- DL manuals

- Panasonic

- Air Conditioner

- CS-MA125KE

- Service Manual

Panasonic CS-MA125KE Service Manual

1

Features

2

2

Functions

3

3

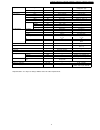

Product Specifications

6

4

Dimensions

12

5

Refrigeration Cycle Diagram

14

6

Block Diagram

15

7

Wiring Diagram

16

8

Operation Details

18

9

Operating Instructions

34

10 Installation Instructions

58

11 2-way, 3-way Valve

67

© 2000 Matsushita Industrial Corp. Sdn. Bhd.

(10969-T) All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-MA95KE CU-MA185KE

CS-MA125KE CU-MA245KE

CS-MA75KE

CS-MA125KE CU-MA195KE

12 Servicing Information

74

13 Troubleshooting Guide

77

14 Technical Data

79

15 Exploded View

84

16 Replacement Parts List

85

17 Exploded View

86

18 Replacement Parts List

87

19 Exploded View

88

20 Replacement Parts List

89

21 Electronic Parts List

90

22 Electronic Circuit Diagram

91

Room Air Conditioner

CONTENTS

Page

Page

Order No: MAC0010058C2

Summary of CS-MA125KE

Page 1

1 features 2 2 functions 3 3 product specifications 6 4 dimensions 12 5 refrigeration cycle diagram 14 6 block diagram 15 7 wiring diagram 16 8 operation details 18 9 operating instructions 34 10 installation instructions 58 11 2-way, 3-way valve 67 © 2000 matsushita industrial corp. Sdn. Bhd. (1096...

Page 2: 1 Features

• high efficiency • compact design • comfort environment − 8 hours of sleep mode operation − air filter with function to reduce dust and smoke − wider range of horizontal discharge air • auto restart − random auto restart after power failure for safety restart operation • removable and washable fron...

Page 3: 2 Functions

2 functions remote control operation off / on off / on i room temperature setting temp. Operation mode selection • auto automatic operation mode • heat heating operation mode • cool cooling operation mode • dry soft dry operation mode mode timer time / timer setting • hours and minutes setting. Cloc...

Page 4

Indoor unit sleep mode auto control • indoor fan operates at low speed. • operation stops after 8 hours. • automatic air swing and manual adjusted by remote control for vertical airflow. • manually adjusted by hand for horizontal airflow. Airflow direction control automatic operation button • press ...

Page 5

Outdoor unit • to protect compressor from reverse rotation when there is a instantaneous power failure. 60 secs. Forced operation control • once the compressor is activated, it does not stop within the first 60 secs. However, it stops immediately with remote control stop signal. Overload protector •...

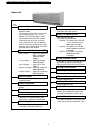

Page 6: 3 Product Specifications

3 product specifications unit cs-ma75ke, cs-ma125ke cu-ma195ke cooling capacity kw kcal/h 2.05 - 2.00, 3.50 - 3.45 1760 - 1720, 3010 - 2970 heating capacity kw kcal/h 2.15 - 2.10, 4.10 - 4.00 1850 - 1800, 3530 - 3440 moisture removal l/h pint/h 1.3, 2.0 2.7, 4.2 power source phase v cycle single 230...

Page 7

Net weight lb (kg) 20 (9.0) 159 (72) compressor type — rotary (1 cylinder) rolling piston type motor type — induction (2-poles) rated output w — 500, 1,100 air circulation type cross-flow fan propeller fan material as + glass fiber 30% aes + glass fiber 12% motor type induction (4-poles) induction (...

Page 8

Unit cs-ma95ke cu-ma185ke cooling capacity kw kcal/h (1 unit) 2.65 - 2.60 (1 unit) 2280 - 2230 (2 units) 2.65 × 2 - 2.60 × 2 (2 units) 2280 × 2 - 2230 × 2 heating capacity kw kcal/h (1 unit) 3.15 - 3.00 (1 unit) 2710 - 2580 (2 units) 3.15 × 2 - 3.00 × 2 (2 units) 2710 × 2 - 2580 × 2 moisture removal...

Page 9

Compressor type — rotary (1 cylinder) rolling piston type motor type — induction (2-poles) rated output w — (1 unit) 750 (2 units) 750 × 2 air circulation type cross-flow fan propeller fan material as + glass fiber 30% aes + glass fiber 12% motor type induction (4-poles) induction (6-poles) input w ...

