- DL manuals

- Panasonic

- Air Conditioner

- CS-F50DTE5

- Service Manual

Panasonic CS-F50DTE5 Service Manual

1 Service Information

3

1.1.

Example of trouble at test operation

3

1.2.

Caution of test operation

3

1.3.

Caution during automatic address setting

3

1.4.

Operation range

4

2 Features

5

2.1.

New design

5

2.2.

Such quietness!

5

2.3.

Easy installation

6

© 2005 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-F50DTE5 CU-L50DBE8

2.4.

Piping

6

2.5.

Easy maintenance

6

2.6.

Auto fan mode (indoor unit)

6

2.7.

Low-noise outdoor units

7

2.8.

Improved workability

8

2.9.

A brand-new control method

9

2.10. Wired Remote Control

10

2.11. Wireless Remote Control

10

Air Conditioner

CONTENTS

Page

Page

Order No. MAC0502038C2

Summary of CS-F50DTE5

Page 1

1 service information 3 1.1. Example of trouble at test operation 3 1.2. Caution of test operation 3 1.3. Caution during automatic address setting 3 1.4. Operation range 4 2 features 5 2.1. New design 5 2.2. Such quietness! 5 2.3. Easy installation 6 © 2005 panasonic ha air-conditioning (m) sdn bhd ...

Page 2

2.12. Group control equipment 11 3 specification 12 3.1. Product specification 12 4 dimensions 13 4.1. Cs-f50dte5 13 4.2. Cu-l50dbe8 14 5 refrigeration cycle 15 6 block diagram 16 6.1. Cs-f50dte5 16 6.2. Cu-l50dbe8 17 7 wiring diagram 18 7.1. Cs-f50dte5 18 7.2. Cu-l50dbe8 19 8 operation details 20 8...

Page 3: 1 Service Information

1 service information notice of address setting for new ceiling / new outdoor unit. The new ceiling / new outdoor models are possible to have address setting for twin control by automatic when main power supply is switched on. (manual address setting is also possible by using dip switch on indoor un...

Page 4

1.4. Operation range 1.4.1. Power supply the applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the ra...

Page 5: 2 Features

2.1. New design 2.1.1. Gentle curved styling • • • • the base has gentle curves which express a functional beauty. It spreads the air quietly over a wide area. 2.2. Such quietness! 2.2.1. Several new mechanism add up to low 46 db noise (l50bt - high fan speed) 1. Delta throat fan a delta throat (pro...

Page 6

2.3. Easy installation 2.3.1. Easy suspension • • • • a suspension bolt fixing bracket with 4-point support is attached to the main unit, which increases the space available for installation. 2.3.2. Two installation methods : standard and wall • • • • in addition to the standard (1) ceiling installa...

Page 7

[product features] 2.7. Low-noise outdoor units 2.7.1. Low-noise design improves in surrounding areas 1. The noise-suppressing winglet fan is a result of new research into vane design theory. The unique curved shape suppresses the generation of vortexes, thus reduces air flow noise. 2. The adoption ...

Page 8

2.8.1. Pipes that are one size larger can also be connected for renewal • • • • if renewing the system, existing refrigerant pipes can be utilized so that only the indoor units need to be replaced. • • • • for example, liquid and gas pipes from 10 years ago can be connected to current pipes with the...

Page 9

2.8.8. Centralized draining method • • • • even when multiple outdoor units are installed to a wall, the drain outlets can be concentrated into a single drain pipe. This makes installation easier and also improve appearance. 2.9. A brand-new control method 1. Easier power supply wiring connection po...

Page 10

2.10. Wired remote control 1. The new design includes an easily-visible red pilot lamp. The power can be turned on and off at a single touch, without opening the cover. 2. Has a build-in thermistor, allowing indoor temperature detection in accordance with indoor conditions by switching with main uni...

Page 11

2.12. Group control equipment wired remote control group control by one remote control • • • • all air conditioner units are controlled as a whole by remote control. • • • • all indoor units operate in the same mode. • • • • a maximum of 16 units can be connected together (sequental starting) [remot...

