- DL manuals

- Panasonic

- Air Conditioner

- CS-KE30NKU

- Technical & Service Manual

Panasonic CS-KE30NKU Technical & Service Manual

AIR CONDITIONER

IMPORTANT

These air conditioners employ new

refrigerant R410A.

Pay special attention when

servicing the unit.

TECHNICAL & SERVICE MANUAL

CS-KE30NKU + CU-KE30NKU

CS-KE36NKU + CU-KE36NKU

DC INVERTER SPLIT SYSTEM AIR CONDITIONER

Outdoor Model No.

CU-KE30NKU

CU-KE36NKU

Product Code No.

1 852 360 82

1 852 360 83

Indoor Unit

Outdoor Unit

CS-KE30NKU

CS-KE36NKU

CU-KE30NKU

CU-KE36NKU

Indoor Model No.

CS-KE30NKU

CS-KE36NKU

Product Code No.

1 852 360 88

1 852 360 89

REFERENCE NO.

SM

700876

Summary of CS-KE30NKU

Page 1

Air conditioner important these air conditioners employ new refrigerant r410a. Pay special attention when servicing the unit. Technical & service manual cs-ke30nku + cu-ke30nku cs-ke36nku + cu-ke36nku dc inverter split system air conditioner outdoor model no. Cu-ke30nku cu-ke36nku product code no. 1...

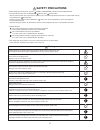

Page 2: Safety Precautions

• before doing repair work, please read the " safety precautions" carefully and fully understand them. • the precautionary items here are divided into " warning" and " caution" items. Items in particular which may cause death or serious injury to the service personnel if the work is not performed co...

Page 3

Warning if refrigerant gas blows off during the work, do not touch the refrigerant gas as it may cause frostbite. If refrigerant gas leaks during the work, ventilate the room. If refrigerant gas catches fire, harmful gas may be generated. Do not mix any gas other than the specified refrigerant gas i...

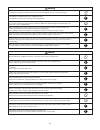

Page 4: Table of Contents

Table of contents safety precautions table of contents 1. Operating range 2. Specifications 2-1. Unit specifications 2-2. Major component specifications 2-3. Other component specifications 3. Dimensional data 4. Refrigerant flow diagram 4-1. Refrigerant flow diagram 5. Performance data 5-1. Temperat...

Page 5

9. Checking electrical components 9-1. Measurement of insulation resistance 9-2. Checking continuity of fuse on pcb ass'y 10. Refrigerant r410a: special precautions when servicing unit 10-1. Characteristics of new refrigerant r410a 10-2. Checklist before servicing 10-3. Tools specifically for r410a ...

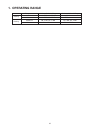

Page 6: 1. Operating Range

95 °f db / 71 °f wb 67 °f db / 57 °f wb 80 °f db / 67 °f wb – db / – wb 1. Operating range maximum minimum maximum minimum 115 °f db 0 °f db 75 °f db / 65 °f wb – db / 0 °f wb temperature indoor air intake temp. Outdoor air intake temp. Cooling heating 6.

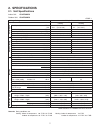

Page 7: 2. Specifications

2. Specifications 2-1. Unit specifications indoor unit cs-ke30nku outdoor unit cu-ke30nku data subject to change without notice. Remarks: rating conditions are: cooling: indoor air temperature 80 °f db / 67 °f wb outdoor air temperature 95 °f db / 75 °f wb heating: indoor air temperature 70 °f db ou...

Page 8

Indoor unit cs-ke30nku outdoor unit cu-ke30nku data subject to change without notice. Vertical db-a db-a indoor : hi/me/lo/qt* outdoor : hi air filter compressor refrigerant / amount charged at shipment ibs (g) refrigerant control shipping volume net shipping package dimensions weight height s width...

Page 9

Indoor unit cs-ke36nku outdoor unit cu-ke36nku data subject to change without notice. Vertical db-a db-a indoor : hi/me/lo/qt* outdoor : hi air filter compressor refrigerant / amount charged at shipment ibs (g) refrigerant control shipping volume net shipping package dimensions weight height s width...

Page 10

Indoor unit cs-ke36nku outdoor unit cu-ke36nku data subject to change without notice. Vertical db-a db-a indoor : hi/me/lo/qt* outdoor : hi air filter compressor refrigerant / amount charged at shipment ibs (g) refrigerant control shipping volume cooling heating net shipping package dimensions weigh...

Page 11

Indoor unit cs-ke30nku 24byj48-1256 flap motor type stepping motor rating model coil resistance ohm (ambient temp. 77 °f (25 °c)) each pair of terminal : 200 +/- 7% dc 12v aluminum plate fin / copper tube 1 and 2 19.5 4.55 (0.423) face area coil rows fins per inch heat exchanger coil ft 2 (m 2 ) dat...