Page 10

Unit cs-ma125ke cu-ma245ke cooling capacity kw kcal/h (1 unit) 3.50 - 3.45 (1 unit) 3010 - 2970 (2 units) 3.50 × 2 - 3.45 × 2 (2 units) 3010 × 2 - 2970 × 2 heating capacity kw kcal/h (1 unit) 4.10 - 4.00 (1 unit) 3530 - 3440 (2 units) 4.10 × 2 - 4.00 × 2 (2 units) 3530 × 2 - 3440 × 2 moisture remova...

Page 11

Compressor type — rotary (1 cylinder) rolling piston type motor type — induction (2-poles) rated output w (1 unit) 1,100 (2 units) 1,100 × 2 air circulation type cross-flow fan propeller fan material as + glass fiber 30% aes + glass fiber 12% motor type induction (4-poles) induction (6-poles) input ...

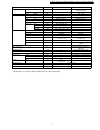

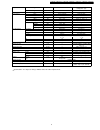

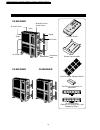

Page 12: 4 Dimensions

4 dimensions 12 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 13

13 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 14

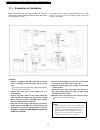

5 refrigeration cycle diagram 14 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 15: 6 Block Diagram

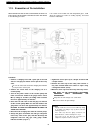

6 block diagram 15 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

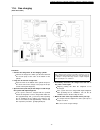

Page 16: 7 Wiring Diagram

Remarks b : blue br : brown bl : black w : white r : red o : orange p : pink y/g : yellow/green resistance of indoor fan motor windings model cs-ma95ke cs-ma125ke connection cwa921032 cwa921031 yellow-blue 451.2 Ω 450.7 Ω yellow-brown 86.7 Ω 68.2 Ω brown-orange 98.4 Ω 56.7 Ω orange-white 51.5 Ω 56.9...

Page 17

Remarks b : blue br : brown bl : black w : white r : red o : orange p : pink y/g : yellow/green resistance of indoor fan motor windings model cs-ma75ke cs-ma125ke connection cwa921033 cwa921031 yellow-blue 707.1 Ω 450.7 Ω yellow-brown 71.1 Ω 68.2 Ω brown-orange 64.7 Ω 56.7 Ω orange-white 15.7 Ω 56.9...

Page 18: 8 Operation Details

Cooling in operation according to remote control setting. Time delay safety control (3 minutes) 7 minutes time save control starting current control anti-freezing control • if the temperature of the indoor heat exchanger falls continuously below 2°c for 4 minutes or more, the compressor turns off to...

Page 19

Compressor protection control automatic fan speed mode • after the compressor starts for 50 seconds but the outdoor fan motor is still off, the compressor will stop and restart automatically. (time delay safety control is valid). • if the above phenomenon is repeated for 3 times, the compressor will...

Page 20

Cooling operation time diagram 20 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 21

Time delay safety control starting current control anti-freezing control compressor reverse rotation protection control compressor protection control automatic fan speed mode 8.2. Soft dry mode operation • the unit starts cooling operation until the room temperature reaches the setting temperature s...

Page 22

Soft dry operation time diagram 22 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 23

Heating in operation according to remote control setting. Time delay safety control 30 minutes time save control overload protection control compressor reverse rotation protection control 4-way valve control outdoor fan motor control 8.3. Heating mode operation • when the compressor is stopped by re...

Page 24

Hot start control anti cold draft control when heating operation starts, indoor fan will not start until the indoor heat exchanger reaches 30°c as diagram shown. Hot start is completed when indoor heat exchanger rises to 39°c. • this operation is to prevent the cold draft during heating mode operati...

Page 25

Automatic fan speed mode heating operating time diagram when automatic fan speed is selected at remote control during heating operation. • fan speed rotates in the range of me → lo according to the heat exchanger temperature. • if use manual fan speed, at above diagram will operate with setting fan ...

Page 26

Deicing control deice starts to prevent frosting at outdoor heat exchanger. • normal deicing deice operations detection commences after 30 minutes of heating operation starts or 60 minutes after previous deice operation. If the trs (thermal reed switch) senses the outdoor piping temperature drops to...

