

10.5.3. Remote controller installation • be sure to turn off the main power before installing and connecting the remote controller. (if the remote controller is connected while the power is still turned on, the remote controller displays may not appear.) if no displays appear on the remote controlle...

Page 58

Note − be sure to use only the accessory screws. − do not bend the lower case when tightening the screws. (if the screws are overtightened, damage may result.) − do not remove the protective tape which is affixed to the upper case circuit board. • if installing the remote controller with the remote ...

Page 59

If remote control cable is embedded if installing with the remote control cable exposed 1. Embed an outlet box (jis c 8336) into the wall, and then secure the remote controller base plate to the outlet box with the two accessory m4 screws. Make sure that the base plate is flat against the wall at th...

Page 60

[manual setting] automatic address resetting for group control • the address settings for group control (air conditioner nos. 1 to 16) can be reset automatically. 1. When operation is stopped, press for 5 seconds, continue the test run switch to display “00” (will be local mode). 2. Press the up (te...

Page 61

10.5.5. Test operation • turn on the main power. • after 3 minutes have passed since the power was turned on, press the off/on switch on the remote controller. (no operation occurs within 3 minutes after the power was turned on.) • press the test run switch within 1 minute of pressing the off/on swi...

Page 62

• you can then switch between the display for the previous problem and the problem before that by pressing the up (timer) down (timer) switches. • press the check switch once more to return to the normal display. Example of previous problem display example of abnormality display before previous disp...

Page 63

11 installation & servicing air conditioner 11.1. Outline 11.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone layer in the ear...

Page 64

D. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine o...

Page 65

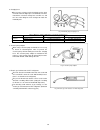

11.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) • this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) • in the r410...

Page 66

5. Charging hose • the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. 6. Vacuum pump adaptor • when using a vacuum pump ...

Page 67

8. Electronic scale for refrigerant charging • because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement scale gla...

Page 68

11.3. Refrigerant piping work when working with refrigerant piping, the following points must be carefully observed: no moisture or dust must be allowed to enter the piping, and there must be no refrigerant leaks. 1. Procedure and precautions for flaring work a. Cut the pipe use a pipe cutter, and c...

Page 69

2. Procedure and precautions for flare connection table 11 r410a flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a (mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut type 1/4 6.35 0.8 0 - 0.5 1.0 - 1.5 1.5 - 2.0 3/8 9.52 0.8 0 - 0.5 1.0 ...

Page 70

Precautions • be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. • make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. • the gas pressure back flow prevention valv...

Page 71

11.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. • check to...

Page 72

3. Fully open the handle lo of the manifold gauge, turn on the power of the vacuum pump and continue the vacuum process for at least one hour. 4. Confirm that the low pressure gauge shows a reading of -0.1 mpa (-76 cmhg), then fully close the handle lo, and turn off the vacuum pump. Wait for 1-2 min...

Page 73

11.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n 2 ) flow. 1. Atta...

Page 74: 12 Trouble Shooting Guide

12 trouble shooting guide if test operation does not proceed correctly carry out test operation after approximately 12 hours have passed since the power was turned on (crankcase heater is energized). If operation is started by using the remote control within 1 minute of turning on the power, the out...

Page 75

(when remote control display shows "power supply") clock setting, and no timer setting (when remote control display shows "no power supply") 75.

Page 76

12.2. During twin operation system example 1. The main power is turned on while the transmission wires between the indoor units are not connected. (open circuit at section a or b) symptom remote control unit : "check" flashes error code : f30-01 (connected indoor capacity error) indoor unit no.1 : l...

Page 77

Error code : f30-01 (connected indoor capacity error) indoor unit : led1 on p.C.B flashes outdoor unit : led6, 7 on p.C.B flashes 4. The main power is turned on and the connection wire is all ok. If operation starts in this condition, combination of the outdoor unit and indoor unit will result in ab...

Page 78

12.3. During group control operation system example 1. The main power is turned on while the transmission wires between the indoor units are not connected. (open circuit at section a or b or c) symptom operation of indoor unit no.1 and no.3 is possible. However "check" flashes in the remote control ...

Page 79

12.4. Test operation and self diagnosis 12.4.1. Test run (forced cooling mode and heating mode) 1. Always use a properly-insulated tool to operate the switch on the circuit board. (do not use your finger or any metallic object.) 2. Never turn on the power supply unit until all installation work has ...

Page 80

12.4.3. Test operation using the wired remote control 1. Check that "cool" is displayed on the lcd, and then press the off/on button to start test operation. 2. After pressing the off/on button, press the test run button within 1 minute. 3. Then, the pipe temperature (gas pipe) will be displayed in ...

Page 81

The air conditioner no."01" appears during normal installation and use. When using group control, a different number may appear. The air conditioner no. Can be displayed by pressing the air conditioner no. Button. (=same as temp. Up and down button) when an abnormality occurs at this unit, "check" f...