Page 12

Indoor unit cs-ke36nku flap motor type rating model coil resistance ohm (ambient temp. 77 °f (25 °c)) face area coil rows fins per inch heat exchanger coil ft 2 (m 2 ) data subject to change without notice. Control pcb control circuit fuse controls part no. Microprocessor 250v 3a cb-cs-ke36nku fan q...

Page 13

Outdoor unit cu-ke30nku 2-2-2. Outdoor unit p.C.Board circuit fuse controls part no. - 250v 25a pow-ch3082-b2 noise filer p.C.B microprocessor 400v 3.15a cr-ch3082-f control p.C.B - - hic-ch3072r-c1 h.I.C.Board data subject to change without notice. Pints (cc) - micro f vac external finish acrylic b...

Page 14

Outdoor unit cu-ke36nku p.C.Board circuit fuse controls part no. - 250v 25a pow-ch3082-b2 noise filer p.C.B microprocessor 400v 3.15a cr-ch3682-f control p.C.B - - hic-ch3072r-c1 h.I.C.Board data subject to change without notice. Pints (cc) - micro f vac external finish acrylic baked-on enamel finis...

Page 15

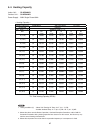

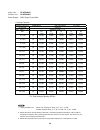

2-3. Other component specifications indoor unit cs-ke30nku cs-ke36nku outdoor unit cu-ke30nku cu-ke36nku 0 32 50 68 86 104 122 140 158 176 194 (0) (10) (20) (30) (40) (50) (60) (70) (80) (90) 40 60 80 100 120 140 160 180 200 20 50 1 0 2 3 4 5 6 7 8 9 10 59 68 77 86 95 104 (10) (15) (20) (25) (30) (3...

Page 16: 3. Dimensional Data

3. Dimensional data indoor unit cs-ke30nku cs-ke36nku unit: inch(mm) (852-0-0010-196-00-0) 41-15/16 (1065) 9-1/16 (230) (3/32) 7-25/32 wide tube dia. 5/8" (15.88) narro w tube dia. 3/8" (9.52) 1-27/32 1-3/32 2-3/32 25/32 5-1/2 6-7/32 16-11/32 17-5/16 19-9/16 16-11/32 17-21/32 22-3/8 5-3/16 3-3/4 3-3...

Page 17

Outdoor unit cu-ke30nku cu-ke36nku unit: inch(mm) (852-0-0010-194-00-1) 6-11/6 25-31/32 4-11/32 2-15/16 2-3/8 2-id:1-1/4 holes (holes f or drain) of the 4-id:1-1/4 holes , use 1 of 2 holes specified f or drain use to install the por t. Use r ubber plugs to seal the remaining 3 holes . 1/2 1/2 2-15/1...

Page 18

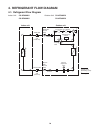

Compressor 4-way valve main accumulator high pressure switch wide tube service valve wide tube sub accumulator narrow tube service valve narrow tube heat e xchanger heat e xchanger muffler cooling cycle (defrosting cycle) heating cycle indoor unit outdoor unit electric expansion valve strainer m o.D...

Page 19: 5. Performance Data

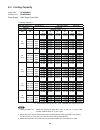

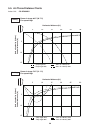

5. Performance data 5-1. Temperature charts indoor unit cs-ke30nku outdoor unit cu-ke30nku • check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value. Note cooling characteristics (rh : 46%, indoor fan speed : high fan) (60hz, 230v) (1) l...

Page 20

Indoor unit cs-ke30nku outdoor unit cu-ke30nku • check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value. • overload prevention operates to protect the air conditioner when outdoor ambient temperature becomes extremely high in heating mo...

Page 21

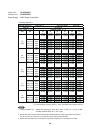

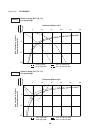

Indoor unit cs-ke36nku outdoor unit cu-ke36nku cooling characteristics (rh : 46%, indoor fan speed : high fan) (60hz, 230v) (1) low pressure performance chart (2) operating current performance chart (3) indoor discharge air performance chart -4 (-20) 5 (-15) 14 (-10) 23 (-5) 32 (0) 41 (5) 50 (10) 59...

Page 22

Indoor unit cs-ke36nku outdoor unit cu-ke36nku indoor discharge air temperature °f(°c) 23 (Ð5) 32 (0) 41 (5) 50 (10) 59 (15) 68 (20) 77 (25) outdoor inlet air db temp. °f(°c) outdoor inlet air db temp. °f(°c) 23 (Ð5) 32 (0) 41 (5) 22 21 20 19 18 17 16 50 (10) 59 (15) 68 (20) 77 (25) operating curren...