Page 12: 3 Specification

3.1. Product specification 3 specification 3.1.1. Cs-f50dte5 cu-l50dbe8 item / model indoor unit outdoor unit main body cs-f50dte5 cu-l50dbe8 remote cz-rd513c (wired) control cz-rl513t (wireless) cooling capacity kw 14.0 btu/h 47,700 heating capacity kw 16.0 btu/h 54,600 refrigerant charge-less m 30...

Page 13: 4 Dimensions

4 dimensions 4.1. Cs-f50dte5 13 cs-f50dte5 cu-l50dbe8.

Page 14

4.2. Cu-l50dbe8 14 cs-f50dte5 cu-l50dbe8.

Page 15: 5 Refrigeration Cycle

5 refrigeration cycle 15 cs-f50dte5 cu-l50dbe8.

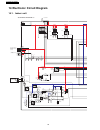

Page 16: 6 Block Diagram

6 block diagram 6.1. Cs-f50dte5 16 cs-f50dte5 cu-l50dbe8.

Page 17

6.2. Cu-l50dbe8 17 cs-f50dte5 cu-l50dbe8.

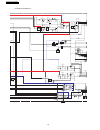

Page 18: 7 Wiring Diagram

7 wiring diagram 7.1. Cs-f50dte5 18 cs-f50dte5 cu-l50dbe8.

Page 19

7.2. Cu-l50dbe8 19 cs-f50dte5 cu-l50dbe8.

Page 20: 8 Operation Details

Remote the off/on button cannot be used. Local all wired remote control buttons can be used. Time/time setting display check display fan speed display operation mode selection display filter reset display (appears after the cumulative running time reaches approximately 2,500 hours of operation.) tem...

Page 21

Transmitter transmits the remote control signal. Airflow direction setting display fan speed display temperature setting display (16°c - 31°c) time/time setting display shows the timer operation setting time or the current time. Address number display operation selection display off/on button used t...

Page 22: 9 Operation Control

Description of basic control functions 9 operation control 9.1. Operation mode 1. Thermostat control 2. Depend on differences between room temperature and setting temperature, compressor running frequency will be decided and start operation. Temperature differences become same as below table, then t...

Page 23

− − − − unit using dc motor as follow the below figure, fan speed changing operation (program air). (rpm center b and is different if capacity rank is different) − − − − unit using ac motor when 1st thermostat on condition from operation start, fan speed is hi (same as manual fan speed), after 2nd t...

Page 24

9.3.4. Freezing prevention control • • • • during cool or dry mode operation, if indoor evaporator temperature is going down, freezing prevention control is operated. • • • • detail of freezing prevention control is as follows; indoor evaporator temperature area is divided into 5 zones, which consis...

Page 25

9.4. Heating mode operation 9.3.6. Drain pump control • • • • during cooling, dry, or defrost operation, drain pump operate by following the below table. • • • • when compressor start, drain pump operation start after 10 second of indoor fan starting. • • • • when operation stop or thermostat is off...

Page 26

Fan speed auto • • • • when operation start, or during operation, fan speed control by detecting indoor heat exchanger as follows: • • • • (k10 = indoor heat exchanger temperature, depend on indoor type) 9.4.2. Hot start control • • • • when heating operation start, hot start control carry out. • • ...

Page 27

9.4.6. Heating high temperature protection • • • • during heating operation, when outdoor temperature is more than 35°c for 15 minute, compressor stop to protect compressor. • • • • after 3 minute (re-start delat control) waiting, if thermostat on condition, outdoor unit re-start. 27 cs-f50dte5 cu-l...

Page 28

9.5. Louver control 9.5.1. Louver control for cassette type • • • • when power is on, at the same time, louver start initializing toward to close direction. • • • • during operation, stopping, thermostat off condition, louver angle set manual or auto depend on remote controller setting. − − − − louv...

