- DL manuals

- Panasonic

- Air Conditioner

- CS-HE12DKE

- Service Manual

Panasonic CS-HE12DKE Service Manual

1 Features

2

2 Functions

3

2.1.

Remote Control

3

2.2.

Indoor Unit

4

2.3.

Outdoor unit

5

3 Product Specifications

6

4 Dimensions

10

4.1.

Indoor Unit / Remote Control

10

4.2.

Outdoor Unit

11

5 Refrigeration Cycle Diagram

12

6 Block Diagram

13

7 Wiring Diagram

14

7.1.

Indoor Unit

14

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights

reserved.

Unauthorized

copying

and

distribution is a violation of law.

CS-HE9DKE CU-HE9DKE

CS-HE12DKE CU-HE12DKE

7.2.

Outdoor Unit

15

8 Electronic Circuit Diagram

16

8.1.

Indoor Unit / Remote Controller

16

8.2.

Outdoor Unit

18

9 Operation Details

20

9.1.

Basic Function

20

9.2.

Indoor Power Relay Control

21

9.3.

Room Temperature Control (Compressor Control)

22

9.4.

Airflow Direction Control

23

9.5.

Quiet operation (Cooling Mode / Cooling area of Dry

Mode)

26

9.6.

Indoor Fan Control

28

9.7.

Powerful Operation

30

Air Conditioner

CONTENTS

Page

Page

Order No. RAC0504012C2

Summary of CS-HE12DKE

Page 1

1 features 2 2 functions 3 2.1. Remote control 3 2.2. Indoor unit 4 2.3. Outdoor unit 5 3 product specifications 6 4 dimensions 10 4.1. Indoor unit / remote control 10 4.2. Outdoor unit 11 5 refrigeration cycle diagram 12 6 block diagram 13 7 wiring diagram 14 7.1. Indoor unit 14 © 2005 matsushita e...

Page 2: 1 Features

9.8. Automatic operation 31 9.9. Sleep timer operation 32 9.10. Timer operation 32 9.11. Auto restart control 32 9.12. Ionizer operation 33 9.13. Oxygen enrich operation 34 9.14. Deice control 36 9.15. Protection control 37 10 operating instructions 39 11 installation instructions 45 11.1. Safety pr...

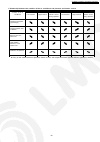

Page 3: 2 Functions

2 functions 2.1. Remote control 3 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 4: 2.2. Indoor Unit

2.2. Indoor unit 4 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 5: 2.3. Outdoor Unit

2.3. Outdoor unit 5 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 6: 3 Product Specifications

3 product specifications unit cs-he9dke cu-he9dke cooling capacity kw kcal/h btu/h 2.60 (0.60 - 3.00) 2,240 (520 - 2,580) 8,870 (2,050 - 10,200) heating capacity kw kcal/h btu/h 3.60 (0.60 - 6.50) 3,100 (520 - 5,590) 12,300 (2,050 - 22,080) moisture removal l/h pint/h 1.5 (3.2) power source phase v ...

Page 7

Unit cs-he9dke cu-he9dke drain hose inner diameter mm 16 — length m 0.65 — power cord length number of core-wire 1.8 m 3-core wires × 1.0 mm 2 — — dimensions height inch (mm) 11 - 23/32 (298) 21 - 1/4 (540) width inch (mm) 34 - 8/32 (870) 30 - 23/32 (780) depth inch (mm) 7 - 27/32 (199) 11 - 3/8 (28...

Page 8

Unit cs-he12dke cu-he12dke cooling capacity kw kcal/h btu/h 3.50 (0.60 - 4.00) 3,010 (520 - 3,440) 11,900 (2,050 - 13,600) heating capacity kw kcal/h btu/h 4.80 (0.60 - 7.70) 4,130 (520 - 6,620) 16,400 (2,050 - 26,100) moisture removal l/h pint/h 2.0 (4.2) power source phase v cycle single 230/240 5...