Page 23

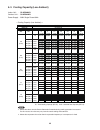

1. Rating conditions (#) : indoor unit entering air temp. 80 °f (26.7 °c) db / 67 °f (19.4 °c) wb : outdoor ambient temp. 95 °f (35 °c) db 2. 3. Above data represents the value when the operation frequency of a compressor is fixed. Above data does not take freeze prevention protection during cooling...

Page 24

Indoor unit : cs-ke36nku outdoor unit : cu-ke36nku power supply : 230v single phase 60hz tc : total cooling capacity (btu/h) shc : sensible heat capacity (btu/h) 1. Rating conditions (#) : indoor unit entering air temp. 80 °f (26.7 °c) db / 67 °f (19.4 °c) wb : outdoor ambient temp. 95 °f (35 °c) db...

Page 25

Indoor unit : cs-ke30nku outdoor unit : cu-ke30nku power supply : 230v single phase 60hz 5-3. Cooling capacity (low ambient) tc : total cooling capacity (btu/h) shc : sensible heat capacity (btu/h) 1. 2. Above data represents the value when the operation frequency of a compressor is fixed. Above dat...

Page 26

Indoor unit : cs-ke36nku outdoor unit : cu-ke36nku power supply : 230v single phase 60hz tc : total cooling capacity (btu/h) shc : sensible heat capacity (btu/h) 1. 2. Above data represents the value when the operation frequency of a compressor is fixed. Above data does not take freeze prevention pr...

Page 27

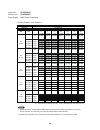

Indoor unit : cs-ke30nku outdoor unit : cu-ke30nku power supply : 230v single phase 60hz 5-4. Heating capacity th : total heating capacity (btu/h) 1. Rating conditions (#) : indoor unit entering air temp. 70 °f (21.1 °c) db : outdoor ambient temp. 47 °f (8.3 °c) db / 43 °f (6.1 °c) wb 2. 3. Above da...

Page 28

Indoor unit : cs-ke36nku outdoor unit : cu-ke36nku power supply : 230v single phase 60hz th : total heating capacity (btu/h) 1. Rating conditions (#) : indoor unit entering air temp. 70 °f (21.1 °c) db : outdoor ambient temp. 47 °f (8.3 °c) db / 43 °f (6.1 °c) wb 2. 3. Above data represents the valu...

Page 29

Horizontal distance (ft.) axis air velocity (ft./sec.) v e rtical distance (ft.) room air temp.:70°f (21.1°c) fan speed:high heating horizontal distance (ft.) axis air velocity (ft./sec.) vertical distance (ft.) room air temp.:80°f (26.7°c) fan speed:high cooling : flap angle 0 , : axis air velocity...

Page 30

Horizontal distance (ft.) axis air velocity (ft./sec.) v e rtical distance (ft.) room air temp.:70°f (21.1°c) fan speed:high heating horizontal distance (ft.) axis air velocity (ft./sec.) vertical distance (ft.) room air temp.:80°f (26.7°c) fan speed:high cooling : flap angle 0 , : axis air velocity...

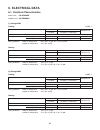

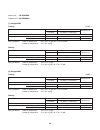

Page 31: 6. Electrical Data

6. Electrical data 6-1. Electrical characteristics indoor unit cs-ke30nku outdoor unit cu-ke30nku indoor unitoutdoor unit fan motor fan motor + compressor performance at 230v single-phase 60hz rating conditions running amp. A 0.4 power input w a w a w a w 39 16.1 3,251 rating conditions: indoor air ...

Page 32

Indoor unit cs-ke36nku outdoor unit cu-ke36nku indoor unitoutdoor unit fan motor fan motor + compressor performance at 230v single-phase 60hz rating conditions running amp. A 0.4 power input w a w a w a w 39 19.6 3,961 rating conditions: indoor air temperature: 80 °f (26.7 °c) db / 67 °f (19.4 °c) w...

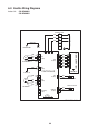

Page 33

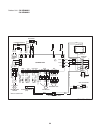

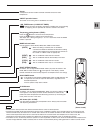

Controller ind lamp assy 1 2 4 5 1 2 4 3 3 5 1 2 3 9 1 2 3 4 5 4 5 6 7 6 7 8 8 9 1 2 3 9 1 2 3 4 5 4 5 6 7 6 7 8 8 9 lamp 9p (wht) 1 2 1 2 coil 2p (wht) room/uv 4p (wht) s-link (rac) 4p (blu) flap 5p (wht) gnd 2p (wht) 1 2 3 4 1 2 3 4 1 2 3 4 wht blk blk blk blk blk blk blk blk flap motor evaporator...