Page 27

Normal deicing time diagram overload deicing time diagram 27 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 28

8.4. Automatic mode operation 1. When the automatic mode operation is selected, the indoor fan operates at lo fan speed for 25 seconds to sense intake air temperature and determine the 1st operation mode. 2. Operation mode will be determine again after 1 hour of operation, if the room temperature re...

Page 29

Cooling or soft dry operation when you press the sleep mode, the following movement will start to avoid overcooling. • the fan speed refer to indoor fan motor control. • the setting temperature will be risen by 0.5°c at the start of operation and by 0.5°c one hour later. • the operation will stop af...

Page 30

8.9. Indoor fan speed control auto fan speed control when set to auto fan speed, the fan speed is shifted automatically between stop to shi depend on each operation as shown below. Manual fan speed control basic fan speed adjustment (3 settings, from lo to hi) can be carried out by using the fan spe...

Page 31

1. Vertical airflow direction cooling and soft dry mode • the louver swings up and down as shown above. • the louver does not swing when the indoor fan stops during operation. 2. Vertical airflow direction heating mode • when the intake air temp. Reaches 38°c, the louver is changed from upper to low...

Page 32

8.11. Economy mode operation purpose of this operation is to save or reduced electrical power consumption of the room air conditioner. However consumer is advised to use economy mode operation after the room temperature reaches the desired temperature. 1. Cooling and soft dry mode • when the economy...

Page 33

8.12. Powerful mode operation purpose of this operation is to be obtain the setting temperature quickly. 1. Cooling and soft dry mode • when the powerful mode is set, the set temperature will be automatically decreased 3°c against the present setting temperature. This operation automatically will be...

Page 34: 9 Operating Instructions

9 operating instructions ■ do not install, remove and reinstall the unit yourself. Improper installation will cause leakage, electric shock or fire. Please engage an authorized dealer or specialist for the installation work. Safety precautions before operating, please read the following “safety prec...

Page 35

Do not share outlet. Power economy powerful sleep timer ! Warning this sign warns of death or serious injury. Do not insert plug to operate the unit. Do not pull out plug to stop the unit. Plug in properly. Do not operate with wet hands. ● operation precautions use specified power cord. Do not damag...

Page 36

Power economy powerful sleep timer do not wash the unit with water. Do not use for other purpose such as preservation or etc. Do not use any combustible equipment at airflow direction. Do not sit or place anything on the outdoor unit. Ventilate the room regularly. ! Caution this sign warns of injury...

Page 37: Name of Each Part

Name of each part ● indoor unit air intake vent power supply cord panel opener signal receptor operation indicators ● power : green ● sleep : orange ● timer : orange air outlet vent vertical airflow direction louver horizontal airflow direction louver (manually adjusted) economy/powerful indicators ...

Page 38

● accessories ● outdoor unit two ro3 dry-cell batteries or equivalent air purifying filters (catechin air purifying filters and deodorizing filters) remote control remote control indication sticker po w er fu l temp off/on cool auto remote control holder cu-ma195ke air intake vents (side) piping gro...

Page 39

Room temperature setting button (self-illuminating button) off/on button (self-illuminating button) powerful mode operation button operation display signal transmitter ■ when the remote control cover is opened ● remote control powerful temp off/on cool auto air swing timer clock 1 2 3 heat cool lo h...

Page 40

■ when the back cover is opened ■ how to use the remote control • maximum distance : 10 m • make sure it is not obstructed. Open notes • do not throw or drop • do not get it wet • certain type of flourescent lamps may affect signal reception. Consult your dealer. Signal receptor • signal received so...

Page 41: Preparation Before Operation

Preparation before operation ! Warning ■ ensure the power plug is securely inserted. A loose plug may cause a fire or an electric shock. 5 insert the air filters 4 insert the air purifying filters 6 close the front panel ■ notes ● indoor unit • if the unit is not going to be used for an extended per...

Page 42

1 press the clock button 2 press to set the current time press continuously for fast forwarding. Press continuously for fast reversing. 3 press the clock button • can be used for approximately one year. Observe the following when replacing the batteries • replace with new batteries of the same type ...