Page 29

9.5.2. Ceiling type louver control • • • • when power is on, at the same time, louver initialize 2 times. • • • • during operation, stopping, thermostat is off condition, louver angle change as below table by manual setting or auto setting of remote controller. Remote controller setting manual auto ...

Page 30

9.6. Odour removing operation • • • • during stop condition, or cooling operation, when pushing the [odour] button for 5 second, operation change to the odour removing operation. • • • • operation detail is as follows; fan mode operation for 180 second, then refrigerant cycle change to heating mode ...

Page 31

9.7. Energy save operation • • • • during cooling operation, or heating operation, when pushing the [economy] button in the wired remote controller, energy save operation start and [eco] sign is displayed at lcd display panel of wired remote controller ([economy] sign is displayed at lcd display pan...

Page 32

9.11. Pump down operation • • • • when pushing the [pump down] button on the outdoor pcb for 1 second, pump down operation start. Detail of pump down operation is shown at below table. • • • • during pump down operation, push the [pump down] button once again for 1 second, pump down operation stop. ...

Page 33

10 installation instruction 10.1. Pipe length • • • • correction of cooling capacity and heating capacities 1. Correction of cooling and heating capacities according to the connecting pipe length. The data of cooling capacities (marked on the name plate) are based on 5 meters connecting pipe and hor...

Page 34

10.2. Refrigerant additional charge 1. Piping installation by standard piping • • • • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of 30 m. (refer the following table) but when the piping length exceeds 30m, additional charge is...

Page 35

This mark means “caution” or “warning”. This mark means “earth”. 10.4. Indoor unit installation ceiling type air conditioners installation instructions precautions in terms of safety carry out installation work with reliability after throughout reading of this “precautions in terms of safety”. • • •...

Page 36

Cautions carry out earthing work. Do not connect the earth return to the gas pipe, water line pipe, lightning rod and telephone lines. Imperfection in earth return may lead to electric shock. Drain piping should be made to ensure secure drainage according to the manual for installation work and carr...

Page 37

1. Open the inlet grille, and remove the side cover fixing screw (right and left) from the internal part of the unit. 2. Move the side cover to about 15mm forward to remove it. Use the packing material (styrene foam) to support, when you reverse the top and bottom of the indoor unit. 3. Remove the h...

Page 38

* use either w3/8 or m10 bolts and nuts (local supplied) • • • • fastening the hanging bracket warning be sure to tighten the nut and bolt to prevent the unit from falling. Fastening the hanging bracket piping hole positions • • • • the refrigerant piping can be installed on the right, right upper o...

Page 39

Flare nut fastening torque n.M (kgf.Cm) ø6.35 mm 18 (180) ø15.88 mm 65 (660) ø9.52 mm 42 (430) ø19.05 mm 100 (1020) ø12.7 mm 55 (560) • • • • be sure to use the drain hose provided (accessory item.) • • • • drain piping must have down-slope (1/50 to 1/100): be sure not to provide up-and-down slope t...

Page 40

Be sure to perform heat insulation on the drain piping. Caution if insulation is insufficient, dew may form. This causes water leakage. Prevent the drain hose from floating and hanging caution down. This causes water leakage. (down figure) wall seal • • • • when the outdoor unit is installed on a hi...

Page 41

Connecting the wires to the control box • • • • remove a two mounting screw, remove the control box cover, and then connect the wires by following the procedure given in the illustration. Caution make sure that screws of the terminal are securely tightened. 10.4.7. Electrical wiring as to the main p...

Page 42

10.4.8. Settings do not operate the remote controller within 1 minute after turning on the power of the indoor unit. When using group control with the standard type, at least 1 unit must be set at no.1 at the indoor unit. Check the settings of the indoor unit in a case where there are no display at ...

Page 43

Is circulation of air adequate? Is draining smooth? Is heat insulation complete (refrigerant and drain piping)? Is there any leakage of refrigerant? Is remote controller switch operated? Is there any faulty wiring? Are the terminal screws loosened? M3...69-98 n.Cm {7-10 kgf.Cm} m4...157-196 n.Cm {16...