Page 34

Outdoor unit cu-ke30nku cu-ke36nku 8fa2-5251-15200-0 25a controller dcfm mv0 fan motor 1 2 3 4 5 6 7 blu red brn wht org blu red brn wht org w w w w w w w 1 2 3 4 5 5 1 2 4 3 1 2 1 2 1 2 3 4 5 6 7 1 2 4 5 6 7 3 1 2 1 2 3 4 3 4 5 5 1 2 1 2 3 3 1 2 1 2 1 2 3 4 1 2 4 3 1 2 3 4 1 2 4 3 2 1 2 1 ferrite c...

Page 35: 7. Functions

Emergency operation sensor dry auto cooling/heating operation selecting the operation mode during dry operation, the system adjusts the room temperature and fan speed according to the conditions in the room, in order to maintain a comfortable room environment. Sensor dry operation • dry operation is...

Page 36

High power night setback lamp colors timer backup this function acts to raise the power but keeps the ac system in the same operating mode. This function is set with the high power button on the remote controller. (it can be set regardless of the temperature and fan speed settings.) high power opera...

Page 37

The noise reducing control is the function used for silent operation of the air conditioner by means of setting the dip switch on the outdoor unit p.C.Board to control the fan and compressor's motor speed. (1) remove the 3 screws fixing the inspection panel and remove the inspection panel. (fig. 2) ...

Page 38

The maximum current value is changed to 14a (for cu-ke30nku) or 17a (for cu-ke36nku) to prevent power breaker tripping. (it is set to 24a (in cooling) or 22a (in heating) when the unit is delivered from the factory.) (1) remove the inspection panel. Refer to fig. 2 in " noise reducing control" for d...

Page 39

Overload prevention during heating during heat operation, the temperature of the indoor heat exchanger is used to control the frequency and lessen the load on the compressor before the protective device is activated. Cold-air prevention during heating compressor discharge temperature control during ...

Page 40

This function prevents the circuit breaker or fuse from operating to open the circuit. This function works when electrical current has increased due to an increase in the cooling / heating load, or to a decrease in the power supply voltage. In these cases, operation frequency is reduced or operation...

Page 41

8. Troubleshooting (before calling for service) 8-1. Precautions before performing inspection or repair note after checking the self-diagnostics monitor, turn the power off before starting inspection or repair. High-capacity electrolytic capacitors are used inside the outdoor unit controller (invert...

Page 42

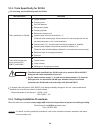

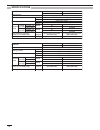

Indication on indoor unit .... Off diagnosis contents possible malfunction room temp. Sensor trouble i/d heat exchanger temp. Sensor trouble humidity sensor trouble compressor temp. Sensor trouble o/d heat exchanger temp. Sensor trouble o/d air temp. Sensor trouble i/d-o/d communication trouble (ser...

Page 43

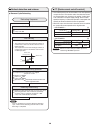

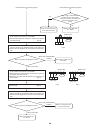

(2) if the self-diagnostics function fails to operate check the indoor unit. Is the fuse blown? Replace the controller. Replace the circuit board or the fuse. No indicators illuminate and the indoor fan does not rotate. Check the power voltage. Normal blown 43.

Page 44

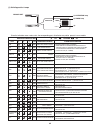

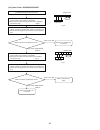

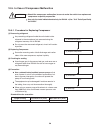

8-3. Checking the indoor and outdoor units (1) checking the indoor unit (2) checking the outdoor unit using the test/t-run terminals control no. Check items (unit operation) t-run : test run (compressor and fan motor turn on). Test/mv : compresses time to 1/60th (accelerates operation by 60 times fa...

Page 45

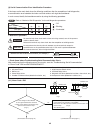

(3) serial communication error identification procedure refer to "method of self-diagnostics" for the self-diagnostics procedure. (3-1) alarm code : e05 if the lamps on the main body show the following conditions after the completion of self-diagnostics, a communication error between the indoor unit...

Page 46

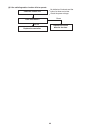

What is the latest self-diagnosis result ? Alarm code : e07/p04/p05/ p20/p27 alarm code : e07/p04/p05/ p20/p27 defect in the outdoor unit p.C. Board. Alarm code : e05 defect or connection error in the inter-unit cable defect in the indoor unit p.C. Board ( continued from the previous page a. ) a ( c...

Page 47

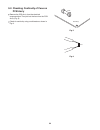

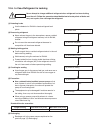

(3-2) alarm code : e07/p04/p05/p20/p27 troubleshooting serial communication 1. Turn off the power and wait until the power lamp (led) of the outdoor unit controller is turned off. 2. Disconnect the cable from the terminal 3 on the indoor unit terminal strip. (fig. 7) defect in the indoor unit p.C. B...