Page 43: How To Operate

Air sw ing timer clock 1 2 3 cool mo de economy fan speed auto manual on off cancel sleep set powerful off/on cool temp how to operate ● automatic, heating, cooling, soft dry display close the cover a heat dry cool hi auto auto lo auto a – automatic operation • at the start of the automatic operatio...

Page 44

● adjusting airflow direction and fan speed ■ operation details * five stages of adjustments can be made in this range. Louver adjustment range press to select fan speed • the display changes in this order automatic low medium high selecting vertical airflow direction press auto, selecting vertical ...

Page 45: Setting The Timer

Air swing timer clo ck 1 2 3 cool on am mode economy fan speed auto manual on off set cancel sleep setting the timer 1 press on-timer flashes → set the on-timer to 7:00am 2 press to set the time increase by 10 minutes decrease by 10 minutes * press continuously for quick setting. Ensure that the cur...

Page 46

● recommended setting of timer ■ when you sleep • set the time at which you will go to sleep with the off-timer. This prevent wastage of electricity. ■ when you wake up • set the time at which you will wake up with the on-timer. You can start the new day at a comfortable temperature. Note: (the abov...

Page 47: Convenience Operation

Convenience operation ■ to set the sleep mode, press sleep. * the sleep indicator on the indoor unit will light up. ■ to cancel the sleep mode, press once more. Air sw ing tim er clock 1 2 3 cool mode economy fan speed auto manual on off set cancel sleep • when the room temperature reaches the setti...

Page 48

Air swing timer clock 1 2 3 cool mode economy fan speed auto manual on off set cancel sleep powerful off/on ● economy or powerful mode ■ operation details cover is closed economy mode to save electrical power consumption. However, please use this mode when the room have reached your desired temperat...

Page 49: Care and Maintenance

5 let it dry and reinstall it. Be sure the “front” mark is facing you. * damaged air filter. Consult the nearest authorized dealer. Part no.: cwd00240. • do not clean using benzene, thinner, scouring powder or cloths soaked in caustic chemicals. 2 remove dirt using a vacuum cleaner. 3 wash back of t...

Page 50

● cleaning the front panel ! Caution 1 raise the front panel to its full extent. 2 slide the two tabs (left and right) to the unlock position. 3 raise the front panel to a position slightly higher than horizontal and pull to remove. • gently wash with water and a sponge. (do not use a scrubbing brus...

Page 51

● replacing the air purifying filters 1 raise the front panel to its full extent. 2 remove the air filters (left and right). • lift up slightly then pull down 3 hold the tabs of the air purifying filters and pull. ! Caution - be careful not to hurt your hands on metal parts. (once every 3 month) • d...

Page 52

• is the discharge air cold (warm)? Operation is normal if, 15 minutes after the start of operation, the temperature difference between the air intake and outlet vents is 8°c or above for cooling and 14°c or above for heating. • are the remote control batteries weak? If the remote control display ap...

Page 53: Troubleshooting

Ssshh power economy powerful sleep timer troubleshooting q - air conditioner has been restarted, but does not operate for 3 minutes. A - this is to protect the air conditioner. Wait until the air conditioner begins operating. Q - it seems that fog is coming out from the air conditioner. A - condensa...

Page 54

• water or foreign material gets into the remote control by mistake. The air conditioner does not operate. • has a circuit breaker been tripped? • has the power plug been removed from the wall outlet? • is the timer being used correctly? Air conditioner operation noise too loud. • is the installatio...

Page 55: Helpful Information

Helpful information auto operation button ■ automatic operation • if the remote control fails to function or misplaced, press auto operation button for automatic operation. • the automatic operation will be activated immediately once the auto operation button is pressed. However, temperature cannot ...

Page 56

Energy saving and operation hints timer and sleep mode to prevent wastage of electricity, use sleep mode when sleeping or timer when going out to save electricity cost. Avoid direct sunlight keep curtains or drapes closed to keep out direct sunlight during cooling operation. Outdoor unit do not bloc...

Page 57

! Warning 1) this appliance must be earthed. 2) if the supply cord is damaged or need to be replaced, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to avoid a hazard. 3) remove power plug or disconnect from the mains before servicing this appli...

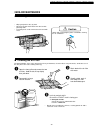

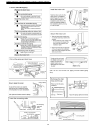

Page 58

10 installation instructions required tools for installation works 1. Phillips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 42 n.M (4.2 kgf.M) 55 n.M (5.5 kgf.M) 3. Electric drill, hole core drill (ø...