Page 9

Unit cs-he12dke cu-he12dke dimensions height inch (mm) 11 - 23/32 (298) 21 - 1/4 (540) width inch (mm) 34 - 8/32 (870) 30 - 23/32 (780) depth inch (mm) 7 - 27/32 (199) 11 - 3/8 (289) net weight lb (kg) 24 (11) 82 (37) compressor type — involute scroll motor type — brushless (4-poles) rated output w ...

Page 10: 4 Dimensions

4 dimensions 4.1. Indoor unit / remote control 10 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 11: 4.2. Outdoor Unit

4.2. Outdoor unit 11 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 12

5 refrigeration cycle diagram 12 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 13: 6 Block Diagram

6 block diagram 13 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 14: 7.1. Indoor Unit

7.1. Indoor unit 7 wiring diagram 14 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 15: 7.2. Outdoor Unit

7.2. Outdoor unit 15 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 16

8 electronic circuit diagram 8.1. Indoor unit / remote controller 16 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 17

17 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 18: 8.2. Outdoor Unit

8.2. Outdoor unit 18 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 19

19 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 20: 9.1. Basic Function

9.1. Basic function 9 operation details inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer maintains th...

Page 21

Table (b): outdoor air temperature shifting mode: outdoor temperature, x (°c): temperature shift (°c) cs-he9dke cs-he12dke cooling/soft dry 38 x 0.00 0.00 30 x 38 0.00 0.00 23 x 30 0.00 0.00 x 23 0.00 0.00 heating 21 x 0.00 0.00 17 x 21 0.00 0.00 9 x 17 0.00 0.00 5 x 9 +0.50 +1.00 1 x 5 +1.00 +1.25 ...

Page 22

• • • • [thermostat-on temperature] = [intake air temperature] - [remote controller setting temperature] • • • • [thermostat-on temperature] = [intake air temperature after 2 minutes] - [remote controller setting temperature] • • • • when room temperature is below thermostat-off temperature for 3 mi...

Page 23

9.4. Airflow direction control 9.4.1. Horizontal and vertical directions vertical louver is controlled by remote control: the vertical airflow direction button on the remote controller and by each operation mode, as shown in the table below. Cooling operation mode manual operation vertical automatic...

Page 24

Heating operation mode manual operation vertical automatic operation powerful-on • • • • five-level setting is possible with the remote controller. 1. When heat exchanger temperature is less than 32°c. 2. When heat exchanger temperature is between 32°c and 56°c. 3. When heat exchanger temperature is...

Page 25

9.4.2. Horizontal airflow direction control operation mode horizontal automatic operation operation for 5 min. After powerful-on or the neural control is stabilized. Cooling • • • • the louver horizontally swings at a fixed cycle. Horizontal automatic operation operation for 5 min. After powerful-on...

Page 26

9.5. Quiet operation (cooling mode / cooling area of dry mode) a. Purpose to provide quiet cooling operation at limited fan speed which lower than manual low fan speed. (see 9.6 fan motor operation table.) • • • • it improves the operation noise approximately 3db compared to manual low fan speed. B....

Page 27

9.5.2. Quiet operation (heating) a. Purpose to provide quiet heating operation at limited fan speed which lower than manual low fan speed. (see 9.6 fan motor operation table.) • • • • it improves the operation noise approximately 3db compared to manual low fan speed. B. Control condition a. Quiet op...

Page 28: 9.6. Indoor Fan Control

9.6. Indoor fan control 9.6.1. Fan motor operation • • • • fan speed is controlled according to operation conditions such as fan speed setting on the remote controller as shown in the table below. • • • • there is a different speed control from setting on the remote controller. • • • • when dry oper...

Page 29

9.6.2. Cooling operation 1. Automatic fan speed odour cut control makes fan stop temporarily for 40 seconds at the beginning of unit operation or thermostat-on in order to wash away odour ingredients from heat exchanger with dehumidifying water. Fan operation is repeated every 20 seconds at a speed ...