Page 48

[trouble symptom 3] motor rotates for some time (several seconds), but then quickly stops, when the indoor unit operates. (there is trouble in the system that provides feedback of motor rotation speed from the motor to the indoor unit controller.) [trouble symptom 4] fan motor rotation speed does no...

Page 49

8-4-2. Outdoor fan motor this outdoor dc fan motor contains an internal control pcb. Therefore, it is not possible to measure the coil resistance, and the following procedure should be used to check the motor. Perform the trouble diagnosis by test run mode described on installation instructions of i...

Page 50

8-5. Noise malfunction and electromagnetic interference an inverter a/c operates using pulse signal control and high frequencies. Therefore, it is susceptible to the effects of external noise, and is likely to cause electromagnetic interference with nearby wireless devices. A noise filter is install...

Page 51

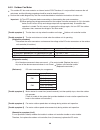

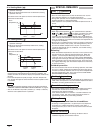

Insulation tester probe clip ground wire terminal plate copper tube or metallic part clip insulation tester probe fig. 1 fig. 2 fig. 3 fig. 4 copper tube or metallic part clip insulation tester probe clip insulation tester probe metallic part from fan motor, compressor and other parts 9. Checking el...

Page 52

Fuse pcb ass'y fig. 5 fig. 6 fuse 9-2. Checking continuity of fuse on pcb ass'y remove the pcb ass'y from the electrical component box. Then pull out the fuse from the pcb ass'y. (fig. 5) check for continuity using a multimeter as shown in fig. 6. 52.

Page 53: 10. Refrigerant R410A:

10. Refrigerant r410a: special precautions when servicing unit 10-1. Characteristics of new refrigerant r410a 10-1-1. What is new refrigerant r410a? R410a is a new refrigerant that contains two types of pseudo-non-azeotropic refrigerant mixture. Its refrigeration capacity and energy efficiency are a...

Page 54

Tubing precautions refrigerant r410a is more easily affected by dust or moisture compared with r22, thus be sure to temporarily cover the ends of the tubing with caps or tape prior to installation. Never use 0.0276" (0.7 mm)-thick copper tubing or tubing which is less than 0.0315" (0.8 mm) in thickn...

Page 55

10-3. Tools specifically for r410a for servicing, use the following tools for r410a gauge manifold charging hose gas leak detector refrigerant cylinder charging cylinder refrigerant recovery unit vacuum pump with anti-reverse flow (*1) (solenoid valve-installed type, which prevents oil from flowing ...

Page 56

10-5. In case of compressor malfunction caution should the compressor malfunction, be sure to make the switch to a replacement compressor as quickly as possible. Use only the tools indicated exclusively for r410a. See "10-3. Tools specifically for r410a." 10-5-1. Procedure for replacing compressor (...

Page 57: No!

Valve single valve charge liquid refrigerant with cylinder in up-side-down position. Single valve (with siphon tube) charge with cylinder in normal position. Liquid valve liquid charging cylinder open refrigerant cylinder liquid no! Caution never charge a large amount of liquid refrigerant at once t...

Page 58

Length of tubing evacuation time less than 33 ft. (10 m) more than 10 minutes more than 33 ft. (10 m) more than 15 minutes 10-6. In case refrigerant is leaking caution never attempt to charge additional refrigerant when refrigerant has been leaking from the unit. Follow the procedure described below...

Page 59

10-7. Charging additional refrigerant 10-7-1. When tubes are extended observe the proper amount of refrigerant as stated in this service manual or the installation manual that came with the indoor unit. Charge additional refrigerant in liquid state only. 10-8. Retro-fitting existing systems 10-8-1. ...

Page 60: Operating Instructions

Operating instructions cs-ke30nku + cu-ke30nku cs-ke36nku + cu-ke36nku (852-6-4181-221-00-2) appendix a a-1.

Page 61: Split System Air Conditioner

Split system air conditioner model no. Indoor units cs-ke30nku cs-ke36nku outdoor units cu-ke30nku cu-ke36nku operating instructions panasonic corporation 1006 kadoma, kadoma city, osaka, japan 85264181221002 cv6233187112 this air conditioner uses the refrigerant r410a. Before operating the unit, re...

Page 62

2 features this air conditioner is an inverter type unit that automatically adjusts capability as appropriate. Details on these functions are provided below; refer to these descriptions when using the air conditioner. • microprocessor controlled operation the interior compartment of the remote contr...

Page 63

3 installation location • we recommend that this air conditioner be installed properly by qualified installation technicians in accordance with the installation instructions provided with the unit. • before installation, check that the voltage of the electric supply in your home or office is the sam...

Page 64

4 names of parts this illustration is based on the external view of a standard model. Consequently, the shape may differ from that of the air conditioner which you have selected. This air conditioner consists of an indoor unit and an outdoor unit. You can control the air conditioner with the remote ...