Page 44

This mark means “caution” or “warning”. This mark means “earth”. 10.5. Outdoor unit installation air conditioners outdoor unit installation instructions precautions in terms of safety carry out installation work with reliability after thorough reading of this “precautions in terms of safety”. • • • ...

Page 45

Part name q’ty diagram application protective bushing 2 for protecting electrical wires banding strap 3 for tying electrical wires together heat pump-types only part name q’ty diagram application drain elbow as 1 for connecting the drain pipe (with ring seat) warnings wiring shall be connected secur...

Page 46

B. Prevention measure for refrigerant piping prevention measure for refrigerant piping is very important work to prevent water-dust-rubbish from getting in. All piping terminals needs sealing such as shown below. Place period of work method of seal outside more than 1 month pinch less than 1 month p...

Page 47

For the use of a gas cylinder without siphon inside, turn it upside down and use it. (we recommend manifold with sight glass.) caution do not use a “charge cylinder”. Caution as a rule, please collect all existing refrigerants in the system outside the system when the refrigerant leakage occurs by t...

Page 48

12. Be sure to leave enough space around the outdoor unit to maintain proper performance and to allow access for routine maintenance. • • • • allow enough space from any obstacles as shown in fig. 1.2 below in order to prevent short-circuits from occurring. (if installing more than one outdoor unit,...

Page 49

• • • • if a drain pipe needs to be installed, insert the accessory drain elbow into the mounting hole at the bottom of the outdoor unit, and connect a hose with an inside diameter of 15mm to this drain elbow. (the hose is not supplied.) if using the drain elbow, install the outdoor unit on a base w...

Page 50

Caution use a material with good heat-resistant properties as the heat insulation for the pipes. Be sure to insulate both the gas-side and liquid-side pipes. If the pipes are not adequately insulated, condensation or water leakages may occur. Liquid-side pipes material that can withstand gas-side pi...

Page 51

• • • • pump down operation − − − − operate the pump down according to the following procedures. Procedure notes 1. Confirm the valve on the liquid side and the gas side is surely open. 2. Press the pump down switch on outdoor printed board for 1 second or more. Perform the cooling operation for fiv...

Page 52

Earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. • • • • power supply specifications model name leakage current circuit breaker (minimum capacity) minimum power 4mm 2 cable maximum permi...

Page 53

10.5.10. Connecting power supply cables caution • • • • for three phase model, never operate the unit by pressing the electromagnetic switch. • • • • never correct the phase by switching over any of the wires inside the unit. 10.5.11. Precautions with regard to test operation caution • • • • always ...

Page 54

Short circuit of the blow-out air smooth flow of the drain reliable thermal insulation leakage of refrigerant mistake in wiring reliable connection of the grand wire looseness in terminal screw, fastening torque m3... 69-98n.Cm {7-10kgf.Cm} m4... 157-196n.Cm {16-20kgf.Cm} m5... 196-245n.Cm {20-25kgf...

Page 55

10.6. Wired remote control installation wired remote control installation manual • • • • before installing the wired remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installation manual provided with the indoor unit. • • • • after installing the wired re...

Page 56

If no displays appear on the remote controller, check while referring to “if no remote controller displays appear” in “5 test operation”. • • • • the remote control cable is live during use, so please be careful with it. Remote controller wiring • • • • connect the indoor unit and the remote control...

Page 57

• • • • strip the end of the remote control cable which is to be connected to the remote controller. (refer to the illustration below) • • • • route the remote control cable inside the lower case in accordance with the intended feeding- out direction. (refer to the illustration below.) securely conn...

Page 58

If remote control cable is embedded if installing with the remote control cable exposed 1. Embed an outlet box (jis c 8336) into the wall, and then secure the remote controller base plate to the outlet box with the two accessory m4 screws. Make sure that the base plate is flat against the wall at th...