Page 30: 9.7. Powerful Operation

• • • • airflow direction, fan speed and setting temperature are optimized. • • • • “[intake air temperature] - [remote controller setting temperature]” is detected every 30 seconds by indication from indoor unit and controlled to each area. Quick cooling → unit forcibly turns to quick cooling opera...

Page 31: 9.8. Automatic Operation

• • • • airflow direction, fan speed and setting temperature are optimized. • • • • “[intake air temperature] - [remote controller setting temperature]” is detected every 30 seconds by indication from indoor unit and controlled to each area. Quick heating → unit forcibly turns to quick heating opera...

Page 32: 9.10. Timer Operation

On timer • • • • according to air-conditioning load, preliminary operation is performed to be a set temperature on set time. Preliminary operation time is as shown in the table on the right. • • • • indoor and outdoor fans operate for 30 seconds in 70 minutes before a set time, and outdoor and intak...

Page 33: 9.12. Ionizer Operation

9.12. Ionizer operation single ionizer operation • • • • the unit turns to single ionizer operation mode by pressing the ion button on the remote controller at stop mode and the ion led (green) on the main unit will light up. * temperature setting is not possible during the operation. Simultaneous i...

Page 34

9.13.1. Oxygen enrich system figure 9.13. Oxygen enrich operation 9.13.2. Indoor fan control single oxygen enrich operation 1. Manual fan speed ............. Not available for the remote controller. 2. Automatic fan speed ............. Fixed. Revolution (rpm) normal fan speed (auto) 480 • • • • when...

Page 35

→ cooling, heating, dry or ionizing air cleaning operation • • • • when "oxygen" is selected with the switch during ionizing air cleaning operation + simultaneous oxygen enrich operation, → ionizing air cleaning operation 2. Common use with on/off timer • • • • when on-time of the timer setting is u...

Page 36: 9.14. Deice Control

• • • • for operation check at installation and breakdown self- diagnosis, continuous operation of 2-way valve and vacuum pump is conducted by checking installation from indoor room. • • • • degree of frosting is expected by operation time, heat exchanger temperature and outdoor air temperature. • •...

Page 37: 9.15. Protection Control

9.15.1. Time delay safety control 9.15. Protection control • • • • compressor will not start for two minutes after stop of the operation. 9.15.2. 30 seconds forced operation • • • • once compressor starts the operation, it will not stop its operation for 30 seconds. However, it can be stopped with t...

Page 38

9.15.8. Four-way valve operation detection control (switching abnormality between cooling and heating) in cooling operation 1. When indoor heat exchanger temperature exceeds 45°c in 4 minutes after compressor starts, compressor will be stopped. 2. If the above excess occurs 4 times per 30 minutes, t...

Page 39: 10 Operating Instructions

10 operating instructions 39 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 40

40 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 41

41 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 42

42 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 43

43 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 44

44 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 45: 11.1. Safety Precautions

11 installation instructions required tools for installation works 1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 42 n.M (4.2 kgf.M) 55 n.M (5.5 kgf.M) 3. Electric drill, hole core drill (ø7...

Page 46

1. The equipment must be earthed and install with earth breaker. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drai...

Page 47

Applicable piping kit cz-3f5, 7bp (he9dke) cz-4f5, 7, 10bp (he12dke) select the best location indoor unit • • • • there should not be any heat source or steam near the unit. • • • • there should not be any obstacles blocking the air circulation. • • • • a place where air circulation in the room is g...

Page 48: 11.2. Indoor Unit

11.2.1. Select the best location (refer to “select the best location” section) 11.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. : : : for left side piping, piping connection for liquid should be this line. For left side piping, pipi...

Page 49

11.2.4. Indoor unit installation 1. For the right rear piping 2. For the right and right bottom piping 3. For the embedded piping pull out the piping and drain hose how to keep the cover insert the connecting cable install the indoor unit secure the indoor unit 49 cs-he9dke cu-he9dke / cs-he12dke cu...

Page 50

(this can be used for left rear piping & left bottom piping also.) exchange the drain hose and the cap. 50 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 51

11.2.5. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 flexible cord, type designation 245 iec 57 (h05...