Page 65

5 remote controller (display) (1) operation mode auto ..................................... Heat ...................................... Mild dry .............................. Cool ..................................... Fan ........................................ (2) fan speed automatic operation .....

Page 66

6 remote controller transmitter when you press the buttons on the remote controller, the mark appears in the display to transmit the setting changes to the receiver in the air conditioner. Display information on the operating conditions is displayed while the remote controller is switched on. If the...

Page 67

7 sensor a temperature sensor inside the remote controller senses the room temperature. (cover closed) clock button acl button (all clear) puts the remote controller into pre-operation status. Always press this button after replacing the batteries. On/off operation button this button is for turning ...

Page 68

8 using the remote controller how to install batteries 1. Slide the cover in the direction indicated by the arrow and remove it. 2. Install two aaa alkaline batteries. Make sure the batteries point in the direction marked in the battery compartment. 3. Use a thin object such as the tip of a pen to p...

Page 69

9 operation with the remote controller 1. Automatic operation this unit automatically switches between cooling operation and heating operation according to the difference between the room temperature and the temperature setting. 2. Manual operation check that the circuit breaker on the power panel i...

Page 70

10 3. Adjusting the fan speed a. Automatic fan speed simply set the fan speed selector button to the position. This automatically sets the best fan speed for the room temperature. B. Manual fan speed if you want to adjust fan speed manually during operation, just set the fan speed selector button as...

Page 71

11 7. High power mode high power mode can be used to increase the output of the indoor unit for all operation modes except automatic operation. Press the high power button while unit is operating. The mark appears in the display. To cancel, press high power button again. • when the high power button...

Page 72

12 a. In heating mode: ( ) b. In cooling mode: ( ) • unoccupied mode triggers heating or cooling operation in response to the room temperature, but when this happens, the remote controller will continue to display the operation mode set by the user. • if the room temperature rapidly changes, the roo...

Page 73

13 setting the timer in the descriptions below, the following settings are used for the temperature and time indicator selector button on the bottom front section of the remote controller. • temperature: °f • time: am, pm 1. How to set the present time (example) to set to 10:30 pm. 2. How to set the...

Page 74

14 4. How to set daily on/off repeat timer (example) to start operation at 7:10 am. And stop the air conditioner at 11:00 am. • the on/off combination timer uses the current time as the reference, and it is activated starting from whichever set time comes first. • with the on/off combination timer, ...

Page 75

15 adjusting the airflow direction 1. Horizontal the horizontal airflow can be adjusted by moving the vertical vanes with your hands to the left or right. When the humidity is high, the vertical vanes should be in the front position during the cooling or dehumidifying operation. If the vertical vane...

Page 76

16 care and cleaning casing and grille (indoor unit) clean the casing and grille of the indoor unit with a vacuum cleaner brush, or wipe them with a clean, soft cloth. If these parts are stained, use a clean cloth moistened with a mild liquid detergent. When cleaning the grille, be careful not to fo...

Page 77

17 troubleshooting (before calling for service) if your air conditioner does not work properly, first check the following points before requesting service. If it still does not work properly, contact your dealer or service center. Operating range the air conditioner is operable within the temperatur...

Page 78

18 specifications model no. Outdoor unit indoor unit cs-ke30nku cu-ke30nku 30,600 [ 10,900 ~ 30,600 ] 55 single-phase, 208-230 v, 60 hz 9.00 [ 3.20 ~ 9.00 ] 9.70 [ 4.10 〜9.70 ] 33,000 [ 14,000 〜33,000 ] - 55 - 35-13/16×37-1/32×13-3/8 (910×940×340) - 49/44/39 49/44/39 - heating capacity operation sou...

Page 80: Installation Instructions

Installation instructions appendix b cs-ke30nku + cu-ke30nku cs-ke36nku + cu-ke36nku (852-6-4190-587-00-0) a-2.

Page 81: Installation Instructions

$/09(08*54+0:054,8;9,9:/,8,-80.,8(4:" >:,84(2+0(3,:,85-9,8 split system air conditioner installation instructions note & contents page important! Please read before starting .................................. 2 1. General .......................................................... 4 1-1. Tools requir...

Page 82

2 important! Please read before starting this air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently. For safe installation and trouble-free op...

Page 83

8vhwkhioduhphwkrgirufrqqhfwlqjwxelqj $sso\uhiuljhudqwoxeulfdqwwrwkhpdwfklqjvxuidfhvri the flare and union tubes before connecting them, then tighten the nut with a torque wrench for a leak- free connection. &khfnfduhixoo\iruohdnvehiruhvwduwlqjwkhwhvwuxq 'rqrwohdnuhiuljhudqwzklohslslqjzruniru...