Page 59

1. Grounding is necessary. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in installati...

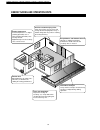

Page 60

Attached accessories applicable piping kit cz-4f5, 7, 10an select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where drainag...

Page 61

10.2.1. Select the best location (refer to “select the best location” section) 10.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. : unit centre should be at more than 450 mm at right and left of the wall. The height should be more tha...

Page 62

3. For the embedded piping (this can be used for left rear piping and left bottom piping also.) 62 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 63

10.2.5. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 5 × 1.5 mm 2 flexible cord, type designation h05 rn-f or hea...

Page 64

How to take out front grille please follow below steps to take out front grille if necessary such as when servicing. 1. Set the vertical airflow direction louver to the horizontal position. 2. Slide down the two caps on the front grille as shown in the illustration below, and then remove the two mou...

Page 65

Cutting and flaring the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping and down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut ...

Page 66

Mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by using poly-e foam with thickness 6 mm or above. Disp...

Page 67: 11 2-Way, 3-Way Valve

11 2-way, 3-way valve 2-way valve (liquid side) 3-way valve (gas side) works shaft position shaft position service port shipping close closed closed (with valve cap) (with valve cap) (with cap) evacuation closed closed open (installation and (counter-clockwise) (clockwise) (push-pin) re-installation...

Page 68

11.1. Evacuation of installation when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. Procedure: 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of a 3-way valve. • be sure to co...

Page 69

11.2. Pumping down procedure: 1. Confirm that both the 2-way and 3-way valves are set to the opened position. • remove the valve stem caps and confirm that the valve stems are in the opened position. • be sure to use a hexagonal wrench to operate the valve stems. 2. Operate the unit for 10 to 15 min...

Page 70

11.3. Evacuation of re-installation when reinstalling an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. Procedure: 1. Connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. • be sur...

Page 71

(lack of refrigerant in the refrigeration cycle) procedure: 1. Confirm that both the 2-way and 3-way valves are set to the open position. 2. Connect the charge set to the 3-way valve’s service port. • leave the valve on the charge set closed. • connect the charge hose with the push-pin to the servic...

Page 72

(no refrigerant in the refrigeration cycle) procedure: 1. Connect the vacuum pump to the charge set’s centre hose. 2. Evacuation for approximately one hour. • confirm that the gauge needle has moved toward -0.1 mpa (-76 cmhg) [vacuum of 4 mmhg or less.] 3. Close the valve (low side) on the charge se...

Page 73

(after evacuation) procedure: 1. Connect the charge hose to the charging cylinder. • connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom of the cylinder. 2. Purge the air from the charge hose. • open the valve at the bottom of the cylinder and press the che...

Page 74: 12 Servicing Information

• inspection points for the indoor electronic controller 1. The electronic controller, a signal receiver and an indicator (fig. 2) can be seen by the below steps: − remove the 2 caps and 2 screws at the bottom of the front grille. (fig. 1) − remove the front grille by releasing the 2 hooks at the to...

Page 75

− finally remove the fan motor by removing the screw. (fig. 5) − reminder - to reinstall the fan motor, adjust the connector of the fan motor as fig. 5. • cross flow fan removal procedure. 1. Remove the control board and the fan motor by referring to the “indoor fan motor removal procedure”. 2. Remo...

Page 76

• remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happen, remove the back cover of the remote control and you will find a resetting terminal, and by shorting it with ...

Page 77: 13 Troubleshooting Guide

In order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air temperature and pressure of the ref...

Page 78

13.1.1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditoner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrige...

Page 79: 14 Technical Data

14 technical data 79 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 80

230v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 2.03 1.54 0.60 1.90 1.48 0.65 1.77 1.42 0.70 1.72 1.35 0.75 19.0°c 2.05 0.66 19.5°c 2.23 1.61 0.62 2.09 1.55 0.66 1.94 1.49 0.71 1.77 1.42 0.76 22.0°c 2.43 1.67 0.63 2.27 1.61 0.67 2.12 1.55 0.72...