Page 59

Automatic address resetting for group control • • • • the address settings for group control (air conditioner nos. 1 to 16) can be reset automatically. 1. When operation is stopped, press for 5 seconds, continue the test run switch to display “00” (will be local mode). 2. Press the up (temp) down (t...

Page 60

10.6.5. Test operation • • • • turn on the main power. • • • • after 3 minutes have passed since the power was turned on, press the off/on switch on the remote controller. (no operation occurs within 3 minutes after the power was turned on.) • • • • press the test run switch within 1 minute of press...

Page 61

• • • • you can then switch between the display for the previous problem and the problem before that by pressing the up (timer) down (timer) switches. • • • • press the check switch once more to return to the normal display. Example of previous problem display example of abnormality display before p...

Page 62

10.7. Wireless remote control installation manual wireless remote control installation manual • • • • before installing the wireless remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installation manual provided with the indoor unit. • • • • after install...

Page 63

• • • • if using a single remote controller to operate several air conditioners, address setting will be required. (refer to later in this manual.) • • • • for twin and triple types, install to the main unit only. (accordingly, the installation and wiring operations described later in this manual ar...

Page 64

1. Route the joint cord for wiring as shown in the figure (figure of the back of decorative panel) below. Pass the cord through the hook of the decorative panel, taking care that the cord does not run on the heat insulator, etc. 2. Remove the control box cover by removing the two fixing screws and c...

Page 65

Receptor unit (for ceiling type) assembly procedure 1 attach the receptor unit onto the indoor main unit as shown in the figure below. 1. Remove the air-intake grille and the side cover. To remove the side cover, remove the fixing screw each on the left and the right and pull the side cover towards ...

Page 66

10.7.4. Address setting for wireless remote controller and receptor unit (only when using more than one indoor unit) • • • • only the air conditioner units which receptor unit address numbers match the remote controller address number can be operated. • • • • at the time of shipment from the factory...

Page 67

Note • • • • if the batteries are replaced or the remote controller is reset, the address setting will return to address1, so you will need to repeat the address setting again. All setting details which are stored in memory will be cleared, so you will need to repeat the setting. • • • • if the addr...

Page 68

[manual setting] 10.7.5. Emergency operation • • • • if you do not have the wireless remote controller (because the batteries are weak, or some other reason prevents the wireless remote controller from being used), emergency operation can be carried out at receptor unit. • • • • press the auto switc...

Page 69

10.8. Twin 10.8.1. Twin operation • • • • simultaneous air conditioning of wide spaces and corners is possible. Indoor units with same horsepowers can even be used in combination. • • • • master unit and slave-units can be set automatically in twin systems. No address setting is necessary. • • • • m...

Page 70

11 installation and servicing air conditioner using r410a 11.1. Outline 11.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone la...

Page 71

D. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine o...

Page 72

11.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) • • • • this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) • • • •...

Page 73

5. Charging hose • • • • the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. 6. Vacuum pump adaptor • • • • when using a ...

Page 74

8. Electronic scale for refrigerant charging • • • • because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement sca...

Page 75

11.3. Refrigerant piping work when working with refrigerant piping, the following points must be carefully observed: no moisture or dust must be allowed to enter the piping, and there must be no refrigerant leaks. 1. Procedure and precautions for flaring work a. Cut the pipe use a pipe cutter, and c...

Page 76

2. Procedure and precautions for flare connection table 11 r410a flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a (mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut type 1/4 6.35 0.8 0 - 0.5 1.0 - 1.5 1.5 - 2.0 3/8 9.52 0.8 0 - 0.5 1.0 ...

Page 77

Precautions • • • • be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. • • • • make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. • • • • the gas pressure back fl...

Page 78

11.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. • • • • ch...

Page 79

3. Fully open the handle lo of the manifold gauge, turn on the power of the vacuum pump and continue the vacuum process for at least one hour. 4. Confirm that the low pressure gauge shows a reading of -0.1 mpa (-76 cmhg), then fully close the handle lo, and turn off the vacuum pump. Wait for 1-2 min...