Page 84

4 1. General this booklet briefly outlines where and how to install the air conditioning system. Please read over the entire set of instructions for the indoor and outdoor units and make sure all accessory parts listed are with the system before beginning. 1-1. Tools required for installation (not s...

Page 85

5 1-5. Additional materials required for installation 1. Refrigeration (armored) tape 2. Insulated staples or clamps for connecting wire (see local codes.) 3. Putty 4. Refrigeration lubricant 5. Clamps or saddles to secure refrigerant tubing 2. Installation site selection 2-1. Indoor unit avoid: dir...

Page 86

6 concerning air-intake side distance “a” (fig. 5a) the minimum for distance “a” is 6" if there are no obstructions on the air-discharge side (wall *1 side) and *2 or *4 is not present. In all other cases, the min- imum for distance “a” is 8". If wall *1 is on the air-discharge side (fig. 5a), or if...

Page 87

7 fig. 5e fig. 5f fig. 5g 2-2-1. Installing the unit in an area with high winds and in a snowy area 425*(:0549=0://0./=04+9(=04+6855-+;*: 9/5;2+),-0::,+(4++08,*:,>659;8,:5:/,=04+ 9/5;2+),( 48,.0549=0:/90.40-0*(4:945=-(22:/,5;:+558;40: 9/5;2+),685 +;*:0.- countermeasures against snow and wind 48,.054...

Page 88

8 11-13/16" 13-3/8" 25-3/16" 22-7/8" (6-21/32") 6-5/16" 21-25/32" (12-9/16") 2-11/16" 35-13/16" 37-1/32" air discharge air discharge air discharge hole for anchor bolt (4-r1/4") / anchor bolt : 3/8" or m10 1 air discharge air discharge 25-31/32" 6-11/16" 13-3/8" 25/32" 25/32" 14-31/32" 13/32" 25/32"...

Page 89

9 required space around the outdoor unit -:/,=04+6855-+;*:09;9,+:/,96(*,9/5=4),25=3;9:),9,*;8,+(85;4+:/,5;:+558;40: -:/,;40:09;9,+=0:/5;::/,8,7;08,+96(*,(685:,*:0 #04.2,;40:049:(22(:054 caution $/,:56(4+)5:/90+,93;9:8,3(0456,4-:/,8,(8,5)9:(*2,9:5:/,-854:(4+8,(85- :/,5;:+558;40::/,5)9:(*2,(:,0:/,8:/,...

Page 90

10 25-13/32" 3/32" 13-3/8" (11-15/16") 16-15/16" air intake air discharge 39-1/4" 27-7/32" 7-1/32" 35-15/16" 28-15/16" 27-5/8" (11-5/8") air intake 13/32" 14-31/32" 25/32" 25/32" 25/32" 13-3/8" 4-11/32" 1 (8-15/16") 25-31/32" air discharge 1 unit: inch hole for anchor bolt (4-r1/4") / anchor bolt: 3...

Page 91

11 reference diagram for snow-proof duct space requirements for setting cu-ke30nku, cu-ke36nku with stk-bdv80e 0458358, #04.2,;40:049:(22(:054 ;2:062,;40:049:(22(:05458358,;40:9 [obstacle to the front of unit] 0458358, [obstacle to the rear of unit] #04.2,;40:049:(22(:054 ;2:062,;40:049:(22(:0545835...

Page 92

12 04 58358, 04 58358, 04 58358, 04 58358, 04 58358, 04 58358, #04.2,;40:049:(22(:054 ) 49:(22(:0540965990)2,=0:/:/,3(>03;35;:+558;40:9 9:(*2,954)5:/90+,9 [installation in front-rear rows] [obstacles to the front and rear of unit] $/,:56(4+)5:/90+,93;9:8,3(0456,40:/,8:/,5)9:(*2,:5:/,-854:58:/,5)9:(*...

Page 93

13 rear panel fig. 7c rear panel fig. 7b set screw only for transportation fig. 6 rear panel marks fig. 7a ,-: :;)04. "0./: :;)04. "0./:8,(8 :;)04. 8,*533,4+,+ "0./:+5=4=(8+ :;)04. ,-:8,(8 :;)04. ,-:+5=4=(8+ :;)04. Fig. 8 3. How to install the indoor unit 3-1. Remove the rear panel from the unit (1)...

Page 94

14 indoor side outdoor side hole should be made at a slight downward slant to the outdoor side. Note fig. 10 plastic cover inside outside wall slight angle pvc pipe (locally purchased) fig. 12 pvc pipe (locally purchased) cut at slight angle fig. 11 (4) using a sabre saw, key hole saw or hole-cuttin...

Page 95

15 3-4. Removing and installing the grille basically, these models can be installed and wired with- out removing the grille. If access to any internal part is needed, follow the steps as given below. How to remove the grille (1) open the front panel until it is nearly horizontal, grasp the sections ...