Page 52: 11.3. Outdoor Unit

11.3.1. Select the best location (refer to “select the best location” section) 11.3.2. Install the outdoor unit • • • • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by b...

Page 53

11.3.5. Connect the cable to the outdoor unit 1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 flexible cord, type designation 245 iec 57 (h05rn-f) or heavier cord....

Page 54

2. Within the next 5 minutes, point the remote controller at the air conditioner, and press the error reset button on the remote controller. (a beep is heard, indicating that this signal was received.) 3. When any button on the remote controller which has been set to “b” is pressed within the next 5...

Page 55: 12.1. Outline

12 installation and servicing air conditioner using r410a 12.1. Outline 12.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone la...

Page 56

D. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine o...

Page 57

12.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) • • • • this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) • • • •...

Page 58

5. Charging hose • • • • the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. 6. Vacuum pump adaptor • • • • when using a ...

Page 59

8. Electronic scale for refrigerant charging • • • • because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement sca...

Page 60

12.3. Refrigerant piping work when working with refrigerant piping, the following points must be carefully observed: no moisture od dust must be allowed to enter the piping, and there must be no refrigerant leaks. 1. Procedure and precautions for flaring work a. Cut the pipe use a pipe cutter, and c...

Page 61

2. Procedure and precautions for flare connection fig. 11 relation between the flare nut structure and flaring tool end table 11 r410a flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a (mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut t...

Page 62

12.3.3. Storing and managing piping materials 1. Types of piping and their storage the following is a general classification of the refrigerant pipe materials used for acs. Because the gas pressure of r410a is approximately 1.6 times as high as that of r22, copper pipes with the thickness shown in t...

Page 63

Precautions • • • • be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. • • • • make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. • • • • the gas pressure back fl...

Page 64

12.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. • • • • ch...

Page 65

Vacuum pump. Wait for 1-2 minutes, then check to make sure that the needle of the low pressure gauge has not returned. See fig. 13 for the remaining steps of this procedure. 5. Set the refrigerant cylinder onto the electronic scale, then connect the hose the cylinder and to the connection port for t...

Page 66

12.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n 2 ) flow. 1. Atta...

Page 67: 13 Servicing Information

13 servicing information 13.1. About lead solder (pbf) distinction of pbf p.C. Board p.C. Boards (manufactured) using lead free solder will have a pbf stamp on the p.C. Board. Caution • • • • pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70 °f (3...

Page 68: 13.2. Troubleshooting

Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air temperat...

Page 69

1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditioner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrigerant...

Page 70

• • • • once abnormality has occurred during operation, the unit will stop its operation, and timer or both timer and ion leds blink. (the unit does not stop under ion abnormality.) • • • • although timer led goes off when power supply is turned off, if the unit is operated under a breakdown conditi...

Page 71

13.2.1.2. Error code table diagnosis display abnormality / protection control abnormality judgement emergency operation primary location to verify h11 indoor / outdoor abnormal communication > 1 min after starting operation indoor fan operation only • • • • internal / external cable connections • • ...

Page 72

13.3. Disassembly of parts 13.3.1. Disassembly of indoor unit 13.3.1.1. Removal of the front grille 1. Pull the front panel up slowly. Note: open it by holding up the curve-in on the grille. Fig. 1 fig. 2 2. Remove it inside by pressing lever arm with finger. 3. Remove the screw (one) in center part...

Page 73

4. Pull up the control board box and remove the control board cover a. Fig. 9 5. Remove a variety of connectors and terminals. Wiring parts from the left side • • • • cn-cln ...... Cleaning unit • • • • cn-th ...... Sensor complete (intake / pipe air temp. • • • • earth wire (yellow) ...... Remove t...

Page 74

4. Remove the fan motor cover by removing the screws (four) on it. Fig. 15 5. Remove the screws (two) on the left side of the heat exchanger. Fig. 16 6. Loosen the screw (one) between the cross-flow fan and fan motor. Fig. 17 7. Remove the fan boss by holding up the heat exchanger a little. Fig. 18 ...