Page 80

11.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n 2 ) flow. 1. Atta...

Page 81: 12 Troubleshooting Guide

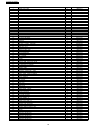

12 troubleshooting guide 12.1. Self-diagnosis error code table • • • • the display screen on the wired remote control unit and the self-diagnosis leds (green) on the outdoor unit printed circuit board in the outdoor unit can be used to indicate where the location of a problem is. Refer to the table ...

Page 82

Wired remote control unit display outdoor unit printed circuit board led location or problem check location abnormal dispaly detail dispaly 302 303 304 305 306 307 308 309 f40 -01 outlet temperature sensor problem outlet temperature sensor lead wire, connector cn-th1 -11 compressor suction temperatu...

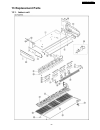

Page 83: 13 Replacement Parts

13.1. Indoor unit 13 replacement parts 83 cs-f50dte5 cu-l50dbe8.

Page 84

84 cs-f50dte5 cu-l50dbe8.

Page 85

85 cs-f50dte5 cu-l50dbe8.

Page 86

No. Part description qty. Cs-f50dte5 1 cabinet top plate 1 cwe001016 2 cabinet front plate 1 cwg07k1008 3 cabinet side plate (l) 1 cwd63k1003 4 vane supporter (l) 1 cwg071144 5 catcher 1 cwh601005 6 cabinet side plate (r) 1 cwd63k1004 7 vane supporter (r) 1 cwg071145 8 blower wheel base ass’y 1 cwd9...

Page 87

Installation instruction 1 cwf612642 all parts are supplied from phaam, malaysia (vendor code: 061) 87 cs-f50dte5 cu-l50dbe8.

Page 88

13.2. Outdoor unit 88 cs-f50dte5 cu-l50dbe8.

Page 89

89 cs-f50dte5 cu-l50dbe8.

Page 90

90 cs-f50dte5 cu-l50dbe8.

Page 91

No. Part description qty. Cu-l50dbe8 1 base pan ass’y 1 cwd52k1110 2 compressor 1 5jd420xba22 3 anti-vibration bushing 3 cwh50055 4 nut for comp. Mount. 3 cwh4582065 4a packing 3 cwb811017 5 crankcase heater 1 cwa341013 6 condenser complete 1 cwb32c1594 7 tube ass’y(pressure switch) 1 cwt023392 8 di...

Page 92

14 electronic circuit diagram 14.1. Indoor unit schematic diagram 1/4 q13 rt1n141c q12 dta114eka d17 hru0183a2 zd4 udzs308 zd3 udzs308 floa t sm lf 2 ss11v-r04520 cn-rem (xh3) 1 2 3 d16 dan217 q9 2sb119ek e b c c b e q10 2sd1782k q7 2sb1198k e b c c b e q8 2sd1782k d14 dan202u d13 dap202u ic5 tc7500...

Page 93

Schematic diagram 2/4 cs 1 3 4 5 6 8 2 d0 vc r/b /cc d1 sk gnd 7 2 4 6 8 1 3 5 7 ic2 br9080af d12 d11 pin2 none pc7 tlp421 (bl) 1 2 4 3 c b e q15 2sc3052f c63 1000p 1 2 3 4 5 6 7 8 9 21 22 23 24 25 26 27 28 29 52 53 54 55 56 57 58 59 60 72 73 74 75 76 77 78 79 80 10 51 30 71 11 50 31 70 12 49 13 48 ...

Page 94

Schematic diagram 3/4 c81 1 275vac ry-con gge-134p r96 39k 2w r63 10k d19 r97 39k 2w pc6 tlp421 (bl) 1 4 2 3 c b e q14 2sc3052f r111 none r112 1k q16 2sc1841 (fa) c5 1000p 250vac r114 4.7k c62 0.1 25v r113 10 d1 ia5-e 600v 1a lf3 sy-110av zd10 rd6.2e zd9 rd6.2e zd8 rd16uj (n3) c b e pc8 tlp421 1 2 4...