Page 96

16 3-5. Shape the indoor side tubing (1) arrangement of tubing by direction a) right or left tubing cut out the corner of the right/left frame with a hacksaw or the like. (figs. 20 and 21) b) right-rear or left-rear tubing in this case, the corner of the frame need not be cut. (2) to mount the indoo...

Page 97

17 3-7. Wire size and length regulations on wiring diameter differ from locality to locality. For field wiring requirements, please refer to your local elec- trical codes. Carefully observe these regulations when carrying out the installation. Refer to the wiring system diagram (fig. 23) for the mea...

Page 98

18 3-8. Wiring instructions for inter-unit connections (1) insert the inter-unit wiring (according to local codes) into the through-the-wall pvc pipe. Run the wiring toward the indoor side allowing approx. 10" (25 cm) to extend from the wall face. (fig. 24) (2) grasp both ends of the front panel, pu...

Page 99

19 when connecting each power wire to the corresponding terminal, follow the instructions “how to connect wiring to the terminal” and fasten the wire securely tight with the fixing screw of the terminal plate. How to connect wiring to the terminal a) for indoor unit (1) cut the wire end with a cutti...

Page 100

20 3-9. Mounting (1) to install the indoor unit, mount the indoor unit onto the 3 tabs on the upper part of the rear plate. (2) hold down the air discharge outlet and press the lower part of the indoor unit until it clicks to securely fasten to the 2 tabs on the lower part of the rear plate. (fig. 3...

Page 101

21 hole in wall bent part narrow tube wide tube rear panel fig. 38 drain cap drain hose clamp fig. 39 left-side tubing (1) lead the tubing and drain hose through the wall, allowing sufficient length for connection. Then bend the tubing using a tube bender to make the attach- ment. (fig. 38) (2) swit...

Page 102

22 to unmount indoor unit press the 2 marks on the lower part of the indoor unit and unlatch the tabs. Then lift the indoor unit and unmount. (fig. 42) 3-10. Frame fastening method (1) remove the screw cover on the bottom surface. (fig. 43) (2) fasten the frame to the rear panel using the 2 sup- pli...

Page 103

23 4. How to install the outdoor unit first refer to section 2. Installation site selection. 4-1. Wiring instructions for the outdoor unit regulations on wire size differ from locality to locality. For field wiring requirements, please refer to your local elec- trical codes. Make sure that the insta...

Page 104

24 5. Refrigerant tubing 5-1. Use of the flaring method many of the conventional split system air conditioners employ the flaring method to connect refrigerant tubes which run between indoor and outdoor units. In this method, the copper tubes are flared at each end and connected with flare nuts. 5-2...

Page 105

25 5-4. Connecting tubing between indoor and outdoor units a) tightly connect the indoor side refrigerant tubing exten- ded from the wall with the outdoor side tubing. (fig. 52) b) to fasten the flare nuts, apply specified torque as: table 6 5-5. Insulation of refrigerant tubing to prevent heat loss...

Page 106

26 6. Air purging air and moisture remaining in the refrigerant system have undesirable effects as indicated below. Therefore, they must be purged completely. Pressure in the system rises operating current rises cooling (or heating) efficiency drops moisture in the air may freeze and block capillary...

Page 107

27 (5) with the vacuum pump still running, close the “lo” knob of the manifold valve. Then stop the vacuum pump. (6) with the hex wrench, turn the valve stem on the nar- row tube service valve counter-clockwise by 90 degrees (1/4 turn) for 10 seconds, and then turn the stem clockwise to close it aga...

Page 108

28 how to test run the air conditioner after turning on the power of the air conditioner, use the remote controller and follow the steps below to conduct the test run. (1) set the remote controller in test run mode. (fig. 59a) a) press and hold the quiet button and the 1hr. Timer button. B) then pre...

Page 109

29 pump down pump down means collecting all refrigerant gas in the system back into the outdoor unit without losing any of the gas. Pump down is used when the unit is to be moved or before servicing the refrigerant circuit. Pump down procedure be sure to carry out pump down with the unit in cooling ...

Page 110

30 ( $,3658(8?*544,*:054 #*8,=04@:;849)?/(4+0.* ) $5-(9:,4:/,-2(8,4;:9(662?96,*0-0,+:587;, (9$()2,(4+0.+ fig. 60c fig. 60d caution $587;,=8,4*/ be sure to tighten the flare nut using the prescribed torque. If the nut is over- tightened, refrigerant leakage may occur. Press set in place remote contro...

Page 111

31 8. Address switch 8-1. Address setting of the remote controller the address can be set in order to prevent interference between remote controllers when 2 indoor units are installed near each other. The address is normally set to “a.” to set a different address, it is necessary to change the addre...

Page 112

Dc1111-0