Page 82

12.5. Emergency operation if there is an abnormality in the temperature thermistor (disconnect or shorted), indoor unit cannot be operated. If abnormality detected in the indoor or outdoor unit, turn off the main power supply and find the cause. Check the resistance of each thermistor of both indoor...

Page 83

12.6. Self-diagnosis error code table • the display screen on the wired remote control unit and the self-diagnosis leds (red) on the outdoor unit printed circuit board in the outdoor unit can be used to indicate where the location of a problem is. Refer to the table below to remove the cause of the ...

Page 84

Led8 unit no. (when twin operation) • the led1 (green) illuminates to indicate that the microprocessor on the printed circuit board is operating normally. If the led is switched off is flashing irregularly. Check the power supply, and turn it off and then back on again. Master unit problem slave uni...

Page 85: 13 Technical Data

13 technical data 13.1. Sound data 85.

Page 86

86.

Page 87

13.2. Sound measurement point 13.2.1. Indoor unit 13.2.2. Outdoor unit 87.

Page 88

13.3. Discharge and suction pressure 13.3.1. Saturation temperature of discharge and suction pressure cooling 88.

Page 89

Heating 89.

Page 90

Tc : cooling capacity shc : sensible heat capacity ipt : cooling power consumption 13.4. Capacity and power consumption 13.4.1. Cooling performance 13.4.1.1. Cs-f14dd3e5 cu-b14dbe5 model cooling capacities are based on conditions cs-f14dd3e5 cu-b14dbe5 single phase, 50hz, 230v cooling capacity indoo...

Page 91

91.

Page 92

Tc : cooling capacity shc : sensible heat capacity ipt : cooling power consumption 13.4.1.2. Cs-f18dd3e5 cu-b18dbe5 model cooling capacities are based on conditions cs-f18dd3e5 cu-b18dbe5 single phase, 50hz, 230v cooling capacity indoor temp. 27°c d.B. 19°c w.B. 5.0 kw outdoor temp. 35°c d.B. Standa...

Page 93

93.

Page 94

13.4.2. Heating performance 13.4.2.1. Cs-f14dd3e5 cu-b14dbe5 model heating capacities are based on conditions cs-f14dd3e5 cu-b14dbe5 single phase, 50hz, 230v heating capacity indoor temp. 20°c d.B. 4.3 kw outdoor temp. 7°c d.B. 6°c w.B. Standard air volume 17 m 3 /min 13.4.2.2. Cs-f18dd3e5 cu-b18dbe...

Page 95

13.5. Fan performance 13.5.1. Cs-f14dd3e5 fan performance test report fan performance curve 95.

Page 96

13.5.2. Cs-f18dd3e5 fan performance test report fan performance curve 96.

Page 97

13.6. Safety device 13.6.1. Indoor unit indoor unit heat pump model cs-f14dd3e5 cs-f18dd3e5 cooling only model for fan motor protection internal off °c 135 135 protector on °c 85 85 for condensation temperature protection control off °c 58 58 heat exchanger reset °c 54 54 thermistor for p.C.B curren...

Page 98

13.7. Operating characteristics s.C. : starting current r.C. : running current ipt : power consumption 98.

Page 99: 14 Replacement Parts

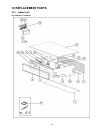

14 replacement parts 14.1. Indoor unit cs-f14dd3e5, cs-f18dd3e5 99.

Page 100

All parts are supplied from taiwan (ptw). Cs-f14dd3e5, cs-f18dd3e5 ref. No. Parts name parts number quantity per 1 unit rohs conformity cs-f14dd3e5 cs-f18dd3e5 1 cabinet (bottom) p02-t08030r 1 1 o 2 drain pan p42-t02900r 1 1 o 3 evaporator p45-t07900r 1 1 o 4 distributor as. P45-t07830r 1 1 o 5 cabi...

Page 101

14.2. Outdoor unit cu-b14dbe5, cu-b18dbe5 101.

Page 102

Cu-b14dbe5, cu-b18dbe5 102.

Page 103

No. Part description qty. Cu-b14dbe5 cu-b18dbe5 1 base pan assy 1 cwd52k1159 ← 2 compressor 1 5ks150dbn21 5ks205dah21 3 anti-vibration bushing 3 cwh50055 ← 4 nut-compressor mount 3 cwh561049 ← 5 packing 3 cwb811017 ← 6 crankcase heater 1 cwa341033 ← 7 condenser complete 1 cwb32c1806 ← 8 tube assy (c...

Page 104: 15 Print Pattern

15 print pattern 15.1. Indoor unit • indoor unit printed circuit board (main) 104.

Page 105

15.2. Outdoor unit • outdoor unit printed circuit board (main) 105 [phaam] printed in malaysia sfyw0605 - 01.