Page 95

Electronic control unit 3 2 1 + + cn-ev 1 2 3 4 5 6 1 3 5 1 3 7 9 schematic diagram 4/4 1 3 cn-t 728-0612 (red) c-fv1 (red) (blu) c c-fv2 red transforner red white white black black cn-fm (vh9-5) cn-drv cn-lyn dndn dc782 lnd2 dc782 fan motor expand valve m 1 2 3 4 5 6 cn-pwr 1 2 3 4 5 r310 80.6k 1% ...

Page 96

14.2. Outdoor unit schematic diagram 1/5 *** cu-l50dbe8 ** electronic circuit diagram b 2 1 2 1 3 2 3 2 1 3 4 2 1 3 electronic control unit 147 148 149 150 7 6 c b c 9 8 ry-v2 gas-bypass valve liquid-bypass valve 4 way valve (vh3-2) (blue) (vh3-2) (green) (vh3-2) (yellow) (vh3-2) (blk) znr2 c30 0.01...

Page 97

C 0 µ 132 1 µ d12 schematic diagram 2/5 5 /adin2 9 6 /adin 30 7/adin31 s t3 s t2 s t1 o ut dd d2 u t u t d d w s 3 /irq07 adin00 adin01 adin10 p83/adin11 p87/adin23 p90/adin24 adin25 adin26 p 5 7/ptm1 5 vdd p 51/tmb 0 v ss p 5 0 /tm1 0 a 0 p42/tm9a1 p3 p3 p3 p3 p p p p 2 1 3 366 299 322 r159 10k 7 5...

Page 98

10 10 8 9 11 c64 100 µ r269 adr ic8 ulm2003adr 3v schematic diagram 3/5 cn-ry1 1 2 c r138 5.6k 2 4 6 8 2 1 3 4 8 5 402 vcc sk di ic6 d15 d16 d15,d16 hru0103c 26 1 q24 rtln432c 65 47 µ r139 6k k 13v ry-ht 13v 5 6 to pressure switch c84 0.047 µ 13v d33 d34 d35 d36 d d33~d36 hru0103a2 expand valve rl4z...

Page 99

5v 7 2 µ r 2 03 r 2 0 2 c µ q10 r201 c115 0.022 µ r260 31.2k r261 1.13k r259 27.4k schematic diagram 4/5 30 31 20 17 61 r263 4.99k r262 39.2k 63 62 r265 39.2k 64 r266 24 25 42 43 44 znr400 ic13 1 3 4 8 +15.7v ic14 + + + + + + c 11 3 1000 p c1 12 1000p c1 11 1000p c99 1000p c98 1000p c97 1000p c ho c...

Page 100

5v sw7 ct 301 n schematic diagram 5/5 c210 1 µ c21 1 1 µ r204 200k 590 589 591 599 400 501 585 584 595 grn fg1 grn fg2 612 613 to (cn-disp2) diagram 2 l1-out l3-out blu blk indoor unit t to (cn-lf) in schematic diagram 1 in schematic diagram 1 sw4 3 1 5v l ed 30 1 l ed302 led303 led304 led305 led306...

Page 101

14.3. Wired remote control 101 cs-f50dte5 cu-l50dbe8.

Page 102

14.4. Wireless remote control 102 cs-f50dte5 cu-l50dbe8.

Page 103

14.5. Print pattern 14.5.1. Indoor unit • • • • indoor unit printed circuit board (main) 103 cs-f50dte5 cu-l50dbe8.

Page 104

• • • • indoor unit printed circuit board (indicator) 104 cs-f50dte5 cu-l50dbe8.

Page 105

14.5.2. Outdoor unit • • • • outdoor unit printed circuit board (main) 105 cs-f50dte5 cu-l50dbe8.

Page 106

• • • • outdoor unit printed circuit board (power) • • • • outdoor unit printed circuit board (service) 106 cs-f50dte5 cu-l50dbe8 [phaam] printed in malaysia.