Page 81

81 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 82

82 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 83

83 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 84: 15 Exploded View

15 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 84 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 85: 16 Replacement Parts List

(note) • “o” marked parts are recommended to be kept in stock. 16 replacement parts list no. Description & name q’ty cs-ma75ke cs-ma95ke cs-ma125ke remarks 1 chassy complete 1 cwd50c338 ← ← 2 particular piece 1 cwd931019 ← ← 3 fan motor 1 cwa921033 cwa921032 cwa921031 0 4 lead wire - fan motor 1 cwa...

Page 86: 17 Exploded View

17 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 86 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 87: 18 Replacement Parts List

18 replacement parts list (note) no. Description & name q’ty cu-ma125ke remarks (upper) (lower) 1 chassy ass’y 1 cwd50k627 cwd50k612a 2 fan motor bracket 1 cwd54113 cwd54155 3 screw - fan motor bracket 8 cwh4580399 4 fan motor 2 cwa95245 0 5 screw - fan motor bracket 6 cwh55027 0 6 propeller fan 2 c...

Page 88: 19 Exploded View

19 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 88 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 89: 20 Replacement Parts List

20 replacement parts list (note) no. Description & name q’ty cu-ma185ke cu-ma245ke remarks 1 chassy ass’y 1 cwd50k562a cwd50k626a 2 fan motor bracket 2 cwd54113 cwd54155 3 screw - fan motor bracket 8 cwh4580399 ← 4 fan motor 2 cwa95245 ← 0 5 screw - fan motor mount 6 cwh55027 ← 6 propeller fan 2 cwh...

Page 90: 21 Electronic Parts List

21 electronic parts list note symbol description & name part no. Bz1 sound generator a48040 ct1 transformer a40322 d1, d4 diode a541sr154-4 d2 diode a54rb501v-40 d3 diode a541ss355t db1 diode a54cs1vb20e fuse fuse xba2c20tr0 fuse holder fuse holder xcscw032 ic1 integrated circuit a52d0022gb14 ic2 in...

Page 91

22 electronic circuit diagram schematic diagram 1/3 • cs-ma95ke / cu-ma185ke • cs-ma125ke / cu-ma245ke • cs-ma75ke / cu-ma195ke • cs-ma125ke (mx-9) a54lnk3171b a54lnk2172b economy (ph-6) stepping motor drive off/on timer sleep powerful 10 7 12 5 11 6 9 g f e cn-stm 1 2 3 4 5 5 4 3 2 1 (mx-5) (zh5) a...

Page 92

Schematic diagram 2/3 0.01 µ c10 10k r15 r14 1k r13 10k c9 0.01 µ 150k r34 x1 8mhz (27pf x 2) 16v c19 0.01 µ 10 µ c18 – + ic2 5 6 8 3 1 rs d6 d1 r/b cs sk 4 vcc gnd 2 7 a52br9020f jx1 r24 10k ry-h c b e 10k 4.7k q8 a55dc143xktx q7 4.7k 10k e b c ry-shi ry-hot ssr2 12v o i g ic5 c1 3300 µ 35v (nhg) 7...

Page 93

Schematic diagram 3/3 sw3 auto 78a05 ic4 g i o (nhg) 16v 100 µ c3 – + 5v + – r2 10k c2 470 µ 25v (nhg) b e c 2sc2412ktx q3 10k r5 r44 10k 6.2k r7 6.2k r6 0.01 µ c7 zd1 7.5el1 (vh-1) (green) yello w br o w n orange white red motor fan cn-fm 7 6 5 4 3 2 1 3 2 blue (green) cn-c 1 (vh-3) cn-fuse1 3 1 ry...

Page 94

94 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 95

How to use electronic circuit diagram timer table test mode name time (when test point remarks short-circuited) sleep mode waiting 1 hr. 6 sec. Sleep mode operation 8 hrs. 48 sec. Real timer 1 hr. 1 min. 10 min. 10 sec. 1 min. 1 sec. Time delay safety control 2 min. 58 sec. 0 sec. Forced operation 6...

Page 96

22.1. Remote control 96 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 97

22.2. Print pattern indoor unit printed circuit board top view 97 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke.

Page 98

22.3. Print pattern indoor unit printed circuit board bottom view 98 cs-ma95ke cu-ma185ke / cs-ma125ke cu-ma245ke / cs-ma75ke / cs-ma125ke cu-ma195ke [macc] printed in malaysia.