Page 75

13.3.1.5. Removal of oxygen discharge outlet 1. Remove the front grille according to the procedure 13.3.1.1. 2. Remove the oxygen discharge outlet from the heat exchanger and remove the oxygen tube by releasing the hooks (four) on the plastic part. Note: the oxygen discharge outlet is on the left si...

Page 76

13.3.1.8. Removal of front panel motor 1. Remove the front grille according to 13.3.1.1. 2. Remove the motor by removing the screw (one). Be careful of the heat exchanger fins. Note: replace a plastic part of the front panel motor with a new plastic complete part for servicing in order to avoid loss...

Page 77

13.3.2.1. Removal of cabinet top plate and cabinet front plate 1. Remove the screws (three: two on the right side and one on the left side) and the cabinet top plate. 2. Remove the screws (six: three on the upper side and another three on the lower side) on the cabinet front plate. Fig. 1 3. Release...

Page 78

13.3.2.3. Removal of control box 1. Remove the cabinet top plate and cabinet front plate according to 13.3.2.1. 2. Remove the control cover and terminal cover according to 13.3.2.2. 3. Remove the control board by releasing the hooks (four: two each on the right and left). Fig. 5 4. Remove the screw ...

Page 79

5. Place the control box reversely and remove the screws (two) on the both sides of the control box b (for terminal plate). Fig. 10 6. Release the hooks (four) on the control box a (lower control pcb cover). Note: be careful of hanging-up of connectors or wiring cables such as the earth wire when th...

Page 80

Fig. 17 13.3.2.6. Removal of vacuum pump 1. Remove the cabinet top plate and cabinet front plate according to 13.3.2.1. 2. Remove the control cover and terminal cover according to 13.3.2.2. 3. Remove the screws (two) fixing terminal part and the cabinet side plate. Fig. 18 4. Remove the cabinet side...

Page 81: 14 Technical Data

14 technical data 14.1. Operation characteristics cs-he9dke cu-he9dke 81 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 82

Cs-he12dke cu-he12dke 82 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 83

14.2. Sensible capacity chart cs-he9dke cu-he9dke 230v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 2.58 2.33 0.46 2.41 2.24 0.50 2.24 2.14 0.54 2.04 2.03 0.59 19.0°c 2.60 0.51 19.5°c 2.83 2.44 0.47 2.65 2.34 0.51 2.46 2.25 0.55 2.24 2.14 0.60 2...

Page 84

15 exploded view and replacement parts list 15.1. Exploded view (indoor unit) note: the above exploded view is for the purpose of parts disassembly and replacement. 84 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 85

The non-numbered parts are not kept as standard service parts. 15.2. Replacement parts list (indoor unit) ref. No. Part name & description qty. Cs-he9dke cs-he12dke remarks d1 chassy complete 1 cwd50c50c1430 ← ← ← ← d2 l-plate 1 cwd601065 ← ← ← ← d3 installation plate 1 cwh361054 ← ← ← ← d4 particul...

Page 86

15.3. Exploded view (outdoor unit) note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 86 cs-he9dke cu-he9dke / cs-he12dke cu-he12dke.

Page 87

15.4. Replacement parts list (outdoor unit) ref no. Description & name qty. Cu-he9dke cu-he12dke remarks d1 chassy complete 1 cwd50k2103 ← ← ← ← d2 fan motor bracket 1 cwd541021 ← ← ← ← d3 fan motor 1 arw44x8p40ac ← ← ← ← d4 screw - fan motor mount 4 cwh55252j ← ← ← ← d5 propeller fan 1 cwh03k1014 ←...

Page 88

Ref no. Description & name qty. Cu-he9dke cu-he12dke remarks s14 oxygen pump supporting plate 1 cwd911284 ← ← ← ← s15 anti-vibration bushing (oxygen pump) 4 cwh501079 ← ← ← ← s16 bolt complete 4 cwh55c1007j ← ← ← ← s17 flexible pipe 1 cwh851077 ← ← ← ← s19 spacer 1 cwh581003j ← ← ← ← s20 tube connec...